The fixed compressors - 10 bars - DMK

The fixed compressors - 10 bars - DMK

The fixed compressors - 10 bars - DMK

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

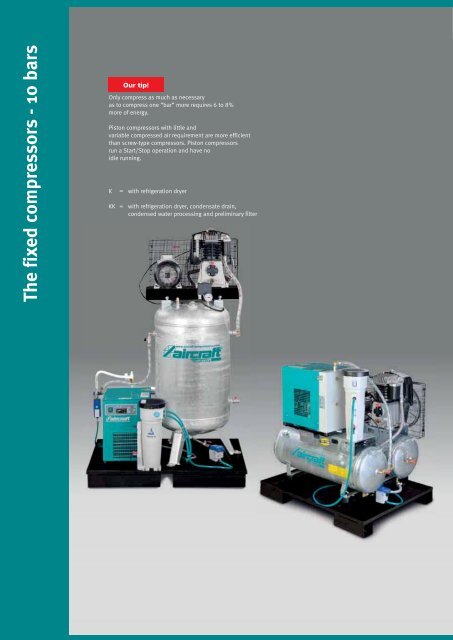

<strong>The</strong> <strong>fixed</strong> <strong>compressors</strong> - <strong>10</strong> <strong>bars</strong>Only compress as much as necessaryas to compress one “bar” more requires 6 to 8%more of energy.Piston <strong>compressors</strong> with little andvariable compressed air requirement are more efficientthan screw-type <strong>compressors</strong>. Piston <strong>compressors</strong>run a Start/Stop operation and have noidle running.KOur tip!= with refrigeration dryerKK = with refrigeration dryer, condensate drain,condensed water processing and preliminary filter

Fixed- <strong>10</strong> <strong>bars</strong>NewSeries AIRSTAR - Robust craftsmen <strong>compressors</strong> incl. proven belt driveand two-stage compressed two-cylinder high-performance unit made of grey cast· Due to the two-stage compressed twocylinderhigh-performance unit a very littlespeed is achieved at which very smooth andlow-vibration running is attained· This grants an even longer service life due toless wear· Large fanwheel and a cooling air deflectoron the cylinder for optimum cooling of thecompressor· Re-cooler and cooling lamellaes andintermediate cooler for re-cooling provide fora low vessel inlet temperature and thus forless humidity in the compressed air· Quality electric motor with high startingtorque is protected from overheating andoverloading via a protective motor switch· Equipped with phase inverter for easymanual inversion of the sense of rotation· Equipped with high quality CONDOR pressureswitch· Equipped with a manometer for vesselpressure and a ball valve on the vessel· Compressed air vessel equipped with safetyvalve, vessel pressure manometer andcondensate drain valve· Vessel with powder coating, <strong>10</strong>-year on thevessel against rust through· With all safety devices· Completely ready for connection· Stable belt grid protection made of metal· Including oscillating elementsPISTON COMPRESSORSAIRSTAR 703/270/<strong>10</strong> HFig. shows the scope of deliveryAIRSTAR 703/270/<strong>10</strong> VFig. shows the delivery volumeTypeItem No€ plus VATTechnical dataCompressor system*Max. volume of currentFilling capacity 6-<strong>10</strong> barMaximum pressureReservoir capacityCylinder/stagesSpeedMotor powerWeightDimensions (LxWxH) in mmSound pressure L PA ***Air outletAIRPROFI AIRSTAR 703/270/<strong>10</strong> 703/<strong>10</strong>0/<strong>10</strong> H202 2273 87531'229.00 1'535.00HOS650 l520 l<strong>10</strong> <strong>bars</strong><strong>10</strong>0 270 l2/2950 1/min.4 kW98 160 kg kg<strong>10</strong>00 1950 x 600 450 x 950 125083 80 dB(A)3/4’’AIRPROFI AIRSTAR 703/270/<strong>10</strong> 853/<strong>10</strong>0/<strong>10</strong> VH202 2283 87521'349.00 1'820.00HOS850 650 l680 520 l<strong>10</strong> <strong>bars</strong><strong>10</strong>0 270 l2/21'240 950 1/min.5.5 4 kW kW1<strong>10</strong> 160 kg<strong>10</strong>00 720 x x 720 450 x x 1770 95083 80 dB(A)3/4’’Safety palettefor side refrigerant dryersWith the optional and space saving safety paletteyou can position your air dryer on a surface of800x600mm directly beside the compressor(Airprofi H models). <strong>The</strong> side palette is optionallyavailable for self-assembly with optional refrigerantdryer and ÖWAMAT ® condensate preparator oralso as complete kit including different refrigerantdryers.Please find further information and prices from Seite on.Built according to CE directives45

Fixed- <strong>10</strong> <strong>bars</strong>Series AIRPROFI V <strong>10</strong> <strong>bars</strong> - Fixed <strong>compressors</strong> with an upright vessel of 270 l vesselMaximum capacity on smallest space.· <strong>The</strong> two stage compressing two cylinder highperformance aggregate allows a very low speedat which particular smooth and low vibrationrunning is being achieved· <strong>The</strong> intercooler and after-cooler provide alow vessel inlet temperature and thus reduce thecondensate formation· <strong>The</strong> largely-dimensioned fanwheel provide anoptimum cooling· Fully automatic ON/OFF operation· <strong>The</strong> quality electric motors are protected fromoverheating and overloading via a protectivemotor switch· Three compressed air outlet positions on thevessel· Vessel inside and outside hot-dip galvanized,15-year guarantee on the vesselagainst rust-through· Equipped with high qualityCONDOR pressure switch· Completely ready for connection with all fittingsAIRPROFI 853/270 VDelivery including oscillating elementsCompressed air stationAIRPROFI 853/270 VKDelivery including safetypaletteFig. with optimum fine filteron the refrigerant dryerType AIRPROFI 703/270/<strong>10</strong> V AIRPROFI 853/270/<strong>10</strong> V AIRPROFI <strong>10</strong>03/270/<strong>10</strong> V AIRPROFI 1253/270/<strong>10</strong> VItem No 202 4712 202 4812 202 4912 202 5012€ plus VAT 2'045.00 2'195.00 2'500.00 3'855.00Type AIRPROFI 703/270/<strong>10</strong> VK AIRPROFI 853/270/<strong>10</strong> VK AIRPROFI <strong>10</strong>03/270/<strong>10</strong> VK AIRPROFI 1253/270/<strong>10</strong> VKItem No 202 4712 K 202 4812 K 202 4912 K 202 5012 K€ plus VAT 3'8<strong>10</strong>.00 4'320.00 4'490.00 5'830.00Type AIRPROFI 703/270/<strong>10</strong> VKK AIRPROFI 853/270/<strong>10</strong> VKK AIRPROFI <strong>10</strong>03/270/<strong>10</strong> VKK AIRPROFI 1253/270/<strong>10</strong> VKKItem No 202 4712 KK 202 4812 KK 202 4912 KK 202 5012 KK€ plus VAT 5'000.00 5'455.00 5'790.00 7'125.00Technical dataCompressor system*Max. volume of currentFilling capacity 6-<strong>10</strong> barMaximum pressureReservoir capacityCylinder/stagesSpeedMotor powerWeightHOS650 l520 l<strong>10</strong> <strong>bars</strong>270 l2/2950 1/min.4 kW160 kgHOS850 l680 l<strong>10</strong> <strong>bars</strong>270 l2/21240 1/min.5.5 kW170 kgHOS960 l750 l<strong>10</strong> <strong>bars</strong>270 l2/2<strong>10</strong>60 1/min.5.5 kW160 kgDimensions (LxWxH) in mm ** 745 x 620 x 1860 850 x 830 x 1860850 x 830 x 1940Sound pressure L PA ***Air outlet83 dB(A)3/4’’83 dB(A)3/4’’82 dB(A)3/4’’*Description of compressor system see Seite 18 ** Dimensions of the basic type***Sound power level at a distance of 1 m according to DIN 45635 T 1346HOS1200 l900 l<strong>10</strong> <strong>bars</strong>270 l2/21220 1/min.5.5 kW160 kg850 x 830 x 194082 dB(A)3/4’’Built according to CE directives

Accessories· Liquid- or oil-recognizingcondensate drain BEKOMAT ®31 on the vessel· Due to the level controlno unnecessary loss ofcompressed air· Condensate preparatorÖWAMAT ® <strong>10</strong> with largelydimensioned exhaust air/coalescence filter and pre- orpost-absorber· <strong>The</strong> fine filter CLEARPOINT ® forthe discharge of condensate andsolid soiling with particles up to 25microns.· Compressed air quality according toISO 8573-1· As pre-filter installed upstream ofthe refrigerant dryer· You will find importantnotes about the condensatepreparationin the chapter compressed airpreparation· “K” type standard with refrigerationdryer with the integrated levelcontrolledcondensate drain BEKOMAT ®· Pressure dew point at 3°C,environmental temperature 25°C,atmospherical melting point at -22°CIllustrated fine filteronly for "KK" typeas standardPISTON COMPRESSORSScope of delivery VK:· Safety palette· Refrigeration dryer AD 35· For type 853/<strong>10</strong>03Refrigerant dryer AD 51Scope of delivery VKK:· Safety palette· Refrigeration dryer AD 35· For type 853/<strong>10</strong>03Refrigerant dryer AD 51· Fine filter CLEARPOINT ®· Condensate preparatorÖWAMAT ® <strong>10</strong>· Condensate drainBEKOMAT ®AIRPROFI 853/270 VKKMaximum equipmenton narrowest spaceWith the KK type your completecompressed air generation andpreparation is housed on about1sqm. Delivery including safetypalette· <strong>The</strong> two-stage compressingtwo-cylinder highperformanceunit with acylinder block made of greycast iron for a smooth runningand a long service life· <strong>The</strong> largely-dimensionedfanwheel provide an optimumcooling· <strong>The</strong> low speed provideshighly efficient air conveyingcapacity, reduces wear· <strong>The</strong> intercooler and aftercoolerwith large-surfacecooking lamellaes provide alow vessel inlet temperatureand thus reduce thecondensate formation· Flexible armoured hoselinewith heat protection for along service life as a vibrationfracture is not possibleTechnical data Refrigerant dryer AD 35 Refrigerant dryer AD 51Capacity at 35°C 580 l / 35 m 3 /h 830 l / 50 m 3 /hPressure max. 16 <strong>bars</strong> 16 <strong>bars</strong>Power 50 Hz 200 W / 230 V 270 W / 230 VConnection IT 1/2” 1/2”Dimensions (LxWxH) 370x515x475 mm 370x515x475 mmPressure dew point 3 °C 3 °CEnvironmental temperature 20°C 20°CCompressed air inlettemperature 35°C 35°COperating pressure 7 <strong>bars</strong> 7 <strong>bars</strong>NewAccessories Item No € plus VAT1 Oscillation element with one-sidedThread <strong>10</strong>0x38 mm / M<strong>10</strong> 250 5640 12.501 Oscillation element with double-sidedThread 70x38 mm / 2xM<strong>10</strong> (for SSP) 250 5650 13.90Safety stand pallet SSP 203 0<strong>10</strong>3 199.00upright stationary 1200 x 800 x 140 mmAutomatic star-delta starting switchWith operating hour counter(Regional from 5.5 kW prescribed) 250 60<strong>10</strong> 595.00Built according to CE directives 47

Fixed- <strong>10</strong> <strong>bars</strong>Series AIRPROFI H <strong>10</strong> <strong>bars</strong> - Fixed <strong>compressors</strong> with reclined vessel,for a maximum of applicable compressed air. "K" type with refrigeration dryer.· <strong>The</strong> two stage compressing two cylinder resp.four cylinder high performance aggregate allowsa very low speed at which particular smooth andlow vibration running is being achieved· <strong>The</strong> large fanwheel provides an optimum cooling· <strong>The</strong> intercooler and after-cooler provide alow vessel inlet temperature and thus reducethe condensate formation***· <strong>The</strong> quality electric motors are protected fromoverheating and overloading via a protectivemotor switch· Vessel inside and outside hot-dip galvanized,15-year guarantee on the vessel against rustthrough· Equipped with high quality CONDOR pressureswitch· Completely ready for connection with all fittings· Flexible reinforced hose with heat protectionprevents vibration fractureAdditional equipment for "K" type:· With compressed air refrigeration dryer fordry compressed air for a higher durability ofcompressed air tools in order to avoid failures inpneumatic controls· With liquid- or oil-recognizing condensate drainBEKOMAT ® 31AIRPROFI 853/<strong>10</strong>0/<strong>10</strong> H· With <strong>10</strong>0 l Tank particularly space-saving· TÜV free - the TÜV approval is omitted· Any installation and recurring tests can this way also beperformed by an authorized person· This only applies in Germany· Scope of delivery including a safety quick action couplingand vibrating elements· Serially equipped with qualityquick coupling and high qualityCONDOR pressure switchAIRPROFI <strong>10</strong>03/500/<strong>10</strong> HK· With 500 l vessel: For a maximum of available air!· Fig. with optional accessories: Bekomat 21, Öwamat<strong>10</strong> as well as fine filter ClearpointType AIRPROFIItem No€ plus VATTypeItem No€ plus VATCold dryer703/<strong>10</strong>0/<strong>10</strong> H202 22731'350.00----853/<strong>10</strong>0/<strong>10</strong> H202 22831'450.00----703/300/<strong>10</strong> H202 57132'075.00703/300/<strong>10</strong> HK202 5713 K3'670.00AD 35853/300/<strong>10</strong> H202 58132'170.00853/300/<strong>10</strong> HK202 5813 K3'880.00AD 51853/500/<strong>10</strong> H202 58152'430.00853/500/<strong>10</strong> HK202 5815 K4'190.00AD 51<strong>10</strong>03/500/<strong>10</strong> H202 59152'830.00<strong>10</strong>03/500/<strong>10</strong> HK202 5915 K4'540.00AD 511253/500/<strong>10</strong> H202 60154'190.001253/500/<strong>10</strong> H202 6015 K5'875.00AD 51Technical dataCompressor system* HOSMax. volume of current 650 lFilling capacity 6-<strong>10</strong> bar 520 lMaximum pressure <strong>10</strong> <strong>bars</strong>Reservoir capacity <strong>10</strong>0 lCylinder/stages 2/2Speed950 1/min.Motor power4 kWWeight98 kgDimensions (LxWxH) in mm <strong>10</strong>95 x 460 x 950Sound pressure L PA **Air outlet83 dB(A)3/4’’HOS850 l680 l<strong>10</strong> <strong>bars</strong><strong>10</strong>0 l2/21,240 1/min.5.5 kW1<strong>10</strong> kg<strong>10</strong>95 x 460 x 95083 dB(A)3/4’’HOS650 l520 l<strong>10</strong> <strong>bars</strong>300 l2/2950 1/min.4 kW190 kg1680 x 540 x 117083 dB(A)3/4’’HOS850 l680 l<strong>10</strong> <strong>bars</strong>300 l2/21240 1/min.5.5 kW195 kg1680 x 540 x 117083 dB(A)3/4’’HOS850 l680 l<strong>10</strong> <strong>bars</strong>500 l2/21240 1/min.5.5 kW235 kg2000 x 600 x 138083 dB(A)3/4’’HOS950 l750 l<strong>10</strong> <strong>bars</strong>500 l2/2960 1/min.5.5 kW245 kg1950 x 600 x 136582 dB(A)3/4’’HOS1200 l900 l<strong>10</strong> <strong>bars</strong>500 l2/21220 1/min.5.5 kW245 kg1950 x 600 x 136582 dB(A)3/4’’*Description compressor systems refer to Seite 18 **Sound pressure level with a distance of 1 m according to DIN 45635 T 13 *** TÜV free only applicable in Germany48Built according to CE directives

Accessories· Liquid- or oil-recognizingcondensate drain BEKOMAT ®31 on the vessel· Due to the level controlno unnecessary loss ofcompressed air· Condensate preparator ÖWAMAT ®<strong>10</strong> with largely dimensionedexhaust air/coalescence filter andlargely dimensioned pre- or postabsorber· You will find important notesabout the condensate preparationin the chapter compressed airpreparation· <strong>The</strong> fine filter CLEARPOINT ® forthe discharge of condensateand solid soiling with particlesup to 25 microns.· Compressed air qualityaccording to ISO 8573-1· As pre-filter installed upstreamof the refrigerant dryer· “K” type standard withrefrigeration dryer with theintegrated level-controlledcondensate drain BEKOMAT ®· Pressure dew point at 3°C,environmental temperature25°C, atmospherical meltingpoint at -22°CPISTON COMPRESSORSNew· Including high quality suction filterfromAirprofi <strong>10</strong>03/500/<strong>10</strong> H onType AIRPROFIItem No€ plus VATTypeItem No€ plus VATCold dryerAIRPROFI I 1400/500/<strong>10</strong> / Hwith 500 l Vessel and four-cylinder unitNew1403/500/<strong>10</strong> H202 70505'580.001403/500/<strong>10</strong> HK202 7050 K7'300.00AD 51New1863/500/<strong>10</strong> H202 70606'000.001863/500/<strong>10</strong> HK202 7060 K7'720.00AD 51Scope of delivery AIRPROFI H:· Starting relief· Oscillating elements· Star-delta-switch fortypes 1403/500/<strong>10</strong> and1863/500/<strong>10</strong>Scope of delivery AIRPROFI HK:· Starting relief· Refrigerant dryer AD 35for type 703/300· Refrigerant dryer AD 51for types 853, <strong>10</strong>03,(Refrigerant dryer AD 35and AD 51 with integratedcondensate drain Bekomat ® 31)· AD 72 for type 1403· AD <strong>10</strong>8 for type 1863· Oscillating elementsTechnical dataCompressor system*Max. volume of currentFilling capacity 6-<strong>10</strong> barMaximum pressureReservoir capacityCylinder/stagesSpeedMotor powerWeightDimensions (LxWxH) in mmSound pressure L PA **Air outletHOS1'4<strong>10</strong> l990 l<strong>10</strong> <strong>bars</strong>500 l4/2820 1/min.7.5 kW315 kg1950 x 600 x 138486 dB(A)HOS1'860 l1'300 l<strong>10</strong> <strong>bars</strong>500 l4/21,080 1/min.11 kW325 kg1950 x 600 x 138487 dB(A)3/4’’Technical dataRefrigerant dryer AD 35 AD 51Capacity at 35°C 580 l / 35 m 3 /h 830 l / 50 m 3 /hPower 50 Hz 200 W / 230 V 270 W / 230 VConnection IT 1/2” 1/2”Dimensions (LxWxH) 370 x 515 x 475 mm 370 x 515 x 475 mmPressure dew point 3 °C 3 °CEnvironmentaltemperature 20°C 20°CCompressed air inlettemperature 35°C 35°COperating pressure 7 <strong>bars</strong> 7 <strong>bars</strong>3/4’’*Description compressor systems refer to Seite 18**Sound pressure level with a distance of 1 m according to DIN 45635 T 13Built according to CE directives 49

Fixed -- Double reclined units - <strong>10</strong> <strong>bars</strong>Series AIRPROFI Tandem <strong>10</strong> <strong>bars</strong> - Fixed <strong>compressors</strong> includinghorizontal vessel and two units for sufficientair reserve at large fluctuating requirements· <strong>The</strong> largely-dimensioned fanwheel for optimumcooling· Intercooler and aftercooler for low vessel inlettemperature and reduction of condensateformation· <strong>The</strong> quality electric motors are protected fromoverheating and overloading via a protectivemotor switch· Vessel inside and outside hot-dip galvanized,15-year guarantee on the vessel against rustthrough· Completely ready for connection with all fittingsBasic load alternate controlYour advantages:· Two two-stage compressing two-cylinder highperformanceunits· Space-saving due to two compressor units onone compressed air vessel perfect for fields ofapplication with narrow space conditions· Sufficient air reservoir also in case ofconsiderable fluctuations in air requirements· Serially equipped with basic loadalternating control· To distribute basicand additional air requirement· <strong>The</strong> basic load alternate controlguarantees the same runtimesfor both compressor levels· Equal wear· Maintenance of both units atthe same timeTypeItem No€ plus VATTechnical dataCompressor system*Max. volume of currentFilling capacity 6-<strong>10</strong> barMaximum pressureReservoir capacityCylinder/stagesSpeedMotor powerWeightDimensions (LxWxH) in mmSound pressure L PA **Air outletAIRPROFI TANDEM703/500/<strong>10</strong> H202 67155'320.00HOS2 x 650 l2 x 520 l<strong>10</strong> <strong>bars</strong>500 l2 x 2/2950 1/min2 x 4.0 kW280 kg1950 x 600 x 129583 dB(A)3/4’’AIRPROFI TANDEM 703/500/<strong>10</strong> HAIRPROFI TANDEM<strong>10</strong>03/500/<strong>10</strong> H202 69156'275.00HOS2 x 960 l2 x 750 l<strong>10</strong> <strong>bars</strong>500 l2 x 2/2<strong>10</strong>60 1/min2 x 5.5 kW300 kg1950 x 600 x 136582 dB(A)3/4’’Safety palettefor side refrigerant dryers800x600mm safety palettefor direct positioning of yourair dryer. <strong>The</strong> side palette isavailable for self-assemblyincluding optional air dryerand ÖWAMAT ® condensatetreatment or also ascomplete kit includingdifferent refrigerant dryers.· Two 2-stage compressing twocylinderhigh-performanceunits are offering a <strong>10</strong>0%guaranteed safety· Flexible reinforced hoseline with heat protectionprevents a vibration fracturePlease find further information and prices*Description compressor systems refer to Seite 18from Seite on.**Sound pressure level with a distance of 1 m according to DIN 45635 T 1350Built according to CE directives

Fixed compressed air station - <strong>10</strong> <strong>bars</strong>Airprofi DUO - Universally applicable compressed air station of 2 x <strong>10</strong>0 lCompressed air vessel ready-mounted on a safety palette,space-saving and transportable· Two-stage compressing two-cylinder high-performance unitwith a cylinder block made of grey cast iron· <strong>The</strong> low speed provides a smooth andlow-vibration running and a long service life· Largely-dimensioned fanwheel for an optimum cooling· <strong>The</strong> quality electric motors are protected from overheatingand overloading via a protective motor switch· Including phase inverter for easymanual inversion of the sense of rotation· Intercooler and after-cooler reduce the condensationformation· Maintenance block including two manometers for thevessel pressure and working pressure and high qualityCONDOR pressure switch· Vessel inside and outside hot-dip galvanized, 15-yearguarantee on the vessel against rust-through· Fully automatic ON/OFF operation· Completely ready for connection with all fittingsIncreased flexibility· By switching the secondcompressed air vessel the volumeis being doubled, by what a higherair supply may be built up· Thus, an increased air requirementmay be covered for a short time· At example for chisel or gritblasting, the second compressedair vessel may be separated fromthe air intake by what the vesselvolume is halved and thus thepressure is built up· “K” type standard withrefrigeration dryer with theintegrated level-controlledcondensate drain BEKOMAT ®· Pressure dew point at 3°C,environmental temperature25°C, atmospherical meltingpoint at -22°CPISTON COMPRESSORS· <strong>The</strong> “KK” typeis additionally equippedwith a pre-filter to separatecondensate and solid soilingwith particles of up to 25microns.· Compressed air qualityaccording to ISO 8573-1· As pre-filter installed upstreamof the refrigerant dryerDUO 853/2x<strong>10</strong>0/<strong>10</strong>TypeDuo 853/2x<strong>10</strong>0/<strong>10</strong>Item No 202 3085€ plus VAT 2'235.00TypeDuo 853/2x<strong>10</strong>0/<strong>10</strong> KItem No 202 3086€ plus VAT 3'800.00TypeDuo 853/2x<strong>10</strong>0/<strong>10</strong> KKItem No 202 3087€ plus VAT 4'930.00DUO 853/2x<strong>10</strong>0/<strong>10</strong> KK**· Liquid- or oil-recognizingcondensate drain BEKOMAT ® 31 onthe vessel· Due to the level control, theBEKOMAT ® 31 is working withoutunnecessary loss of compressed airTechnical dataCompressor system *HOSMaximum volume flow850 lFilling capacity680 lScope of delivery K:Maximum pressure<strong>10</strong> <strong>bars</strong>· With refrigeration dryer AD 35 · Condensate preparatorVessel capacity2 x <strong>10</strong>0 lÖWAMAT ® <strong>10</strong> with largelyCylinder/stages 2/2dimensioned exhaust air/Speed1240 1/min.Scope of delivery KK:coalescence filter and largelyMotor power5.5 kW/400 V· Fine filter CLEARPOINT ®dimensioned pre- or postabsorberWeight235 kg· Refrigeration dryer AD 35Dimensions (LxWxH) in mm 1200 x 900 x 1250· Condensate drain· You will find importantSound pressure L PA ***83 dB(A)BEKOMAT ®notes about the condensateAir outlet on the vessel 3/4’’· Condensate preparatorpreparationAir outlet on the refrigerant dryer 1/2’’ÖWAMAT ® <strong>10</strong>in the chapter compressed air* Description compressor systems refer to Seite 18preparation** TÜV free only applicable in Germany***Sound pressure level at a distance of 1 m according to DIN 45635 T 13Built according to CE directives 51

Fixed auxiliary <strong>compressors</strong> - <strong>10</strong> <strong>bars</strong>Series AIRPROFI BK - providing cost-efficient auxiliary <strong>compressors</strong>using side <strong>compressors</strong> perfect as peak load <strong>compressors</strong>· <strong>The</strong> two stage compressing two cylinder highperformance aggregate allows a very low speed at whichparticular smooth and low vibration running is beingachieved· <strong>The</strong> large fanwheel provides an optimum cooling· <strong>The</strong> intercooler and after-cooler provide alow vessel inlet temperature andthus reduce the condensate formation· <strong>The</strong> quality electric motors are protected from overheatingand overloading via a protective motor switch· Ready-to-connect to all fittings such as pressure switchfor fully automatic ON/OFF switching, operation,safety and check valve, condensate and air bleeder forautonomous operation· Vessel inside and outside hot-dip galvanized, 15-yearguarantee on the vessel against rust-through· Equipped with high quality CONDOR pressure switch· Completely ready for connection with all fittings**· High-performance grey cast ironunit with little speed· <strong>The</strong> aftercooler with large surfacecooling lamellaes provides a lowvessel inlet temperature· <strong>The</strong> flexible armoured hose linewith heat protection avoidsvibration fracturesNewAIRPROFI BK 703/13/<strong>10</strong>Auxiliary <strong>compressors</strong> are used:· If the available air quantity is too little· If the maximum outputs need to be covered· If a <strong>10</strong>0% safety needs to be guaranteed· If old appliances would require expensive repairsRecommended accessory· AIRCRAFT RAFT Vessel batteryas battery of 2 or 4 vessels· For an additional air supply ofup to 400 l without TÜV acceptancePlease find further information on Seite Type AIRPROFI BK 703/13/<strong>10</strong> AIRPROFI BK <strong>10</strong>03/13/<strong>10</strong>Item No 202 9711 202 9911€ plus VAT 1'440.00 1'935.00Technical dataCompressor system* HOS HOSMaximum volume flow 650 l 960 lFilling capacity 6 to <strong>10</strong> <strong>bars</strong> 520 l 750 lMaximum pressure <strong>10</strong> <strong>bars</strong> <strong>10</strong> <strong>bars</strong>Reservoir capacity 13 l 13 lCylinder/stages 2/2 2/2Speed 950 1/min. 1'060 1/min.Motor power 4 kW/400 V 5.5 kW/400 VWeight 55 kg 80 kgDimensions (LxWxH) in mm 685 x 745 x 675 685 x 790 x 745Sound pressure L PA *** 83 dB(A) 83 dB(A)Air outlet 3/4’’ 3/4’’*Description compressor systems refer to Seite 18 ** TÜV free only applicable in Germany*** Sound pressure level at a distance of 1 m according to DIN 45635 T 1352NewBasic load alternate control· With two integrated operating hour counters· For a time-dependant control of 2 <strong>compressors</strong> with aperformance of 4.0 kW or 5.5 kW each· Display of actual pressure value by pressure sensor on the tank· Automatic compressor shift point cascading· All parameters are adjustable by means of a power-failure-proofEEPROM memoryPlease find a more detailed description on Seite AccessoriesItem No € plus VATBasic load alternate control fortwo <strong>compressors</strong> 250 6014 1.439,00Built according to CE directives

Only compress as much as necessaryas to compress one “bar” more requires 6 to 8%more of energy.Piston <strong>compressors</strong> with little andvariable compressed air requirement are more efficientthan screw-type <strong>compressors</strong>. Piston <strong>compressors</strong>run a Start/Stop operation and have noidle running.KOur tip!= with refrigeration dryerKK = with refrigeration dryer, condensate drain,condensed water processing and preliminary filterWe are doing savings for you - 13 <strong>bars</strong> instead of 15 <strong>bars</strong>!Our 15 <strong>bars</strong> <strong>compressors</strong> are preset to 13 <strong>bars</strong> cutting-offpressure.<strong>The</strong> reason is that from experience 90% of all users requirea maximumoperating pressure or 13 <strong>bars</strong>.However if you require maximum pressure of 15 <strong>bars</strong> you canset it yourself at any time by pressing the pressure switch.<strong>The</strong> <strong>fixed</strong> <strong>compressors</strong> - 13 - 15 <strong>bars</strong>FixedNew

Fixed- 13-15 <strong>bars</strong>Series AIRPROFI 13 and 15 bar - Fixed <strong>compressors</strong> with uprightor horizontal vessel with an operating pressure more than <strong>10</strong> <strong>bars</strong>· <strong>The</strong> two stage compressing two cylinder highperformance aggregate allows a very low speedat which particular smooth and low vibrationrunning is being achieved· <strong>The</strong> large fanwheel provides an optimumcooling· <strong>The</strong> intercooler and after-cooler provide alow vessel inlet temperature and thus reducethe condensate formation· <strong>The</strong> quality electric motors are protected fromoverheating and overloading via a protectivemotor switch· Vessel inside and outside hot-dip galvanized,15-year guarantee on the vessel against rustthrough· Equipped with high quality CONDOR pressureswitch· Completely ready for connection with all fittingsAdditional equipment for "K" type:· With compressed air refrigeration dryer fordry compressed air for a higher durability ofcompressed air tools in order to avoid failuresin pneumatic controls· With liquid- or oil-recognizing condensate drainBEKOMAT ® 31Maximum equipmenton narrowest space<strong>The</strong> KK typehouses your completecompressed air generationand treatmenton a surface of about 1sqmAIRPROFI 753/270 VDelivery includingOscillating elementsAIRPROFI 753/270 VKKIncluding safety paletteType AIRPROFI 703/270/15 V AIRPROFI 753/270/15 VItem No 202 4752 202 4852€ plus VAT 2'220.00 2'690.00Type AIRPROFI 703/270/15 VK AIRPROFI 753/270/15 VKItem No 202 4752 K 202 4852 K€ plus VAT 3'945.00 4'500.00Type AIRPROFI F 703/270/15 VKK AIRPROFI 753/270/15 VKKItem No 202 4752 KK 202 4852 KK€ plus VAT 5'125.00 5'590.00Technical dataCompressor system* HOSMax. volume of current 575 lFilling capacity460 lMaximum pressure*** 13 (15) <strong>bars</strong>Reservoir capacity 270 lCylinder/stages2/2Speed850 1/min.Motor power4 kWWeight190 kgDimensions (LxWxH) in mm 745 x 620 x 1860Sound pressure L PA ** 83 dB(A)Air outlet3/4’’54* Description compressor systems refer to Seite 18** Sound pressure level with a distance of 1 m according to DIN 45635 T 13*** Preset ex works to a shutdown pressure of 13 <strong>bars</strong>,maximum pressure of 15 <strong>bars</strong> can be set at the pressure switchHOS750 l525 l13 (15) <strong>bars</strong>270 l2/2785 1/min.5.5 kW190 kg800 x 620 x 193082 dB(A)3/4’’Scope of delivery VK:· Refrigeration dryer AD 35· Safety paletteScope of delivery VKK:· Refrigeration dryer AD 35· Fine filter CLEARPOINT ®· Condensate preparatorÖWAMAT ® <strong>10</strong>· Condensate drainBEKOMAT 31 ®· Safety paletteSafety palettefor side refrigerant dryersWith the optional andspace saving safety palette you canposition your air dryer on a surfaceof 800x600mm directly beside thecompressor (Airprofi H types). <strong>The</strong>side palette is available for selfassembly including optimumrefrigerantdryer and ÖWAMAT ® condensatetreatment or as a complete kitmade up of differentair dryers.Please find further information and prices from Seite on.Built according to CE directives

Accessories· Please find matching refrigeranttype dryers, condensatedrain BEKOMAT ® , condensateconditioner ÖWAMAT ® andCLEARPOINT ® fine filters frompage Seite onNewPISTON COMPRESSORS****NewAIRPROFI I1203/500/15 Hwith 500 l Container andfour-cylinder unitScope of delivery AIRPROFI H:· 1 Safety quick action couplingfor type 703/75/13 H· Starting relief· Oscillating elements· Star-delta-switch for types903/500/15 and 1203/500/15AIRPROFI 703/75/13 Hsimilar Fig.· With 75 l Vessel· Professional compressor with 13 <strong>bars</strong>operating pressure TÜV-free· You have 13 <strong>bars</strong> operating pressureavailable in your shop without theotherwise required TÜV testingfor <strong>compressors</strong> with a shutdownpressure of more than <strong>10</strong> <strong>bars</strong>· It can be performed by an authorisedperson on the AIRPROFI 703/75/13· A shutdown pressure of 13 <strong>bars</strong>is regarded as common practiceType AIRPROFIItem No€ plus VATTypeItem No€ plus VATCold dryerNew703/75/13 H202 22751'555.00----703/300/15 H202 57532'095.00703/300/15 HK202 5753 K3'620.00AD 35AIRPROFI 903/500/15 Hwith 500 l vessel:For a maximum of available air!753/300/15 H202 58532'570.00753/300/15 HK202 5853 K4'220.00AD 35753/500/15 H202 58552'890.00753/500/15 HK202 5855 K4'520.00AD 35903/500/15 H202 59553'225.00903/500/15 HK202 5955 K4'975.00AD 51Scope of delivery AIRPROFI HK:· Automatic stardelta starting switch· Starting relief· Refrigeration dryer AD 35For type 903 and 1200refrigerant dryer AD 51(Refrigerant dryers AD 35and AD 51 with integratedcondensate drain Bekomat ® 31)· Oscillating elementsNew1203/500/15 H202 71505'740.001203/500/15 HK202 7150 K7'470.00AD 51Technical dataCompressor system*Max. volume of currentFilling capacityMaximum pressureReservoir capacityCylinder/stagesSpeedMotor powerWeightHOS500 l400 l13 <strong>bars</strong>75 l2/2850 1/min.4 kW<strong>10</strong>3 kgHOS575 l460 l13 (15) bar ***300 l2/2850 1/min.4 kW220 kgHOS750 l525 l13 (15) bar ***300 l2/2785 1/min.5.5 kW230 kgHOS750 l525 l13 (15) bar ***500 l2/2785 1/min.5.5 kW270 kgHOS<strong>10</strong>30 l765 l13 (15) bar ***500 l2/2<strong>10</strong>50 1/min.7.5 kW300 kgDimensions (LxWxH) in mm 940 x 440 x 945 1695 x 500 x 1195 1695 x 500 x 1265 1950 x 600 x 1365 1950 x 600 x 1365Sound pressure L PA ** 79 dB(A)83 dB(A)82 dB(A)82 dB(A)82 dB(A)Air outlet3/4’’3/4’’3/4’’3/4’’*Description compressor system refer to Seite 18 ** sound pressure level at a distance of 1 m according to DIN 45635 T 133/4’’*** preset ex works to a shutdown pressure of 13 <strong>bars</strong>, can be set to a maximum pressure of 15 bar at the pressure switch **** TÜV-free only applicable in GermanyBuilt according to CE directivesHOS1'200 l820 l13 (15) bar ***500 l4/2690 1/min.7.5 kW350 kg1950 x 600 x 138486 dB(A)3/4’’55

Fixed- 13-15 <strong>bars</strong>Series AIRPROFI Tandem 15 <strong>bars</strong> - Fixed <strong>compressors</strong> includinghorizontal vessel and two units for sufficientair reserve at large fluctuating requirements· <strong>The</strong> largely-dimensioned fanwheel for optimumcooling· Intercooler and aftercooler for low vessel inlettemperature and reduction of condensate formation· <strong>The</strong> quality electric motors are protected fromoverheating and overloading via a protective motorswitch· Vessel inside and outside hot-dip galvanized,15-year guarantee on the vessel against rust-through· Completely ready for connection with all fittingsBasic load alternate controlYour advantages:· Two 2-stage compressing two-cylinder highperformanceunits· Space-saving due to two compressor units onone compressed air vessel perfect for fields ofapplication with narrow space conditions· Sufficient air reservoir also in case ofconsiderable fluctuations in air requirements· Serially equipped with basic loadalternating control· To distribute basicand additional air requirement· <strong>The</strong> basic load alternate controlguarantees the same runtimesfor both compressor levels· Equal wear· Maintenance of both units atthe same timeTypeItem No€ plus VATTechnical dataCompressor system*Max. volume of currentFilling capacityMaximum pressure***Reservoir capacityCylinder/stagesSpeedMotor powerWeightDimensions (LxWxH) in mmSound pressure L PA **Air outlet* Description compressor systems refer to Seite 18 **Sound pressure level with a distance of 1 m according to DIN 45635T 13 *** Preset ex works to a shutdown pressure of 13 <strong>bars</strong>, maximum pressure of 15 <strong>bars</strong> can be set at the pressure switch56AIRPROFI TANDEM703/500/15 H202 67555'520.00HOS2 x 575 l2 x 460 l13(15) <strong>bars</strong>500 l2 x 2/2850 1/min2 x 4 kW3<strong>10</strong> kg1950 x 600 x 129583 dB(A)3/4’’AIRPROFI TANDEM 853/500/15 HAIRPROFI TANDEM753/500/15 H202 68556'435.00HOS2 x 750 l2 x 525 l13(15) <strong>bars</strong>500 l2 x 2/2785 1/min2 x 5.5 kW320 kg1950 x 600 x 136583 dB(A)3/4’’Safety palettefor side refrigerant dryers800x600mm safety palettefor direct positioning of yourair dryer. <strong>The</strong> side palette isavailable for self-assemblyincluding optional air dryerand ÖWAMAT ® condensatetreatment or also ascomplete kit includingdifferent refrigerant dryers.Please find further information andprices from Seite on.· Two 2-stage compressing twocylinderhigh-performanceunits are offering a <strong>10</strong>0%guaranteed safety· Flexible reinforced hoseline with heat protectionprevents a vibration fractureBuilt according to CE directives

Fixed- 13-15 <strong>bars</strong>Series AIRPROFI BK - providing cost-efficient auxiliary <strong>compressors</strong>using side <strong>compressors</strong> perfect as peak load <strong>compressors</strong>· <strong>The</strong> two stage compressing two cylinder highperformance aggregate allows a very low speed atwhich particular smooth and low vibration running isbeing achieved· <strong>The</strong> largely-dimensioned fanwheel for optimum cooling· Intercooler and aftercooler for low vessel inlettemperature and reduction of condensate formation· <strong>The</strong> quality electric motors are protected fromoverheating and overloading via a protective motorswitch· Ready-to-connect to all fittings such as pressure switchfor fully automatic ON/OFF switching, operation,safety and check valve, condensate and air bleeder forautonomous operation· Vessel inside and outside hot-dip galvanized, 15-yearguarantee on the vessel against rust-through· Equipped with high quality CONDOR pressure switch· Completely ready for connection with all fittings· High-performance grey cast ironunit with little speed· <strong>The</strong> aftercooler with largesurface cooling lamellaesprovides a low vessel inlettemperature· <strong>The</strong> flexible armoured hose linewith heat protection avoidsvibration fracturesPISTON COMPRESSORSAuxiliary <strong>compressors</strong> are used, if:· the available air quantity is too little· the maximum outputs need to be covered· a <strong>10</strong>0% safety needs to be guaranteed· old appliances would require expensive repairsAIRPROFI BK 703/13/15NewBasic load alternate control· To control 2 <strong>compressors</strong> with a performance of 4.0kW or 5.5 kW each· Cyclic change of basic and peak load <strong>compressors</strong>· With two integrated operating hour counters· Recording of the actual value of the pressure bymeans of the pressure sensor0-16 <strong>bars</strong>· All parameters are adjustable by means of a powerfailure-proofEEPROM memory· Adjustable engine protection 8-12 A· Including control for relief valves 24 VDC (e.g.magnetic valve item No 250 6016, the magneticvalve is not included in the scope of delivery)· Including connection option for safety pressureswitch (e.g. Condor MDR2, item No 250 6214, thepressure switch is not included in the scope ofdelivery)Basic load alternate controlAccessoriesItem No € plus VATBasic load alternate control forup to three <strong>compressors</strong> 250 6014 1.439,00Type AIRPROFI BK 703/13/15 AIRPROFI BK 753/13/15Item No 202 9751 202 9851€ plus VAT 1'440.00 1'935.00Technical dataCompressor system* HOS HOSMaximum volume flow 575 l 750 lFilling capacity 460 l 525 lMaximum pressure*** 13(15) <strong>bars</strong> 13(15) <strong>bars</strong>Reservoir capacity 13 l 13 lCylinder/stages 2/2 2/2Speed 850 1/min. 785 1/min.Motor power 4 kW/400 V 5.5 kW/400 VWeight 55 kg 75 kgDimensions (LxWxH) in mm 685 x 745 x 675 685 x 790 x 745Sound pressure L PA *** 83 dB(A) 82 dB(A)Air outlet 3/4’’ 3/4’’*Description compressor systems refer to Seite 18 / TÜV free only applicable in Germany ** Sound pressure level at a distance of 1 m accordingto DIN 45635 T 13 *** Preset ex works to a shutdown pressure of 13 <strong>bars</strong>, maximum pressure of 15 <strong>bars</strong> can be set at the pressure switch**We are doing savings for you -13 <strong>bars</strong> instead of 15 <strong>bars</strong>!Our 15 <strong>bars</strong> <strong>compressors</strong> are preset to13 <strong>bars</strong> cutting-off pressure.<strong>The</strong> reason is that from experience 90%of all users require a maximumoperating pressure orf 13 <strong>bars</strong>.Any pressure generated above thisvalue means an additional energyconsumptionof about 8%per bar.However if you require maximumpressure of 15 <strong>bars</strong> you can set ityourself at any time by pressing thepressure switch.Built according to CE directives 57

Fixed- 13-15 <strong>bars</strong>NewAirprofi DUO - Universally applicable compressed air station of 2 x 75 lCompressed air vessel ready-mounted on a safety palette,Space saving and can be transported - TÜV-free· Two-stage compressing two-cylinder high-performanceunit with a cylinder block made of grey cast iron· <strong>The</strong> low speed provides a smooth andlow-vibration running and a long service life· Largely-dimensioned fanwheel for an optimum cooling· <strong>The</strong> quality electric motors are protected from overheatingand overloading via a protective motor switch· Including phase inverter for easymanual inversion of the sense of rotation· Intercooler and after-cooler reduce the condensationformation· Maintenance block including two manometers for thevessel pressure and working pressure and high qualityCONDOR pressure switch· Fully automatic ON/OFF operation· Completely ready for connectionwith all fittings· You have 13 <strong>bars</strong> operating pressure available in your shopwithout the otherwise required TÜV testing for <strong>compressors</strong>with a shutdown pressure of more than <strong>10</strong> <strong>bars</strong>.· It can be performed by anauthorised person on the DUO 703/2x75/13.**· “K” type standard withrefrigeration dryer with theintegrated level-controlledcondensate drain BEKOMAT ®· Pressure dew point at 3°C,environmental temperature25°C, atmospherical meltingpoint at -22°CIncreased flexibility· By switching the secondcompressed air vessel the volumeis being doubled, by what a higherair supply may be built up· Thus, an increased air requirementmay be coveredfor a short time· At example for chisel or gritblasting, the second compressedair vessel may be separated fromthe air intake by what the vesselvolume is halved and thus thepressure is built upDUO 703/2x75/<strong>10</strong> KKSimilar figure· <strong>The</strong> “KK” typeis additionally equippedwith a pre-filter to separatecondensate and solidsoiling with particles of upto 25 microns.· Compressed air qualityaccording to ISO 8573-1· As pre-filter installedupstream of the refrigerantdryerTypeDuo 703/2x75/13Item No 202 3185€ plus VAT 2'570.00TypeDuo 703/2x75/13 KItem No 202 3186€ plus VAT 4'140.00TypeDuo 703/2x75/13 KKItem No 202 3187€ plus VAT 5'260.00Technical dataCompressor system *HOSMaximum volume flow500 lFilling capacity400 lMaximum pressure13 <strong>bars</strong>Reservoir capacity2 x 75 lCylinder/stages 2/2Speed850 1/min.Motor power4 kW/400 VWeight230 kgDimensions (LxWxH) in mm 1200 x 900 x 1250Sound pressure L PA ***79 dB(A)Air outlet on the vessel 3/4’’Air outlet on the refrigerant dryer 1/2’’*Description compressor systems refer to Seite 18 ** TÜV free only applicable in Germany***Sound pressure level at a distance of 1 m according to DIN 45635 T 1358Scope of delivery K:· With refrigeration dryer AD 35Scope of delivery KK:· Fine filter CLEARPOINT ®· Refrigeration dryer AD 35· Condensate drainBEKOMAT ®· Condensate preparatorÖWAMAT ® <strong>10</strong>· Liquid- or oil-recognizingcondensate drain BEKOMAT ®31 on the vessel· Due to the level control, theBEKOMAT ® 31 is workingwithout unnecessary loss ofcompressed air· Condensate preparatorÖWAMAT ® <strong>10</strong> with largelydimensioned exhaust air/coalescence filter and largelydimensioned pre- or postabsorberBuilt according to CE directives

Series AIRPROFI SilentFixed59

Compressors, sound-absorbentAIRPROFI 321/<strong>10</strong>0 Silent - mobile <strong>compressors</strong> with sound-absorbent housing -for fields of application where silent operation is required· Only <strong>fixed</strong> screwed joints on themaintenance block,no hose joints· You may adjust infinitely variablethe working pressure with thestandard filter pressure control,at the same time, you will haveseparation of soil, oil andcondensed water· Two manometers indicate thevessel and working pressure· Three compressed air outlets forfiltered compressed air, filteredand oiled compressed air anda compressed air direct outletfrom the vessel via quality safetyquick-action couplings and aquality ball valve· Serially equipped with highquality CONDOR pressure switch· With silent sound-absorbenthousing· Designed for users who areworking in direct proximity ofthe compressor and need asilent environmentAIRPROFI 321/<strong>10</strong>0 OF Silent· Including oil-free HDS compressor· <strong>The</strong> system has been developedfor the hard continuous use whenoil-free and clean compressed airis required· Hard chromed cylinder faces withmicro smooth surface reducingthe friction to an absoluteminimum· <strong>The</strong> high-performance pistonring made of a special mixture ofgraphite, Teflon and carbon has amuch higher service life than thepiston ring made of Teflon· Ergonomic well-formedextended bow for acomfortable and easytransportation· <strong>The</strong> standard rubberisedcarrier handle preventsfrom slipping off· Serially equipped withball valve at the outletof the compressed airreservoirAIRPROFI 321/<strong>10</strong>0 OF SilentOne-hand safetycoupling according to DIN EN 983AIRCRAFT is the firstmanufacturer using it serially· Serially equipped with two one-handsafety coupling according to DIN EN 983· Considerably improved occupationalsafety by venting technique with 2separate locking systems· <strong>The</strong> stable steerable chassisincluding parking brake inlinewith the large wheels withtires made of puncture proof PUfoam allowscomfortable transportation sinceit is not necessary to lift thecompressor when driving· High-grade, inside and outsidehot-dip galvanized vessel· 15-year guarantee on the vesselagainst rust through60Built according to CE directives

AIRPROFI 321/<strong>10</strong>0 Silent - low-noise, mobile <strong>compressors</strong> with directlyflanged two cylinder V aggregate· With silent sound insulation case and newdeveloped noise reduced air filters· Designed for users who need a silent workingenvironment· Intercooler and after-cooler reducethe condensation formation· <strong>The</strong> quality electric motor is protected fromoverheating and overloading via a protectivemotor switch· Equipped with filter pressure controller withmanometer and CONDOR push button· Completely ready for connection with all fittings· Fully automatic ON/OFF operation· Air outlets by default with quality safety quickaction coupling· Two manometer for vessel pressureand working pressure**· Compressed air vessel equipped with safetyvalve, vessel pressure manometerand condensate drain valve· High-grade, inside and outside hot-dipgalvanized vessel, 15-year guarantee againstrust through· With all safety devicesPISTON COMPRESSORS· Complex type of aggregate· Two-cylinder V aggregate withone-stage compression· Very low speed· Directly flanged, no power lossfrom the motor to the compressor· This way increase of the efficiencyand of the filling capacity as wellas extension of the service life· Silent noise insulation caseadditionally equipped withtemperature controlled ventilatorAIRPROFI 321/<strong>10</strong>0 SilentType AIRPROFI 321/<strong>10</strong>0 Silent AIRPROFI 321/<strong>10</strong>0 OF SilentItem No 202 2300 202 23<strong>10</strong>€ plus VAT 2'095.00 2'265.00Technical dataCompressor system* HOS HDSMaximum volume flow 3<strong>10</strong> l 320 lFilling capacity about 240 l 230 lMaximum pressure <strong>10</strong> <strong>bars</strong> <strong>10</strong> <strong>bars</strong>Reservoir capacity <strong>10</strong>0 l <strong>10</strong>0 lCylinder/stages 2/1 2/1Speed 1420 1/min. 1'420 1/min.Motor power 2.2 kW/230 V 2.2 kW/230 VWeight 88 kg 96 kgDimenions (LxWxH) in mm 1275 x 480 x 930 1275 x 480 x 930Sound pressure L WA *** 82 dB(A)82 dB(A)*Description compressor systems refer to Seite 18 ** TÜV free only applicable in Germany*** Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)Built according to CE directives61

Compressors, sound-absorbentSeries AIRPROFI SILENT - <strong>fixed</strong> <strong>compressors</strong> with sound-absorbent housing -ideal to install directly in the working environment· Designed for the professional and industrial usewhere a silent working environment is required· Equipped with Silent noise insulation case to beinstalled even in sensible areas· <strong>The</strong> two stage compressing two cylinder highperformance aggregate allows a very low speedat which particular smooth and low vibrationrunning is being achieved· Equipped with high quality CONDOR pressureswitch· User-friendly installation· Large ventilator flywheel for optimum cooling· Equipped with electrical oil control systemincluding oil level indicator at the outside of thehousing· Intermidiate- and aftercooler as well as anadditional air duct between the motor and thecompressor reduce the formation of condensate· <strong>The</strong> quality electric motor is protected fromoverheating and overloading via aprotective motor switch· Belt tension settingaccessible from the outside· Fully automatic ON/OFF operation· With all safety devices· Completely ready for connection with allfittings· Incl. automatic star delta switch asstandard1 234AIRPROFI 853/<strong>10</strong> Silent· Serially equipped with motorprotection, manometer, on/off switch,operating hour counter, electricalcontrol unit, star-delta startingswitch, start discharge and oscillatingelements<strong>The</strong> operating elements(1) Emergency Stop switch(2) On/off switch(3) Operating hour counter(4) ManometerAIRPROFI 853/270/<strong>10</strong> V SilentType AIRPROFI 853/<strong>10</strong> Silent 853/270/<strong>10</strong> V Silent 853/300/<strong>10</strong> H Silent <strong>10</strong>03/<strong>10</strong> Silent <strong>10</strong>03/500/<strong>10</strong> H SilentItem No 202 2800 202 2827 202 2830 202 2850 202 2860€ plus VAT 3'040.00 4'415.00 4'415.00 4'415.00 5'840.00Technical dataCompressor system* HOS HOS HOS HOS HOSMaximum volume flow 850 l/min. 850 l/min. 850 l/min. <strong>10</strong>80 l.min. <strong>10</strong>80 l.min.Filling capacity 680 l/min. 680 l/min. 680 l/min. 845 l/min. 845 l/min.Maximum pressure <strong>10</strong> <strong>bars</strong> <strong>10</strong> <strong>bars</strong> <strong>10</strong> <strong>bars</strong> <strong>10</strong> <strong>bars</strong> <strong>10</strong> <strong>bars</strong>Reservoir capacity - 270 l 300 l - 500 lCylinder/stages 2/2 2/2 2/2 2/2 2/2Speed 1240 1/min. 1240 1/min. 1240 1/min. 1<strong>10</strong>0 1/min. 1<strong>10</strong>0 1/min.Motor power 5.5 kW/400 V 5.5 kW/400 V 5.5 kW/400 V 7.5 kW / 400 V 7.5 kW / 400 VWeight 155 kg 225 kg 250 kg 180 kg 364 kgDimensions (LxWxH) in mm 790 x 780 x 700 840 x 840 x 2070 1695 x 840 x 1370 9<strong>10</strong> x 790 x 8<strong>10</strong> 1950 x 800 x 1570Sound pressure level LPA ** 67 dB(A) 67 dB(A) 67 dB(A) 73 dB(A) 73 dB(A)Air outlet 3/4’’ 3/4’’ 3/4’’ 3/4’’ 3/4’’*Description compressor systems refer to Seite 18 **Sound pressure level with a distance of 1 m according to DIN 45635 T 13NewNew62Built according to CE directives

AIRPROFI SilentLittle noise emission -at 67 db(A) - very noiseless.PISTON COMPRESSORS1423AIRPROFI 853/300/<strong>10</strong> H Silent· Inside and outside hot-dipgalvanized vessel - 15-yearguarantee on the vessels againstrust-through· Fixed Silent types equipped withpressure switch for fully automatedON-/OFF mode, motor protection,safety valve, manometer, unloadedstart,non-return valve, star-delta switch,condensate drain valve, ballvalve and oscillating elements asstandardQuality in every detail(1) High-quality suction filter(2) Serially equipped withCONDOR pressure switch(3) More cooling due to aseparate air duct betweenthe motor and thecompressor(4) Low vessel inlettemperature and reduced condensate formation inthe intermediate- and recooler with large coolinglamellas14NewNewType AIRPROFI 703/15 Silent 903/15 Silent 703/270/15 V Silent 703/300/15 H Silent 903/500/15 H SilentItem Nr. 202 2805 202 2855 202 2829 202 2835 202 2865€ plus VAT 3'045.00 4'115.00 4'590.00 4'465.00 5'965.00Technical dataCompressor system* HOS HOS HOS HOS HOSMaximum volume flow 705 l/min. 900 l/min. 705 l/min. 702 l/min. 900 l/min.Filling capacity 545 l/min. 675 l/min. 545 l/min. 545 l/min. 675 l/min.Maximum pressure 15 <strong>bars</strong> 15 <strong>bars</strong> 15 <strong>bars</strong> 15 <strong>bars</strong> 15 <strong>bars</strong>Reservoir capacity - - 270 l 300 l 500 lCylinder/stages 2/2 2/2 2/2 2/2 2/2Speed <strong>10</strong>45 1/min. 920 1/min. <strong>10</strong>45 1/min. <strong>10</strong>45 1/min. 920 1/min.Motor power 5.5 kW/400 V 7.5 kW/400 V 5.5 kW/400 V 5.5 kW / 400 V 7.5 kW / 400 VWeight 155 kg 180 kg 255 kg 280 kg 4<strong>10</strong> kgDimensions (LxWxH) in mm 790 x 780 x 700 940 x 830 x 830 840 x 840 x 2070 1695 x 840 x 1370 1950 x 800 x 1570Sound pressure level LPA ** 70 dB(A) 70 dB(A) 70 dB(A) 70 dB(A) 70 dB(A)Air outlet 3/4’’ 3/4’’ 3/4’’ 3/4’’ 3/4’’New*Description compressor systems refer to Seite 18 **Sound pressure level with a distance of 1 m according to DIN 45635 T 13NewNew63

Special salesSpecial sale ofAIRCRAFT ® discontinued models,used machines and machinesshowing slight deficienciesOn our platform of special items you will find discontinuedmodels, machines with transport damages, items of 2ndrate quality, individual pieces, exhibition machines andsamples of our range of products.<strong>The</strong> offered machines and the accessories had beentested and maintained in our service workshop.Always state-of-the-art: automatic update of the articlesevery two hours.Reserving articles by auser-friendly form.Viewing and reserving special items atattractive prices online at any time!Please find the Aircraft ® platform for special items under:www.aircraft-kompressoren.de/sonderposten64

Advantages of the ROTAL techniqueNewAIRCRAFT PREMIUM - the energy-saving <strong>compressors</strong> working with highest efficiency!Suitable for continuous operation due to patented Rotal technique· Revolutionary, patented compressor technology(Rotal technique)· HHigh degree of efficiency Efficiencyobtains more efficient delivery quantitiesat the same engine performance· Energy-saving: at the same performance,less power consumption;comparable with A++· With powerful industrial motor - designed forcontinuous operation· Very low vibrations and low wear, suitable forcontinuous operation· Optimised forced lubrication (patented)also in inclined position· Other patents for valve plate and control valve· Very high performance from 230 volts· With minimum oil consumption· Switch IP 55 (protected against dustand jets of water)· Low maintenance(about 1250 hours maintenance interval)· User-friendly, easily accessible· Low operating costs· Large fan to provide low working temperature· Highest processing quality and severe qualitycontrols for long service life, even for continuousoperationFascination of performance<strong>10</strong>0%up to 25%up to 50%Duty cyclethus considerablymore performanceEnergy savinglow maintenancecost<strong>The</strong> advantages of the PREMIUM-Rotal <strong>compressors</strong>:Efficient Rotal techniqueConventional piston drive14341Energy saving by converting the rotating drive movement ina linear movement of the piston· A purely linear movement of the piston is attained due tothe patented innovative planetary drive· In this way, considerably less friction forces develop· Up to 25% energy saving due to less power lossMore efficient compressed air generation· Due to the linear movement of the piston alonger piston stroke is enabled and the dead space in the pistonis reduced to a minimum· <strong>The</strong> smaller the dead space, the higher the degree of efficiency1Higher losses of power· Forces acting diagonally on the piston andminimum canting at each piston stroke· Thus, higher dissipation and more wear on thecylinder running surfaces and on the piston22Construction-related loss of power due to· High acceleration and breaking power· Limited piston length of stroke· Larger dead space· Transport of oil to the cylinder3Targeted lubrication of trouble spots· Due to the patented forced lubrication the trouble spotsare selectively supplied with oil,thus there is less oil in the compressed air· Optimum lubrication also at inclined positionsfor a long service life3No targeted lubrication· No targeted lubrication of the compressor· <strong>The</strong>re is an oil bath in the crank housing pistonsare oiled by means of the drive needle of thepiston rod after submerging in the oil bath4Less oil consumption - <strong>10</strong>00 hours maintenance interval· Due to the patented forced lubrication with an oil pump no oil is whirledup· Thus a minimum oil consumption is achieved· Possible maintenance interval of about 1'250 hours without oil change4Increased oil consumption· Oil is distributed on the piston as well as in thecylinder the by air turbulences in the crankcase· Thus, increased oil consumption and more oil inthe compressed air665Low vibration running and running smoothness· Piston and piston rod made from cast iron, yield onecomponent· Due to linear movement less friction,less heat and less vibrations· Thus sparing the components and longer service life5Increased occurrence of vibrations· Due to the drive via the crank shaft there are highacceleration, braking and friction powers at eachrevolution· This causes more heat and higher vibrations anda higher load on the components

AIRCRAFT PREMIUM - This is what you ought to know!Energy saving by revolutionary techniqueForce impacts in the AIRCRAFT Rotal technique· <strong>The</strong> rotating drive is converted via a patented innovativeplanet drive in a linear movement (F1=F2).· Laterally resulting forces F3 which effect an increased wear arecompletely used for sealing.Your advantages when using the Rotal technique:· Considerably less wear· Up to 50% lower maintenance cost· Up to 25% higher performance is obtained resp.up to 25% less drive energy is requiredpatentedForce effects at traditional piston driveF1F2F3Energy spent· <strong>The</strong> force which has to be used in order tomove the pistonEffective power· Really usable force which moves the piston in the directionto which it shall be movedPower loss· Resulting of the power spent· It presses the piston against the cylinder wall and thusincreases the friction and the wearPiston <strong>compressors</strong>F1=F2F2F3 = 25%F1 = F2 = <strong>10</strong>0%F3F1F1F2 = 75 %Targeted lubrication of trouble spots· <strong>The</strong> lubrication of lots of conventional piston <strong>compressors</strong> is performed by means of a submersible needle· This needle whirls the oil upward and thus dampens the interior of the crank housing and the cylinder wall· Thus the compressor causes a relative large amount of oil in the compressed air due to the construction of the compressor· Also in case of continuous use oil is escaping at the aeration of the crank housing due to an important oil fog formation in the crank housing<strong>The</strong> patented solution for the Rotal technique:· Forced lubrication at a trouble spot of the PREMIUMcompressorYour advantage:· Also in extreme sloping positions an optimum lubrication isbeing guaranteed· Little oil quantities in the compressed airpatentedFor conventional lubrication:· <strong>The</strong> oil level is extremely important forconventional oil lubrication· Too little oil: <strong>The</strong> submersible needle does not attain theoil surface = dry running· Too much oil: <strong>The</strong> big end and the gyrating mass strike the oilsurface at high speed at every rotation = great stress, increasedwear of the big end bearings and of the crank shaft bearing· If the compressor is installed inclined as did often cannot beavoided when using it at construction sites it may happen that theoil sump is no longer attained by the submersible needle = dryrunning.Oil level too highInclined position of thecompressor67

PREMIUM <strong>compressors</strong> - mobileNewAIRCAR PREMIUM - Professional assembly compressor for use under hard conditions· Universally applicable in the range of assemblyand craft· <strong>The</strong> frame is at the same time tool shelf aswell as an all-round protection for all sensitivecomponents· One manometer each to display the vesselpressure and the set working pressure· Three compressed air outlets incl. quality quickactioncouplingsfor filtered compressed air, filtered and oiledcompressed air and a compressed air directoutlet from the vessel· High quality CONDOR push-button switch· Fail-safe PU foam wheels in connection with thebroad wheelbase provide for comfortable andsafe transportation· Vessel with powder coating, <strong>10</strong>-year guaranteeagainst rust-through· With all safety devices· Completely ready for connectionUse at an inclination of 35°, no problem· Due to the optimized forced lubrication(patented) it is also possible to use thecompressor even in extreme inclined positionsof up to 35°· This way it is possible to use the compressoralso on roof slopes, e.g. for carpenter workson construction sites without impairing thelubrication· Possible for the mobile types AIRCAR PREMIUMdue to their wide wheel basePerfect for assembly:370 l Filling capacityfrom 230 voltsEnergy-saving - only 2.6 kW<strong>The</strong> AIRCAR-advantages· On/off switch is protected at the top and easilyaccessible· <strong>The</strong> ergonomic control panel is clearly structuredand self-explanatory· One manometer each to display the vesselpressure and the set working pressure· Three compressed air outlets for filteredcompressed air, filtered and oiled compressedair and a compressed air direct outlet from thevessel on the control panel· Serially equipped withquality quick couplingsand high quality CONDORpressure switchup to max. 35°AIRCAR 461/22 PREMIUM· <strong>The</strong> Fig. shows a collapsible handytransportation handle in its transportationpositionTypeItem No€ plus VATAIRCAR 461/22 PREMIUM203 22011'585.00AIRCAR 583/22 PREMIUM203 22031'585.00Technical dataCompressor systemRTSMaximum volume flow 455 lFilling capacity about 370 lMaximum pressure<strong>10</strong> <strong>bars</strong>Reservoir capacity2 x 11 lCylinder/stages2/1Speed1400 1/min.Motor power2.6 kW / 230 VWeight66 kgDimensions (LxWxH) in mm 780 x 685 x 670Sound power level L WA* 80 dB(A)* Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)RTS577 l480 l<strong>10</strong> <strong>bars</strong>2 x 11 l2/11450 1/min.3.7 kW / 400 V68 kg780 x 685 x 67081 dB(A)68

AIRPROFI PREMIUM - <strong>The</strong> mobile machines working around theclock for the craftsmen· Fully automatic ON/OFF operation· Extended bow with rubberised handle· Puncture-proof PU foam wheels and stablesteering chassis with fixing break allow easytransportation since it is not necessary to lift thecompressor when driving· Vessel inside and outside hot-dip galvanized,15-year guarantee on the vessel against rustthrough· Equipped with quality quick couplings and highquality CONDOR pressure switch· With all safety devices· Completely ready for connectionNewOne-hand safetycoupling according to DIN EN 983AIRCRAFT is the firstmanufacturer using it seriallyOne-hand safety couplings· Two separate locking systemsfor maximum working safety· <strong>The</strong> hose line will no longerlash aboutPiston <strong>compressors</strong>AIRPROFI 461/<strong>10</strong>0 PREMIUM· Filter pressure control forinfinitely setting of the workingpressure, at the same timedeposition of soil, oil andcondensed water· Two manometers indicate thevessel and working pressure· Three compressed air outletsfor filtered compressed air,filtered and oiled compressedair and a compressed air directoutletfrom the vessel· Air withdrawal with one-handsafety quick couplings· Serially equipped with highquality CONDOR pressureswitch (Fig. 230 volts)TypeItem No€ plus VATAIRPROFI 461/<strong>10</strong>0 PREMIUM203 90401'530.00AIRPROFI 583/<strong>10</strong>0 PREMIUM203 90501'530.00Technical dataCompressor system RTSMaximum volume flow 455 lFilling capacity about 370 lMaximum pressure <strong>10</strong> <strong>bars</strong>Reservoir capacity <strong>10</strong>0 lCylinder/stages2/1Speed1400 1/min.Motor power2.6 kW / 230 VWeight87 kgDimensions (LxWxH) in mm 1275 x 480 x 930Sound power level L WA* 80 dB(A)* Sound power level according to DIN EN ISO 3744 (RL 2000/14/EC)RTS577 l480 l<strong>10</strong> <strong>bars</strong><strong>10</strong>0 l2/11450 1/min.3.7 kW / 400 V89 kg1275 x 480 x 93081 dB(A)AIRPROFI I 461/<strong>10</strong>0 PREMIUMBuilt according to CE directives 69

PREMIUM <strong>compressors</strong> - <strong>fixed</strong>NewSeries AIRPROFI PREMIUM V / H - Fixed energy saving <strong>compressors</strong>incl. premium piston compressor. Suitable for continuous operation.· Revolutionary, patented compressor technology· Very low vibrations and low wear, suitable forcontinuous operation· Energy- and thus cost-saving,comparable to A++· Also available as 230 volts type· High degree of efficiencyobtains more efficient delivery quantitiesat the same engine performance· With powerful industrial motor - designed forcontinuous operation· Optimised forced lubrication, with minimum oilconsumption (patented)· Low maintenance (1250 hours maintenanceinterval)· User-friendly, easily accessible· Low operating costs· Large fan to provide low working temperature· Highest processing quality and severequality controls for long service life, even forcontinuous operation· Vessel inside and outside hot-dip galvanized,15-year guarantee on the vessel against rustthrough· Equipped with high quality CONDOR pressureswitch· Completely ready for connection with all fittings<strong>The</strong> <strong>fixed</strong> <strong>compressors</strong>PREMIUMClosing the gap between piston- andscrew <strong>compressors</strong> for the shopSuitable for interruptedand continued operationTandem:Double power!AIRPROFI 461/270/<strong>10</strong> V PREMIUMAIRPROFI 583/270/<strong>10</strong> V PREMIUMAIRPROFI 583/300/<strong>10</strong> H PREMIUMAIRPROFI TANDEM 583/500/<strong>10</strong> H PREMIUM· Equipped with base load alternate controlto distribute basic and addition air requirement as standard· Space-saving due to two compressor units on onecompressed air reservoir· Sufficient air reservoir also in case of considerablefluctuations in air requirementsAIRPROFI PREMIUMItem No€ plus VAT461/270/<strong>10</strong> V203 27<strong>10</strong>2'085.00583/270/<strong>10</strong> V203 27152'085.00583/300/<strong>10</strong> H203 27252'095.00TANDEM 583/500/<strong>10</strong> H203 27655'355.00Technical dataCompressor system*Maximum volume flowFilling capacity aboutMaximum pressureReservoir capacityCylinder/stagesSpeedMotor powerWeightDimensions (LxWxH) in mmSound pressure L PA**Air outletRTS455 l370 l<strong>10</strong> <strong>bars</strong>270 l2/11400 1/min.2.6 kW / 230 V132 kg700 x 620 x 172080 dB(A)3/4’’RTS577 l480 l<strong>10</strong> <strong>bars</strong>270 l2/11'450 1/min3.7 kW / 400 V135 kg700 x 620 x 172081 dB(A)3/4’’RTS577 l480 l<strong>10</strong> bar300 l2/11'450 1/min3.7 kW / 400 V127 kg1695 x 500 x <strong>10</strong>5581 dB(A)3/4’’RTS2 x 577 l2 x 480 l<strong>10</strong> <strong>bars</strong>500 l2/11450 1/min.2 x 3.7 kW / 400 V238 kg1950 x 600 x 115582 dB(A)3/4’’*Description compressor system refer to Seite 66 **Sound pressure level with a distance of 1 m according to DIN 45635 T 1370Built according to CE directives

NewAccessories<strong>The</strong> addition to the compressed air preparation· With refrigeration dryer for dry compressedair for a higher durability of compressed airtools in order to avoid failures in pneumaticcontrols· with liquid or oil recognising condensatedrain BEKOMAT® 31, level controlled andthus without compressed air loss on therefrigerant dryerYou can place your compressed airtreatment on the space-savingside safety palette on a floorspace of 800x600mm. <strong>The</strong>safety pallet is available ascomplete kit with differentrefrigerant dryers.Please find information andprices on page Our recommendation for automatic condensatedrain on the vessel:Liquid-/oil recognizing condensate drainBEKOMAT® 31, Item No 204 9049,€ plus VAT 166.00Please find further informationregarding condensate drainingon page .Piston <strong>compressors</strong>PREMIUM Silent and Supersilent - For users working in near proximity of the compressor!Silent - 70 dB(A)Super-Silent - 63 dB(A):Extra silentAIRPROFI 583/300/<strong>10</strong> SILENT H PREMIUM· For users working in immediateproximityof the compressor!· With silent sound-absorbent housing· Optimum cooling of the compressed airdue to a special fanwheelAIRPROFI 461/90/<strong>10</strong>SUPERSILENT PREMIUM· at 90 l Compressed air reservoir· Super-Silent sound insulationhousing for very quiet operationAIRPROFI PREMIUMItem No€ plus VAT583/300/<strong>10</strong> SILENT H203 24704'465.00461/90/<strong>10</strong> SUPERSILENT203 25<strong>10</strong>3'885.00583/90/<strong>10</strong> SUPERSILENT203 25203'885.001163/<strong>10</strong> SUPERSILENT203 25505'730.00Technical dataCompressor system* RTSMaximum volume flow 577 lFilling capacity about 480 lMaximum pressure <strong>10</strong> <strong>bars</strong>Reservoir capacity 300 lCylinder/stages 2/1Speed1'450 1/minMotor power3.7 kW / 400 VWeight190 kgDimensions (LxWxH) in mm 1695 x 640 x 1165Sound pressure L PA**Air outlet70 dB(A)3/4’’RTS455 l370 l<strong>10</strong> <strong>bars</strong>90 l2/11400 1/min.2.6 kW / 230 V156 kg<strong>10</strong>90 x 670 x <strong>10</strong>4063 dB(A)1/2’’RTS577 l480 l<strong>10</strong> <strong>bars</strong>90 l2/11'450 1/min3.7 kW / 400 V158 kg<strong>10</strong>90 x 670 x <strong>10</strong>4063 dB(A)1/2’’RTS1154 l960 l<strong>10</strong> <strong>bars</strong>90 l4/11450 1/min.7.4 kW / 400 V260 kg1<strong>10</strong>0 x 770 x 124066 dB(A)1/2’’* Description compressor system refer to Seite 66 ** Sound pressure level with a distance of 1 m according to DIN 45635 TBuilt according to CE directives 71

Piston <strong>compressors</strong> or screw-type <strong>compressors</strong>?<strong>The</strong> basic decision when installing acompressor station is to determine the typeof compressor.Both compressor systems have theirparticular advantages:NewArguments piston <strong>compressors</strong>:· Intermittent demandPiston <strong>compressors</strong> are suitable for variablecompressed air consumption with peakdemands. <strong>The</strong>y can be used as peak loadmachines in a compressor combinationsystem. For frequent load changes, thepiston <strong>compressors</strong> are the best choice.· Piston <strong>compressors</strong> are working withintermittent duty. <strong>The</strong>y have no idle running.· Little delivery quantitiesAt little delivery quantities, the pistoncompressor is working more cost-efficientthan the screw-type compressor.· Piston <strong>compressors</strong> can compress to highfinal pressures (8 <strong>bars</strong>, <strong>10</strong> <strong>bars</strong>,15 <strong>bars</strong>, 30 <strong>bars</strong> and 35 <strong>bars</strong>)** Piston <strong>compressors</strong> with operating pressures of 30<strong>bars</strong> and 35 <strong>bars</strong> upon request.<strong>The</strong> series PREMIUM<strong>The</strong> piston <strong>compressors</strong> of the PREMIUMseries are closing the gap between the screw<strong>compressors</strong> and the piston <strong>compressors</strong>.Another advantage of the PREMIUM seriesis that they can easily work in the switch offmode compared to screw <strong>compressors</strong>.Premium <strong>compressors</strong> generate lesscondensate in the oil due to their design. Thisis the reason why screw <strong>compressors</strong> shouldideally run continuously. Frequent switchingintervals should be avoided when workingwith screw <strong>compressors</strong>.However, the <strong>compressors</strong> of the Premiumseries can work in both modes:In the switch off mode as well asin continuous operation.This is optimum with regard to often deviatingair requirement.Arguments screw-type <strong>compressors</strong>:· High power-on timeScrew-type <strong>compressors</strong> are speciallydesigned to be used for continuouscompressed air consumption without highpeak demands (power-on time = <strong>10</strong>0 % ).<strong>The</strong>y are perfectly appropriate as basic loadmachines in compressor combined systems.· Large delivery quantitiesWhen ordering large delivery quantities, thescrew-type compressor is the most costefficientvariant.· Pulsation-free volume flowDue to the even compression, the screwtypecompressor can also be used for verysensible compressed air consumers.· Screw-type <strong>compressors</strong> are working atUltimate pressures of the compressor from 5to 14 <strong>bars</strong> most cost-efficient.· Almost vibration-free and very silent· Latest drive and control technologyNewNewConclusionIf an operation with varying compressed airconsumption is required and you want toextend the installation only later on, a pistoncompressor is being recommended.If there is an extensive constant highcompressed air requirement , you should usea screw-type compressor.<strong>The</strong> choice of the correct system should notdepend from the purchasing price, since itwill rapidly pay off if you are saving on theoccurring operating cost. Recurrent operatingcost are not only energy cost for compressedair generation but also idle running cost andmaintenance cost.72Built according to CE directives