Classicline - Bennett + Sauser AG, Solothurn

Classicline - Bennett + Sauser AG, Solothurn

Classicline - Bennett + Sauser AG, Solothurn

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ClassicLine<br />

a sTROKE OF GEniUs - THE Bs ClassiC FUEl pUMps<br />

The EM800 consumer fuel pumps are plinth-mounted and can<br />

be operated from either side. Depending on the model, any<br />

two products can be dispensed simultaneously.<br />

Each filling nozzle has a separate piston meter. The ClassicLine<br />

is available with a litre volume/cash amount display for applications<br />

where official weights and measures calibration is<br />

required, or a litre volume display only where calibration is not<br />

required. Both versions have a back-lit LCD display.<br />

Classic fuel pumps can be operated either in «stand-alone»<br />

mode or via a fuel prepayment system (serial or impulse<br />

interface).<br />

TECHniCal spECiFiCaTiOns<br />

Chassis<br />

• Side casing and front panels made from stainless chromium<br />

steel sheet, polished<br />

• Front panels painted in RAL colour of your choice (one colour)<br />

Hydraulics<br />

• <strong>Bennett</strong> SB100 piston meter with very simple calibration<br />

• <strong>Bennett</strong> Type 75 compact rotary pump with filter, air<br />

separator and bypass valve<br />

Electronic calculator ER5<br />

• The ER5 is a fuel pump calculator designed on a modular<br />

principle, intended for use in conjunction with other components<br />

to meet current modern market requirements<br />

• 2 x 2 wire serial interfaces, galvanically isolated with two<br />

optocouplers or optionally with a galvanically isolated<br />

impulse interface<br />

• LCD display<br />

• Pulse generator with integrated totaliser<br />

Drive system pump<br />

Electric motor 380 – 420 V, 50 Hz, 0.75 kW, 2 A<br />

V-belt Antistatic type<br />

<strong>Classicline</strong> model range<br />

With litre/price/amount display:<br />

EM813-1 1 nozzle Diesel 45 l/min.<br />

EM813 1 nozzle Petrol 40 l/min.<br />

EM825-2 2 nozzles Diesel / Diesel 45 l/min. each<br />

EM825-1 2 nozzles Diesel 45 l/min.<br />

Petrol 40 l/min.<br />

EM825 2 nozzles Petrol 40 l/min. each<br />

EM813-D/2-1 2 nozzles Diesel 45 / 85 l/min.<br />

not simultaneously<br />

EM825-1p-1 1 nozzle Diesel 120 l/min.<br />

EM825-1p-1 1 nozzle Diesel 160 l/min.<br />

EM825-2p-1 2 nozzles Diesel 45 / 120 l/min.<br />

not simultaneously<br />

Delivery hoses<br />

Standard,<br />

delivery volume 45 l/min. Standard length 4.2 m<br />

High output,<br />

delivery volume 85 l/min. Standard length 4.2 m<br />

High output,<br />

delivery volume 120 l/min. Standard length 4.2 m<br />

Fuel pump nozzles<br />

Standard, delivery volume 45 l/min. ZVA 6.B0-R<br />

High output, delivery volume 85 l/min. ZVA 25<br />

High output, delivery volume 120 l/min. ZVA 25<br />

Options<br />

• Motor pump group 230 V, 50 Hz, 0.75 kW, 4.5 A<br />

• Double solenoid valves for connection to fuel prepayment<br />

systems accepting banknotes<br />

• Externally readable totaliser<br />

• Supplementary switch (turbo) for truck refuelling<br />

ca. 70 l/min. for diesel<br />

• 85 l/min. deliveries for diesel<br />

• Monofront versions<br />

• Motor protection switch<br />

• Pressure-fed versions<br />

• Spring mast<br />

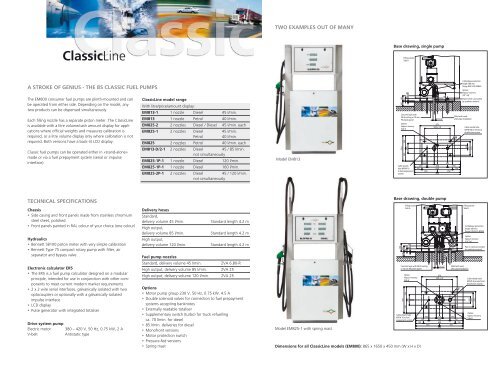

TWO EXaMplEs OUT OF ManY<br />

Model EM813<br />

Model EM825-1 with spring mast<br />

Base drawing, single pump<br />

Base drawing, double pump<br />

150<br />

100 105<br />

50<br />

10–20<br />

Filling nozzle<br />

Side A<br />

Concrete layer with SIKA coating<br />

or 10 mm PE plastic panel<br />

500<br />

Filling nozzle<br />

Side A<br />

105<br />

50<br />

10 – 20<br />

Option:<br />

Vapour recovery<br />

Side A<br />

250<br />

250<br />

200<br />

Cable sheath tube<br />

KRFW 16 to fuel<br />

prepayment system<br />

Dimensions for all <strong>Classicline</strong> models (EM800): 865 x 1650 x 450 mm (W x H x D)<br />

100<br />

Concrete layer with<br />

SIKA coating or 10 mm<br />

PE plastic panel<br />

Option:<br />

Vapour recovery<br />

Side A<br />

500<br />

250 250<br />

200<br />

Cable sheath<br />

tube KRFW 16<br />

to fuel prepayment<br />

system<br />

Ø 1 1/2“<br />

676<br />

500 ± 10<br />

390 510<br />

250 400250 150 600150<br />

450 450<br />

900<br />

Ø 1 1/2“<br />

676<br />

500 ± 10<br />

150<br />

Filling nozzle<br />

Side B<br />

Filled with sand<br />

after pipe installation<br />

M10<br />

390 120 390<br />

250<br />

400<br />

250<br />

150<br />

600 150<br />

450 450<br />

900<br />

Cathodique protection<br />

length 180 mm<br />

flange DIN 5435 NW40<br />

Filled with sand<br />

after pipe installation<br />

M10<br />

Option:<br />

Vapour recovery<br />

3/4“ <strong>AG</strong><br />

Pipe in steel surrounded<br />

by synthetic material<br />

Cable sheath tube<br />

KRFW 36 to electrical<br />

distribution system<br />

60<br />

270<br />

330<br />

Cathodique protection<br />

length 180 mm<br />

flange DIN 5435 NW40<br />

Option:<br />

Vapour recovery<br />

3/4“ <strong>AG</strong><br />

Pipe in steel surrounded<br />

by synthetic material<br />

Cable sheath tube<br />

KRFW 36 to electrical<br />

distribution system<br />

120<br />

270<br />

330<br />

Option:<br />

Vapour recovery<br />

Side B

ClassicLine<br />

Model EM825 -1<br />

WHaT YOU Can DEpEnD On Us<br />

TO pROViDE<br />

• Maintenance contracts<br />

• Customer service and repairs<br />

• Vapour recovery checks as contractual partner<br />

of the filling station inspectorate <strong>AG</strong>VS (TSI)<br />

• Installations and pipework installations<br />

• Modernisations<br />

• Plant planning<br />

• Journey and operating data monitoring<br />

• Inspections in the area of effluents, waste, storage<br />

of water polluting liquids and paint shops; control<br />

body of the environment inspectorate <strong>AG</strong>VS (UWI)<br />

OUR paRTnERs aRE aT HOME anYWHERE<br />

Mastrapumps NV<br />

B – Nieuwerkerken<br />

Hülsmann Behältertechnik GmbH<br />

D – Drensteinfurt<br />

G&B Tankanlagen GmbH<br />

D – Thann/Zolling<br />

Hectronic GmbH<br />

D – Bonndorf<br />

Hockman UK Ltd<br />

GB – Egham<br />

Petroltech SA<br />

B – Bruxelles<br />

<strong>Bennett</strong>+<strong>Sauser</strong> <strong>AG</strong><br />

CH – <strong>Solothurn</strong><br />

aT YOUR sERViCE<br />

Vink b.v.<br />

NL – Barneveld<br />

Rohe Hungaria Kft<br />

H – Budapest<br />

<strong>Bennett</strong>+sauser aG Refuelling systems<br />

Bielstrasse 80 l CH-4503 <strong>Solothurn</strong><br />

Tel. +41 32 625 93 11 l Fax +41 32 623 15 35<br />

mail@bennett-sauser.ch l www.bennett-sauser.ch<br />

Rohe Lithuania UAB<br />

LT – Kaunas<br />

Engell & Kristiansen as<br />

N – Skedsmokorset<br />

Ask for details of our 3-stage programme:<br />

TYpE appROVals<br />

Weights and measures legislation-related<br />

Nederlands Meetinstituut (Nmi)<br />

Test Report / R117/1995-NL-01.05/06/07<br />

Physikalisch-Technische Bundesanstalt (PTB)<br />

Approval number 5.101/01.10<br />

safety-related<br />

SNCH 0499<br />

L-5230 Sandweiler / Luxembourg (SNCH)<br />

SNCH 03 ATEX 3443<br />

Rohe Latvia SIA<br />

LV – Riga<br />

Rohe Eesti<br />

EE – Tallinn<br />

smartLine I ClassicLine I MultiLine smartLine I ClassicLine I MultiLine<br />

A company of <strong>Sauser</strong> Holding <strong>AG</strong>, CH-<strong>Solothurn</strong><br />

0499<br />

E/08-08