MT HS Series -10. 02 - Compumachine

MT HS Series -10. 02 - Compumachine

MT HS Series -10. 02 - Compumachine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Namsan Plant Jungdong Plant Banwol Plant Gwangju PlantHorizontal Machining CenterHead Office FA PlantPosung Plant Seosan Plant China PlantHead Office & Factory391-8 Kaumjung-Dong, Changwon, Gyeongnam, KoreaTEL : +82 55 280 9114, FAX : +82 55 282 9680http : //www.hyundai-wia.com, E-mail : trade@hyundai-wia.comSeoul Office10th Floor Landmark Tower 837-36, Yeoksam Dong,Gangnam-Gu, Seoul, KoreaTEL : +82 2 2112 8451, FAX : +82 2 2112 8400Horizontal Machining Center<strong>HS</strong> <strong>Series</strong><strong>HS</strong>400(i) | <strong>HS</strong>500(i) | <strong>HS</strong>500(50) | <strong>HS</strong>630 | <strong>HS</strong>800HYUNDAI-KIA AMERICA CORP.30 Murray Hill Parkway, Suite 300. East Ruthergord, NJ 07073 U.S.A.TEL : +1 201 489 2887 FAX : +1 201 489 2723http ://www.hyundai-kiamachine.comE-mail : sales@hyundai-kiamachine.comChicago Office751 Landmeier Rd. Elk Grove Village, IL 60007 U.S.A.TEL : +1 847 640 8870(#201) FAX : +1 847 640 8701http ://www.hyundai-kiamachine.comE-mail : sales@hyundai-kiamachine.comL.A Office11155 Knott Ave, Suit F, Cypress, CA 90630 U.S.ATEL : +1 714 373 5480 FAX : +1 714 373 5485http ://www.hyundai-kiamachine.comE-mail : sales@hyundai-kiamachine.comArgentina OfficeAV, Alicia Moreau de Justo 1848 of 4-6 Puerto Madero(C1107AFL).Buenos Aires, ArgentinaTEL : +54 11 4313 1917 FAX : +54 11 4313 1929http ://www.hyundai-kiamachine.comE-mail : sales@hyundai-kiamachine.comHYUNDAI-KIA EUROPE GmbHKaiserleipromenade 5, D-63067 Offenbach,GermanyTEL : +49 69 271 472700 FAX : +49 69 271 472719http ://www.hyundai-kia.deE-mail : sales@hyundai-kia.deRaunheim Service CenterKelsterbacher Str. 38-46 D-65479 Raunheim, GermanyTEL : +49 6142 834 0 FAX : +49 6142 834 100http ://www.hyundai-kia.deE-mail : service@hyundai-kia.de<strong>MT</strong> <strong>HS</strong> <strong>Series</strong> E-<strong>10.</strong> <strong>02</strong>. 1,000CHINA Beiging OfficeRoom 908 No. 38 Xiaoyun Road, Chaoyang District, Beijing China 100<strong>02</strong>7TEL : +86 10 8453 9850~2 FAX : +86 10 8453 9853E-mail : sangho@hyundai-wia.comSanghai OfficeRoom 501 Ocular B/D, No.1366 Wu Zhong Road, 201103 Shanghai, ChianTEL : +86 21 3431 0370~2 FAX : +86 21 3431 0376E-mail : ymlee@hyundai-wia.comGuangzhou OfficeRoom 906, International Finance Place, No.8 Huaxia Road, Pearl River NewTown, Tianhe District, Guangzhou, China, 510623TEL : +86 20 8550 6595~6 FAX : +86 20 8550 6597E-mail : iclee@hyundai-wia.comChengdu OfficeRoom 2103, Block A, Times Plaza, Zongfu Road, Chengdu, China 610016TEL : +86 28 8665 5550 FAX : +86 28 8665 2985E-mail : nlee@hyundai-wia.comWuhan OfficeRoom 43-05, New World International Trade Building(Wuhan) No.568 JiansheAvenue, Jianghan District, Hankou, Wuhan, Hubei 430<strong>02</strong>2TEL : +86 - 27 - 5952- 3256~7 FAX : +86 - 27 - 5952 - 3258E-mail : bhyun@hyundai-wia.comQingdao OfficeRoom 1207, Zhaoyin Building, 36 Hongkong Middle Road, Qungdao,shandong 266071, ChinaTEL : +86 - 532 - 8667-9333~5 FAX : +86 - 532 - 8667-9338E-mail : parkpal@hyundai-wia.comINDIA India Office6B, EGA Trade Center, 809 Poonamallee High Load, Kilpauk,Chennai - 600 0<strong>10.</strong> Tamilnadu, IndiaTEL : +91 44 4305 7112 FAX : +91 44 4305 7116E-mail : bikehyk@hyundai-wia.com※ Specifications are subject to change for improvement without notice.

World Top Class Quality<strong>HS</strong> <strong>Series</strong>HYUNDAI WIA Machine ToolsHigh-productive & performed machining center with cutting edge Mechanism<strong>HS</strong> <strong>Series</strong>Horizontal Machining CenterRevolution of Productivity, Next Generation,High Performance, High EfficiencyHorizontal Machining Center•Adopt Roller Guide for each axes•Double Winding Powerful Spindle Motor•The heaviest maximum load in its class•Big plus Spindle (BT Tool Common)•2 steps gear driven type for the heavy duty cutting (<strong>HS</strong>630/800)23

<strong>HS</strong>400/i, <strong>HS</strong>500/i Horizontal Machining Center <strong>HS</strong> <strong>Series</strong>The most advanced Mechanism, revolutionizedproductivity, and high performanceHorizontal Machining CenterWide Range of Machining Capability with High Quality,High Performance, High Productivity,Super Powerful Horizontal Machining CenterBIG PLUS#40Contact SurfaceHigh Accuracy, High RigiditySpindle Structure•2-surface restraint type spindle(Big Plus #40) that frontspindle surface and spindle taper surface are contactedsimultaneously has excellent clamping condition withoutvibration, which enable high speed machining to bepossible.■ Tool Number : 40EA [60, 80, 120EA]■ Rapid Traverse Speed50 m/min (1,969 ipm)■ Tool Changing Time (T-T/C-C)<strong>HS</strong>400i/400 : 1.2/3.6 sec<strong>HS</strong>500i/500 : 1.5/4.0 sec■ Spindle Speed<strong>HS</strong>400i/500i : 12,000rpm<strong>HS</strong>400/500 : 15,000rpmSpindle Torque Diagram•With the structure designed to minimize a vibration andheat as small as possible during high spindle rotation,accomplishment of fast acceleration & deceleration andsupporting by P4 class bearing, the stabilized accuracycan maintain even during heavy duty cutting.•Spindle rpm 12,000 / 15,000rpm•Spindle Output 25/22kW(33.5/29.5HP)•Spindle Torque Max. 166.6Nm(123lbf-ft)■ Spindle Motor25/22kW (33.5/30HP)Torque(Nm)12,000rpmPower(kW)Torque(Nm)15,000rpmPower(kW)[ ] : OptionHigh Accuracy, High Rigid Machine Structure•Adopt Roller Guide for every axes and double winding high torque spindle motor for high speed,high accuracy, heavy duty cutting and satisfy both speed and rigidity.•High speed rapid traverse and fast tool changing time minimize non-cutting time, whicheventually advance your productivity enormously with confidence and without any nonoperationaltime.Spindle Speed(rpm)<strong>HS</strong>400i/500iSpindle Speed(rpm)<strong>HS</strong>400/50045

AccuracyHorizontal Machining Center <strong>HS</strong> <strong>Series</strong>Accomplishment of High Rigidity, Stability withOne-piece Casting StructureHigh Speed, High Accuracy, High Rigid,Super Powerful, High PerformanceAutomatic Tool ChangerTable & PalletPallet Changer - APCTool NumberAdopt highly reliable and rigid CAM type mechanismto minimize non-cutting time■ <strong>HS</strong>400i/400• Tool to Tool : 1.2 sec • Chip to Chip : 3.6 sec■ <strong>HS</strong>500i/500• Tool to Tool : 1.5 sec • Chip to Chip : 4.0 secTap Type (Std.) T-Slot Type (Opt.)■ Pallet Size- <strong>HS</strong>400i/400 : 400×400mm (15.8″×15.8″)- <strong>HS</strong>500i/500 : 500×500mm (19.7″×19.7″)■ Max. Load : 500kg (1,1<strong>02</strong> lb)Rotary type high speed pallet changer (APC) was adopted as standardfigure. Also, designed for high reliability and simple set-up with big workspace.■ Pallet Changing Time• <strong>HS</strong>400i/400 : 8.0 sec• <strong>HS</strong>500i/500 : 9.5 secHigh Speed Rapid Traverse & Axis Movement StructureSpecial cleaning system, blows high pressure air into fixing pin, wasapplied to prevent slight wrong positioning of pallet due to chipaccumulation on table fixing pin, which connect table and pallettogether.Each axes are supported by 4 rowsangular trust bearings and low noise,high accuracy ball-screws for highaccuracy axis' movement. Also, eachaxes are pre-tensioned to preventinfluences from heat growth as small aspossible.40 Tools (Standard figure) offer wide access tooperator, and the most advanced drive waywas adopted to find right tool path in theshortest time. Also, the fixed tool numbersystem was adopted to prevent operatorchoose tool number, which could occur seriousimproper tool change.67

<strong>HS</strong>630/800 Horizontal Machining Center <strong>HS</strong> <strong>Series</strong>Innovation of Productivity byCutting-edge Mechanism,High Efficient Horizontal Machining Center■ Applying the oil chiller on the spindle unit whichmaintains the proper temperature, guarantees thehigh precision accuracy machining.■ Linear scale can be installed (opt.)■ Automatic Work Measuring Device (opt.)Astonishing power, Utmost performanceBig Plus#50Contact SurfacePowerful High Precision SpindleSymmetrical formation (for the minimum heat distortion)angular ball bearing spindle and housing are designedfor rigidity and the powerful tool clamping force (4,629.7lbs). AC spindle motor has 30 HP output with 8,000rpm for the heavy duty cutting, as well as the highspeed precision cutting.Built-In High Precision Spindle [Option]By adopting Built-in motor & Ceramic Bearing, it makes 12,000rpm & max. torque 420.4Nm possible.Also, Spindle Water Chiller maintains the spindle accurate & stable for long hours’machining.■ Rapid TraverseX/Y/Z Axis : 50m/min (1,969 ipm)■ Cutting feedrate1~50,000mm/min (1,969ipm)■ Tool Storage Capacity40ea [60,90,120EA]■ Spindle Speed8,000rpm [12,000rpm]Spindle Output / Torque Diagram[ ] : OptionHigh Accurate & Rigid Machine StructureBed, column, saddle, and head stock are designed to maintain strong rigidity andto minimize heat distortion.High Productivity•The Rapid Traverse of X, Y, & Z axis is 50m/min (1,969 ipm), which saves a Non-cutting time.•The travel of X-Axis 1,050mm (41.3″), Y-Axis 875mm (34.4″) & Z-Axis 875mm (34.4″) allowsa large size work piece to be processed.89

AccuracyHorizontal Machining Center <strong>HS</strong> <strong>Series</strong>One-piece Constructionguarantees Stability and Precision8 pieces of CoolantNozzle (Std.)8 pieces of nozzles can change direction tosupply proper coolant for the maintainingprecision process.Double Anchor SupportingFeed SystemThe large diameter ball screw was supportedby pre-tensioned double anchor at thebracket of bed and column, which improvesaccuracy and rigidity.Linear Roller GuideLinear Roller Guide design is adopted to minimize non-cuttingtime and maximize acceleration & deceleration as well asrigidity. The rigid feed-rate system has been heavy improved toconfront possible challenges during face mill, drill etc.Table & PalletThere are 4 taper cones on the table, 4 taper cones under thepallet that make high level positioning decision.Taper cones have built-in clamp system to do heavy dutycutting safely also high-precise curvic coupling makes highaccurateIndexingAstonishing power, Utmost performanceAPC (Automatic Pallet Changer)The lift rotary design been applied for Pallet Exchangefor the best excess to a work area. Also, APC time isonly 12 second for the high productivity.(<strong>HS</strong>800 : 25sec.)■ Max. Working size<strong>HS</strong>630 : Ø930×H1,000mm (Ø36.6″×H39.4″)<strong>HS</strong>800 : Ø1,200×H1,100mm (Ø47.2″×H43.3″)Central IntegratedOperational PanelCentral Integrated Operational Panel was designed tominimize non-necessary movement of operator utmost,and maximize performance. Also, 90°rotating panelallows even more efficiency for operator.Double Anchor Supporting■ Table size <strong>HS</strong>630 : 630×630mm (24.8″×24.8″)<strong>HS</strong>800 : 800×800mm (31.5″×31.5″)■ Max. load on the table <strong>HS</strong>630 : 1,200kg (2,646 lb)StandardNCRT(OPT) : 1,000kg (2,204lb)Finite Element MethodATC (Automatic Tool Changer)ATC, isolated from chip & coolant, provides you perfectly cleanenvironment.Cam Type ATC exchanger has been adopted in terms ofminimizing tool changing time.■ Chip to Chip : 7secVarious Magazine (40/60/90/120)One piece & rugged cast bed is designed perfectly byF.E.M.(Finite Element Method) with CAD system, which cananalyze all characteristics including vibration, rigidity and etcthat might be issued during the machining.The bed of <strong>HS</strong>630/800 is designed like "T" shape which hasbeen engineered for the perfect height and depth of castingto meet the highest standard. Also, this bed can standperfectly for the very heavy duty cutting because of thespecial double wall construction design.40EA60EA90EA120EA10 11

SpecificationHorizontal Machining Center <strong>HS</strong> <strong>Series</strong>Table Dimensions● Unit:mm(in)80(3.1)400 (15.7) 500 (19.7)100 100 10080 80 80(3.1) (3.1) (3.1)(3.9) (3.9) (3.9)120 120150 (5.9) 150 (5.9)(4.7) (4.7)100(3.9)160 (6.3) 160 (6.3)400 (15.7)460 (18.1)18 (0.7)25 (1)Ø18 (Ø0.7)200 (7.9) 200 (7.9)500 (19.7)560 (22)18 (0.7)25 (1)Ø18 (Ø0.7)18 (0.7)210 (8.3) 2-Ø18 (Ø0.7)250 (9.8)55 5575 75(2.2) (2.2)(3) (3)12(0.5)18 (0.7)2-Ø18 (Ø0.7)25 (1)30(1.2)Tool Shank● Unit:mm(in)<strong>HS</strong>400i/400<strong>HS</strong>500i/500<strong>HS</strong>400i/400<strong>HS</strong>500i/500BBT #40 (Standard)36(1.4)12 (0.5)<strong>HS</strong>K-A63 (Option)18 (0.7)30 (1.2)18 (0.7)30 (1.2)Tap Type<strong>HS</strong>630 (<strong>HS</strong>800)T-Slot TypeCAT40CAT40 <strong>HS</strong>630/800(3.94)(3.35)(1.22)(0.59)(1.37)(2.75)(0.1)(1.77)(0.43)(0.98)(1)(1.5)(4)(5.5) (1.39)MAS403 BT50(1)(0.8)(1)(1)(0.19) (0.3)(1.57)(3.35)(0.39)(0.67)(0.9)(1.37)(1.77) (0.19)(0.19) (1.18)(0.23)Ø6TOOL SHANK (CAT50) TAPT-Slot12 13

SpecificationHorizontal Machining Center <strong>HS</strong> <strong>Series</strong>External Dimmension<strong>HS</strong>400i/400 <strong>HS</strong>500i/500● Unit:mm(in)SpecificationsITEM <strong>HS</strong>400i <strong>HS</strong>500iA<strong>HS</strong>400i 2,737 (107.8″) 2,986 (117.6″)<strong>HS</strong>500i 2,878 (113.3″) 3,051 (120.1″)<strong>HS</strong>400 2,627 (103.4″) 2,986 (117.6″)<strong>HS</strong>500 2,767 (108.9″) 3,051 (120.1″)A : STD.B : ATC 60EA(OPT)External DimmensionB<strong>HS</strong>630 / 800Max. Work Area ● Unit:mm(in)TablefeedSpindleFeed rateATCAPCCoolantPowerSourceMachineControllerTable Sizemm(in) 400×400 (15.8″×15.8″) 500×500 (19.7″×19.7″) Maximum Load CapacityMaximum Working Sizekg(lb)mm(in)500 (1,1<strong>02</strong>)Ø660×H650 (Ø26″×H25.6″) Ø760×H850 (Ø29.9″×H33.5″)Table Indexing Timesec/90° 2.0Min. Indexing Angledeg 1° [0.001°]X/Y/Z Axismm(in) 640/560/650 (25.2″/22″/25.6″) 850/700/750 (33.5″/27.6″/29.5″)Distance From Table Surface to Sp. Center mm(in)50 ~ 610 (2″ ~ 24″) 50~750 (2″ ~ 29.5″)Distance From Table Center to Sp. Nose mm(in) 150 ~ 800 (5.9″ ~ 31.5″) 150 ~ 900 (5.9″ ~ 35.4″)Guide Type-Roller GuideSpindle Taper- Big Plus #40 [<strong>HS</strong>K-A63)Spindle RPMrpm 12,000Spindle Motor Output (Max./Cont.) kW(HP) 25/22 (33.5/30)Spindle Torque (Max./Cont.) kgf-m(lbf-ft) 17/9.7 (123/70.2)Type-Built-inCutting Feed Rate (X/Y/Z) m/min(ipm) 50 (1,969)Rapid Feed Rate (X/Y/Z)m/min(ipm) 50 / 50 / 50 (1,969/1,969/1,969)Number of ToolsEA 40 [60, 80]Tool Type- BBT #40 [CAT#40, <strong>HS</strong>K-A63]Max. Tool Dia. / Without Adjacent Tool mm(in) Ø75/Ø140 (Ø3″/Ø5.5″)Max. Tool Lengthmm(in)300 (11.8″) 400 (15.7″)Max. Tool Weightkg(lb) 8 (17.6)Tool Selection Method-Fixed AddressTool Change Time (T-T/C-C)sec1.2/3.6 1.5/4.0 No. of PalletEA 2APC Type-Rotary TypePallet Change Timesec8 9.5Tank Capacityl(Gal)600 (158.5) 630 (166.4)Hydraulic Tank Capacityl(Gal) 45 (11.9)Air Consumption Ratekgf/cm2(psi) 500 (132.1)Required Power Capacity (220V/60Hz) KVA 60Floor space(L×W)mm(in) 2,350×4,600 (92.5″×181.1″) 2,770×4,950 (109.1″×194.9″)Heightmm(in)2,664 (104.9″) 2,804 (1<strong>10.</strong>4″)Machine Weightkg(lb)10,000 (22,046) 15,000 (33,069)Memory Capacitym 320CNC-Fanuc 21i-MB※ Specifications are subject to change for improvement without notice. [ ] : OptionStandard•Total Splash Guard•Hand Tools Kit•Leveling Bolts & Pads•Work Light•Spindle Cooling Device•Door Interlock•Internal Chip Conveyor•Nozzle Coolant•Jet Coolant•Bed Flushing Coolant•1 degree TableOption•Extended ATC (60, 80EA)•Spindle Thru Coolant (20, 30, 70bar)•Gun Coolant•Tool Broken Detection Device•Air Gun•Oil Mist Collector•Chip Conveyor & Chip Bucket (Side)•Tool Length Measuring Device•Linear Scale•Patrol Call Light (3 colors)•NC Rotary Table (including Hyd. I/F,4x4ports)•Oil & Water Separator•Buzzer for Cycle End•Auto Electric Breakage•Auto Door at APC side•Hydraulic Oil Supply Device(2x2ports)•Spindle Load Meter•Spindle rpm Meter14 15

SpecificationHorizontal Machining Center <strong>HS</strong> <strong>Series</strong>SpecificationsSpecificationsTableTravelSpindleFeedATCAPCcoolantPowerSourceMachineControllerStandardITEM <strong>HS</strong>400 <strong>HS</strong>500/40 <strong>HS</strong>500/50Table Sizemm(in) 400×400 (15.8″×15.8″) 500×500 (19.7″×19.7″)Maximum Load Capacitykg(lb) 500 (1,1<strong>02</strong>) 800 (1,764)Maximum Working Sizemm(in) Ø660×H650 (Ø26″×H25.6″) Ø760×H850 (Ø29.9″×H33.5″) Ø800×H980 (Ø31.5″×H38.6″)Table Indexing Timesec/90° 2.0Min. Indexing Angledeg 1° [0.001°]X/Y/Z Axismm(in) 620/560/650 (24.4″/22″/25.6″) 850/700/750 (33.5″/27.6″/29.5″)Distance From Table Surface to Sp. Center mm(in) 50 ~ 610 (2″~ 24″) 50~750 (2″~ 29.5″) 75~775 (3″~ 30.5″)Distance From Table Center to Sp. Nose mm(in) 150 ~ 800 (5.9″~ 31.5″) 150 ~ 900 (5.9″~ 35.4″)Guide Type- Roller GuideSpindle Taper- Big Plus #40 [<strong>HS</strong>K-A63] Big Plus #50 [<strong>HS</strong>K-A100]Spindle RPMrpm 15,000 12,000Spindle Motor Output (Max./Cont.) kW(HP) 25/22 (33.5/30) 30/25 (40.2/33.5)Spindle Torque (Max./Cont.) kgf-m(lbf-ft) 17/9.7 (123/70.2) 12.9/24.3 (92.9/175.8)Type- Built-inCutting Feed Rate (X/Y/Z) m/min(ipm) 50 (1,969) 40 (1,575)Rapid Feed Rate (X/Y/Z) m/min(ipm) 50/50/50 (1,969/1,969/1,969)Number of ToolsEA 40 [60]Tool Type-BBT #40 [CAT#40, <strong>HS</strong>K-A63] BBT #50 [CAT#50, <strong>HS</strong>K-A100]Max. Tool Dia. / Without Adjacent Tool mm(in) Ø75/Ø140 (Ø3″/Ø5.5″) Ø125/Ø250 (Ø4.9″/Ø9.8″)Max. Tool Lengthmm(in) 300 (11.8″) 400 (15.7″) 450 (17.7″)Max. Tool Weightkg(lb) 8 (17.6) 25 (54.7)Tool Selection Method- Fixed AddressTool Change Time (T-T/C-C)sec1.2/3.6 1.5/4.0 2.0/6.0No. of PalletEA2APC Type- Rotary TypePallet Change Timesec8 9.5 12Tank Capacityl(Gal) 600 (158.5) 630 (166.4) 700 (184.9)Hydraulic Tank CapacityAir Consumption Ratel(Gal)l/min (gal/min) 45 (11.9)500 (132.1)Required Power Capacity (220V/60Hz) KVA 60Floor space(L×W)mm(in) 2,350×4,600 (92.5″×181.1″) 2,770×4,950 (109.1″×194.9″) 3,225×4,990 (127″×196.4″)Heightmm(in) 2,610 (1<strong>02</strong>.8″) 2,767 (108.9″) 3,067 (120.7″)Machine Weightkg(lb) 10,000 (22,046) 15,000 (33,069) 17,000 (37,478)Memory Capacitym 320CNC- Fanuc 18i-MB•Total Splash Guard•Hand Tools Kit•Leveling Bolts & Pads•Work Light•Spindle Cooling Device•Door Interlock•Internal Chip Conveyor•Nozzle Coolant•Jet Coolant•Bed Flushing Coolant•1 degree TableOption•Extended ATC (60, 80EA)•Spindle Thru Coolant (20, 30, 70bar)•Gun Coolant•Tool Broken Detection Device•Air Gun•Oil Mist Collector•Chip Conveyor & Chip Bucket (Side)•Tool Length Measuring Device•Linear Scale•Patrol Call Light (3 colors)•NC Rotary Table (including Hyd. I/F,4x4ports)•Oil & Water Separator•Buzzer for Cycle End•Auto Electric Breakage•Auto Door at APC side•Hydraulic Oil Supply Device(2x2ports)•Spindle Load Meter•Spindle rpm MeterTableFeedSpindleFeed RateATCAPCcoolantPowerSourceMachineControllerITEM <strong>HS</strong>630 <strong>HS</strong>800Table Sizemm(in) 630×630 (24.8″×24.8″) 800×800 (31.5″×31.5″)Maximum Load Capacitykg(lb)1,200 (2,646) 1,600 (3,527)Maximum Working Sizemm(in) Ø930×H1,000 (Ø36.6″×H39.4″) Ø1,200×H1,100 (Ø47.2″×H43.3″)Table Indexing Timesec/90°4Min. Indexing AngleX/Y/Z Axisdegmm(in)1° [0.001°]1,050/875/875 (41.3″/34.4″/34.4″)Distance FromTAP(Std.) mm(in) 100 ~ 975 (3.9″ ~ 38.4″) Table Surface to Sp. Center T-Slot(Opt.) mm(in)75~950 (2.9″~37.4″) 80~955 (3.1″ ~ 37.6″)Distance From Table Center to Sp. Nose mm(in) 150 ~ 1,<strong>02</strong>5 (5.9″ ~ 40.4″) 210 ~ 1,<strong>02</strong>5 (8.3″ ~ 40.4″)Guide TypeSpindle Taper--Roller GuideNT #50Spindle RPMrpm8,000 [12,000] 8,000 [12,000]Spindle Motor Output (Max./Cont.)Spindle Torque (Max./Cont.)TypeCutting Feed Rate (X/Y/Z)Rapid Feed Rate (X/Y/Z)Number of ToolsTool TypekW(HP)Nm(lbf-ft)-m/min(ipm)m/min(ipm)EA-22/18.5 (30/25) [26/22 (35/30)]780/656.6 (576/485) [922.2/781.1 (126.2/106.9)]2 Steps Gear [Built-in]50 (1,969)50 / 50 / 50 (1,969/1,969/1,969)40 [60 / 90 / 120]BBT#50 (CAT #50)Max. Tool Dia. / Without Adjacent ToolMax. Tool LengthMax. Tool WeightTool Selection MethodTool Change Time (T-T/C-C)APC TypeNo. of Palletmm(in)mm(in)kg(lb)-sec-EAØ125/Ø245 (Ø4.9″/Ø9.6″)500 (19.7)15 (33.1) [25 (55.1)]Fixed Address3.5/7Direct Turn2Pallet Change Timesec12 25Tank Capacityl(Gal)800 (211.3)Hydraulic Tank Capacityl(Gal) 60 (15.9)Air Consumption Ratel/min (gal/min) 500 (132.1)Power Capacity (220V/60Hz)KVA 53 [60]Floor space(L×W)mm(in) 3,975×5,913 (156.5″×232.8″) 3,975×6,043 (156.5″×237.9″)Heightmm(in)3,525 (138.8″) 3,525 (138.8″)Machine Weightkg(lb)25,000 (55,116) 26,000 (57,320)Memory Capacitym 320CNC-Fanuc 18i-MB※ Specifications are subject to change for improvement without notice. [ ] : OptionStandard•Coolant Tank (800 liter)•Flood Coolant System•Leveling Bolts & Pads•Work Light•Total Splash Guard•Call Light (1 color)•Door Interlock•Internal Chip Conveyor•1 degree TableOption•ATC 60EA, 90EA, 120EA•6 PPL (for <strong>HS</strong>630)•Heavy weight Tool (25kg)•Jet Coolant•Spindle Thru Coolant (30, 70bar)•Gun Coolant•Tool Broken Detection Device•Air Gun•Oil Mist Collector•Bed Flushing•Flushing Coolant for Table Surface•Chip Conveyor & Chip Bucket(Front-Side)•Mesh Drum Chip Conveyor•Tool Length Measuring Device•Pallet Clamp Confirmation•Patrol Call Light (3 colors)•Spindle Load Meter•Spindle rpm Meter•Spindle Motor Power Up(8,000rpm Only)16 17

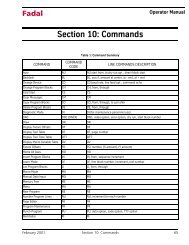

SpecificationHorizontal Machining Center <strong>HS</strong> <strong>Series</strong>ControllerFANUC 21i-MBControllerControllerFANUC 18i-MBControllerAxis control / Display unitControlled axes4 (X, Y, Z, B) axesProgram input & Interpolation functionsThreading/synchronous feedData input/output & Editing functionsMemory card input/outputAxis control / Display unitControlled axes4 (X, Y, Z, B) axesProgram input & Interpolation functionsThreading/synchronous feedData input/output & Editing functionsMemory card input/outputSimultaneous3 axes (G00 & G01 : 3 axes,Manual reference point returnEmbedded ethernet10 MbpsSimultaneous3 axes (G00 & G01 : 3 axes,Manual reference point returnEmbedded ethernet10 Mbpscontrollable axesG<strong>02</strong> & G03 : 2 axes)1st Reference point returnG28Part program storage length320 m (128Kbyte)controllable axesG<strong>02</strong> & G03 : 2 axes)1st Reference point returnG28Part program storage length320 m (128Kbyte)Least input increment0.001 mm (0.0001″)/1 degReference point return checkG27Registered programs125 eaLeast input increment0.001 mm (0.0001″)/1 degReference point return checkG27Registered programs125 eaLeast command increment0.001 mm (0.0001″)/1 deg2nd Reference point returnG30Memory lockLeast command increment0.001 mm (0.0001″)/1 deg2nd Reference point returnG30Memory lockInch / metric conversionG20 / G21Program stop/endM00, M01 / M<strong>02</strong>, M30Back ground editingInch / metric conversionG20 / G21Program stop/endM00, M01 / M<strong>02</strong>, M30Back ground editingInterlockMachine lockEmergency stopStored stroke check 1Mirror imageEach axis / All axesAll axesOver-travelTape codeOptional block skipMaximum programmabledimensionsEIA RS-244 / ISO 840(Automatic recognition)1 ea+/- 9999.9999″ (+/- 8 digits)Extended part program editing Copy, move, change of NC programExternal messageSetting, display, diagnosisSelf-diagnosis functionHistory displayAlarm & operator messageInterlockMachine lockEmergency stopStored stroke check 1Mirror imageEach axis / All axesAll axesOver-travelTape codeOptional block skipMaximum programmabledimensionsEIA RS-244 / ISO 840(Automatic recognition)1 ea+/- 9999.9999″ (+/- 8 digits)Extended part program editing Copy, move, change of NC programExternal messageSetting, display, diagnosisSelf-diagnosis functionHistory displayAlarm & operator messageFollow-upProgram numberO4 digitHelp functionFollow-upProgram numberO4 digitHelp functionServo offAbsolute and incremental commandG90 / G91Run hour / Parts count displayServo offAbsolute and incremental commandG90 / G91Run hour / Parts count displayBacklash compensation+/- 0~9999 pulse(rapid traverse & cutting feed)Decimal point inputPlane selectionG17, G18, G19Actual cutting feedrate displayGraphic displayBacklash compensation+/- 0~9999 pulse(rapid traverse & cutting feed)Decimal point inputPlane selectionG17, G18, G19Actual cutting feedrate displayGraphic displayPosition switchWork coordinate system settingG52~G59Spindle / Servo setting screenPosition switchWork coordinate system settingG52~G59Spindle / Servo setting screenStored pitch errorAdditional work coordinate system48 pairsMulti-language displayStored pitch errorAdditional work coordinate system48 pairsMulti-language displaycompensationManual absolute“ON” fixedErase CRT screen displayScreen savercompensationManual absolute“ON” fixedErase CRT screen displayScreen saverLCD/MDIOperationAutomatic operation (memory)MDI operationSearch functionProgram restart<strong>10.</strong>4″ color LCDSequence, programProgrammable data inputSub program callCustom macro BCircular interpolation by radius RCanned cycleOptional chamfering/corner RG104 levels of nesting#100 to #199G73, G74, G76, G80 ~ G89OptionAdditional 1 axisAddition to custom macrocommon variables#500 to #999LCD/MDIOperationAutomatic operation (memory)MDI operationSearch functionProgram restart<strong>10.</strong>4″ color LCDSequence, programProgrammable data inputSub program callCustom macro BCircular interpolation by radius RCanned cycleOptional chamfering/corner RG104 levels of nesting#100 to #199G73, G74, G76, G80 ~ G89OptionAdditional 1 axisAddition to custom macrocommon variablesPolar coordinate command /#500 to #999Dry runSkip functionG31Polar coordinate command /Dry runSkip functionG31interpolationSingle blockAutomatic coordinateinterpolationSingle blockAutomatic coordinateCylindrical interpolationBuffer registerFeed functionsManual jog feedManual handle feed rateFeed commandRapid, jog, handlex1, x10 , x100F code feedrate direct commandsystem settingCoordinate system rotationProgrammable mirror imageAuxiliary / Spindle functionsMiscellaneous function M2 digitsCylindrical interpolationSingle direction positioningTool length measurement3rd and 4th Reference pointreturnG60G30P3, G30P4Buffer registerFeed functionsManual jog feedManual handle feed rateFeed commandRapid, jog, handlex1, x10 , x100F code feedrate direct commandsystem settingCoordinate system rotationProgrammable mirror imageAuxiliary / Spindle functionsMiscellaneous function M2 digitsSingle direction positioningTool length measurementExternal data inputRemote bufferEthernetG60100 MbpsFeedrate override0~200% (10% unit)Miscellaneous function lockExternal data inputFeedrate override0~200% (10% unit)Miscellaneous function lockData serverJog feed0~5,000 mm/min (197 ipm)Spindle speed commandS5 digits, binary outputRemote bufferJog feed0~5,000 mm/min (197 ipm)Spindle speed commandS5 digits, binary outputAi contour control (AICC)Rapid traverse overrideF0, F25%, F50%, F100%Spindle speed override50% ~ 120% (10% unit)Ethernet100 MbpsRapid traverse overrideF0, F25%, F50%, F100%Spindle speed override50% ~ 120% (10% unit)Ai nano contour controlOverride cancelSpindle orientationData serverOverride cancelSpindle orientation(AI nano CC)Rapid traverse bell-shapedacceleration/decelerationProgram input & Interpolation functionsLabel skipRigid tappingTool functions / Tool compensationTool functionMax. T8 digitsCutter compensation C G40~G42Ai contour control (AICC)Ai nano contour control(AI nano CC)Manual Guide iRapid traverse bell-shapedacceleration/decelerationProgram input & Interpolation functionsLabel skipRigid tappingTool functions / Tool compensationTool functionMax. T8 digitsCutter compensation C G40~G42Ai high precision contourcontrol (AI HPCC)Ai nano hpccManual Guide iControl in/outTool length compensationG43, G44, G49Optional block skip add9 ea (Application can be limited)Control in/outTool length compensationG43, G44, G49Optional block skip add9 ea (Application can be limited)Interpolation functionsPositioning/Linear/Circular(G00/G01/G<strong>02</strong>/G03)Tool offset amountTool offset pairs+/- 6 digits99 pairsHandle interruptManual handle feed3 unitInterpolation functionsPositioning/Linear/Circular(G00/G01/G<strong>02</strong>/G03)Tool offset amountTool offset pairs+/- 6 digits99 pairsHandle interruptManual handle feed3 unitExact stop mode / Exact stopDwellHelical interpolationG61 / G09G04, 0~9999.9999secTool life managementData input/output & Editing functionsReader/Puncher interface RS232CPart program storageDynamic graphic displayDNC operation640 m (256 Kbyte) / 1280 m (512 Kbyte)KDNC (S/W)Exact stop mode / Exact stopDwellHelical interpolationG61 / G09G04, 0~9999.9999secTool life managementData input/output & Editing functionsReader/Puncher interface RS232CPart program storageDynamic graphic displayDNC operation640 m (256 Kbyte) / 1280 m (512 Kbyte)KDNC (S/W)•Figures in inch are converted from metric values.•Design and specifications subject to change without notice.•Figures in inch are converted from metric values.•Design and specifications subject to change without notice.18 19