PULSAFEEDER Isochem - Viking Pump Canada

PULSAFEEDER Isochem - Viking Pump Canada

PULSAFEEDER Isochem - Viking Pump Canada

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

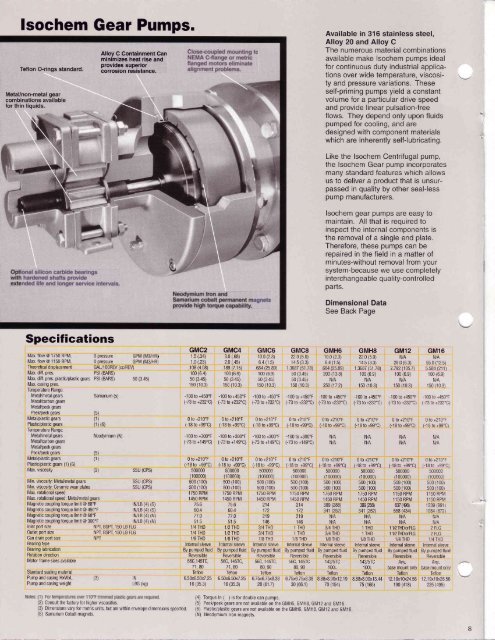

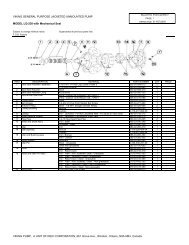

lsochem Gear <strong>Pump</strong>s,Alloy G Containment Ganminimizes heat rise andprovides superiorcorrosion resistance.Close-coupled mounting toNEMA C-flange or metricflanged motors eliminatealignment problems.Available in 316 stainless steel,Alloy 20 and Alloy CThe numerous material combinationsavailable make lsochem pumps idealfor continuous duty industrial applicationsover wide temperature, viscosityand pressure variations. Theseself-priming pumps yield a constantvolume for a particular drive speedand provide linear pulsation-freeflows. They depend only upon fluidspumped for cooling, and aredesigned with component materialswhich are inherently self-lubricating.Optional silicon carbide bearingswith hardened shafts provideextended life and longer service intervals.Neodymium lron andSamarium cobalt permanent magnetsprovide high torque capability.Like the lsochem Centrifugal pump,the lsochem Gear pump incorporatesmany standard features which allowsus to deliver a producthat is unsurpassedin quality by other seal-lesspump manufacturers.lsochem gear pumps are easy tomaintain. All that is required toinspecthe internal components isthe removal of a single end plate.Therefore, these pumps can berepaired in the field in a matter ofminutes-without removal from yoursystem-because we use completelyi nterchangeable quality-controlledparts.Dimensional DataSee Back PageSpecificationsMax flow @ 1750 RPM, 0 pressure cPM (M3/HR)Max flow @ 1150 RPM, 0 pressure cPM (MS/HR)Theoretical displacementMax diff presGAU1 00REV (cclREV)PSr (BARS)Max. diff. pres. plastic/plastic gearsPSr(BARS) 50 (3.45)Max. casing presTemperature Range:Metal/metal gearsSamarium (s)Metal/carbon gearsMetal/peek gearsPeek/peek gears (5)Metal/plastic gears (1)Plastic/plastic gears (1)(6)Temperature Range:Metal/metal gearsNeodymium (N)Metal/carbon gearsMetal/peek gearsPeek/peek gears (5)Metal/plastic gears (1)Plastic/plastic gears (1)(6)Max. viscosity (2) SSU (CPS)Min viscosity: Metal/metal gearsssu (cPS)Min viscosity: Ceramic wear platesssu (cPS)Max rotational speedMax rotational speed: Metal/metal gearsMagnetic coupling torque limit @ 6B"F|N/LB (4)(S)Magnetic coupling torque limit @ 450'F|N/LB (4)(S)Magnetic coupling torque limit @ 68'Fll\YLB (4)(N)Magnetic coupling torque limit @ 300'FrN/LB (4)(N)Inlet port sizeNPT, BSPI 150 LB FLG0utlet port sizeNPI BSPT, l5O LB FLGCan drain poft sizeNPTBearing typeBearing lubricationRotation directionMotor frame sizes availableStandard sealing material<strong>Pump</strong> and casing HxWxL<strong>Pump</strong> and casing weight(3)INLBS (kq)GMC2 GMC415 (.34) 3.0 ( 68)1.0 (.23) 2.0 (.45).108(408) .18e(7.15)100 (64) 100 (6.9)50 (3.45) 50 (345)150 (10.3) 150 (10.3)0 to +210'F 0 to +210"Ffl B to +99'C) (-18 to +99"C)-1 00 to +300"F -1 00 to +300'F(-73 to +149'C) f73 to +149'C)GMC6100 (23) GMCS22.0 (50) GMH610.0 (23)64 (15) 14.5 (3.3) 6.4 (15)684(25.89) 1.3687(51 78) .684(2589)100 (69) 50 (3.4s) 200 (13 B)50 (345) 50 (3.45) N/A150 (10.3) 150 (103) 2s0 (172)0 to +210'F 0 to +210'F 0 to +210'Ffl B to +99'C) f1 B to +99'C) fl B to +99'C)-100 to +300'F -100 to +300'Ff73 to +149'C) (-73 to +149'C)0 to +21 0"F 0 to +21 0'F 0 to +210"F 0 to +210'F 0 to +210'F 0 to +21 0"F 0 to +210'F 0 to +210"Ffl8to +99'C) fl8to +99'C) fl8to +99'C) (-1Bto +99'C) fl8to +99'C) (-1Bto +99"C) flBto +99'C) (-18 to +99'C)500000 500000 500000 500000 500000 500000 500000 500000(100000) (100000) (100000) (100000) (100000) (100000)(100000)(100000)500 (100) 500 (100) 500 (100) 500 (100) 500 (100) 500 (100)500 (100)500500 (100) 500 (100) 500 (100) 500 (100) 500 (100) 500 (100)500 (100) 500 (100)1750 RPM 1750 RPM 1750 RPM 1750 RPM 1750 RPM 1750 RPM 1150RPM 1150 RPt\41450 RPM 1450 RPM ]450 RPM 1450 RPM 1450 RPM 1450 RPM 1150 RPM 1150 RP[/75.6 756214 214 389 (2BB) sm(2BB) 637(4S) 1239(991)60.4 604172 172 341 (252) 341 (252) 558 (434) 1084(872)77.0 770219 219 N/AN/AN/AN/A515 515146 146 N/ANiAN/AN/A1/4 THD 1I2THD 3/4 THD 1 THD 3/4 THD 1 THD l12lHDorH-G 2 FLG1I IHD 1I2THD 3/4 THD 1 THD 3/4 THD 1 THD 1lZlHDorH-G 2 FLG1/8 THD 1/B THD 1/B THD 1/B THD 1/8 THD 1/8 THD 1/4 THD 1/4 THDlnternal sleeve Internal sleeve Internal sleeve Internal sleeve Internal sleeve lnternal sleeve lnternal sleeve lnternal sleeveBy pumped fluid By pumped fluid By pumped fluid By pumped fluid By pumped tluid By pumped fluid By pumped fluid By pumped fluidReversible Reversible Reversible Reversible Reversible Reversible Reversible Reversible56C,145TC, 56C,145TC. 56C,145TC, 56C,145TC 143/5TC 143t5TC Any, Any,71, B0 71, B0 80,90 80,90 1001 1001base mount only base mount onlyTeflon Teflon Teflon Teflon Teflon Teflon Teflon Teflon6.50x6.50x7 25 6.50x650x7.256.75x675x8.386"75x6.75x8.38B.BBxB.0Ox12 19 B.BBxB.00x1 3.44 12.19x10x24.5612 19x10x265616 (3s 3) 16 (3s.3) 28 (61.7) 30 (661) 70 (154) 75 (r65) 190 (418) 225 (495\N/AN/AGMHs22.0 (5.0)14.5 (3.3)1.3687 (5178)100 (6 e)N/A150 (10.3)0 to +210"F(-18 to +99'C)N/AN/AGM12N/A28.0 (6.3)2752 (105.7)100 (6.e)N/A150 (103)-100 to +450'F -100 to +450'F -1 00 to +450'F -1 00 to +450'F -1 00 to +450'F -1 00 to +450'F -1 00 to +450"F -1 00 to +450'Ff73 to +232'C) f73 to +232"C) f73 to +232'C) (-73 to +232'C) f73 to +232'C) f73 to +232"C) f73 to +232"C) (-73 to +232"C)0 to +210'F(-18 to +99'C)N/AN/AGM16N/A55.0 (12.s)5584 (211)100(6e)N/A150 (103)0 to +21 0'F(-1 B to +99'C)N/ANiANotes: ( 1 ) For temperatures over 110'F trimmed plastic gears are required(4) Torque In ( ) is for double can pumps(2) Consultthefactorylorhigherviscosities. (5) Peek/peekgearsarenotavailableontheGMH6,GI\IH8,G[il12andGMl6(3) Dimensionsvaryformetricunits,butarewithinenvelopedimensionsspecified.(6) Plastic/plasticgearsarenotavailableontheGMH6,GMHB,GMl2andGMl6(S) Samarium Cobalt magnets(N) Neodymium lron magnets.