Fluidized Bed Screens PDF - Rubber Fab Mold and Gasket

Fluidized Bed Screens PDF - Rubber Fab Mold and Gasket

Fluidized Bed Screens PDF - Rubber Fab Mold and Gasket

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

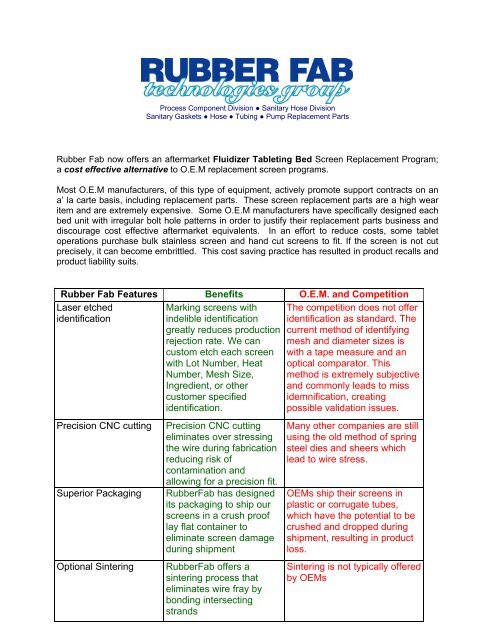

Process Component Division ● Sanitary Hose DivisionSanitary <strong>Gasket</strong>s ● Hose ● Tubing ● Pump Replacement Parts<strong>Rubber</strong> <strong>Fab</strong> now offers an aftermarket Fluidizer Tableting <strong>Bed</strong> Screen Replacement Program;a cost effective alternative to O.E.M replacement screen programs.Most O.E.M manufacturers, of this type of equipment, actively promote support contracts on ana’ la carte basis, including replacement parts. These screen replacement parts are a high wearitem <strong>and</strong> are extremely expensive. Some O.E.M manufacturers have specifically designed eachbed unit with irregular bolt hole patterns in order to justify their replacement parts business <strong>and</strong>discourage cost effective aftermarket equivalents. In an effort to reduce costs, some tabletoperations purchase bulk stainless screen <strong>and</strong> h<strong>and</strong> cut screens to fit. If the screen is not cutprecisely, it can become embrittled. This cost saving practice has resulted in product recalls <strong>and</strong>product liability suits.<strong>Rubber</strong> <strong>Fab</strong> Features Benefits O.E.M. <strong>and</strong> CompetitionLaser etchedidentificationPrecision CNC cuttingSuperior PackagingOptional SinteringMarking screens withindelible identificationgreatly reduces productionrejection rate. We cancustom etch each screenwith Lot Number, HeatNumber, Mesh Size,Ingredient, or othercustomer specifiedidentification.Precision CNC cuttingeliminates over stressingthe wire during fabricationreducing risk ofcontamination <strong>and</strong>allowing for a precision fit.<strong>Rubber</strong><strong>Fab</strong> has designedits packaging to ship ourscreens in a crush prooflay flat container toeliminate screen damageduring shipment<strong>Rubber</strong><strong>Fab</strong> offers asintering process thateliminates wire fray bybonding intersectingstr<strong>and</strong>sThe competition does not offeridentification as st<strong>and</strong>ard. Thecurrent method of identifyingmesh <strong>and</strong> diameter sizes iswith a tape measure <strong>and</strong> anoptical comparator. Thismethod is extremely subjective<strong>and</strong> commonly leads to missidemnification, creatingpossible validation issues.Many other companies are stillusing the old method of springsteel dies <strong>and</strong> sheers whichlead to wire stress.OEMs ship their screens inplastic or corrugate tubes,which have the potential to becrushed <strong>and</strong> dropped duringshipment, resulting in productloss.Sintering is not typically offeredby OEMs

26 Brookfield Drive ● Sparta, NJ 07871Tel: 973-579-2959 ● Tollfree: 866-442-2959 ● Fax: 973-579-7275www.rubberfab.com