MT HS Series -10. 02 - Compumachine

MT HS Series -10. 02 - Compumachine

MT HS Series -10. 02 - Compumachine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

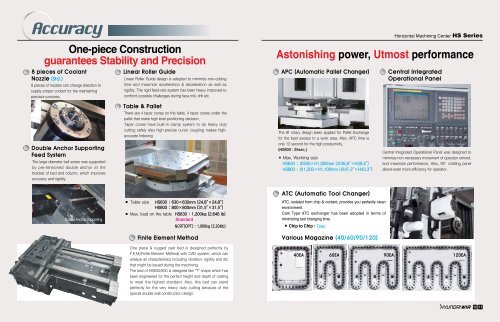

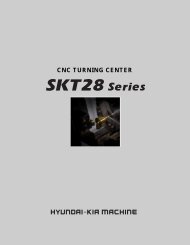

AccuracyHorizontal Machining Center <strong>HS</strong> <strong>Series</strong>One-piece Constructionguarantees Stability and Precision8 pieces of CoolantNozzle (Std.)8 pieces of nozzles can change direction tosupply proper coolant for the maintainingprecision process.Double Anchor SupportingFeed SystemThe large diameter ball screw was supportedby pre-tensioned double anchor at thebracket of bed and column, which improvesaccuracy and rigidity.Linear Roller GuideLinear Roller Guide design is adopted to minimize non-cuttingtime and maximize acceleration & deceleration as well asrigidity. The rigid feed-rate system has been heavy improved toconfront possible challenges during face mill, drill etc.Table & PalletThere are 4 taper cones on the table, 4 taper cones under thepallet that make high level positioning decision.Taper cones have built-in clamp system to do heavy dutycutting safely also high-precise curvic coupling makes highaccurateIndexingAstonishing power, Utmost performanceAPC (Automatic Pallet Changer)The lift rotary design been applied for Pallet Exchangefor the best excess to a work area. Also, APC time isonly 12 second for the high productivity.(<strong>HS</strong>800 : 25sec.)■ Max. Working size<strong>HS</strong>630 : Ø930×H1,000mm (Ø36.6″×H39.4″)<strong>HS</strong>800 : Ø1,200×H1,100mm (Ø47.2″×H43.3″)Central IntegratedOperational PanelCentral Integrated Operational Panel was designed tominimize non-necessary movement of operator utmost,and maximize performance. Also, 90°rotating panelallows even more efficiency for operator.Double Anchor Supporting■ Table size <strong>HS</strong>630 : 630×630mm (24.8″×24.8″)<strong>HS</strong>800 : 800×800mm (31.5″×31.5″)■ Max. load on the table <strong>HS</strong>630 : 1,200kg (2,646 lb)StandardNCRT(OPT) : 1,000kg (2,204lb)Finite Element MethodATC (Automatic Tool Changer)ATC, isolated from chip & coolant, provides you perfectly cleanenvironment.Cam Type ATC exchanger has been adopted in terms ofminimizing tool changing time.■ Chip to Chip : 7secVarious Magazine (40/60/90/120)One piece & rugged cast bed is designed perfectly byF.E.M.(Finite Element Method) with CAD system, which cananalyze all characteristics including vibration, rigidity and etcthat might be issued during the machining.The bed of <strong>HS</strong>630/800 is designed like "T" shape which hasbeen engineered for the perfect height and depth of castingto meet the highest standard. Also, this bed can standperfectly for the very heavy duty cutting because of thespecial double wall construction design.40EA60EA90EA120EA10 11