Plastic Material Selection Guide - Curbellplastics.com

Plastic Material Selection Guide - Curbellplastics.com

Plastic Material Selection Guide - Curbellplastics.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

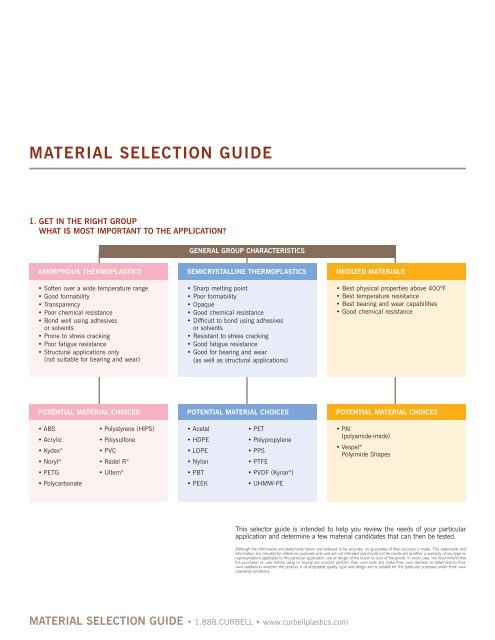

MATERIAL SELECTION GUIDE1. GET IN THE RIGHT GROUPWHAT IS MOST IMPORTANT TO THE APPLICATION?GENERAL GROUP CHARACTERISTICSAMORPHOUS THERMOPLASTICS• Soften over a wide temperature range• Good formability• Transparency• Poor chemical resistance• Bond well using adhesivesor solvents• Prone to stress cracking• Poor fatigue resistance• Structural applications only(not suitable for bearing and wear)SEMICRYSTALLINE THERMOPLASTICS• Sharp melting point• Poor formability• Opaque• Good chemical resistance• Difficult to bond using adhesivesor solvents• Resistant to stress cracking• Good fatigue resistance• Good for bearing and wear(as well as structural applications)IMIDIZED MATERIALS• Best physical properties above 400ºF• Best temperature resistance• Best bearing and wear capabilities• Good chemical resistancePOTENTIAL MATERIAL CHOICESPOTENTIAL MATERIAL CHOICESPOTENTIAL MATERIAL CHOICES• ABS• Acrylic• Kydex ®• Noryl ®• Polystyrene (HIPS)• Polysulfone• PVC• Radel R ®• Acetal• HDPE• LDPE• Nylon• PET• Polypropylene• PPS• PTFE• PAI(polyamide-imide)• Vespel ®Polyimide Shapes• PETG• Ultem ®• PBT• PVDF (Kynar ® )• Polycarbonate• PEEK• UHMW-PEThis selector guide is intended to help you review the needs of your particularapplication and determine a few material candidates that can then be tested.Although the information and statements herein are believed to be accurate, no guarantee of their accuracy is made. The statements andinformation are included for reference purposes only and are not intended and should not be construed as either a warranty of any type orrepresentations applicable to the particular application, use or design of the buyer or user of the goods. In every case, we re<strong>com</strong>mend thatthe purchaser or user before using or buying any product perform their own tests and make their own decision to determine to theirown satisfaction whether the product is of acceptable quality, type and design and is suitable for the particular purposes under their ownoperating conditions.MATERIAL SELECTION GUIDE • 1.888.CURBELL • www.curbellplastics.<strong>com</strong>

MATERIAL SELECTION GUIDECROSS-SECTIONALAREA (SQ. IN.)LOAD (LBS.)LOAD (LBS.)ORIGINAL LENGTHCHANGE IN LENGTH3. COMPARE THE MECHANICAL PROPERTIESIS TENSILE STRENGTH (RESISTANCE TO BEING PULLED APART) IMPORTANT?AMORPHOUS THERMOPLASTICSTensile strength - pull apart (psi)• Ultem ® 15,200• Polysulfone 10,200• Radel R ® 10,100• Acrylic 10,000• Noryl ® 9,600• Polycarbonate 9,500• PETG 7,700• PVC 7,500• Kydex ® 6,100• ABS 4,100• Polystyrene (HIPS) 3,500SEMICRYSTALLINE THERMOPLASTICSTensile strength - pull apart (psi)• PEEK 14,000• Nylon (6 cast) 10,000-13,500• PPS 12,500• Nylon (6/6 extruded) 12,400• PET 11,500• Acetal (Homopolymer) 10,000• Acetal (Copolymer) 9,800• PBT 8,690• PVDF (Kynar ® ) 7,800• Polypropylene (Homopolymer) 5,400• HDPE 4,000• Polypropylene (Copolymer) 3,800• UHMW-PE 3,100• PTFE 1,500-3,000• LDPE 1,400IMIDIZED MATERIALSTensile strength - pull apart (psi)• PAI (polyamide-imide) 21,000• Vespel® Polyimide SP-1 12,500• Vespel® Polyimide SP-21 9,500• Vespel® Polyimide SP-3 8,200• Vespel® Polyimide SP-22 7,500• Vespel® Polyimide SP-211 6,500MATERIAL SELECTION GUIDE • 1.888.CURBELL • www.curbellplastics.<strong>com</strong>

MATERIAL SELECTION GUIDELOAD(LBS.)NEUTRAL AXIS(NO STRESS)SQUEEZINGSTRETCHING4. COMPARE THE MECHANICAL PROPERTIESIS FLEXURAL MODULUS (BENDING STIFFNESS) IMPORTANT?AMORPHOUS THERMOPLASTICSFlexural modulus - stiffness (psi)• Ultem ®(30% glass-filled) 1,300,000• Polycarbonate(20% glass-filled) 800,000• PVC 481,000• Ultem ® 480,000• Acrylic 480,000• Polysulfone 390,000• Noryl ® 370,000• Radel R ® 350,000• Polycarbonate 345,000• Kydex ® 335,000• Polystyrene (HIPS) 310,000• PETG 310,000• ABS 304,000SEMICRYSTALLINE THERMOPLASTICSFlexural modulus - stiffness (psi)• PPS 600,000• PEEK 590,000• Nylon (6 cast) 420,000-500,000• Acetal (Homopolymer) 420,000• Nylon (6/6 extruded) 410,000• PET 400,000• Acetal (Copolymer) 370,000• PBT 330,000• PVDF (Kynar ® ) 310,000• Polypropylene (Homopolymer) 225,000• Polypropylene (Copolymer) 215,000• HDPE 200,000• UHMW-PE 110,000• PTFE 72,000• LDPE 30,000IMIDIZED MATERIALSFlexural modulus - stiffness (psi)• PAI (polyamide-imide) 711,000• Vespel® Polyimide SP-22 700,000• Vespel® Polyimide SP-21 550,000• Vespel® Polyimide SP-3 475,000• Vespel® Polyimide SP-211 450,000• Vespel® Polyimide SP-1 450,000www.curbellplastics.<strong>com</strong> • 1.888.CURBELL • MATERIAL SELECTION GUIDE

MATERIAL SELECTION GUIDE5. COMPARE THE MECHANICAL PROPERTIESIS IZOD IMPACT (TOUGHNESS) IMPORTANT?AMORPHOUS THERMOPLASTICSIzod impact (notched) - toughness (ft-lbs/in)• Kydex ® 18• Polycarbonate 12.0-16.0• Radel R ® 13• ABS 7.7• Noryl ® 3.5• Polystyrene (HIPS) 2.0• PETG 1.7• Polysulfone 1.3• Ultem ® 1.0• PVC 1.0• Acrylic 0.4SEMICRYSTALLINE THERMOPLASTICSIzod impact (notched) - toughness (ft-lbs/in)• LDPEno break• UHMW-PE 18.0• Polypropylene (Copolymer) 12.5• PTFE 3.5• PVDF (Kynar ® ) 3.0• PEEK 1.6• PBT 1.5• Acetal (Homopolymer) 1.5• Polypropylene (Homopolymer) 1.2• Nylon (6/6 extruded) 1.2• Acetal (Copolymer) 1.0• Nylon (6 cast) 0.7-0.9• PET 0.7• PPS 0.5IMIDIZED MATERIALSIzod impact (notched) - toughness (ft-lbs/in)• PAI (polyamide-imide) 2.3• Vespel® Polyimide SP-21 0.8• Vespel® Polyimide SP-1 0.8• Vespel® Polyimide SP-3 0.4MATERIAL SELECTION GUIDE • 1.888.CURBELL • www.curbellplastics.<strong>com</strong>

MATERIAL SELECTION GUIDEVOLTAGE6. COMPARE THE PROPERTIESIS DIELECTRIC STRENGTH (ELECTRICAL INSULATION) IMPORTANT?AMORPHOUS THERMOPLASTICSDielectric strength - insulation (v/mil)• Ultem ® 830• PVC 544• Kydex ® 514• Noryl ® 500• Acrylic 430• Polysulfone 425• PETG 410• Polycarbonate 380• Radel R ® 360SEMICRYSTALLINE THERMOPLASTICSDielectric strength - insulation (v/mil)• Nylon (6 cast) 500-600• Acetal (Homopolymer) 500• Acetal (Copolymer) 500• PTFE 400-500• PEEK 480• PPS 450• PET 400• PBT 400• Nylon (6/6 extruded) 300-400• PVDF (Kynar ® ) 280IMIDIZED MATERIALSDielectric strength - insulation (v/mil)• PAI (polyamide-imide) 600• Vespel® Polyimide SP-1 560www.curbellplastics.<strong>com</strong> • 1.888.CURBELL • MATERIAL SELECTION GUIDE

MATERIAL SELECTION GUIDE7. THINK ABOUT THE APPLICATION - IS FDA COMPLIANCE IMPORTANT?AMORPHOUS THERMOPLASTICSFDA <strong>com</strong>pliant grades available:SEMICRYSTALLINE THERMOPLASTICSFDA <strong>com</strong>pliant grades available:• Acrylic• PETG• Polycarbonate• Polystyrene (HIPS)• Polysulfone• PVC• Radel R ®• Ultem ®• Acetal• HDPE• LDPE• Nylon• PBT• PEEK• PET• Polypropylene• PTFE• PVDF (Kynar ® )• UHMW-PEThe virgin, natural, unfilled formulations ofthe sheet, rod, tube, and film products listedhere are available from Curbell <strong>Plastic</strong>s, Inc.in grades that <strong>com</strong>ply with one or more of theFDA’s guidelines for direct food contact atroom temperature.It is important to specify FDA <strong>com</strong>pliantmaterial at the time of the order to ensurethat FDA <strong>com</strong>pliant material is provided.8. THINK ABOUT THE APPLICATION - IS CHEMICAL RESISTANCE IMPORTANT?SEMICRYSTALLINE THERMOPLASTICSGood chemical resistance:• Acetal• PET• HDPE• Polypropylene• LDPE• PPS• Nylon• PTFE• PBT• PVDF (Kynar ® )• PEEK• UHMW-PESee pages 76-77 for more specific informationIMIDIZED MATERIALSGood chemical resistance:• PAI (polyamide-imide)• Vespel ® Polyimide ShapesSee pages 76-77 for more specific informationMATERIAL SELECTION GUIDE • 1.888.CURBELL • www.curbellplastics.<strong>com</strong>