June - Modern Materials Handling

June - Modern Materials Handling

June - Modern Materials Handling

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

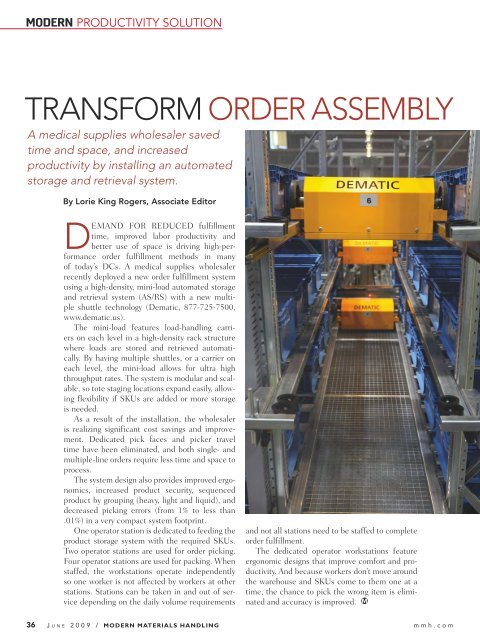

modern PRODUCTIVITY SOLUTIONTRANSFORM ORDER ASSEMBLYA medical supplies wholesaler savedtime and space, and increasedproductivity by installing an automatedstorage and retrieval system.By Lorie King Rogers, Associate EditorDEMAND FOR REDUCED fulfillmenttime, improved labor productivity andbetter use of space is driving high-performanceorder fulfillment methods in manyof today’s DCs. A medical supplies wholesalerrecently deployed a new order fulfillment systemusing a high-density, mini-load automated storageand retrieval system (AS/RS) with a new multipleshuttle technology (Dematic, 877-725-7500,www.dematic.us).The mini-load features load-handling carrierson each level in a high-density rack structurewhere loads are stored and retrieved automatically.By having multiple shuttles, or a carrier oneach level, the mini-load allows for ultra highthroughput rates. The system is modular and scalable,so tote staging locations expand easily, allowingflexibility if SKUs are added or more storageis needed.As a result of the installation, the wholesaleris realizing significant cost savings and improvement.Dedicated pick faces and picker traveltime have been eliminated, and both single- andmultiple-line orders require less time and space toprocess.The system design also provides improved ergonomics,increased product security, sequencedproduct by grouping (heavy, light and liquid), anddecreased picking errors (from 1% to less than.01%) in a very compact system footprint.One operator station is dedicated to feeding theproduct storage system with the required SKUs.Two operator stations are used for order picking.Four operator stations are used for packing. Whenstaffed, the workstations operate independentlyso one worker is not affected by workers at otherstations. Stations can be taken in and out of servicedepending on the daily volume requirementsand not all stations need to be staffed to completeorder fulfillment.The dedicated operator workstations featureergonomic designs that improve comfort and productivity.And because workers don’t move aroundthe warehouse and SKUs come to them one at atime, the chance to pick the wrong item is eliminatedand accuracy is improved.36 J UNE 2009 / MODERN MATERIALS HANDLING mmh.com