RZ-8 Seiter Engl. 09 - Udo Plante GmbH

RZ-8 Seiter Engl. 09 - Udo Plante GmbH

RZ-8 Seiter Engl. 09 - Udo Plante GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

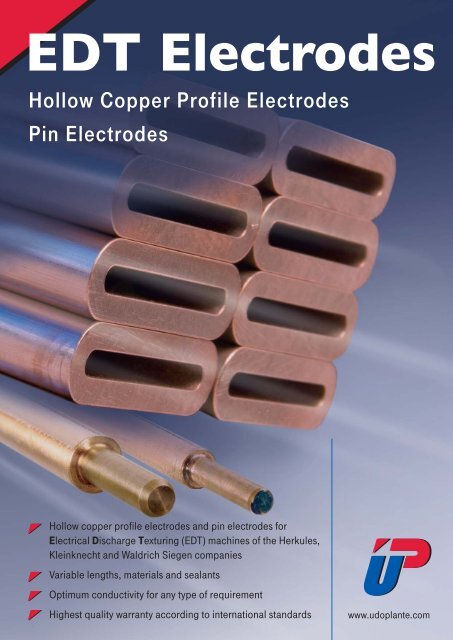

EDT Electrodes<br />

Hollow Copper Profile Electrodes<br />

Pin Electrodes<br />

Hollow copper profile electrodes and pin electrodes for<br />

Electrical Discharge Texturing (EDT) machines of the Herkules,<br />

Kleinknecht and Waldrich Siegen companies<br />

Variable lengths, materials and sealants<br />

Optimum conductivity for any type of requirement<br />

Highest quality warranty according to international standards<br />

www.udoplante.com

The World of EDT Electrodes<br />

<strong>Udo</strong> <strong>Plante</strong> <strong>GmbH</strong> is among the world<br />

leaders in the production of electrodes for<br />

roll texturing machines.<br />

Ever since in 1996 we have been supplying<br />

high quality electrodes to leading operators<br />

of EDT roll shop. The product range<br />

includes copper hollow profile electrodes<br />

and pin electrodes in a variety of different<br />

grades and dimensions.<br />

<strong>Udo</strong> <strong>Plante</strong> <strong>GmbH</strong> offers consultation and<br />

service for EDT electrodes worldwide.<br />

Publication of the photo<br />

on the left with the kind permission<br />

of H. Kleinknecht & Co. <strong>GmbH</strong><br />

CE hollow copper profile electrodes in a variety<br />

of different lengths and material grades<br />

Hollow profile electrodes without sealants, with<br />

firmly bonded polyurethane sealants and with<br />

attachable multiple use NB rubber sealants<br />

Transparent protective coating<br />

made visible under ultraviolet light<br />

Hollow copper profile electrode IN

Hollow Copper Profile Electrodes CE<br />

<strong>Udo</strong> <strong>Plante</strong>n <strong>GmbH</strong> supplies hollow copper<br />

profile electrodes for EDT machines made<br />

by Herkules, Kleinknecht and Waldrich<br />

Siegen in any required length.<br />

The Product Range:<br />

E-Cu, SE-Cu, OF-Cu<br />

For normal applications the electrodes for<br />

EDT machines are made of EC-U material.<br />

In the case of highly sensitive texturing<br />

processes it may make sense or even be<br />

imperative to use higher quality materials<br />

such as SE-Cu or OF-Cu.<br />

3 Performance Grades<br />

<strong>Udo</strong> <strong>Plante</strong> <strong>GmbH</strong> meets these requirements<br />

with a range of 3 performance<br />

grades depending on the sensitivity of<br />

the EDT process and the quality demanded<br />

by the customer.<br />

Standard Performance 1CE<br />

1 CE electrodes consist of electrolytically<br />

refined, oxygen-containing copper with a<br />

high conductivity of at least 57 m/Ω mm 2 .<br />

1 C E 010<br />

0 - - -<br />

Advanced Performance 2CE<br />

2 CE electrodes consist of high purity<br />

deoxidized copper with a low residual<br />

phosphorous content and a high conductivity<br />

of at least 58 m/Ω mm 2 .<br />

2 C E 010<br />

0 - - -<br />

All CE electrodes are<br />

hardstamped with the UP logo.<br />

High Performance 3CE<br />

3 CE electrodes consist of high purity,<br />

non-deoxidized, oxygen-free copper that<br />

contains no elements that can be vacuumvaporized<br />

and has a high conductivity of<br />

up to 59 m/Ω mm 2 .<br />

3 C E 010<br />

0 - - -<br />

CE electrode<br />

Higher demands –<br />

higher quality<br />

In normal applications the standard<br />

performance electrodes are<br />

sufficient for the EDT machines.<br />

The utilization of higher quality<br />

electrodes is required in highly<br />

sensitive texturing processes.

4<br />

Sealants for Hollow Copper Profile Electrodes CE<br />

Firmly bonded<br />

polyurethane sealant<br />

Performance<br />

Attachable NB rubber<br />

multi-use sealants<br />

Type of Electrode<br />

Sealant<br />

Length<br />

Sealants<br />

There are two different types of sealants to<br />

choose from for the hollow copper profile<br />

electrodes:<br />

• CE1 attachable NB rubber multi-use sealants<br />

2 C E11 0 0 - - -<br />

• CE2 firmly bonded polyurethane sealants<br />

2 C E21 0 0 - - -<br />

• CE0 no sealants<br />

2 C E01 0 0 - - -<br />

Electrode Lengths<br />

Hollow copper profile electrodes can be supplied<br />

in all the lengths required for Waldrich Siegen<br />

EDT machines.<br />

Standard lengths are 100 mm, 130 mm<br />

and 150 mm.<br />

2 C<br />

E01 0 0 - - -<br />

Ordering Code for CE Electrodes<br />

This example shows the easy use of the right code<br />

for a precise and error-free order:<br />

1 C E 0100-<br />

--

Hollow Copper Profile Electrodes IN<br />

Closure:<br />

either bonded or soldered<br />

NEW<br />

All types of<br />

electrode ends<br />

are reusable.<br />

Type of electrode<br />

Sealant<br />

Length<br />

IN Electrodes<br />

With IN electrodes it is possible to re-use the<br />

residual ends. They are newly soldered to<br />

hollow copper profile electrodes.<br />

• IN 1 attachable NB rubber multi-use sealants<br />

• IN 2 firmly bonded polyurethane sealants<br />

• IN 0 no sealant<br />

Ordering code for IN Electrodes<br />

Here’s how simple the coding is for a precise<br />

and error-free order:<br />

2 I N 1102-<br />

--<br />

Performance<br />

2 I N1 1 0 2 - - -<br />

2 I N2 1 0 2 - - -<br />

2 I N0 1 0 2 - - -<br />

IN electrode<br />

All IN electrodes are hard stamped with the UP logo.<br />

5

Higher demands –<br />

higher quality<br />

The protective layer consists of<br />

a flexible, transparent protectivepaint<br />

made from modified silicon<br />

resin. It meets the high demands<br />

of the US and British defense<br />

specifications. Approvals by the<br />

British Ministry of Defense (MOD)<br />

DEF STAN 59/47 – as well as by<br />

the relevant test laboratories (UL)<br />

QMJU2 – have been obtained.<br />

6<br />

Performance<br />

Pin Electrodes PE<br />

<strong>Udo</strong> <strong>Plante</strong> <strong>GmbH</strong> supplies pin electrodes<br />

for EDT machines of the Herkules company<br />

in all required lengths.<br />

Pin electrodes are made from a specially<br />

modified alloy with tightly restricted analysis<br />

tolerances. These electrodes have<br />

met the quality assurance standards according<br />

to DIN EN ISO 9001.<br />

The additional machining process is performed<br />

on highly advanced CNC machines,<br />

in accordance to the quality management<br />

system DIN EN ISO 9002.<br />

Electrodes can be supplied in any length<br />

and diameter to meet the specific needs of<br />

a particular Sarclad and Herkules EDT<br />

machine.<br />

The standard length amounts to 126 mm.<br />

4 P E31 2 6 - 9 5<br />

Type of electrode<br />

Paint<br />

Length<br />

Protective Coating<br />

The working section of the electrode is<br />

coated with a protective paint. Good dielectric<br />

properties at all frequencies, according<br />

to DEFSTAN59-4/2 Annex C, characterize<br />

the electrodes. The thickness of the<br />

protective coating ranges between 25 and<br />

50 microns.<br />

4 P E31 0 0 - 9 6<br />

Protective coating made visible<br />

under ultraviolet light<br />

Ordering code for PE Electrodes<br />

Here’s how simple the coding is for a precise<br />

and error-free order:<br />

4 P E31 26- 95<br />

Diameter

Materials, Dimensions, Weights<br />

Copper hollow profile electrodes CE/IN, Cu grades<br />

Survey of materials<br />

All CE and IN copper hollow profiles are extruded and drawn.<br />

All materials are free of Beryllium.<br />

Description<br />

Material number<br />

Electrical conductivity<br />

Min. Cu content 1<br />

Dimensions CE<br />

Dimensions IN<br />

Length CE<br />

150 mm<br />

130 mm<br />

120 mm<br />

100 mm<br />

Pin Electrodes PE<br />

Survey of materials<br />

495<br />

429<br />

396<br />

330<br />

Composition (weight %)<br />

Physical properties<br />

Density<br />

Melting range<br />

Modulus of elasticity<br />

Thermal conductivity<br />

Weight 2 in g/piece<br />

Coefficient of thermal expansion<br />

Electrical conductivity<br />

Spec. electrical resistance<br />

old<br />

new<br />

m<br />

Ω · mm 2<br />

%<br />

mm<br />

mm<br />

°C<br />

m<br />

Ω · mm2 kg<br />

dm 3<br />

kN<br />

mm 2<br />

W<br />

m · K<br />

1<br />

K<br />

min. 57<br />

Length IN<br />

72 mm<br />

102 mm<br />

E-Cu SE-Cu<br />

4 P E31 0 0 - 9 6<br />

CR021A<br />

99,90 1 99,95 1<br />

Cu Rest<br />

Sn<br />

4,50 — 5,50<br />

P<br />

0,15 — 0,25<br />

Others<br />

max. 0,5<br />

Ω · mm<br />

m<br />

2<br />

1CE / 1IN 2 CE / 2IN 3 CE / 3IN<br />

8,8<br />

910 — 1040<br />

115<br />

75<br />

- 6<br />

18,5 · 10<br />

9,5 — 10,5<br />

min. 58 min. 58<br />

45 x 12 x 4 x length<br />

75 x 16 x 5,5 x length<br />

Weight 2 in g/piece<br />

527<br />

620<br />

0,<strong>09</strong>5 — 0,105<br />

OF-Cu<br />

Cu-HCP Cu-OFE<br />

3<br />

1 incl. Ag<br />

CR0<strong>09</strong>A<br />

99,99 1<br />

2 approximate weight<br />

3<br />

left open<br />

length tolerance +1 – 0 mm<br />

sawed at a right angle and cleanly deburred<br />

7

8<br />

H. Kleinknecht & Co. <strong>GmbH</strong> from<br />

Siegen has equipped a total of more<br />

than 250 roll grinding machines in different<br />

control variations and from<br />

several manufacturers (e.g. Waldrich,<br />

Voith, Naxos, Herkules, Meuselwitz).<br />

With the Kleinknecht know-how from<br />

more than 6 decades of working on<br />

roll grinding machines and the supply<br />

of more than 60 EDT controlsystems<br />

H. Kleinknecht & Co. <strong>GmbH</strong> is among<br />

the leading suppliers of control<br />

systems in these areas.<br />

Operators of roll grinding and EDT<br />

machines rely on first-class service as<br />

well as a secure long-term supply of<br />

spare parts.<br />

EDT-Electrodes<br />

Consulting & Sales<br />

Manufacturer<br />

Angermunder Straße 270 d<br />

47269 Duisburg<br />

Germany<br />

phone +49 203 76 67 33<br />

fax +49 203 76 67 34<br />

mobil +49 171 4 70 74 44<br />

info@udoplante.com<br />

www.udoplante.com<br />

EDT-Electrodes<br />

Consulting & Sales<br />

American Anodes, LLC<br />

4029 Fairman Street<br />

Lakewood, CA<br />

USA<br />

phone +1562-881-33 30<br />

fax +1562-420-65 96<br />

info@american-anodes.com<br />

www.american-anodes.com<br />

Our partner:<br />

H. Kleinknecht & Co. <strong>GmbH</strong><br />

Eiserntalstraße 358<br />

57080 Siegen-Eisern<br />

Germany<br />

phone +49 271 39 83 - 0<br />

fax +49 271 39 83 -100<br />

vertrieb@kleinknecht.de<br />

www.kleinknecht.de