PVC Products for the Production of Rigid Films - Vinnolit

PVC Products for the Production of Rigid Films - Vinnolit

PVC Products for the Production of Rigid Films - Vinnolit

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

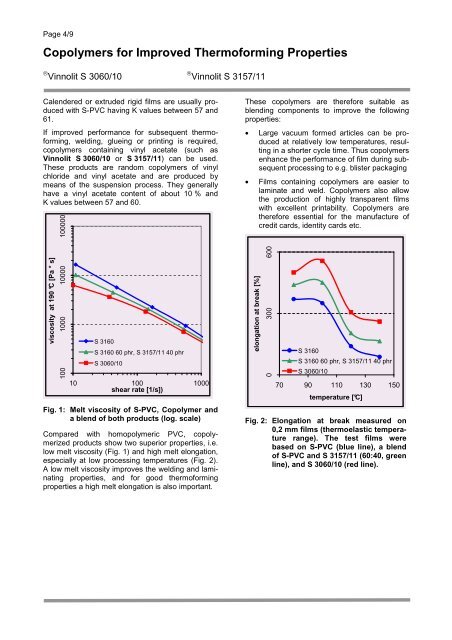

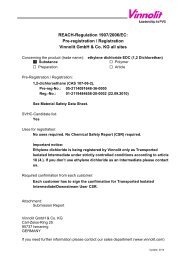

Page 4/9Copolymers <strong>for</strong> Improved Thermo<strong>for</strong>ming Properties® <strong>Vinnolit</strong> S 3060/10® <strong>Vinnolit</strong> S 3157/11Calendered or extruded rigid films are usually producedwith S-<strong>PVC</strong> having K values between 57 and61.If improved per<strong>for</strong>mance <strong>for</strong> subsequent <strong>the</strong>rmo<strong>for</strong>ming,welding, glueing or printing is required,copolymers containing vinyl acetate (such as<strong>Vinnolit</strong> S 3060/10 or S 3157/11) can be used.These products are random copolymers <strong>of</strong> vinylchloride and vinyl acetate and are produced bymeans <strong>of</strong> <strong>the</strong> suspension process. They generallyhave a vinyl acetate content <strong>of</strong> about 10 % andK values between 57 and 60.viscosity at 190 °C [Pa * s]100 1000 10000 100000S 3160S 3160 60 phr, S 3157/11 40 phrS 3060/1010 100 1000shear rate [1/s])Fig. 1: Melt viscosity <strong>of</strong> S-<strong>PVC</strong>, Copolymer anda blend <strong>of</strong> both products (log. scale)Compared with homopolymeric <strong>PVC</strong>, copolymerizedproducts show two superior properties, i.e.low melt viscosity (Fig. 1) and high melt elongation,especially at low processing temperatures (Fig. 2).A low melt viscosity improves <strong>the</strong> welding and laminatingproperties, and <strong>for</strong> good <strong>the</strong>rmo<strong>for</strong>mingproperties a high melt elongation is also important.These copolymers are <strong>the</strong>re<strong>for</strong>e suitable asblending components to improve <strong>the</strong> followingproperties:• Large vacuum <strong>for</strong>med articles can be producedat relatively low temperatures, resultingin a shorter cycle time. Thus copolymersenhance <strong>the</strong> per<strong>for</strong>mance <strong>of</strong> film during subsequentprocessing to e.g. blister packaging• <strong>Films</strong> containing copolymers are easier tolaminate and weld. Copolymers also allow<strong>the</strong> production <strong>of</strong> highly transparent filmswith excellent printability. Copolymers are<strong>the</strong>re<strong>for</strong>e essential <strong>for</strong> <strong>the</strong> manufacture <strong>of</strong>credit cards, identity cards etc.elongation at break [%]0 300 600S 3160S 3160 60 phr, S 3157/11 40 phrS 3060/1070 90 110 130 150temperature [°C]Fig. 2: Elongation at break measured on0,2 mm films (<strong>the</strong>rmoelastic temperaturerange). The test films werebased on S-<strong>PVC</strong> (blue line), a blend<strong>of</strong> S-<strong>PVC</strong> and S 3157/11 (60:40, greenline), and S 3060/10 (red line).