SP 1000 - Herkules Garten

SP 1000 - Herkules Garten

SP 1000 - Herkules Garten

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

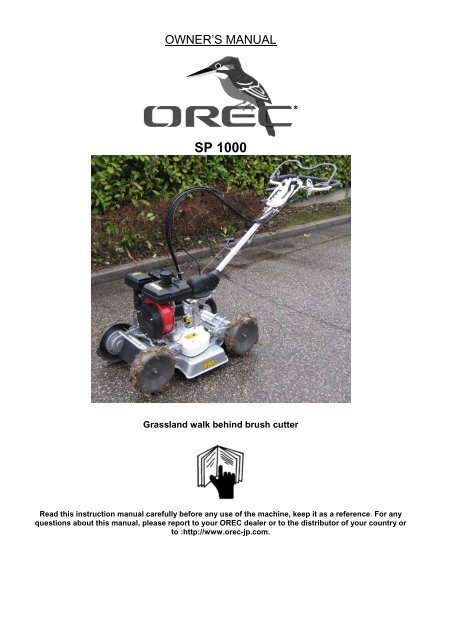

OWNER’S MANUAL<strong>SP</strong> <strong>1000</strong>Grassland walk behind brush cutterRead this instruction manual carefully before any use of the machine, keep it as a reference. For anyquestions about this manual, please report to your OREC dealer or to the distributor of your country orto :http://www.orec-jp.com.

INTRODUCTIONForword to the userRead this manual before any use of your mower, only the herein instructions shall help you to achievean efficient and safe work.A safe use will only result from the manner you will use the machine in accordance with therestrictions described in this manual. Thus, you must know and follow all the safety measures in thismanual and those relating to the use of your mower.The machine that you have just bought has been designed and manufactured for your entiresatisfaction. As any other mechanical machine, it requires a proper maintenance and must be keptclean. Grease the machine like indicated. Follow the rules and safety indications as described in thismanual and as showed on the preventive instruction stickers.About maintenance, always mind that your OREC dealer has the skills, the genuine parts and thenecessary tools to solve the possible problems.Use only the OREC original parts : “ non genuine ” parts will not assure you of a correct and safeworking and are likely to make the guarantee null and void. Write the name and the serial number ofyour machine hereunder :MODEL :.......................................................................................SERIAL NUMBER (refer to the pictures herein) :.........................Always mention these informations to your dealer in order to obtain the right parts.Concerned about constant progress, OREC keeps the right to modify the machines without beingcompelled to modify those already sold.The illustrations and characteristics in this manual might lightely differ from your machine because ofthe constant improvements made by our engineering department.In this manual, the left and the right hand or the rear and the front position are determined accordingto the mower handlebar.All along this manual the word IMPORTANT is used to indicate that a fault might cause damage tothe machine. The words WARNING, CAUTION and DANGER are used with the “ safety/warning ”pictogram (triangle with an exclamation mark) in order to indicate a hazard for your safety.This symbol indicates that you must be very attentive because your safety is at stake. It reminds thatyou must follow the safety instructions and pay attention to hazardous operations that might causeinjuries.WARNINGReminds the safety rules that might cause injury if they are not respectedCAUTIONRemembers to pay attention to a real danger that is likely to cause injury or even death if no properprecaution is taken.DANGERIndicates a major hazard that is most likely to cause irremediable injury or death if the rightprecautions are not taken.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20102

CONTENTSINTRODUCTION ................................................................................................................................................2CONTENTS ........................................................................................................................................................3<strong>SP</strong>ECIFICATIONS..............................................................................................................................................3CHECK LIST.......................................................................................................................................................3SAFETY RULES.................................................................................................................................................4DIFFERENT PARTS OF THE MACHINE...........................................................................................................6SAFETY INSTRUCTION STICKERS .................................................................................................................7CONTROLS........................................................................................................................................................8OPERATION.....................................................................................................................................................10MAINTENANCE OPERATIONS TO BE CARRIED OUT BY THE USER........................................................12BREAKDOWNS AND SOLUTIONS 1 ..............................................................................................................18BREAKDOWNS AND SOLUTIONS 2 ..............................................................................................................18TIGHTENING TORQUES (daNm)....................................................................................................................19CONFORMITY CERTIFICATE.........................................................................................................................20MEASUREMENT OF VIBRATIONS.................................................................................................................20LIMITED WARRANTY ......................................................................................................................................21NOTES..............................................................................................................................................................21<strong>SP</strong>ECIFICATIONSModelEngineTransmissionForward speed (km/h)Reverse speed (km/h)Cutting widthHeight of cutWeightFuel tank capacityBlade transmissionBlade engagementblade speed (rpm)HeightLengthOver all width<strong>SP</strong><strong>1000</strong>MITSUBISHI GB100Mecanical(1) 1,2 km/h (2) 2,3 km/h(1) 1,2 km/h (2) 2,3 km/h500 mm50-87 mm61 kg1.6 literbeltbelt tension2900 tr/min1235 mm1920 mm550 mmCHECK LISTINSTRUCTIONS TO THE DEALER• The assembling, the installation and the first application of the machine is under the OREC dealer’sresponsibility.• Read the instruction manual as well as the safety measures. Check that all the before delivery andat delivery check points specified in the following lists have been verified and possibly modified beforedelivering the machine to its owner.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20103

CHECKS BEFORE DELIVERY• Check that all the shields, grids and safety guards are in place and in a good state.• Check that the wires are in place and in a good state. Replace them if necessary.• Check that there is no oil leak, repair if necessary.• Check that the safety instruction stickers are in place and in a good condition. Replace them if theyaren’t.• Check that all the bolts and screws are properly tightened with the right torque (refer to accordingpage).• Protect the grease nipples by coating them with grease and lubricate the machine.• Check that the machine can work properly before use.CHECKS ON DELIVERY• Show the user how to perform the adjustments.• Explain to the user the importance of the lubrication and show him the different greasing points onthe machine.• Show him the safety devices, grids, guards and the optional equipments.• Give the instruction manual to the customer, ask him to read it carefully.SAFETY RULESCAUTIONSome of the illustrations show the machine with no guard, no shield. Never use the machinewithout these devices.• Learn to stop the machine in case emergency.• Read this manual.• Do not let anybody use the machine before having read and understood thismanual.• Do not let children use the machine.• Do not wear loose clothes. They might be grasped by moving parts.• Always wear protection equipments for when using the machine.• Only work during daylight or with a good artificial light.• Check that the safety instruction stickers are in place and in a good condition.• Keep the machine free from debris or mud.• Check that the machine can work properly before any use.• Check that all the shields, grids and safety guards are in place and in a good condition.• It is strictly forbidden to carry persons or animals onto the machine during the work or during thetransportation.• Never stop or start roughly when working on a slope. Never use the machine to work on a steppingterrain.• Reduce the ground speed when running on a slope and when turningstraight in order to prevent from any risk of losing control.• Be very careful when bordering ditches.• Stop the engine, and remove the sparking plug ignition cover before anyadjustment or maintenance on the machine.• Never work under the machine or its parts when lifted, unless they areblocked and maintained into position with sufficient security.• Stay clear of unsteady embankments, holes or rocks. They might bedangerous during maneuver or transport.• Keep away from electric wires and obstacles. A contact with electric wires cause electrocution anddeath.• Stop the machine progressively when lifting or lowering the machine.• When stopping the work, stop the engine and remove the sparking plug ignition cover beforeleaving the mower.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20104

• Engage all the safety equipments.• Move the controls only when correctly set down in the mower• Visually check hydraulic leaks and if some parts are faulty or missing. Repair before use.•Never change the adjusment of the regulator, it is set in the factory. Unsetting this valve would causefailures.• Ensure that the user of the machine has already read and understood thismanual and that he is aware of all the safety instructions before any use.• Always use a chuck and bronze hammer when replacing or interveningon the pins and bolts at the end of rams, rod … etc in order to avoid theprojection of metal fragments.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20105

DIFFERENT PARTS OF THE MACHINErearSpeed leverRelease leverBlade clutchleverHandlebaradjustmentleftTravel lever2 action leverHandlebarlockHeight of cutadjustmentFuel tankStarter handleExhaustsilencerrightFigure 1frontOREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20106

SAFETY INSTRUCTION STICKERSNote their location and replace them immediately in case of damage or when missingRead owner’s manualBeware of hot surfaces near theengineAlways wear protective equipmentagainst noise, dust and wear googlesBeware of belts under theprotective shieldBeware of thrown objectsBeware of the rotating bladesunder the deckRead owner’s manual Keep away from the machine Keep away hands and feet fromrotating bladesOREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20107

CONTROLSStart the engineTurn the switch (7, Figure 3) to “on”, push the choke (Figure 2)to the left. Pull the starting handle (Figure 1). When the enginehas started, push the choke lever to the right.Do not use the choke when the engine is hot, it did notstart.Travel leverTo make the machine moving, grip the 2 action lever then,push the travel lever to the handlebar (1, Figure 3). As soon asFigure 2the lever is released, the machine stops.Cutting blade clutch leverCutting blade Clutch lever makes the engine drive theblade to mow (2, Figure 3). Push the blade clutch leverforward to make the blade turning.57362WARNINGNever try to start or stop the engine with bladeengaged.214Cutting height adjustmentAdjust the height of cut adjustment lever (3, Figure 3)8remember it is better to mow a small amount at a time.Figure 3WARNINGStop machine before to change travel speedSpeed leverIt allows you to choose the travel speed, (2, Figure 4). 1 isthe slower speed, 2 is the faster speed. Select the speedaccording the amount of material to cut. Select the speed11 or 2 from the left of the neutral to go on reverse and thespeed to the right of the neural to go forward.2Figure 4Control the speed lever always after engine rpm getslow when travel lever is releaseed. If speed lever is controlled with enigne rpm high or duringdriving, gear gives noise and speed is not changed correctly, and inside of transmission maybe damaged.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20108

Release lever3When the travel lever(3 Figure 5) is released, thedriving clutch is locked. Push on the release lever toallow the machine to move without the engine.1WARNINGAlways use release lever only on flat area. It isdangerous to use release lever on slope whichmakes machine to slip down.Figure 522Fuel cockThe engine is feeded of gasoline when the fuel cock is downwards(Figure 6). The fuel cock is closed when turned to the right.Figure 6Handlebar adjustment :DANGERDo not modify the handlebar adjustment when the machine is inmotion. Perform adjustment only when the machine is on a level flatsurface.Pull the lever rearward to adjust the handlebar (Figure 7) from up and toFigure 7low and from left to right. Check that the lever is locked when theadjustment is performed.Unscrew the lever (Figure 8) to fold the handlebar as required, screwagain the lever to work with the machine.Figure 8Pull the lever backward (Figure 9) to adjust the length of thehandlebar(4 position). Check that the lever is locked whenthe adjustment is performed.Figure 9OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/20109

OPERATIONCAUTIONCheck the tightening of bolts, refering to the tightening torque chartsThe safety was one of our main worry when designing and manufacturing this machine. Therefore,negligence in the use of the machine should reduce our efforts to nothing. The prevention strictlydepends on the care and on the skill of the user when applying and maintening the machine.Thebest safety method remains a careful and skilled user ; we wish you to be this kind of user.The user of this machine is responsible for its safe use. He must be a skilled user specially trained forthe use of this machine. Read the safety instructions. This machine has been designed to mow grass.It is not designed for any other operation. It is no designed to transport other tools or materials thatmight damage it and cause injuries to the user. It must not be used to carry persons.DANGERNever use the machine without having priorly carried out all the maintenance operations asdescribed in the daily maintenance chapter.CAUTIONNever let children or unskilled persons use the machine. Check that nobody or no objectstands near the machine when at work. They could be hit by the moving parts.Nobody muststand on the machine except the driver. Never put your hands under moving parts.Starting of the engine• Turn the fuel cock "ON".• Check the cutting blade is disengaged, and travel lever in neutral position « N ».• Pull choke lever if engine is cold or push throttle lever half if engine is hot. Pull the starter handle.When the engine has started, push back the choke lever.Mowing• Adjust the height of cut control bar as needed.WARNINGDo not forget that it is better to mow a few grass often than many grass in one operation. Rememberthat short grass deteriorate rapidly in hot and dry weather. When the cutting blade is low, the blademay hit the ground and it causes damage to the blade. The thrown objects can injure the operator,the bystanders or cause damage to their properties.• Select the travel speed, then press the travel lever and start to mow.• The best cutting speed depends of quantity and the density of the grass. A tall grass will be cutslowly and a low grass will be cut faster.WARNING• Never work in slopes more than 45 degree and it is also dangerous to use the bridge of over 15degree when the machine is loaded on the track.• Do not release the travel lever when working in slopes. The machine might be slipped to valleryside• When driving on the border(between slope and flat), pay attension to prevent to downfall andturnover.• It is dangerous for operators to be above(Mountain side) on slopes. Operator would enter underthe deck by slipping especially on wet field. Please avoid working on wet slopes and wait for thedry.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201010

• Operator must stand on the flat and steady place. It is dangerous for operators to standunder(Valley side against) the machine on slopes.• Cylinder head must always be headed to(mountain side). If it is headed to(Valley side) the,engine would be broken(Burned engine)• Check that there is nobody stay in the mowing path. Stop the machine immediately when hittingsomething. Let the machine get cold, clean the machine from dust and debris.• Check the machine or ask your dealer to check if the machine is not damaged.CAUTION• Release the travel lever when engine is stalled by much load and, then please push the travellever little by little and check if engine rotation is rising or not. If engine rotation is rising, start towork again.• If engine rotaion is not rising, the knives may twine with many grasses. Thus, remove the grassesand clean after engine is OFF. Moreover, please try to adjust the cutting height one more higher.• If the machine is kept working with much load, the centrifugal clutch will be burned and it mightcause unexpected accident.How to stop the machine• Release travel lever and turn the blade clutch lever to “off”• Turn the engine switch to “off”.• Close the fuel cockCAUTIONNever park the machine on slopes. Stop it on a level and flat surface.Storing the machineThoroughly clean the machine. Use touch up paint to prevent rust. Check for worn and damage parts,install new parts as required. Preform the normal maintenance of the machine according tomaintenance chart. Store the machine in a dry protected area. Remove sparking ignition wire from thesparking plug.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201011

MAINTENANCE OPERATIONS TO BE CARRIED OUT BY THE USERDANGERBEFORE perform any maintenance operation on the machine, cut off the engine, and removethe sparking wire from the sparking plug.If maintenance operation are not realized, damages can occur to the machine and personnal injuriesto the user and/or spectators. These damages and injuries will not be covered by the warranty.• Daily maintenance will be performed by the user.• Maintenance opérations for first 20 hours, 100 and 300 should be realized by the dealer.• Ask your dealer to check the machine if you meet some problems.• Ask your distributor the name of your dealer.Daily maintenance, before start mowingOil level : The machine stopped since 5 minutes on a level flat surface. Unscrew the gauge (Figure 17,Figure 16). Oil level should appear in the middle of the gauge, when the gauge is let on his locationwithout screwing it.• Use only good quality motor oil.• Ask to your dealer to change every 50 hours of use.Fuel (Figure 10)Check tank level is full before start to work. Checkthat tank plug is fully closed, and check for leaks.Use only a good quality unleaded gasoline.DANGERCheck if fuel tank is closed, wipe fuel spillagesbefore start the machine. Check there is no fire,electric sparks, cigarettes near the machine whenrefuelling.Check tires are not cut, cracked or worn.Figure 10Blade and blade holder conditionCAUTIONYou can be cut and injured by cutting blade. Always wear gloves when holding blades.Check rotary blades are in good condition, change worn or damaged parts.• Changing blade : unscrew and washer from the knife Neck Guard.• Check the blade condition. Change it if it is worn bent or crackled.• Check tightening of screws according to the chart at the end of the manual.Knives installed :-Please install the knives according to following instrustions…..OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201012

-Directon of knife rotary is always inside against direction of working. Therefore, it is not possible tochange the right knife to left knife and left knife to right knife as each replacement. Please replace 4knives when replacement.-Right screws are used for both of knives so please pay attension when neck guard or knife isremoved.-According to following reference, please set 4 knives so that they are located as cross position foreach knives(90 degree). If knives are set incorrectly, it causes blade interference. Thus, knives maybreak and clips and make the vibration.-Tighten the bolts and nuts securely and completely after knives are set.Knife Neck guardAttention to blade interfereceKnifeWasherNut(Right screw)Air filterRemove the air filter cover "A"(Figure 11), Cleanthe foam « B » with water and soap. Dry the foambefore and oil slightly with engine oil, thenassembling againEngine :Refer to engine manual delivered with themachine.AFigure 11BWires adjustment:CAUTION• Stop the engine and choose the flat space for adjustment. Please also make sure if engine isOFF.• When the machine is checked, please pulled out the ignition plug from plug cap to avoid anunexpected starting.Adjust nutDriving clutch wire adjustment(Red wire)Adjust the driving clutch wire with adjust nut according to left figure.It is not possible to go forward&rearward(knife can work)(Loose)---Move the adjust nut to B directionLock nutIt is possible to go forward&rearward but it is not possible to push themachine when engine is stopped(Tight).---Move the adjust nut to A directionOREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201013

Lock nutLock nutAdjust nutAdjust nutForward&Reverse wire adjustment(Yellow wire)Adjust the Forward&Reverse wire with adjust nutt according to leftfigure.It is possible to go rearward but it is not possible to goforward(Loose)---Move the adjust nut to B directionIt is possible to go forward but it is not possible to go rearward(Tight)---Move the adjust nut to A directionChanging speed wire adjustment(Blue wire)Adjust the Changing speed wire with adjust nut according to leftfigure.It is possible to go forward&rearward by 2nd speed but it is notpossible to go forward&rearward by 1st speed(Tight)---Move the ajust nut to A directionIt is possible to go(forward&rearward) by 1st speed but it is notpossible to go(forward&rearward) by 2nd speed(Loose)---Move the adjust nut to B directionWIRE COLOR LOOSEN FOR TIGHTEN FORDRIVING CLUTCH WIRE RED ON OFFFORWARD&REVERSE WIRE YELLOW REARWARD FORWARDCHANGING <strong>SP</strong>EED WIRE BLUE SIDE OF 1st <strong>SP</strong>EED SIDE OF 2 nd <strong>SP</strong>EEDCAUTIONWire and V belt would may get loose in the initial period so adjust them again after using 2or 3 hours.Tightening of bolts :Check that the bolts, nut are properly tightened. The vibrations tend to loosen the bolts.• Lubrication :OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201014

Grease the point G (figures 20 et 21) with light oil.Grease the points (D figure 22, 23) with grease NLGI N°2.DGFigure 12 Figure 13GDCleaning :Clean the machine from flamable materials, dust or grass, especially around the engine and theexhaust system to prevent fire.Blade brake :Check the blade brake every use of the machine, check the time for the blade to stop when bladeclutch lever is released. If more than 7 seconds are necessary for the blade to stop, ask immediatelyto your dealer to check the blade brake system.Engine oil draining(0.5 Liter) :Figure 14 Figure 15Refer to the engine manual : drain oil by the screw B Figure 17. Check the level with the gauge “A”.Level must be between the two arrows in Figure 16.MinBAFigure 17Figure 16OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201015

Transmission oil supply and replacement :Please fill the oil gradually. If you try to fill the oil at once, the oil may spill out from the oil hole due toair.Bottom of right side(200cc)Oil holeSupply-----Quantity of oil must be cared1) There are 2 oil holes which is located each side of transmissioncase.Please fill the 200cc to bottom of right side and 50cc to upper part ofleft side from oil holeReference:Please exchange the oil if oil is old or shortage of oil according tofollowing instructionBottom of left side(50cc)Oil holeReplacement-----2) Please prepare the container to receive the oil3) Remove 2 drain plugs located left side of transmission case anddrain the oil.Reference:Please pull down the handle and tilt the transmission and remove theoil hole as well so that you can drain the oil easily.Drain plug4) Please make sure if drain plug is installed and then, lubricate theproper quantity.tiltEstimated replacementFirst/ 10 hours, or later/every 50 hoursCAUTIONIn case such as using for a long time and using in bad condition(much load/hot), please replace theoil 2 times earlier than estimated replacement.OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201016

Maintenance chartAsk your dealer to realize this operation needing special tools and knowledge.⊕ Inspection to realize by the owners before starting the engine⊗ Inspection to realize by the owners after starting the enginePart to inspectInspectionEveryusefirst 20hoursEvery les100hoursEvery 300hours everyyearBlade beltCheck belt tensionCheck wearFuel refuelling ⊕Fuel cock⊕Flammables matérialsClean the machine from flammablesmatérials⊕Travel levercheck machine do not move whenlever is on “N”⊗Brake Check efficiency of the brake ⊗ChâssisCheck for rust, and cracksSafety stickersCheck they are in place and in goodcondition⊕Guards & shieldsCheck they are bolted in their placeand in good condition⊕Tank and fuel hosesCheck for leaks and good conditionReplace if needed⊕Throttle lever Check for efficiency ⊗BladesCheck they are bolted in their placeand in good condition⊕Blade clutch controlleverCheck the adjustment of the wire⊕Blade brake Check the adjustment ⊕Blade beltCheck they tension and conditionEngineRefer to engine manualOREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201017

BREAKDOWNS AND SOLUTIONS 1PROBLEME CAUSE SOLUTIONSNo fuelRefuel the tankEngine does not start Engine switches are working Check brakes, blade clutch and seatand travel leverThe machine does not travel Release lever is locked unlock Release leverThe machine does not stop travel wires unadjusted Adjust travel wiresThe blade does not rotateBlade clutch lever is notengageSafety switches are workingengage Blade clutch leverCheck brakes, blade clutch and seatand travel leverBREAKDOWNS AND SOLUTIONS 2PROBLEME CAUSE SOLUTIONSGrass is wetWait until grass is dryGrass is highAdjust cutting height high and cutGrass is not dischargeabletwiceCutting height is lowAdjust cutting height highEngine rpm is lowAdjust engine rpm highWorking speed is fastWorking slowly.Working speed is fastWork slowlyEngine rpm is lowAdjust engine rpmGrass is not mowed perfectlyGrass is highWork twiceKnife has damageReplace the knifeGrass is pilled inside of knife Clean the inside of knife covercoverCutting height is lowAdjust cutting heightTurning speed is fastTurning slowlyHit the groundGround has waveChange the direction of cuttingGround has unevenAdjust cutting height highKnife is bendingReplace the knifeBelt tension is not enoughAdjust the knife wireKnife is slippingGrass is pilled on Knife cover Remove the grass from knife coverGrass is pilled on pulleyClean the pulleyBelt has damageReplace to new oneChanging wire is not adjusted Adjust the changing wireCannot change the speedcorrectlyTransmission has wrongRepair transmissionBalance of knife is not goodRepair knife(all)Knife has damageReplace to new knifeGrass is pilled inside of knife Clean the knife neck guardToo much vibrationneck guardKnife shaft is bendingReplace to new oneBelt has damageReplace to new oneMixed new and old knives Do not mix new and old knivesOREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201018

Too much loadEngine rpm is lowWorking speed is fastGrass is coiling to knife shaftGrass is highCutting height is lowMake engine rpm high(3200 rpm)Work slowlyClean the knifeAdjust cutting height high and worktwiceAdjust cutting height highSpike Tires are slippingGrass is piled on knives or insideof knife coverGround is softCutting height is lowClean the knives and inside of knifecoverWait until Ground is dryAdjust the cutting height high andwork twiceRemove the load from wheelsShare the load with 4 spike tiresTorque limiter is workingSpike tire does not move Unbalance the load for SpiketiresHandle is turned left side Handle must be turned right sideThrown objects Objects in field Adjust the cutting height high or removethe objects before workingCannot push the machine Driving clutch is ON Release the Driving clutch leverOil leak near theMist oil goes out of internalpressure from the transmissionDriving clutch is OFFNo problemSlipping in SlopesGrip the Travel lever and make thedriving clutch ONOil stopper comes off much oil reduce the oil quantityKnife interference Knives are installed incorrectly Install the knives correctlyFuel leakDirection of Fuel cock points Direction of Fuel cock must bedown(Valley side)pointed up(Mountain side)Knife belt rotates around with Adjust the belt holder or replace toKnives does not stoppulleynew oneRotation of engine idling is high Adjust the rotation of engine idlingaccording to regulationEngine rotation does not riseafter engine restart.Grass might be coiling to theknife or knife shaftRemove the grass from the knife orknife shaftTIGHTENING TORQUES (daNm)Diameter of <strong>SP</strong>ANNER Mark on the screw headthe screw(mm) SIZE (mm) 8.8 10.98 13 2.5 3.510 16 5 7.512 18 8.5 1314 21 12.87 18.1116 24 21.5 31.518 27 26.6 37.420 30 43.5 6222 32 51 71.7124 36 75 10730 46 149.5 213OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201019

CONFORMITY CERTIFICATE(following annexe II of directive 2000/14/CE and 2006/42/CE)I undersigned : OREC CO LTD 548-22 HIYOSHI HIROKAWA-MACHI YAME-GUN JAPON manufacturerS.A.T. sarl - Force 7 – ZA – 38110 ROCHETOIRIN France owner of the technical documentsUKAS - 71 fenchurch street London EC3S 4BS UK notified body following the complete quality insurancesystemCertify that the brush cutter :1. Class : ……..................................internal combustion engine.......................................................2. Mark : ........................................................OREC........................................................................3. Type : ......................................................<strong>SP</strong><strong>1000</strong>...........................................................................4. Serial Identification (to be completed) : .........................................................................................Granted acoustic power level measured on a representative sample : ...........................103,5.dB(A)Granted acoustic pressure level : ..................................103,5....………………………………….dB(A)is complying with directive 2000/14 EC, 2006/42 and european norm EN12733 specifications.made at .......Fukuoka.........…....... Date : .........april 5 th 2010............Signed : Haruhiko ImamuraFonction : Managing directorMEASUREMENT OF VIBRATIONSMark : OREC Type : mower Type : <strong>SP</strong><strong>1000</strong>Engine : Mistibishi GB100Speed during test : 3000+/- 50 rpmACCELEROMETER POSITIONAwp100 mm of the end of handlebar (left side) 1,65 m/s²100 mm of the end of handlebar (right side) 2,36 m/s²OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201020

LIMITED WARRANTYEach new product manufactured by OREC is guaranteed under the cope of the following terms. The warrantyapplies to defective parts due to defect in assembling and construction or/and in material imputable to us. It isvalid for a period of one year and for normal use of the machine. It does not apply to engines manufactured byother companies that also guarantee their materials and whose guarantee is supplied with the machine.1° This guarantee is limited to the sole replacement of the defective parts during one year commencingwith the purchasing date of the machine. The guarantee is limited to the parts that are previouslyshown to and acknowledged by OREC.2° Each part concerned by a guarantee claim must be returned to OREC’s in order to be inspected,repaired or replaced. The part(s) must be returned with freight prepaid and must be accompanied witha proof of the purchase. The part(s) must be packed with the greatest of care to ensure their protection.3° The machine must not have been worn out, repaired or maintained by anyone without OREC’sprevious authorization. The machine must not have been damaged in a road accident, roughly handledor unproperly used.This guarantee does not compell OREC or its dealer to reimburse the labour costs or the carriagecosts to the repairer.NO OTHER GUARANTEE SHALL BE APPLIED TO THIS MACHINE EXCEPT THE LEGAL GUAR-ANTEE. OREC SHALL NOT BE LIABLE FOR ANY DAMAGE OR COST INVOLVED BY THE MA-CHINE, FOR EXAMPLE :1. HIRING COSTS2. TURNOVER LOSSES3. WORK DONE BY A REPLACING MACHINEOREC DOES NOT TAKE ON ANY OTHER OBLIGATION AND DOES NOT AUTHORIZE ANYBODYTO TAKE ON ANY OTHER OBLIGATION THAN THOSE MENTIONED IN THE 3 PARAGRAPHSABOVE.To know the name of your dealer, report to: ORECNOTES.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................OREC <strong>SP</strong><strong>1000</strong> - © SAT 06/201021