PULSAFEEDER Isochem - Viking Pump Canada

PULSAFEEDER Isochem - Viking Pump Canada

PULSAFEEDER Isochem - Viking Pump Canada

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

lsochemFor Economical Leak-Free ServiceCOUPLING DESIGN PRINCIPLEDriven Magnet Containment Can Drive MagnetDriven MagnetContainment CanEngineered For Environmental Safety.Pulsafeeder's lsochem pumps safely handle hazardous,highly corrosive, explosive or toxic chemicals. They providesafe, leak-free service because the magnetic couplingeliminates the need for traditional sealing methods, suchas mechanical seals or packing, the main source of leakageproblems on pumps. As a result, downtime and maintenancecosts are greatly reduced. And there are no wornseals to replace.lsochem pumps are offered in two different designs, centrifugaland positive displacement gear type, providingextensive capabilities. The CM Series of centrifugalpumps is available as single-or multi-stage units (up to fivestages). Our GMC Series gear pumps are ideal for usewhen you encounter viscosity or suction lift applications.They are available in 316 stainles steel Alloy 20 and AlloyC construction for maximum chemical resistance.Advanced Magnetic Technology.State-of-the-art magnetic technology provides a safe andreliable pump for difficult applications. The drive magnelassembly is fixed to the motor shaft. The driven magnetassembly is attached to the pump shaft and rotates whenthe drive magnet rotates as a result of magnetic force. Thehigh torque capability of the neodymium iron and rare earthsamarium cobalt permanent magnets alleviates the possibilityof coupling slippage. The 316 SS and Alloy C Canseparates the magnetic assemblies and contains the liquid.lsochem Offers Many Benefits.. Minimizes exposure of your personnel tohazardous chemicals.. Eliminates contacting seal faces which areprone to wear and leakage.. Provide superior corrosion resistance andminimizes heating (due to eddy-current effect)by utilizing an Alloy C Containment Can.. Eliminates costly seal flush systems requiredon all pumps with double mechanical seals.. Reduces downtime and maintenance coststhrough extended service intervals.. Eliminates alignment problems inherentin direct-coupled units.Applications.lsochem Series pumps offer two principaldesigns to handle a broad range of applicationsover wide temperature, viscosity and pressurevariations. They are ideal for vacuum serviceand transfer of expensive, hazardous and/orcorrosive chemicals over the entire pH range.Seal-less features make them perfect for environmentsubjecto federal regulations.

lsochem Gentrifugal <strong>Pump</strong>s.I 50 lb. Al{Sl ralsed-facaflanges optional.' ' , ;gW la;Silicolt'oaiblde axial.andr .raaial.bearins$ miRlmlzq,"w ar.Tsf bn O{ingt rt*ngar,.{t.Alloy C Containment Can minimizesheat rise, reeists corrosion.. :lAvailable in 316 stainlesssteel, Alloy 20 and Alloy G.The lsochem centrifugal pumpwas designed with the user inmind. The features found in theCMC and CMH Series provide theuser with a safe, leak-free installationand long operating life.As illustrated, lsochem centrifugalsare designed with thehighest quality materials. Thishelps insure maximum operatinglife under the mostdemanding process conditions.For example, our advancedbearing design supporting themagnetic assembly utilizessilicon carbide, providing superiorwear and corrosion resistanceassuring longer life.High Efficiency.Hydraulic efficiency has beenraised to a level unmatched inpumps of this size. Precisioncast closed impellers and housingsreduce flow resistance toa minimum, resulting in lowerhorse-powerequi rements.Operating Lirnits.lsochem standard centrifugalpumps are rated at temperaturesup to 450'F, and viscosities up to100 centipoises. For extendedapplication ranges consult yourlocal representative.FLow tMJltiRt9 1 2 1 5MH5t'1H90658075Io200UI 1EO160'\IMH2i\7 0 GEr o 5- ^ iNl5c flHl0Our unique forced product circulation system lubricates our bearings and provides cooling to alleviateheat rise induced by magnetic eddy-current in the containment can.

The graphs on the following pages depicthe performance ranges of our single-stage or multi-stage pumps based on cleanwater at 60'F with flooded suction and 3450 r.p.m.motor operating speeds.cMclCMHlF_to0 1 2100LUI908070603 /.4-J-0lA50l0201003 8 8 DI 31%tlFLow {v3ruRl5 6 7 8 9 10 11 12 13 14-L,t..ṣ< i+'% EFF C IENt 0 6 D\>40%i-.\I"_lI L-1o -l-6JNPSIS1R (F FUI L D20 30 40FLOW (6PM)4{l. tt T'5 H P20n EtuFul. - tl l -10otll=r100906070o5oUI403020100so D'tt 2l%5r?%\{rFLow mllHR )\ \llr :"1-;l * SHR {FT FUL L9 1 2 1 50 1 0 2 0 3 0 1 0 5 0 6 0 7 0 8 0FLOW (GPP1)\18z120@&Frs 3'10ou!6 5 0All dimensions in inchesAll dimensions in inchesMotor dimensions may vary by manufacturer Consult manufacturer's drawing for specificsGcneral specificotiongModelAlloycMcl 316SS,Alloys 20 & CcMHl 31655,Alloys 20 & CInletL"FNPTtTz'FNPTOutlet3/4t'FNPTt,'FNPTBest Eff.Point (BEP)30 GPMat 58 ft.51 GPMat 78 ft.Max.Flow (GPM)5494Shut-offHead (FT)7293HP SpeedRange (RPM)3/q to tr/z 3450tr/z to 3 3450Weight(<strong>Pump</strong> & Adaptor)5O lbs.7O lbs.

FLoW t!3/HR )FLow tt,t3znRt2009 12 152/,09 1 2 1 5FI1801601 /.0120o 100UI6056 *i36X- l\\NX EFFlEN' Y\_+ S.40^a&uJUFU:oUI[220200180160ofi 1r.0E124L 5 6 Dt3x15%\Nl*"L\ENT60@&U50 Fzou40r6040200'"7)l-,l *"= FUL Lt0 /,0 50 60 70 60 90 100FLOW {6Pil)5 H P10060605-t:l-" llJn".IFULL DIAI4 h P30 40 50 60 70 60 90 100FL0W ( 6Pt'l )6 5 0All dimensions in inchesAll dimensions in inchesMotor dimensions may vary by manufacturer Consult manufacturer's drawing for specificsGenercl specificotionoModelcMH2Alloy316SS.Alloys 20 & CcMH3 31655,Alloys 20 & Clnlett1/z'FNPTLt/zuFNPTOutletl"FNPTt,,FNPTBest Eff.Point (BEP)51 GPMat 132 ft.51 GPMat 178 ft.Max.Flow (GPM)9494Shut-offHead (FT)165235HPRange3to53 to 7r/zSpeed(RPM)34503450Weight(<strong>Pump</strong> & Adaptor)79lbs.88lbs.

CMH4GMH5FLOW (M]/HR)3209 12 151204001ZO1103601103202EO 456tirE\?lto200tsLo160U T 12080/.00o"r- -NL.unNTlfP \6%,,t:rl-;_l ,"SHR (5FULLotA.N.\7 5HP/.0 50 60 70 60 90 100FLOW (GPH)100908070qE60 uF u:50*O40y3020100FIoUI3202EO2tO20016012060t,o0100908 0 ^qtU70 Fu:6o ou50r/.03020'10040 50 60 70 80 90 100FLOW (6PM)E 5 0All dimensions in inchesMotor dimensions may vary by manufacturer Consult manufacturer's drawing for specificsGenerol opecificotionoModelcMH4cMHsAlloy3n6SS,Alloys 20 & C316SS.Alloys 20 & Clnlettr/2"FNPTt7/2"FNPTOutlett"FNPTt,FNPTBest Eff.Point (BEP)51 GPMat225tt.51 GPMat273tt.Max.Flow (GPM)9494Shut-offHead (FT)297365HPRange3to1O5to10Speed(RPM)34503450Weight(<strong>Pump</strong> & Adaptor)1O7lbs.116 ]bs.

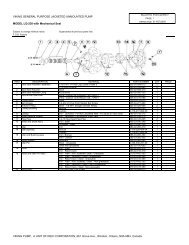

How To Select The Right <strong>Pump</strong>,All lsochem pump identification plates include the basic modelnumber. These numbers fully describe the pump specificationsnecessary for the future identification of your pump, and thereplacement of parts or equipment, as needed.Look at the sample model number (below) to see what informationthese numbers contain.Note: Be sure to provide complete nameplate data when you orderSpare parts or replacement pump-motor assemblies.lsochemGentrifuqal<strong>Pump</strong> Oitions.Pulsafeeder will modify or adapt ourpumps to meet severe or unusualservice conditions. Also, we canmanufacture specialized pumps tomeet specific application requirements.Contact your local lsochem representativefor assistance in determining what- if any - modifications you need.In addition to the many standardfeatures offered on the lsochemcentrifugal pump, the following arealso available:Position No.Model No.r 2 3 4 to 7172OptionsMotorOutlet portInlot portNon-varlable-magnotlccoupllnglmpollor dlamotor<strong>Pump</strong> materlal<strong>Pump</strong> identificationnumber selection table<strong>Pump</strong> staSoModelCent?lfugal MagnotlcdrlvePower Frame Assembly: When NEMAC-flanged motors are not available, orwhen base mounting is required. Theassembly is equipped with single ordouble row anti-friction bearings.PositionNo. 1&2 CM = Centrifugal Magnetic drivePosition No.3 Model Standard lmpeller Diameterc 3.88"H4.56'Position No. 4Position No. 5Position No.6<strong>Pump</strong> Stage1 = Single Stage2 = Two Stage3 = Three Stage4 = Four Stage5 = Five StaoeAvailable <strong>Pump</strong> MaterialsA=JIODJB = 316655 (Pickle& Passivate)C = Alloy CD = Allov 20lmpeller DiameterS = Standard lmpellerA = 3.44"Q-enA,l^ _ A 1 E rcXXXXXXXModelHXXXXXXXXXXxPosition No.7 N = Non-variable-Maqnetic couplinqPosition No.8Inlet PortE = 1" FNPTF = 1'l," FNPTL = 1'' .150 Ib, FLANGEM = 1'l." - 150 lb. FLANGEPosition No.9Outlet PortD = %" FNPTE = 1" FNPTK="li' - 150 lb. FLANGEL = 1' . 150 Ib. FLANGEPosition No. 10 MotorY = <strong>Pump</strong> and MotorN = <strong>Pump</strong> Wet End OnlyPosition No. 11 & 12* OptionsSS = No OptionsAX = Vents and DrainsMA = 140TC Frame Motor MountingMW = Welded Driven Magnet AssemblyXXXXXXXXxXxXXXXXXxFlanged Ports: Raised-face 150 lb.ANSI flanges are available on thesuction and discharge ports of theCMH and CMC models.Vents and Drains: NPT tappedconnections provide easy and safeaccess for draining or venting product..Standard mounting arrangement is 56C for CMC and 140 TC for CMH.

lsochem Gear <strong>Pump</strong>s,Alloy G Containment Ganminimizes heat rise andprovides superiorcorrosion resistance.Close-coupled mounting toNEMA C-flange or metricflanged motors eliminatealignment problems.Available in 316 stainless steel,Alloy 20 and Alloy CThe numerous material combinationsavailable make lsochem pumps idealfor continuous duty industrial applicationsover wide temperature, viscosityand pressure variations. Theseself-priming pumps yield a constantvolume for a particular drive speedand provide linear pulsation-freeflows. They depend only upon fluidspumped for cooling, and aredesigned with component materialswhich are inherently self-lubricating.Optional silicon carbide bearingswith hardened shafts provideextended life and longer service intervals.Neodymium lron andSamarium cobalt permanent magnetsprovide high torque capability.Like the lsochem Centrifugal pump,the lsochem Gear pump incorporatesmany standard features which allowsus to deliver a producthat is unsurpassedin quality by other seal-lesspump manufacturers.lsochem gear pumps are easy tomaintain. All that is required toinspecthe internal components isthe removal of a single end plate.Therefore, these pumps can berepaired in the field in a matter ofminutes-without removal from yoursystem-because we use completelyi nterchangeable quality-controlledparts.Dimensional DataSee Back PageSpecificationsMax flow @ 1750 RPM, 0 pressure cPM (M3/HR)Max flow @ 1150 RPM, 0 pressure cPM (MS/HR)Theoretical displacementMax diff presGAU1 00REV (cclREV)PSr (BARS)Max. diff. pres. plastic/plastic gearsPSr(BARS) 50 (3.45)Max. casing presTemperature Range:Metal/metal gearsSamarium (s)Metal/carbon gearsMetal/peek gearsPeek/peek gears (5)Metal/plastic gears (1)Plastic/plastic gears (1)(6)Temperature Range:Metal/metal gearsNeodymium (N)Metal/carbon gearsMetal/peek gearsPeek/peek gears (5)Metal/plastic gears (1)Plastic/plastic gears (1)(6)Max. viscosity (2) SSU (CPS)Min viscosity: Metal/metal gearsssu (cPS)Min viscosity: Ceramic wear platesssu (cPS)Max rotational speedMax rotational speed: Metal/metal gearsMagnetic coupling torque limit @ 6B"F|N/LB (4)(S)Magnetic coupling torque limit @ 450'F|N/LB (4)(S)Magnetic coupling torque limit @ 68'Fll\YLB (4)(N)Magnetic coupling torque limit @ 300'FrN/LB (4)(N)Inlet port sizeNPT, BSPI 150 LB FLG0utlet port sizeNPI BSPT, l5O LB FLGCan drain poft sizeNPTBearing typeBearing lubricationRotation directionMotor frame sizes availableStandard sealing material<strong>Pump</strong> and casing HxWxL<strong>Pump</strong> and casing weight(3)INLBS (kq)GMC2 GMC415 (.34) 3.0 ( 68)1.0 (.23) 2.0 (.45).108(408) .18e(7.15)100 (64) 100 (6.9)50 (3.45) 50 (345)150 (10.3) 150 (10.3)0 to +210'F 0 to +210"Ffl B to +99'C) (-18 to +99"C)-1 00 to +300"F -1 00 to +300'F(-73 to +149'C) f73 to +149'C)GMC6100 (23) GMCS22.0 (50) GMH610.0 (23)64 (15) 14.5 (3.3) 6.4 (15)684(25.89) 1.3687(51 78) .684(2589)100 (69) 50 (3.4s) 200 (13 B)50 (345) 50 (3.45) N/A150 (10.3) 150 (103) 2s0 (172)0 to +210'F 0 to +210'F 0 to +210'Ffl B to +99'C) f1 B to +99'C) fl B to +99'C)-100 to +300'F -100 to +300'Ff73 to +149'C) (-73 to +149'C)0 to +21 0"F 0 to +21 0'F 0 to +210"F 0 to +210'F 0 to +210'F 0 to +21 0"F 0 to +210'F 0 to +210"Ffl8to +99'C) fl8to +99'C) fl8to +99'C) (-1Bto +99'C) fl8to +99'C) (-1Bto +99"C) flBto +99'C) (-18 to +99'C)500000 500000 500000 500000 500000 500000 500000 500000(100000) (100000) (100000) (100000) (100000) (100000)(100000)(100000)500 (100) 500 (100) 500 (100) 500 (100) 500 (100) 500 (100)500 (100)500500 (100) 500 (100) 500 (100) 500 (100) 500 (100) 500 (100)500 (100) 500 (100)1750 RPM 1750 RPM 1750 RPM 1750 RPM 1750 RPM 1750 RPM 1150RPM 1150 RPt\41450 RPM 1450 RPM ]450 RPM 1450 RPM 1450 RPM 1450 RPM 1150 RPM 1150 RP[/75.6 756214 214 389 (2BB) sm(2BB) 637(4S) 1239(991)60.4 604172 172 341 (252) 341 (252) 558 (434) 1084(872)77.0 770219 219 N/AN/AN/AN/A515 515146 146 N/ANiAN/AN/A1/4 THD 1I2THD 3/4 THD 1 THD 3/4 THD 1 THD l12lHDorH-G 2 FLG1I IHD 1I2THD 3/4 THD 1 THD 3/4 THD 1 THD 1lZlHDorH-G 2 FLG1/8 THD 1/B THD 1/B THD 1/B THD 1/8 THD 1/8 THD 1/4 THD 1/4 THDlnternal sleeve Internal sleeve Internal sleeve Internal sleeve Internal sleeve lnternal sleeve lnternal sleeve lnternal sleeveBy pumped fluid By pumped fluid By pumped fluid By pumped fluid By pumped tluid By pumped fluid By pumped fluid By pumped fluidReversible Reversible Reversible Reversible Reversible Reversible Reversible Reversible56C,145TC, 56C,145TC. 56C,145TC, 56C,145TC 143/5TC 143t5TC Any, Any,71, B0 71, B0 80,90 80,90 1001 1001base mount only base mount onlyTeflon Teflon Teflon Teflon Teflon Teflon Teflon Teflon6.50x6.50x7 25 6.50x650x7.256.75x675x8.386"75x6.75x8.38B.BBxB.0Ox12 19 B.BBxB.00x1 3.44 12.19x10x24.5612 19x10x265616 (3s 3) 16 (3s.3) 28 (61.7) 30 (661) 70 (154) 75 (r65) 190 (418) 225 (495\N/AN/AGMHs22.0 (5.0)14.5 (3.3)1.3687 (5178)100 (6 e)N/A150 (10.3)0 to +210"F(-18 to +99'C)N/AN/AGM12N/A28.0 (6.3)2752 (105.7)100 (6.e)N/A150 (103)-100 to +450'F -100 to +450'F -1 00 to +450'F -1 00 to +450'F -1 00 to +450'F -1 00 to +450'F -1 00 to +450"F -1 00 to +450'Ff73 to +232'C) f73 to +232"C) f73 to +232'C) (-73 to +232'C) f73 to +232'C) f73 to +232"C) f73 to +232"C) (-73 to +232"C)0 to +210'F(-18 to +99'C)N/AN/AGM16N/A55.0 (12.s)5584 (211)100(6e)N/A150 (103)0 to +21 0'F(-1 B to +99'C)N/ANiANotes: ( 1 ) For temperatures over 110'F trimmed plastic gears are required(4) Torque In ( ) is for double can pumps(2) Consultthefactorylorhigherviscosities. (5) Peek/peekgearsarenotavailableontheGMH6,GI\IH8,G[il12andGMl6(3) Dimensionsvaryformetricunits,butarewithinenvelopedimensionsspecified.(6) Plastic/plasticgearsarenotavailableontheGMH6,GMHB,GMl2andGMl6(S) Samarium Cobalt magnets(N) Neodymium lron magnets.

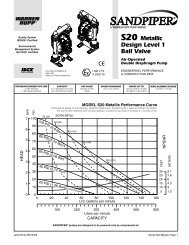

GMC2GMC4tL,,L:Lto *,,Ial50FLU ID V I SCOS I TY ,1 CPSE0 7n:)3 0FLUID VISCOSITY 1 CPSo :o lī'0 25rt'0 20[Io 15F250075(I/ W- I0_utU)EtLi:aE/ u 4 fo(LL!nt" T .Lll:

GMC6GMCstE7 8:Lt!IAlFLUTD VtSCOStTY 1 CPScE7E0*l,a)FLUID VISCOSITY 1 CPS1 501 2 5E.8 H- IUuJYE.1510V1 o o 9o(]-UU)trIU)tE.50 d)1OO PSIG800 kPo5O PSIG400 kPoEE2 8:0_|'alFLUID VISCOSITY lOO CPSLE7:0-L,6)FLUID VISCOSITY 1OO CPSx.8 9OUJU1&A- IOU)au.t, ^^ tuI vu 30-UaEIU)

lGMCSGMH6Lr t OE/ frI6l-IIE0-L'-tn5l- - ll1 7 0IFLUID VISCOSITY 1 CPS1 501 2 5E1 o o *o-UU1cl 6? 12 01.61.2&@)12106FLUID VISCOSITY 1 CPS3.0z )U2 oE LUe.Ut lE.I0 8LI d g, " oU:

GMHsGM12r3 00730FLUID VISCOSITY 1 CPS6 0t 15A Rph7 5 06255 0t2 00 > OLL1l" - ^ oI )U Ia(ttr_l543860 Re.2015{90_gpr4 03 0gatrl3oLUv)tr:oILll)l1 00um?10Z'^og-99uOo:m50151 002A40 6A80800kPo:Ir-fl/- -"Il5LIlt0252A15FLUID VISCOSITY 1OO CPSRPI'1I 5-e-RPl'*6o-/ - $3 007 5 0xll_l2 00 3 oLtr,lnJ:1 5 0 ?tl-l30232015r 50 RPIn6O actFLUID VISCOSITY 1OO CPS7:.'t'6" --"6 05 04 03 0rLUO0-UnIIoIil10600 RPflu1 0 0 m10]OO RPM6-o-o- 99Y'? otmII1lI0 L05300505?99-9P-U060 80 20 4A 60 80'1 0800kPa

lsochem Gear<strong>Pump</strong> Options.GM16In addition to the many standard featuresoffered on the lsochem gear pumps; thefollowing options are also available:. Silicon carbide bearings with hardenedshafts provide added life, extendedservice intervals.Pedestal assembly:0_t?6FLUID VISCOSITY 1 CPS). A pedestal assembly equipped with antifrictionbearings is ideal when specifyinga base mount or pulley drive unit, orwhen a C face motor is not available.. Bolt-on jackets can enable the userto maintain close control of pumping temperatures.The jackets are designed toconform closely to pump contours totransfer heat evenly. The heating mediummay be steam of a heat transfer fluid.10TT0 =OLlrlag:^Oova:.mt0*UalFLUID VISCOSITY 1OO IPS. Flanged Ports: Raised-face 150 lb. ANSIflanges are available on the suction anddischarge ports of the GH1 2 and GM16models.12IIuoLlrlaxo ?Uoxm1OO PSIGConsult your local representative for optionsto meet your special requirements.

How To Select The Right <strong>Pump</strong>.Position No.Model No.OptionsMounting arrangen:e.:Bearing materialWear plate materiarldler gear materialDrive gear material<strong>Pump</strong> materialModel*SizeGear Magnetic driveAll lsochem pump identificationplates include the basic modelnumber. These numbers fullydescribe the pump specificationsnecessary for the futureidentification of your pump, andthe replacement of parts orequipment, as needed.Look at the sample model number(above) to see what informationthese numbers contain.Note: Be sure to provide completenameplate data when youorder spare parts or replacementpump-motor assemblies.Position 1 lsochem' Magnetically Driven SeallessGMC = C-Face Motor Mounting Assembly-2, 4,6,8GM = C-Face Motor Mounting Assembly- tz! toGMH = Higher Pressure Model, C-Face Motor Mountinq Assemblv' -6, 8Position 2 Pumo Size 2 4 6 8 . 6 ' : 1 2 1 6Port Size (inches)qnn.25' .7s' '1.00'.13 : f,u 2.00Capacity (GPM MAX)3 10 22 10 22 28 55Differential Pres. (PSIG MAX)100 100 100 50 200'::1c0'100Position 3 Available <strong>Pump</strong> Metallurqies and Tvpe Port ConnectionA = 31655 FNPTX X X XXXC=ALLOYC FNPTX X X XXD = ALLOY 20 FNPTX X X XXK = 31635 FBSPTX X XXXM=ALLOYC FBSPTX X XXXN = ALLOY 20 FBSPTX X X X XXU = 31655 FlangedX XV=ALLOYC FlangedW - l x XALLOY 20 Flanqed] X XPosition 4 Drive Gear MaterialC = ALLOY CX X X X XXD = ALLOY 20X X X XT = TFE (GLASS FTLLED) (1)X X X XE = PEEK (1)XX XPosition 5 ldler Gear MaterialC=ALLOYC (2,12) X XXXD = ALLOY 2o (2)X X X XK = CARBONX XX XT = TFE (GLASS FILLED)XXXE = PEEKX X X X X X X XPosition 6 Wear Plate MaterialK = CARBONX X X X X X X XT = TFE (GLASS FTLLED)X X XX Xz = OERAMIC (3)X XXE = PEEKXX X XXPosition 7 Bearing and Shaft MaterialK = Standard Carbon (4\X XX X xL = Extended Life Carbon (4\X X X XX XT = TFE (Glass Filled) (4, 11)X X X XX X4 = Standard Carbon - Slotted (4)XC = Extended Life Carbon - "CW" (5)X X XXX XB = Silicon Carbide - "CW"Shaft (5. 6)X X X XX X XPosition 8 Mag Dlrve Mounting ArrangementSTANDARD US MOUNTINGSF = 56C Frame, SGL. Can Cntnmnt 1e\XX XO = 143TC- 184C frame, SGL. Can Cntnmnt13)XXXD = 143TC- 184C frame, DBL.. Can Cntnmnt 1e\XR = @1.125Input shaft, SGL. Can Cntnmnt 14)X XT = Q|j25Input shaft, DBL. Can Cntnmnt'14)X XIiIANUAHIJ ME IRIO MOUNTINGSJ = 71 frame, SGL. CAN (O 85.00 B.C.) (13)X XK = 80 frame, SGL. CAN (O100,00 B.C,) (19)X X X XL = 90 frame, SGL. CAN (O115.00B.C.) (13)X XP = 100 frame, SGL. CAN (O130.00 B.C.) (13)Q = 100 frame, DBL. CAN (O130.00 B.C.) (13)XU = 28mm input shaft, SGL. CAN cntnmnt (1+1X XV = 28mm input shaft, DBL. CAN cntnmnt fi4\X XPosition 9, 10, and 11 optionsconsult your local representative for options to meet your special requirementsNotes: (1) Maximum differential pressure for plastic/plastic gears is 50 pSlG.(2) <strong>Pump</strong>s with metallic drive and idler gears require minimum viscosity of 100 cps and are limitedto 1440 RPM maximum speed for GMC2-GMH8 and 1150 RPM for GM12-16 pumps.(3) Ceramic wear plates with metallic gears require minimum viscosity of 100 cps.(4) Shaft material is same as material of pump.(s)"CW" means corrosion/wear shaft material.(6) Recommended for speeds above 1150 RPM and viscosities above 1 cps.GMH8, GMl2i16 pumps require minimum viscosity of 100 cps.(11)GM12 TFE bearings can not be used above 100 psi differential pressure.GMl6TFE bearings can not be used above 50 psi differential pressure.(12) GMl2 pumps with metal idler gear can be operated150 psi differentialpressure.(13) GMC2, GMC4, GMC6, and GMCS pumps require motors with feet.(14) GM12, GM16 pumps are not available with integrally mounted motors.( -) High Pressure Mode(16) Use"F" in position 8 when using a power frame13

Dimensional DataA5.625.626.477.099.129.75.<strong>Pump</strong> Dimension In lnchesB l c l C r l o t E l r.so l i.44 T- l .zsolr.slLst.75 11.66 1 | .75.7s .75 I | z.oo 2.00 | I | r.oc 1.00 | 9.94 |.zsJr.eel- 1.66 I.7s Illl l2.ool 2.00 | 1.oo lrg.rgls.ssz.so 2.50 | - lr.soruprl I.zs lrr.s+l+.zs6M2/6MC2 THRU, GM8/6MC8DIMENSIONS SHOWN ARE FOR 56C FRAIYE MOTORSl*N'rsoJ| |_.12.141__| 1"' -6MH6 AND GMHSD NPTORGM12 AND 16I01125lrI ,url|,, 1lsochem Express DeliversThe <strong>Pump</strong>s When You Need Them.Pulsafeeder will give you prompt technical service with off-the-shelf solutions to your pumping needs.Call you local lsochem representative today for the pumps, parts and service you need.lGar tt a. tr t-r-t-a1,a-t)JATUENFEEUE'IA Unit of IDEX GorporationEngineered <strong>Pump</strong> Operations2883 Brighton-Henrietta Townline RoadRochester, NewYork 14623 USATelephone: (585) 292-8000 Fax: (585) 424-5619http://www.pulsa.comEmail: pulsa@ idexcorp.com,HPrinted in U.S.A.