PVC Products for the Production of Rigid Films - Vinnolit

PVC Products for the Production of Rigid Films - Vinnolit

PVC Products for the Production of Rigid Films - Vinnolit

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

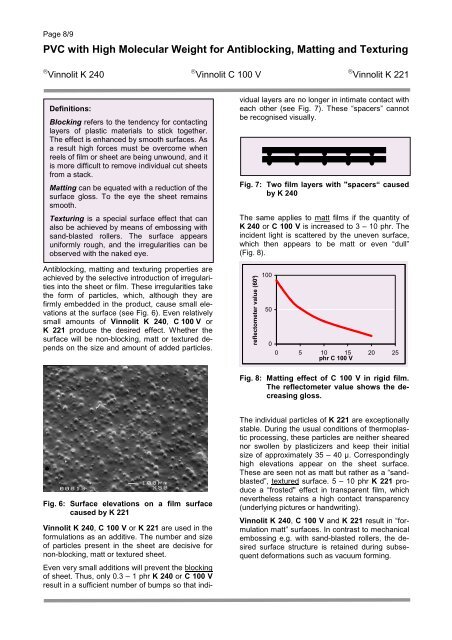

Page 8/9<strong>PVC</strong> with High Molecular Weight <strong>for</strong> Antiblocking, Matting and Texturing® <strong>Vinnolit</strong> K 240® <strong>Vinnolit</strong> C 100 V® <strong>Vinnolit</strong> K 221Definitions:Blocking refers to <strong>the</strong> tendency <strong>for</strong> contactinglayers <strong>of</strong> plastic materials to stick toge<strong>the</strong>r.The effect is enhanced by smooth surfaces. Asa result high <strong>for</strong>ces must be overcome whenreels <strong>of</strong> film or sheet are being unwound, and itis more difficult to remove individual cut sheetsfrom a stack.Matting can be equated with a reduction <strong>of</strong> <strong>the</strong>surface gloss. To <strong>the</strong> eye <strong>the</strong> sheet remainssmooth.Texturing is a special surface effect that canalso be achieved by means <strong>of</strong> embossing withsand-blasted rollers. The surface appearsuni<strong>for</strong>mly rough, and <strong>the</strong> irregularities can beobserved with <strong>the</strong> naked eye.Antiblocking, matting and texturing properties areachieved by <strong>the</strong> selective introduction <strong>of</strong> irregularitiesinto <strong>the</strong> sheet or film. These irregularities take<strong>the</strong> <strong>for</strong>m <strong>of</strong> particles, which, although <strong>the</strong>y arefirmly embedded in <strong>the</strong> product, cause small elevationsat <strong>the</strong> surface (see Fig. 6). Even relativelysmall amounts <strong>of</strong> <strong>Vinnolit</strong> K 240, C 100 V orK 221 produce <strong>the</strong> desired effect. Whe<strong>the</strong>r <strong>the</strong>surface will be non-blocking, matt or textured dependson <strong>the</strong> size and amount <strong>of</strong> added particles.Even very small additions will prevent <strong>the</strong> blocking<strong>of</strong> sheet. Thus, only 0.3 – 1 phr K 240 or C 100 Vresult in a sufficient number <strong>of</strong> bumps so that individuallayers are no longer in intimate contact wi<strong>the</strong>ach o<strong>the</strong>r (see Fig. 7). These “spacers” cannotbe recognised visually.Fig. 7: Two film layers with "spacers“ causedby K 240The same applies to matt films if <strong>the</strong> quantity <strong>of</strong>K 240 or C 100 V is increased to 3 – 10 phr. Theincident light is scattered by <strong>the</strong> uneven surface,which <strong>the</strong>n appears to be matt or even “dull”(Fig. 8).reflectometer value (60°)1005000 5 10 15 20 25phr C 100 VFig. 8: Matting effect <strong>of</strong> C 100 V in rigid film.The reflectometer value shows <strong>the</strong> decreasinggloss.Fig. 6: Surface elevations on a film surfacecaused by K 221<strong>Vinnolit</strong> K 240, C 100 V or K 221 are used in <strong>the</strong><strong>for</strong>mulations as an additive. The number and size<strong>of</strong> particles present in <strong>the</strong> sheet are decisive <strong>for</strong>non-blocking, matt or textured sheet.The individual particles <strong>of</strong> K 221 are exceptionallystable. During <strong>the</strong> usual conditions <strong>of</strong> <strong>the</strong>rmoplasticprocessing, <strong>the</strong>se particles are nei<strong>the</strong>r shearednor swollen by plasticizers and keep <strong>the</strong>ir initialsize <strong>of</strong> approximately 35 – 40 µ. Correspondinglyhigh elevations appear on <strong>the</strong> sheet surface.These are seen not as matt but ra<strong>the</strong>r as a “sandblasted”,textured surface. 5 – 10 phr K 221 producea “frosted" effect in transparent film, whichnever<strong>the</strong>less retains a high contact transparency(underlying pictures or handwriting).<strong>Vinnolit</strong> K 240, C 100 V and K 221 result in “<strong>for</strong>mulationmatt” surfaces. In contrast to mechanicalembossing e.g. with sand-blasted rollers, <strong>the</strong> desiredsurface structure is retained during subsequentde<strong>for</strong>mations such as vacuum <strong>for</strong>ming.