MULTI PURPOSE TRUSS: X/H30 AND H40 SERIES

MULTI PURPOSE TRUSS: X/H30 AND H40 SERIES

MULTI PURPOSE TRUSS: X/H30 AND H40 SERIES

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 30 WWW.PROLYTE.COM

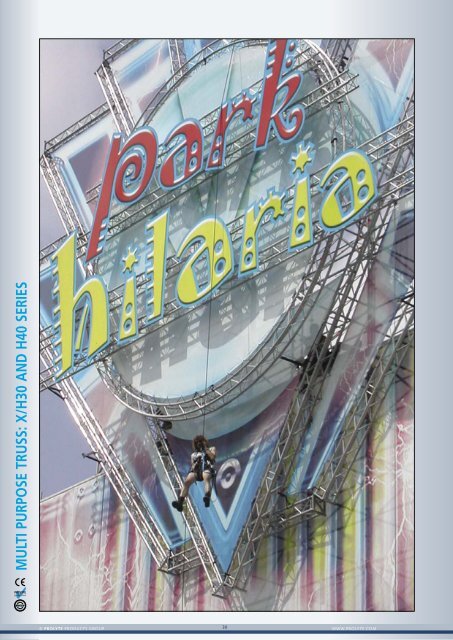

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong> INTROStrength and flexibility are featuresthat make the multi purpose trussfit for many applications.The multi purpose truss is suitablefor outdoor as well as indoor useTHE 30- <strong>AND</strong> 40-<strong>SERIES</strong> ARE DESIGNED ASA LIGHT TO MEDIUM DUTY <strong>TRUSS</strong> SYSTEMFOR USE IN THE INSTALLATION, RENTAL <strong>AND</strong>EXHIBITION MARKETS THAT DESIRE STRENGTH<strong>AND</strong> FLEXIBILITY AS WELL AS COMPACTNESS.THE POSSIBLE APPLICATIONS FOR THE <strong>MULTI</strong><strong>PURPOSE</strong> <strong>TRUSS</strong> ARE NUMEROUS.DUE TO ITS VERSATILITY <strong>TRUSS</strong> FROM THE<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>SERIES</strong> IS POPULAR IN THERENTAL AS WELL AS THE EXHIBITION MARKET.THEIR RELATIVE STRENGTH RELATED TOTHEIR RELATIVELY SMALL DIMENSIONS MAKEIT IDEAL FOR COMPLEX STRUCTURES LIKEDISPLAYS OR BOOTHS. THE MANY ST<strong>AND</strong>ARDOPTIONS, LIKE CORNERS <strong>AND</strong> CIRCLES MAKEDESIGN <strong>AND</strong> CONSTRUCTING EASY.<strong>TRUSS</strong>ES FROM THE <strong>MULTI</strong> <strong>PURPOSE</strong> <strong>SERIES</strong>COMBINE STRENGTH, COMPACTNESS <strong>AND</strong>FLEXIBILITY.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong> X/H 30&40 <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 31 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 32 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/H 30 <strong>SERIES</strong> SPECIFICATIONS30 <strong>SERIES</strong>A LIGHT TO MEDIUMDUTY <strong>TRUSS</strong> THATCOMBINES STRENGTHWITH FLEXIBILITY. THESETWO FACTORS HAVEMADE THE 30 <strong>SERIES</strong> ONEOF THE MOST POPULARSYSTEMS IN THE WORLDThe 30-serie has two different versions, theX version and the H version. The X and Htrusses have almost the same appearance, buttheir application and technical specificationsare different.The X series is truss with comparativelythin walled main chord tubes (2 mm)which is designed for use in permanent orsemi permanent installations; for example,decorative and architectural set pieces, theatresets, shop displays, studio grids, showroomsetc.The H series is truss with increased wallthickness for the main chord tubes (3 mm),which guarantees extended durability. The Hseries is primarily designed for high frequencyusers like rental or exhibition companies or forsemi permanent installations in demandingcircumstances i.e., moving lighting rigs indiscotheques, scenery or touring exhibitionstands.The X and H series are distinguished by thenumber of recessed rings in the couplerreceiver (see part 3 for details).The main characteristics of the 30 series trussare compactness, strength, versatility, low unitweight and easy of assembly.These features have made the X/<strong>H30</strong> series astandard in the exhibition and rental markets.The conical coupling system (CCS6) allows forfast, efficient ad highly aesthetic assembly ofpermanent and temporary structures.Prolyte supplies a variety of X/<strong>H30</strong> elementsthat provide maximum flexibility:- 3 types; ladder, triangle, square- several lengths, standard or custom- circles or arches- box- & book-corner system- several standard corners- several accessories- custom made pieces- colour coatingPlayful structures can de designedusing the 30 series truss.The <strong>H30</strong> truss is sturdy enoughto build even larger structureswithout affecting the safety of theconstruction.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>The X•<strong>H30</strong> truss combines strength and flexibility. These two factors have made the X•<strong>H30</strong> series one ofthe most popular systems in the world.© PROLYTE PRODUCTS GROUP 33 WWW.PROLYTE.COM

TypesAlloyMain tubes (chords)BracesCoupling systemTECHNICAL SPECIFICATIONS X30 <strong>SERIES</strong>X: Ladder (L), Triangle (D), Square (V)X: EN-AW 6082 T6X: 51 x 2 mmX: 16 x 2 mmX: CCS6 seriesTypeAllowable NormalForce in Main ChordAllowable NormalForce in DiagonalsSurface areaComplete TrussMoment ofInertia Y-axisMoment ofInertia Z-axisAllowable bendingmoment Y-axisAllowable bendingmoment Z-axisAllowable shearforce Z-axisAllowable shearforce Y-axisN N A Iy Iz My Mz Qz/Vz Qy/Vy gkN kN cm 2 cm 4 cm 4 kNm kNm kN kN kN/mX30D 21,55 6,60 9,24 907 907 4,46 5,15 8,08 4,67 0,038X30V 21,55 6,60 12,32 1796 1796 10,30 10,30 9,33 9,33 0,051Selfweight30 <strong>SERIES</strong> - ST<strong>AND</strong>ARD AVAILABLE LENGTHS<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>Meters 0,25m / 1,00m in steps of 5mm 0,25 0,29 0,50 0,71 1,00 1,50 2,00 2,50 3,00 3,50 4,00 4,50 5,00Feet 0,82’ / 3,28’ in steps of 0,2” 0,82 0,95 1,64 2,33 3,28 4,92 6,56 8,20 9,84 11,48 13,12 14,76 16,40CodeX30•-L025 X30•-L029 X30•-L050 X30•-L071 X30•-L100 X30•-L150 X30•-L200 X30•-L250 X30•-L300 X30•-L350 X30•-L400 X30•-L450 X30•-L500*on • indicate L for ladder, D for triangle or V for Square truss. Example: X30V-L200Top view X30L-L200Side view X30L-L2002000 mmTop view X30D-L200Side view X30D-L2002000 mmTop view X30V-L200Side view X30V-L200290290258290290LDV2392392392392072000 mm© PROLYTE PRODUCTS GROUP 34 WWW.PROLYTE.COM

Loading figures Mark approval certificate No. 538/96Test report No. 537/96UNIFORMLY DISTRIBUTED LOADPROLYTE X30D - ALLOWABLE LOADINGMAXIMUM ALLOWABLE POINT LOADSm040506070809101112DEFLECTIONft total kg kg/m lbs/ft mm inch kg lbs kg lbs kg lbs kg lbs weight13,1 888,0 222,0 149,4 13,0 0,5 444,0 980,1 333,0 735,1 222,0 490,1 184,7 407,7 18,316,4 710,0 142,0 95,5 21,0 0,8 355,0 783,7 266,3 587,7 177,5 391,8 147,7 326,0 21,919,7 594,0 99,0 66,6 30,0 1,2 297,0 655,6 222,8 491,7 148,5 327,8 123,6 272,7 25,223,0 504,0 72,0 48,4 41,0 1,6 252,0 556,3 189,0 417,2 126,0 278,1 104,8 231,4 28,626,2 440,0 55,0 37,0 53,0 2,1 220,0 485,7 165,0 364,2 110,0 242,8 91,5 202,0 32,129,5 387,0 43,0 28,9 67,0 2,6 194,0 428,3 145,5 321,2 97,0 214,1 80,7 178,2 35,732,8 350,0 35,0 23,5 83,0 3,3 175,0 386,3 131,3 289,7 87,5 193,2 72,8 160,7 39,336,1 319,0 29,0 19,5 100,0 3,9 160,0 353,2 120,0 264,9 80,0 176,6 66,6 146,9 43,039,4 288,0 24,0 16,1 118,0 4,6 144,0 317,9 108,0 238,4 72,0 158,9 59,9 132,2 46,41 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgMax. allowable CPL between 2 node points at each of the main chords = 120 kg. The total applied load should not exceed the data in the loading table.Loading figures only valid for static loads and spans with two supporting points. Spans must be supported at each end. If dynamic loads or more supporting pointsare applied contact a structural engineer or Prolyte. Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loadingdata have to be multiplied with 0,85Loading figures Mark approval certificate No. 546/96Test report No. 545/96m040506070809101112LOAD (KG)10009008007006005004003002001000UNIFORMLY DISTRIBUTED LOADPROLYTE X30D - LOADING4 5 6 7 8 9 10 11 12UNIFORMLY DISTRIBUTED LOADLOAD PER METERPROLYTE X30V - ALLOWABLE LOADINGDEFLECTIONPOINT LOADDEFLECTIONDEFLECTION in MM1009080706050403020100SPAN (M)MAXIMUM ALLOWABLE POINT LOADSft total kg kg/m lbs/ft mm inch kg lbs kg lbs kg lbs kg lbs weight13,1 1048,0 262,0 176,3 8,0 0,3 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 20,416,4 1050,0 210,0 141,3 16,0 0,6 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 25,519,7 1050,0 175,0 117,7 27,0 1,1 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 30,623,0 1050,0 150,0 100,9 43,0 1,7 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 35,726,2 1024,0 128,0 86,1 63,0 2,5 512,0 1130,2 384,0 847,7 256,0 565,1 213,0 470,2 40,829,5 909,0 101,0 68,0 80,0 3,1 455,0 1004,4 341,3 753,3 227,5 502,2 189,3 417,8 45,932,8 820,0 82,0 55,2 99,0 3,9 410,0 905,1 307,5 678,8 205,0 452,5 170,6 376,5 51,036,1 748,0 68,0 45,8 120,0 4,7 374,0 825,6 280,5 619,2 187,0 412,8 155,6 343,5 56,139,4 684,0 57,0 38,4 142,0 5,6 342,0 755,0 256,5 566,2 171,0 377,5 142,3 314,1 61,21 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgMax. allowable CPL between 2 node points at each of the main chords = 90 kg. The total applied load should not exceed the data in the loading table.Loading figures only valid for static loads and spans with two supporting points. Spans must be supported at each end. If dynamic loads or more supporting pointsare applied contact a structural engineer or Prolyte. Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loadingdata have to be multiplied with 0,85LOAD (KG)1250112510008757506255003752501250PROLYTE X30V - LOADING4 5 6 7 8 9 10 11 12UNIFORMLY DISTRIBUTED LOADLOAD PER METERPOINT LOADDEFLECTIONDEFLECTION in MM1501351201059075604530150SPAN (M)<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 35 WWW.PROLYTE.COM

TypesAlloyMain tubes (chords)BracesCoupling systemTECHNICAL SPECIFICATIONS <strong>H30</strong> <strong>SERIES</strong>H: Ladder (L), Triangle (D), Square (V)H: EN-AW 6082 T6H: 48 x 3 mmH: 16 x 2 mmH: CCS6 seriesTypeAllowable NormalForce in Main ChordAllowable NormalForce in DiagonalsSurface areaComplete TrussMoment ofInertia Y-axisMoment ofInertia Z-axisAllowable bendingmoment Y-axisAllowable bendingmoment Z-axisAllowable shearforce Z-axisAllowable shearforce Y-axisN N A Iy Iz My Mz Qz/Vz Qy/Vy gkN kN cm 2 cm 4 cm 4 kNm kNm kN kN kN/m<strong>H30</strong>D 24,23 6,60 12,72 1244 1244 5,02 5,79 8,08 4,67 0,047<strong>H30</strong>V 24,23 6,60 16,96 2466 2466 11,58 11,58 9,33 9,33 0,063Selfweight30 <strong>SERIES</strong> - ST<strong>AND</strong>ARD AVAILABLE LENGTHS<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>Meters 0,25m / 1,00m in steps of 5mm 0,25 0,29 0,50 0,71 1,00 1,50 2,00 2,50 3,00 3,50 4,00 4,50 5,00Feet 0,82’ / 3,28’ in steps of 0,2” 0,82 0,95 1,64 2,33 3,28 4,92 6,56 8,20 9,84 11,48 13,12 14,76 16,40Code<strong>H30</strong>•-L025 <strong>H30</strong>•-L029 <strong>H30</strong>•-L050 <strong>H30</strong>•-L071 <strong>H30</strong>•-L100 <strong>H30</strong>•-L150 <strong>H30</strong>•-L200 <strong>H30</strong>•-L250 <strong>H30</strong>•-L300 <strong>H30</strong>•-L350 <strong>H30</strong>•-L400 <strong>H30</strong>•-L450 <strong>H30</strong>•-L500*on • indicate L for ladder, D for triangle or V for Square truss. Example: <strong>H30</strong>V-L200Top view <strong>H30</strong>L-L200Side view <strong>H30</strong>L-L2002000 mmTop view <strong>H30</strong>D-L200Side view <strong>H30</strong>D-L2002000 mmTop view <strong>H30</strong>V-L200Side view <strong>H30</strong>V-L200287239287287255287LDV2392392392072000 mm© PROLYTE PRODUCTS GROUP 36 WWW.PROLYTE.COM

Loading figures Mark approval certificate No. 540/96Test report No. 539/96UNIFORMLY DISTRIBUTED LOADPROLYTE <strong>H30</strong>D - ALLOWABLE LOADINGMAXIMUM ALLOWABLE POINT LOADSm040506070809101112DEFLECTIONft total kg kg/m lbs/ft mm inch kg lbs kg lbs kg lbs kg lbs weight13,1 936,0 234,0 157,4 10,0 0,4 468,0 1033,1 351,0 774,8 234,0 516,6 194,7 429,8 18,816,4 935,0 187,0 125,8 20,0 0,8 468,0 1033,1 351,0 774,8 234,0 516,6 194,7 429,8 23,519,7 816,0 136,0 91,5 30,0 1,2 408,0 900,7 306,0 675,5 204,0 450,3 169,7 374,7 28,223,0 700,0 100,0 67,3 41,0 1,6 350,0 772,6 262,5 579,5 175,0 386,3 145,6 321,4 32,926,2 616,0 77,0 51,8 54,0 2,1 308,0 679,9 231,0 509,9 154,0 340,0 128,1 282,8 37,629,5 549,0 61,0 41,0 69,0 2,7 275,0 607,1 206,3 455,3 137,5 303,5 114,4 252,5 42,332,8 490,0 49,0 33,0 84,0 3,3 245,0 540,8 183,8 405,6 122,5 270,4 101,9 225,0 47,036,1 451,0 41,0 27,6 103,0 4,1 226,0 498,9 169,5 374,2 113,0 249,4 94,0 207,5 51,739,4 408,0 34,0 22,9 121,0 4,8 204,0 450,3 153,0 337,7 102,0 225,2 84,9 187,3 56,41 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgMax. allowable CPL between 2 node points at each of the main chords = 130 kg. The total applied load should not exceed the data in the loading table.Loading figures only valid for static loads and spans with two supporting points. Spans must be supported at each end. If dynamic loads or more supporting pointsare applied contact a structural engineer or Prolyte. Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loadingdata have to be multiplied with 0,85Loading figures Mark approval certificate No. 548/96Test report No. 547/96m040506070809101112LOAD (KG)10009008007006005004003002001000UNIFORMLY DISTRIBUTED LOADPROLYTE <strong>H30</strong>D - LOADING4 5 6 7 8 9 10 11 12UNIFORMLY DISTRIBUTED LOADLOAD PER METERPROLYTE <strong>H30</strong>V - ALLOWABLE LOADINGDEFLECTIONPOINT LOADDEFLECTIONDEFLECTION in MM130117104917865523926130SPAN (M)MAXIMUM ALLOWABLE POINT LOADSft total kg kg/m lbs/ft mm inch kg lbs kg lbs kg lbs kg lbs weight13,1 1048,0 262,0 176,3 6,0 0,2 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 25,216,4 1050,0 210,0 141,3 12,0 0,5 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 31,519,7 1050,0 175,0 117,7 20,0 0,8 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 37,823,0 1050,0 150,0 100,9 32,0 1,3 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 44,126,2 1048,0 131,0 88,1 47,0 1,9 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 50,429,5 1053,0 117,0 78,7 67,0 2,6 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 56,732,8 1050,0 105,0 70,6 92,0 3,6 525,0 1158,9 393,8 869,2 262,5 579,5 218,4 482,1 63,036,1 1001,0 91,0 61,2 117,0 4,6 501,0 1106,0 375,8 829,5 250,5 553,0 208,4 460,1 69,339,4 924,0 77,0 51,8 140,0 5,5 462,0 1019,9 346,5 764,9 231,0 509,9 192,2 424,3 75,61 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgMax. allowable CPL between 2 node points at each of the main chords = 100 kg. The total applied load should not exceed the data in the loading table.Loading figures only valid for static loads and spans with two supporting points. Spans must be supported at each end. If dynamic loads or more supporting pointsare applied contact a structural engineer or Prolyte. Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loadingdata have to be multiplied with 0,85LOAD (KG)1250112510008757506255003752501250PROLYTE <strong>H30</strong>V - LOADING4 5 6 7 8 9 10 11 12UNIFORMLY DISTRIBUTED LOADLOAD PER METERPOINT LOADDEFLECTIONDEFLECTION in MM130117104917865523926130SPAN (M)<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 37 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: ST<strong>AND</strong>ARD CORNERS INTRO<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>Prolyte supplies a wide variety ofstandard corners for the 30 seriestruss.The X•<strong>H30</strong> truss series is completed witha broad range of standard corners. Thestandard corner range provides 2 to 6-waycorners at several angles, from 45 to 135degrees.We make more Standard corners than weshow here, custom corners can be made onrequest.Different configurations and structures canbe build if lengths, arches and corners arecombined.For loading consequences for your completestructure, please read part 3.© PROLYTE PRODUCTS GROUP 38 WWW.PROLYTE.COM

87791344950010001000X or <strong>H30</strong>L - C001U45°X or <strong>H30</strong>L - C002U60°X or <strong>H30</strong>L - C003U90°949449 500500500471479949X or <strong>H30</strong>L - C004UX or <strong>H30</strong>L - C005uX or <strong>H30</strong>L - C016U120°135°449500949X or <strong>H30</strong>L - C017U500210X or <strong>H30</strong>L - C003F90°710210 5007105001000X or <strong>H30</strong>L - C001F45°500333X or <strong>H30</strong>L - C004F120°210 5007103005004981000X or <strong>H30</strong>L - C002F60°500380X or <strong>H30</strong>L - C005F135°U= LADDER UPF= LADDER FLAT<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>X or <strong>H30</strong>L - C016FX or <strong>H30</strong>L - C017F© PROLYTE PRODUCTS GROUP 39 WWW.PROLYTE.COM

30049821050010001000X or <strong>H30</strong>D - C00145°X or <strong>H30</strong>D - C00260°X or <strong>H30</strong>D - C00390°500333380500500242X or <strong>H30</strong>D - C004120°X or <strong>H30</strong>D - C005135°X or <strong>H30</strong>D - C007<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>500500500210X or <strong>H30</strong>D - C012710210 500X or <strong>H30</strong>D - C017710500210242500500742242500210500242X or <strong>H30</strong>D - C013710210 500500242X or <strong>H30</strong>D - C018710210 500710242500500710210 500X or <strong>H30</strong>D - C016710210 500X or <strong>H30</strong>D - C020710242500X or <strong>H30</strong>D - 021X or <strong>H30</strong>D - C024© PROLYTE PRODUCTS GROUP 40 WWW.PROLYTE.COM

30049850010001000210X or <strong>H30</strong>V - C00145°X or <strong>H30</strong>V - C00260°X or <strong>H30</strong>V - C00390°500500210500500210333380X or <strong>H30</strong>V - C004120°X or <strong>H30</strong>V - C005135°X or <strong>H30</strong>V - C012710710710210 500710X or <strong>H30</strong>V - C016710210 500210X or <strong>H30</strong>V - C024500710210 500X or <strong>H30</strong>V - C017500500210 500X or <strong>H30</strong>V - C020210500<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 41 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: BOX CORNERS INTROThe box corner is a unique and revolutionarytype of corner invented by Prolyte.The box corner is manufactured usinga combination of the Nord-Lock systemdeveloped by NASA and standard Prolyteparts. The different parts are all producedusing the latest CNC and laser techniques.Prolyte has designed this product to enablethe creation of 2,3,4,5 or 6 way corners byutilising just one basic part. The attachmentsare bolted to the corners, using femalereceivers.The flexibility and fixed dimensions of the boxcorner makes it a handy and cost efficientinvestment.The box corners are, due to their design,capable of taking 100% of the applied load ina vertical or horizontal direction.This fact makes the box corner a full-fledgedconstruction element, unlike traditional typesof corners.The revolutionary box corner concept pares flexibility and efficiency with strength.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>BOX-30V. Box corner for X•<strong>H30</strong>V truss. Measurements.BOX-30D. Triangular box corner forX•<strong>H30</strong> truss. Measurements.BOX-30V. Assembly.BOX-30V. Boxcorner attachment,pre- assembled couplers.BOX-30D. Assembly and part names.© PROLYTE PRODUCTS GROUP 42 WWW.PROLYTE.COM

290710500742500257257710BOX-30D/50. Triangular box corner forX•<strong>H30</strong> truss. Measurements.BOX-30D-50-A-VSBOX-30D-50-A-HLBOX-30D-50-A-HLBOX-30D-50-A-HSHEXAGON SOCKET HEADCAP SCREW M12X35BOX-30L. Ladder box corner for X•<strong>H30</strong> truss. Measurements.BOX-30DBOX-30D/50. Assembly and part names.1 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgTECHNICAL SPECIFICATIONS X/<strong>H30</strong>D BOXCORNERS0-WAY A-VS A-HL A-HS A-VL COUPLER BOLD SPRINGKG LBS KG LBS KG LBS KG LBS KG LBS WASHERBOX-30D 7,1 15,7 1,4 3,1 1,2 2,6 1,0 2,2 2,0 4,4 CCS6-651 M12x35 M12BOX-30D/50cm 7,1 15,7 2,1 20,3 2,1 20,3 1,9 19,9 2,8 21,9 DIV. M12x35 M121 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgBOX-30D-50-A-HLBOX-30D-50-A-VLTECHNICAL SPECIFICATIONS X/<strong>H30</strong>V BOXCORNERS0-WAY 2-WAY 3-WAY 4-WAY 5-WAY 6-WAY COUPLER BOLD SPRINGKG LBS KG LBS KG LBS KG LBS KG LBS KG LBS WASHERBOX-30V 9,9 21,2 12,2 26,9 13,5 29,8 14,8 32,7 16,1 35,5 17,4 38,4 CCS6-651 M12x35 M12<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 43 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: BOOK CORNERS INTROThe book corner is designed as a corner witha flexible angle. Angles from 0 to 180 degreescan be made with just one corner. Theattachments are bolted to the corner, usingmale or female receivers. The required angle isset with the addition of a fixation set.The book corner can be used for triangular aswell as square truss.The hinges from the book corner are notdesigned as load bearing parts and thereforecannot be part of a structural component.Support the book corner on both sides of thehinge.The book corner is designed as a corner with a flexible angle.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>BOLT M12X55SPRING WASHER M12BOOK-30D/VSPRING WASHER M12BOLT M12X60CCS6-602SPRING WASHER M12PREVALING TORQUETYPE HEXAGON NUTSCCS6-651BOOK-30D/VTECHNICAL SPECIFICATIONS X/<strong>H30</strong> BOOKCORNERSKG LBS MALE BOLT FEMALE BOLT NUT SPRINGCOUPLER COUPLER WASHERBOOK-30D/V 12,0 26,5 CCS6-602 M12x55 CCS6-651 M12x60 M12 M121 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kg© PROLYTE PRODUCTS GROUP 44 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: <strong>H40</strong> <strong>SERIES</strong> SPECIFICATIONS40 <strong>SERIES</strong>A MEDIUM DUTY<strong>TRUSS</strong> SYSTEM THATCOMBINES STRENGTHWITH FLEXIBILITY.ALSO APPROPRIATEFOR BUILDING LARGERCOMPLEX STRUCTURES.The 40-series truss is a larger version ofthe 30-series. Generally this truss seriescan be used in similar situations as the 30-series, however, the loading and deflectioncharacteristics are much better.The main characteristics of the 40 series trussare strength, versatility, low unit weight andeasy of assembly.On request Prolyte can supply truss from the40-series in an X version as well.The conical coupling system (CCS6) allows forfast, efficient ad highly aesthetic assembly ofpermanent and temporary structures.Prolyte supplies a variety of <strong>H40</strong> elements thatprovide maximum flexibility:- 3 types; ladder,triangle, square- several lengths, standard or custom- circles or arches- box- & book-corner system- several standard corners- several accessories- custom made pieces- colour coating An excellent way to display yourproduct in an open air surrounding.Aluminium will keep its good looks.Complex structures can beassembled fast and easy due to aperfect fit of the trusses.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>The <strong>H40</strong> truss is the ideal substitute for the 30-series truss in situations witha higher demand on loading capacity.© PROLYTE PRODUCTS GROUP 45 WWW.PROLYTE.COM

TypesAlloyMain tubesBracesCoupling systemTECHNICAL SPECIFICATIONS <strong>H40</strong> <strong>SERIES</strong>H: ladder (L), Triangle (D), Square (V)H: EN-AW 6082 T6H: 48 x 3 mmH: 20 x 2 mmH: CCS6 seriesTypeAllowable NormalForce in Main ChordAllowable NormalForce in DiagonalsSurface areaComplete TrussMoment ofInertia Y-axisMoment ofInertia Z-axisAllowable bendingmoment Y-axisAllowable bendingmoment Z-axisAllowable shearforce Z-axisAllowable shearforce Y-axisN N A Iy Iz My Mz Qz/Vz Qy/Vy gkN kN cm 2 cm 4 cm 4 kNm kNm kN kN kN/m<strong>H40</strong>D 24,23 8,48 12,72 2476 2469 9,35 10,78 10,39 6,00 0,049<strong>H40</strong>V 24,23 8,48 16,96 4917 4917 21,57 21,57 12,00 12,00 0,069Selfweight40 <strong>SERIES</strong> - ST<strong>AND</strong>ARD AVAILABLE LENGTHS<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>Meters 0,25m / 1,00m in steps of 5mm 0,25 0,30 0,50 0,75 0,81 1,00 1,50 2,00 2,50 3,00 3,50 4,00 5,00Feet 0,82’ / 3,28’ in steps of 0,2” 0,83 0,98 1,64 2,46 2,65 3,28 4,92 6,56 8,20 9,84 11,48 13,12 16,40Code• indicate L for ladder, D for triangle or V for Square truss. Example: <strong>H40</strong>V-L200Top view <strong>H40</strong>L-L200Side view <strong>H40</strong>L-L200Top view <strong>H40</strong>D-L200Side view <strong>H40</strong>D-L200Top view <strong>H40</strong>V-L200Side view <strong>H40</strong>V-L200<strong>H40</strong>•-L025 <strong>H40</strong>•-L030 <strong>H40</strong>•-L050 <strong>H40</strong>•-L075 <strong>H40</strong>•-L081 <strong>H40</strong>•-L100 <strong>H40</strong>•-L150 <strong>H40</strong>•-L200 <strong>H40</strong>•-L250 <strong>H40</strong>•-L300 <strong>H40</strong>•-L350 <strong>H40</strong>•-L400 <strong>H40</strong>•-L500LDV© PROLYTE PRODUCTS GROUP 46 WWW.PROLYTE.COM

Loading figures Mark approval certificate No. 544/96Test report No. 543/96UNIFORMLY DISTRIBUTED LOADPROLYTE <strong>H40</strong>D - ALLOWABLE LOADINGMAXIMUM ALLOWABLE POINT LOADSm040506070809101112DEFLECTIONft total kg kg/m lbs/ft mm inch kg lbs kg lbs kg lbs kg lbs weight13,1 1008 252 169,6 6 0,2 505 1114,8 378,8 836,1 252,5 557,4 210,1 463,8 19,616,4 1010 202 135,9 11 0,4 505 1114,8 378,8 836,1 252,5 557,4 210,1 463,8 24,519,7 1008 168 113,0 19 0,7 504 1112,6 378,0 834,4 252,0 556,3 209,7 462,8 29,423,0 994 142 95,5 30 1,2 497 1097,1 372,8 822,8 248,5 548,6 206,8 456,4 34,326,2 872 109 73,3 39 1,5 436 962,5 327,0 721,9 218,0 481,2 181,4 400,4 39,229,5 774 86 57,9 49 1,9 387 854,3 290,3 640,7 193,5 427,2 161,0 355,4 44,132,8 700 70 47,1 61 2,4 350 772,6 262,5 579,5 175,0 386,3 145,6 321,4 49,036,1 638 58 39,0 73 2,9 319 704,2 239,3 528,1 159,5 352,1 132,7 292,9 53,939,4 588 49 33,0 88 3,5 294 649,0 220,5 486,8 147,0 324,5 122,3 270,0 58,81 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgMax. allowable CPL between 2 node points at each of the main chords = 90 kg. The total applied load should not exceed the data in the loading table.Loading figures only valid for static loads and spans with two supporting points. Spans must be supported at each end. If dynamic loads or more supporting pointsare applied contact a structural engineer or Prolyte. Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loadingdata have to be multiplied with 0,85Loading figures Mark approval certificate No. 552/96Test report No. 551/96m450607080910111213141516LOAD (KG)1000900800700600500400300200UNIFORMLY DISTRIBUTED LOADPROLYTE <strong>H40</strong>D - LOADINGPROLYTE <strong>H40</strong>V - ALLOWABLE LOADINGDEFLECTIONDEFLECTION in MM1009080706050403020MAXIMUM ALLOWABLE POINT LOADSft total kg/m lbs/ft mm inch kg lbs kg lbs kg lbs kg lbs weight13,1 1165 291 195,9 3 0,1 582 1284,8 436,5 963,6 291,0 642,4 242,1 534,5 27,616,4 1165 233 156,8 6 0,2 582 1284,8 436,5 963,6 291,0 642,4 242,1 534,5 34,519,7 1164 194 130,5 11 0,4 582 1284,8 436,5 963,6 291,0 642,4 242,1 534,5 41,423,0 1162 166 111,7 18 0,7 581 1282,6 435,8 961,9 290,5 641,3 241,7 533,5 48,326,2 1160 145 97,6 26 1,0 580 1280,4 435,0 960,3 290,0 640,2 241,3 532,6 55,229,5 1161 129 86,8 37 1,5 580 1280,4 435,0 960,3 290,0 640,2 241,3 532,6 62,132,8 1160 116 78,1 51 2,0 580 1280,4 435,0 960,3 290,0 640,2 241,3 532,6 69,036,1 1166 106 71,3 68 2,7 580 1280,4 435,0 960,3 290,0 640,2 241,3 532,6 75,939,4 1152 96 64,6 87 3,4 576 1271,6 432,0 953,6 288,0 635,7 239,6 532,6 82,842,7 1066 82 55,2 103 4,1 533 1176,6 399,8 882,5 266,5 588,3 221,7 489,5 89,745,9 994 71 47,8 119 4,7 497 1097,1 372,8 822,8 248,5 548,6 206,8 456,4 96,649,2 930 62 41,7 137 5,4 465 1026,5 348,8 769,9 232,5 513,2 193,4 427,0 103,552,5 864 54 36,3 155 6,1 432 953,6 324,0 715,2 216,0 476,8 179,7 396,7 110,41 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kgMax. allowable CPL between 2 node points at each of the main chords = 60 kg. The total applied load should not exceed the data in the loading table.Loading figures only valid for static loads and spans with two supporting points. Spans must be supported at each end. If dynamic loads or more supporting pointsare applied contact a structural engineer or Prolyte. Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loadingdata have to be multiplied with 0,85LOAD (KG)125011251000875750625500375250PROLYTE <strong>H40</strong>V - LOADINGDEFLECTION in MM200180160140120100806040<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>100101252004 5 6 7 8 9 10 11 12UNIFORMLY DISTRIBUTED LOADLOAD PER METERPOINT LOADDEFLECTION0SPAN (M)04 5 6 7 8 9 10 11 12 13 14 15 16UNIFORMLY DISTRIBUTED LOADLOAD PER METERPOINT LOADDEFLECTION0SPAN (M)© PROLYTE PRODUCTS GROUP 47 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: ST<strong>AND</strong>ARD CORNERS INTRO<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>Prolyte supplies a wide variety ofstandard corners for the 40 seriestruss.The <strong>H40</strong> truss series is completed witha broad range of standard corners. Thestandard corner range provides 2 to 6-waycorners at several angles, from 45 to 135degrees.We make more standard corners than weshow here, custom corners can be made onrequest.Different configurations and structures canbe build if lengths, arches and corners arecombined.For loading consequences for your completestructure, please read part 3.© PROLYTE PRODUCTS GROUP 48 WWW.PROLYTE.COM

1078111254960012001200<strong>H40</strong>L - C001U45°<strong>H40</strong>L - C002U60°<strong>H40</strong>L - C003U90°1149549 6006006005725791149<strong>H40</strong>L - C004U<strong>H40</strong>L - C005U<strong>H40</strong>L - C016U120°135°5496001149<strong>H40</strong>L - C017U600210<strong>H40</strong>L - C003F90°810210 600<strong>H40</strong>L - C016F8106002581200<strong>H40</strong>L - C001F45°600376<strong>H40</strong>L - C004F120°210 600810<strong>H40</strong>L - C017F6001200600525<strong>H40</strong>L - C002F60°439<strong>H40</strong>L - C005F135°U= LADDER UPF= LADDER FLAT<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 49 WWW.PROLYTE.COM

25852521060012001200<strong>H40</strong>D - C00145°<strong>H40</strong>D - C00260°<strong>H40</strong>D - C00390°600376439600600255<strong>H40</strong>D - C004120°<strong>H40</strong>D - C005135°<strong>H40</strong>D - C007600210210600810210 600<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>600600<strong>H40</strong>D - C012810210 600<strong>H40</strong>D - C017810600210255600600255855255810<strong>H40</strong>D - C013810210 600<strong>H40</strong>D - C018810210 600600600600255600255<strong>H40</strong>D - C016810210 600<strong>H40</strong>D - C020810255600<strong>H40</strong>D - C021<strong>H40</strong>D - C024© PROLYTE PRODUCTS GROUP 50 WWW.PROLYTE.COM

25852560012001200210<strong>H40</strong>V - C00145°<strong>H40</strong>V - C00260°<strong>H40</strong>V - C00390°600600600210600210376439<strong>H40</strong>V - C004120°<strong>H40</strong>V - C005135°<strong>H40</strong>V - C012810810210 600810210 600210 600810<strong>H40</strong>V - C016810210 600<strong>H40</strong>V - C024810210600<strong>H40</strong>V - C017600600<strong>H40</strong>V - C020210600<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 51 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: BOX CORNERS INTROThe box corner is a unique and revolutionarytype of corner invented by Prolyte.The box corner is manufactured usinga combination of the Nord-Lock systemdeveloped by NASA and standard Prolyteparts. The different parts are all producedusing the latest CNC and laser techniques.Prolyte has designed this product to enablethe creation of 2,3,4,5 or 6 way corners byutilising just one basic part. The attachmentsare bolted to the corners, using femalereceivers.The flexibility and fixed dimensions of the boxcorner makes it a handy and cost efficientinvestment.The box corners are, due to their design,capable of taking 100% of the applied load ina vertical or horizontal direction.This fact makes the box corner a full-fledgedconstruction element, unlike traditional typesof corners.The revolutionary box corner concept pares flexibility and efficiency with strength.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>BOX-40V. Box corner for <strong>H40</strong>V truss. Measurements.12520050390BOX-40D. Triangular box cornerfor <strong>H40</strong> truss. Measurements.BOX-40L. Ladder box corner for <strong>H40</strong> truss. Measurements.BOX-40V. Assembly.TECHNICAL SPECIFICATIONS <strong>H40</strong> BOXCORNERSBOX-40V. Boxcorner attachment,pre- assembled couplers.BOX-40D. Assembly and part names.0-WAY 2-WAY 3-WAY 4-WAY 5-WAY 6-WAY COUPLER BOLD SPRINGKG LBS KG LBS KG LBS KG LBS KG LBS KG LBS WASHERBOX-40V 11,5 25,4 14,1 31,1 15,4 34,0 16,7 36,9 18,0 39,7 19,3 42,6 CCS6-651 M12x35 M120-WAY A-VS A-HL A-HS A-VLBOX-40D 9,9 21,8 1,5 3,3 1,4 3,0 1,1 2,4 2,5 5,5 CCS6-651 M12x35 M121 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kg© PROLYTE PRODUCTS GROUP 52 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: BOOK CORNERS INTROThe book corner is designed as a corner witha flexible angle. Angles from 0 to 180 degreescan be made with just one corner. Theattachments are bolted to the corner, usingmale or female receivers. The required angle isset with the addition of a fixation set.The book corner can be used for triangular aswell as square truss.The hinges from the book corner are notdesigned as load bearing parts and thereforecannot be part of a structural component.Support the book corner on both sides of thehinge.The book corner is designed as a corner with a flexible angle.BOOK-40D/VBOOK-40D/VTECHNICAL SPECIFICATIONS <strong>H40</strong> BOOKCORNERSKG LBS MALE BOLT FEMALE BOLT NUT SPRINGCOUPLER COUPLER WASHERBOOK-40D/V 15,5 34,2 CCS6-602 M12x55 CCS6-651 M12x60 M12 M12<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>1 inch = 25.4 mm | 1m = 3.28 ft | 1 lbs = 0.453 kg | 1 daN = 10 N ~ 1 kg© PROLYTE PRODUCTS GROUP 53 WWW.PROLYTE.COM

Fanciful structures can be built using combinations of straight and curved trusses.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: CIRCULAR <strong>TRUSS</strong> INTRO<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>In addition to straight lengths Prolyte manufactures circular trusses, curved trusses and arcs.These arched trusses are manufactured with a high degree of accuracy ensuring aperfect fit with no distortion.Thanks to the production by means of semi automated welding jigs all producedparts are identical.This guarantees that every segment of a circle can be mounted at any position orbe replaced by a new part, without affecting the integrity or overall shape of thecircle. For more information and technical details read part 3.INNER RADIUSCircular or curved trusses are manufactured in different diameters or degrees. Ifyou order a complete circular truss you have to indicate the amount of cuttingswanted. A cutting divides the circle into segments. Individual segments cannot belonger than 5 meters, we advise segment lengths between 3-4 metres.Product code:•30•-R•••-••40•-R•••-•Example: <strong>H30</strong>V-R400-4<strong>H30</strong>V= <strong>H30</strong> square truss, R400= circle with radius 400cm (diameter = 800cm), 4= cut in 4 segmentsPROLYTE X30D CIRCULAR <strong>TRUSS</strong> - ALLOWABLE LOADING3 SUSPENSION POINTS 4 SUSPENSION POINTS 6 SUSPENSION POINTS 8 SUSPENSION POINTS 10 SUSPENSION POINTSDIAMETER UDL CPL UDL CPL UDL CPL UDL CPL UDL CPLm ft kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS4,00 13,1 110 73,76 302 667 195 131,02 434 958 389 262,13 652 1440 590 397,37 798 1762 789 530,79 892 19686,00 19,7 55 37,30 220 486 105 70,52 331 731 227 153,00 538 1187 361 242,76 695 1534 495 333,00 806 17798,00 26,2 33 22,22 173 382 66 44,08 267 590 151 101,88 457 1009 249 167,90 616 1359 350 235,76 735 162310,00 32,8 22 14,51 142 314 45 30,04 224 494 107 72,08 374 825 185 124,52 503 1110 265 178,54 631 139412,00 39,4 15 10,04 121 267 32 21,21 193 425 74 49,60 309 681 133 89,34 417 921 209 140,45 524 115814,00 45,9 11 7,22 105 231 23 15,18 165 365 54 36,04 262 578 97 65,24 355 784 153 102,79 448 989PROLYTE <strong>H30</strong>D CIRCULAR <strong>TRUSS</strong> - ALLOWABLE LOADING3 SUSPENSION POINTS 4 SUSPENSION POINTS 6 SUSPENSION POINTS 8 SUSPENSION POINTS 10 SUSPENSION POINTSDIAMETER UDL CPL UDL CPL UDL CPL UDL CPL UDL CPLm ft kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS4,00 13,1 114 76,81 316 698 203 136,93 455 1004 408 274,59 684 1509 619 416,60 837 1848 827 556,69 935 20656,00 19,7 57 38,52 230 508 109 73,40 346 765 238 160,01 563 1243 378 254,25 729 1609 519 349,01 845 18668,00 26,2 34 22,69 181 399 68 45,64 279 617 158 106,32 478 1056 261 175,64 645 1424 367 246,91 771 170110,00 32,8 22 14,60 148 328 46 30,91 234 516 113 76,16 416 918 193 130,11 551 1216 278 186,82 674 148812,00 39,4 15 10,04 126 278 33 22,10 201 443 85 57,30 362 798 150 100,83 467 1031 219 147,61 588 129814,00 45,9 11 7,22 109 240 24 16,41 176 388 63 42,10 306 675 114 76,58 397 877 179 120,21 502 1107All loading figures are based on; Uniformly divided suspension points and a suspended load in each of the fields. In any other case loading data is not valid. Instabilitywill occur. For more details and loading figures of other diameters we refer to our website.Absence of diagonal braces in top and/or bottom side of the truss causes dramatic reduction of the allowable loading. A structural report per situation is required forthese models.Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loading data have to be multiplied with 0,85.SEGMENTCUTTINGOUTER RADIUS© PROLYTE PRODUCTS GROUP 54 WWW.PROLYTE.COM

PROLYTE X30V CIRCULAR <strong>TRUSS</strong> - ALLOWABLE LOADING3 SUSPENSION POINTS 4 SUSPENSION POINTS 6 SUSPENSION POINTS 8 SUSPENSION POINTS 10 SUSPENSION POINTSDIAMETER UDL CPL UDL CPL UDL CPL UDL CPL UDL CPLm ft kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS4,00 13,1 179 120,57 547 1208 291 195,52 721 1592 521 350,60 952 2102 747 503,05 1078 2380 969 652,14 1149 25376,00 19,7 97 65,53 422 933 167 112,70 588 1297 320 215,57 838 1849 474 318,95 991 2187 624 420,28 1084 23928,00 26,2 61 41,10 343 758 110 74,15 495 1093 223 149,85 747 1649 339 227,94 916 2022 453 304,97 1025 226310,00 32,8 42 27,96 289 637 78 52,62 427 944 166 111,58 674 1488 259 174,06 852 1880 351 236,25 972 214612,00 39,4 30 20,05 248 549 58 39,23 376 829 129 86,85 614 1355 206 138,67 796 1757 283 190,78 924 204014,00 45,9 22 14,89 218 481 45 30,27 335 739 104 69,75 563 1242 169 113,79 746 1648 236 158,57 881 1944PROLYTE <strong>H30</strong>V CIRCULAR <strong>TRUSS</strong> - ALLOWABLE LOADING3 SUSPENSION POINTS 4 SUSPENSION POINTS 6 SUSPENSION POINTS 8 SUSPENSION POINTS 10 SUSPENSION POINTSDIAMETER UDL CPL UDL CPL UDL CPL UDL CPL UDL CPLm ft kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS4,00 13,1 187 125,98 573 1264 304 204,56 755 1667 546 367,39 998 2203 785 528,21 1130 2495 1016 684,00 1206 26616,00 19,7 101 68,13 441 974 175 117,59 615 1357 335 225,61 877 1937 498 334,90 1038 2292 655 440,55 1136 25088,00 26,2 63 42,45 358 790 115 77,12 517 1142 233 156,61 782 1726 356 239,34 960 2118 475 319,48 1074 237110,00 32,8 43 28,65 300 663 81 54,51 446 984 173 116,41 705 1556 272 182,77 892 1968 367 247,31 1018 224712,00 39,4 30 20,33 258 570 60 40,44 391 864 134 90,45 641 1415 216 145,60 832 1837 297 199,57 967 213614,00 45,9 22 14,91 226 499 46 31,04 348 769 108 72,49 587 1297 178 119,48 780 1722 246 165,76 921 2034PROLYTE <strong>H40</strong>D CIRCULAR <strong>TRUSS</strong> - ALLOWABLE LOADING3 SUSPENSION POINTS 4 SUSPENSION POINTS 6 SUSPENSION POINTS 8 SUSPENSION POINTS 10 SUSPENSION POINTSDIAMETER UDL CPL UDL CPL UDL CPL UDL CPL UDL CPLm ft kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS4,00 13,1 170 114,64 494 1091 289 194,30 681 1502 544 366,38 957 2112 800 538,53 1122 2477 1051 707,13 1221 26966,00 19,7 89 60,06 370 818 161 108,34 537 1184 327 220,03 816 1801 499 335,95 1006 2222 669 450,50 1130 24958,00 26,2 54 36,66 296 653 103 69,49 442 976 223 149,92 711 1570 352 236,60 912 2014 481 323,42 1052 232210,00 32,8 36 24,40 246 542 72 48,30 376 830 163 109,71 597 1319 265 178,29 804 1774 369 248,05 983 217112,00 39,4 25 17,16 210 463 50 33,92 317 699 118 79,25 493 1089 209 140,34 666 1471 295 198,44 838 184914,00 45,9 19 12,51 183 404 36 24,29 265 584 86 57,60 418 923 155 104,24 568 1253 243 163,49 715 1579PROLYTE <strong>H40</strong>V CIRCULAR <strong>TRUSS</strong> - ALLOWABLE LOADING3 SUSPENSION POINTS 4 SUSPENSION POINTS 6 SUSPENSION POINTS 8 SUSPENSION POINTS 10 SUSPENSION POINTSDIAMETER UDL CPL UDL CPL UDL CPL UDL CPL UDL CPLm ft kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS kg/m LBS/ft kg LBS6,00 19,7 148 99,67 677 1494 243 163,58 900 1986 441 296,64 1202 2654 636 427,71 1369 3023 826 555,89 1465 32358,00 26,2 96 64,28 562 1240 164 110,32 777 1715 312 209,78 1097 2421 460 309,30 1289 2846 604 406,76 1405 310110,00 32,8 67 44,76 480 1059 119 79,92 683 1508 236 158,63 1008 2225 355 238,80 1217 2687 472 317,61 1349 297812,00 39,4 49 32,75 418 922 90 60,65 609 1344 186 125,20 932 2057 286 192,20 1153 2545 384 258,43 1297 286314,00 45,9 37 24,79 369 815 71 47,55 548 1211 151 101,83 866 1912 237 159,25 1095 2416 321 216,36 1249 2757All loading figures are based on; Uniformly divided suspension points and a suspended load in each of the fields. In any other case loading data is not valid. Instabilitywill occur. For more details and loading figures of other diameters we refer to our website.Absence of diagonal braces in top and/or bottom side of the truss causes dramatic reduction of the allowable loading. A structural report per situation is required forthese models.Loading figures are based on the German DIN standards. To comply to the BS and ANSI standards the loading data have to be multiplied with 0,85.<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> X/<strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 55 WWW.PROLYTE.COM

<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: FITTINGS INTRO<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>For the connection of the several lengthsof truss Prolyte has designed the innovativeconical coupling system (CCS®). The conicalcoupling system has many advantages overother types of connection systems and hasgained a world-wide reputation for excellenceand efficiency.The conical coupling system makes theCCS6-600Conical coupler12168866CCS6-604Spigot with thread M8M8Weight = 0,148 kgWeight = 0,040 kgTo be used withselflocking nut M8assembly of your truss system safe, fast andeasy. The connection is rigid and strong.Underneath we display all the fittings neededto assemble your truss system.The CCS6 Coupler is designed for the X•<strong>H30</strong>an <strong>H40</strong> Trusses.ø 12CCS6-603SpigotCCS6-605Safety R-spring6760ø 3ø 2Prolyte supplies a variety of lengths,corners and accessories, all ofwhich are designed to providemaximum flexibility in an infinitenumber of applications.Weight = 0,042 kgTo be used with CCS6-605safety R-springWeight = 0,003 kg© © PROLYTE PRODUCTS GROUP 2156 WWW.PROLYTE.COM

631944ø 35ø 3526M1212M12CCS6-602Offset half Conical couplerWeight = 0,116kgOffset 19 mm, thread M12CCS6-650Half Conical couplerWeight = 0,069 kgOffset 0 mm, thread M1275ø 50ø 48ø 1315XCCS6-651Female conical couplerWeight = 0,280 kgWith 13 mm hole for boltsM12CCS6-S05 through CCS6-S50SpacersWeight = 0,187 - 0,404 kgX= 5 mm to 50 mm in stepsof 5 mm168ø 1640 40ø 48CCS6-HHinge for MPT Tower or ST Tower28559329515BASE 30DBaseplate for X•<strong>H30</strong>D truss38459429515BASE 40DBaseplate for <strong>H40</strong>D trussWeight = 0,590 kg4 hinges per tower neededWeight = 1,160 kgWeight = 2,700 kg329329BASE 30VBaseplate for X•<strong>H30</strong>V truss429429BASE 40VBaseplate for <strong>H40</strong>V truss5951559515Weight = 1,860 kgWeight = 2,820 kg<strong>MULTI</strong> <strong>PURPOSE</strong> <strong>TRUSS</strong>: X/<strong>H30</strong> <strong>AND</strong> <strong>H40</strong> <strong>SERIES</strong>© PROLYTE PRODUCTS GROUP 57 WWW.PROLYTE.COM