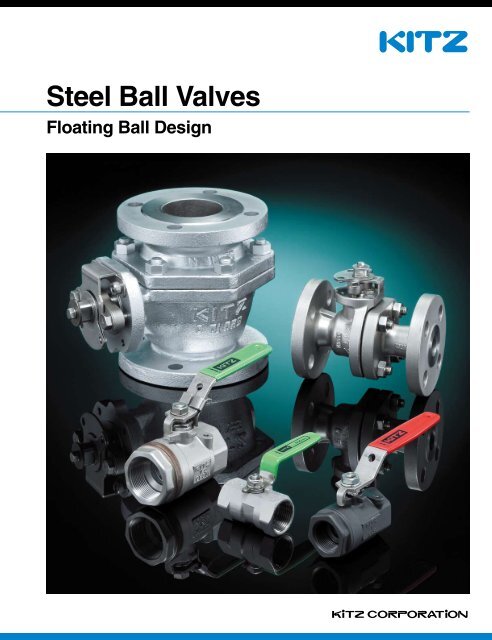

Steel Ball Valves E-205=11 (2.6MB)

Steel Ball Valves E-205=11 (2.6MB)

Steel Ball Valves E-205=11 (2.6MB)

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Floating <strong>Ball</strong> DesignDesign and Inspection Standards of KITZ Flanged <strong>Ball</strong> <strong>Valves</strong> Product Coding for KITZ Flanged <strong>Ball</strong> <strong>Valves</strong>Example:150 U TA (Uni-body, end entry design)G- 300 SC TDZ 1H M -FS(Split body, side entry design) Valve operation measureNone ········· Lever handleG ··············· Worm gearB ··············· KITZ Type B double action pneumatic actuatorBS ············· KITZ Type BS Spring return pneumatic actuatorBSW ·········· KITZ Type BSW Spring return pneumatic actuatorwith manual operation deviceFA ············· KITZ Type FA double action pneumatic actuatorFAS ··········· KITZ Type FAS spring return pneumatic actuatorHAS ··········· KITZ Type HAS Spring return pneumatic actuatorE ················ Electric actuator ASME pressure class150, 300, 600 or 1500 & Shell material & Trim materialU: Symbol of stainless or high alloy steelSC: Symbol of carbon or low alloy steelU/None ······ CF8U/M ··········· CF8MU/V ··········· CF3U/O ··········· CF3MU/CB ········· CF8CU/CG ········· CG8MU/CK ········· CK20U/SD ········· CD3MWCuNU/CN ··················· CN7MU/HB ··················· N-12MVU/HC ··················· CW-12MWSC/None/None* ··· WCB/CF8SC/None/M* ········ WCB/CF8MSC/CL/None* ······ LCC/CF8SC/CL/M* ············ LCC/CF8MValve design & typeTDZ ······· Type TDZTDZXL ··· Extended bonnet, Type TDZTB ········· Type TBTR ········· Type TRTBP ······· Pocketless, Type TBTB2L ····· 3-way 2-seat, L-port, Type TBTB2T ····· 3-way 2-seat, T-port, Type TBTB4LA ··· 3-way 4-seat, L-port, Type TBTB4TA ··· 3-way 4-seat, T-port, Type TBTBT ······· Direct mouting to tank bottomTBJ ······· Jacketed, Type TBTRJ ······· Jacketed, Type TRTBLN ····· PFA lined, Type TBTA ········· Type TASeat MaterialNone ····· HYPATITE ® PTFE1H** ······· FILLTITE ®3H** ······· Hard graphite seat for low abrasion service, 500˚C5H** ······· Metal seat for abrasive service, 300˚C6H** ······· Metal seat for high abrasive service, 500˚C** Type TDZ onlySeeNo symbol suffixed for PTFEpacking and gasket."FS" or "S" suffixed for flexiblegraphite packing and gasket forsuper-firesafe provisionThis catalog uses MPa, a SI unit, for indication of pressures. psi and kgf/cm 2 are also added for readers convenience.1

Bore design: F=Full port, R=Reduced portWorm gear operation is standardised for the sizes marked with the prefix “G-” on each KITZ product code.Please contact KITZ Corporation for details.Refer to KITZ Ductile Iron <strong>Valves</strong> catalog (No. E-140) for detailes.Refer to KITZ Cast Iron <strong>Valves</strong> catalog (No. E-120) for detailes.Reduced port.1 23 4 1 4 1 2 1 2Flanged Floating <strong>Ball</strong> <strong>Valves</strong> KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignProduct Range2

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignProduct RangeFlanged High Performance <strong>Ball</strong> <strong>Valves</strong> 1 23 4 1 4 1 2 1 2 ® Bore design: F=Full portOperation: L=Lever, G=GearWorm gear operation is standardised for the sizes marked with the prefix “G-” on each KITZ product code.Refer to KITZ -port Quarter-Turn Control <strong>Valves</strong> catalog (No. E-203) for detailes.Refer to KITZ <strong>Steel</strong> <strong>Ball</strong> Valve for High Temperature (No. E-204) for detailes.Please contact KITZ Corporation for details.3

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignProduct RangeFlanged High Performance <strong>Ball</strong> <strong>Valves</strong> 1 23 4 1 4 1 2 1 2Please contact KITZ Corporation for details.Flanged Trunnion Mounted <strong>Ball</strong> <strong>Valves</strong> Bore design: F=Full port (Reduced port type is also available.)Worm gear operation is standard for the sizes marked with the prefix “G-” on each KITZ product code.Non firesafe types are also available.Refer to KITZ Trunnion Mounted <strong>Ball</strong> <strong>Valves</strong> catalog (No. E-202) for details.Trunnion Mounted <strong>Ball</strong> <strong>Valves</strong>4

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignProduct RangeThreaded or Welded <strong>Ball</strong> <strong>Valves</strong> 1 43 81 23 4 1 4 1 2 1 2 Bore design: F=Full port, R=Regular port, D=Reduced portRc threaded ends are standard. Prefix “AK” means NPT threaded end.Rc threaded ends are standard. Prefix “AK” means NPT threaded ends and “AW” means socket welded ends.NPT threaded ends are only available.Please contact KITZ Corporation for details.Refer to KITZ Ductile Iron <strong>Valves</strong> catalog (No. E-140) for detailes.Refer to KITZ Cast Iron <strong>Valves</strong> catalog (No. E-120) for detailes.-port <strong>Ball</strong> <strong>Valves</strong>5

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignPressure-Temperature RatingsThe pressure-temperature ratings of ball valves are determined,not only by valve shell materials, but more essentially by sealingmaterials, used for ball seats, gland packing and gaskets.Sealing materials may be high molecule, or rubber, but thechoice is limited by the characteristics of the service fluid,working temperatures, working pressures, velocity of fluid, andoperational frequency of valves.As it is very difficult to predetermine the exact pressuretemperaturerating for all kinds of fluid under all imaginableconditions, we have prepared general rating charts for nonshockfluid service here, based on our past experiences both inthe field and in our laboratory.In case of extraordinary service conditions as mentioned below,contact KITZ Corporation or its distributors for technical advice:1. <strong>Valves</strong> shall be left fully closed for a long period of time underhigh temperature or high differential pressure.2. <strong>Valves</strong> shall be frequently operated under high temperatureor high differential pressure.3. Frequent change of line pressure or temperature.HYPATITE ® PTFE is the standard seat material for KITZ ball valves. Specify virgin PTFE or carbon-filled PTFE when required. The body ratings shownhere are for ASTM A216 Gr. WCB and A351 Gr. CF8M. For the pressure ratings of other valve shell materials, refer to the latest edition of ASME B16.34.FILLTITE ® is a specially reinforced ball seat, made by using carbon based fillers into PTFE at higher rate than conventional carbon filled PTFE, whichgreatly improves heat and abrasion resistance. The material shows excellent operability, durability, chemical resistance and sealing performance at a hightemperature of 300. In addition, the ball seat is replaceable with the most of our conventional ball seats, so it also has the cost advantage.6

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignPressure-Temperature Ratings150/300 UTDZM/SCTDZ: 1 2˝, 3 4˝ 150/300 UTDZM/SCTDZ: 1˝2 1 2˝MPa876.96.26.165Seat: A : Virgin PTFEB : HYPETITE ® PTFEC : FILLTITE ®psi11601000800MPa876.265.35Seat: A : Virgin PTFEB : HYPETITE ® PTFEC : FILLTITE ®psi11601000800Pressure4Class 300 WCB body ratingClass 300 CF8M body rating600Pressure4Class 300 WCB body ratingClass 300 CF8M body rating6003A B C4003A B C4002Class 150 WCB body rating2Class 150 WCB body rating1Class 150 CF8M body rating2001Class 150 CF8M body rating200029 0 50 100 15020100 200 300Temperature000270 270200 250 300 C29 0 50 100 150 200 250 300 C400 500 572 F20100 200 300 400 500 572 FTemperature150/300 UTDZM/SCTDZ: 3˝, 4˝ 150/300 UTDZM/SCTDZ: 5˝, 6˝MPa87Seat: A : Virgin PTFEB : HYPETITE ® PTFEC : FILLTITE ®psi11601000MPa87Seat: A : Virgin PTFEB : HYPETITE ® PTFEC : FILLTITE ®psi1160100065.2580065.25800Pressure4Class 300 WCB body ratingClass 300 CF8M body rating600Pressure4Class 300 WCB body ratingClass 300 CF8M body rating6003A B C4003A B C4002Class 150 WCB body rating2Class 150 WCB body rating1Class 150 CF8M body rating2001Class 150 CF8M body rating200029 0 50 100 150270200 250 300 C029 0 50 100 1500270200 250 300 C20100200300Temperature400500572 F20100200300Temperature400500572 F150/300 UTDZM/SCTDZ: 8˝, 10˝MPa87Seat: A : Virgin PTFEB : HYPETITE ® PTFEC : FILLTITE ®psi1160100065800Pressure4Class 300 WCB body ratingClass 300 CF8M body rating6003A B C4002Class 150 WCB body rating1Class 150 CF8M body rating200029 0 50 100 15020100 200 300Temperature200 2502700300 C400 500 572 F7

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignPressure-Temperature Ratings150 UTBM : 1 2˝ & 3 4˝*150/300 SCTA/UTAM : 1 2˝ to 1˝150 UTBM : 1˝ to 2 1 2˝*150/300 SCTA/UTAM : 1 1 2˝ to 3˝MPapsi1000MPaSeat: A : Virgin PTFE6.20 B : HYPETITE ® PTFE6.206.08C : FILLTITE ®5.88* 5.88FILLTITE ® is onlyapplicable toSCTA/UTAM series.8005.305.115.115.00Seat: A : Virgin PTFEB : HYPETITE ® PTFEC : FILLTITE ®* FILLTITE ® is onlyapplicable toSCTA/UTAM series.psi1000800Pressure3.92A B CClass 300 WCB body ratingClass 300 CF8M body rating600400Pressure3.92A B CClass 300 WCB body ratingClass 300 CF8M body rating6004001.961.96Class 150 WCB body ratingClass 150 CF8M body rating200Class 150 WCB body ratingClass 150 CF8M body rating200029 0 50 100 1500200 250 300 C029 0 50 100 1500200 250 300 C20100200300Temperature400500572 F20100200300Temperature400500572 F150 UTBM : 3˝ & 4˝ *150/300 SCTA/UTAM : 4˝ & 6˝150 UTBM : 5˝ & 6˝ *150/300 SCTA/UTAM : 8˝ & 10˝MPapsi1000MPaSeat: A : Virgin PTFEB : HYPETITE ® PTFE5.88C : FILLTITE ®* FILLTITE ® is only5.885.20applicable toSCTA/UTAM series.8005.205.115.11Seat: A : Virgin PTFEB : HYPETITE ® PTFEC : FILLTITE ®* FILLTITE ® is onlyapplicable toSCTA/UTAM series.psi1000800Pressure3.92A B CClass 300 WCB body ratingClass 300 CF8M body rating600400Pressure3.92A B CClass 300 WCB body ratingClass 300 CF8M body rating6004001.961.96Class 150 WCB body ratingClass 150 CF8M body rating200Class 150 WCB body ratingClass 150 CF8M body rating200029 0 50 100 1500200 250 300 C029 0 50 100 1500200 250 300 C20100200300Temperature400500572 F20100200300Temperature400500572 F150 UTBM : 8˝ & 10˝MPa5.885.11Seat: A : Virgin PTFEB : HYPETITE ® PTFEpsi1000800Pressure3.921.96AB6004000.92Class 150 CF8M body rating200029 0 50 100 15020100200300Temperature0200 250 300 C400 500 572 F8

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignPressure-Temperature RatingsRefer to 150UTBM ratingsfor 150UTB2LM/2TMMPa24.52psi3500MPa2.0Max. velocity:Liquid3m/secGas30m/secSeatHYPATITE ® PTFEpsi29025019.61Class 1500 WCB body rating30001.5Class 150 CF8M body rating200Pressure14.71Class 1500 CF8M body rating25002000Pressure1.00.515010010.799.81Class 600 WCB body rating1500504.90Class 600 CF8M body rating100050002920 00 50100100200150300Temperature0200 250 300 C400 500 572 F0 029 20 0 50 80 100 120 150 170 200 250 C20 0 50 100 150 200 250 300 350 400 450 500FTemperature<strong>Ball</strong> Seat Materials: KITZ HYPATITE ® orCarbon-filled PTFE: Glass-filled PTFE with MoS2: Virgin PTFE: Nylon with MoS2150/300 UTDZXLMPa8.07.06.915A20AO-ring Upper Limit: 1FKM2Low-temperature FKM: 1EPDM2ECOEpichlorohydrin Copolymer: 1NBR2Low-temperature NBRO-ring Lower Limit: FKM* O-rings made of others than FKMcan wichstand -29˚C (-20˚F)SeatHYPATITE ® PTFEpsi3500PressureMPa2.01.91.51.371.00.5029 0 50 10020 010K body rating50100SeatHYPATITE ® PTFE150 200 250TemperatureDegree of vacuum (Torr)760Torr0100Torr0Torr150C300Fpsi290250200150100506.030005.35.025A65AASME B16, 34-1996 Class 300 CF880A, 100A2500Pressure4.0125A, 150A20003.0200A, 250A15002.0ASME B16, 34-1996 Class 150 CF810001.05000 0104 50 0 50100 150 C15550 0 50 100 150 200 250 300 FTemperature9

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignPressure-Temperature RatingsType 600:SCTK/UTKMType 1000:UTFMMPa6.86psi1000MPa6.86psig1000SeatReinforced PTFESeatHYPATITE ® PTFE5.888005.888004.904.90Pressure4.123.922.94600400Pressure3.922.946004001.961.960.982000.98200029 0 50 100 1500200 250 300 C029 0 50 100 1500200 250 300 C20 0100200300Temperature400500572 F20 0100200300Temperature400500572 FType 800:UTHMClass 800 and Type 3000:SCTKMPa6.86psi1000MPapsi5.885.49SeatPTFE80020.5919.613000WOG Seat: 1 : PTFE2 : PCTFE*30004.90Pressure3.922.94600400Pressure14.7113.739.81BS Class 800 body rating20001.960.982006.864.90Class 800 1000029 0 50 100 1500200 250 300 C029 0 50 100 1500200 250 300 C20 0100200300Temperature400500572 F20 0100200300Temperature400500572 F* Polychloro-Trifluoro-EthyleneType 800:UTH4LM/4TMType 1000:SC3TZ/U3TZ SeriesMPa2.452.01.96Max. velocity:Liquid3m/secGas30m/secSeatHYPATITE ® PTFEpsi1000800MPa9.80SeatHYPATITE ® PTFEpsig15007.85Pressure1.470.98600400Pressure6.865.883.9210005000.492001.96029 0 50 100 1500200 250 300 C029 0 50 100 1500200 250 300 C20 0100200300Temperature400500572 F20 0100200300Temperature400500572 FNote: Type 1500 is optionally available10

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignPressure-Temperature RatingsType 1500/2000:AKSCTHZM/AKSCTHWZM/AKUTHZM/AKUTHWZMClass 150:AK150UTMMPa17.16SeatHYPATITE ® PTFEpsi250013.73 2000MPa2.94SeatPTFEpsi400Pressure10.30 15006.86 1000Pressure1.961.373002000.983.43 500100000 50 100 150 200 250 C0 100200300400500F20 0Temperature029 0 50 100 150100200300Temperature0200 250 300 C400 500 572 F11

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignKITZ 150/300 SCTDZ/UTDZM SeriesFull Port, Split Body, Side Entry <strong>Ball</strong> <strong>Valves</strong>This is an illustrated cross-section of a typical KITZ split bodyfloating type full port ball valve to exhibit the basic designconcept. The actual design of a valve may be slightly differentfrom this illustration, depending on its size and pressure class.Low emission(ISO 15848/EPA Method 21)stem packingStem head conformwith CAPI ADDS2.02dimension(Double “D” designparallel to flowpassage)ISO 17292 positionstopsKey lock plateLive loading springUpper and lowerstem bearingISO5211 actuatormounting padMetal-to-metalcontact forfire safeLow emissionbody seal gasketAntistatic devicePrecisionmachined ballThrust washerBodyHYPATITE ® PTFEball seat with cavitypressure reliefprovisionBody capNote:Dimension of stem head are in accordancewith CAPI ADDS 2.02, but the maximumspecified dimension in CAPI ADDS 2.02 is“F14”For NPS 8 and 10, mounting pads are F16/ISO 5211.2˝ KITZ 150UTDZBubble-tight sealing performance withHYPATITE ® PTFE ball seatsHYPATITE ® PTFE ball seats, standard stem seals of KITZ ballvalves, are made of denatured PTFE, a molecularly reinforcedPTFE copolymer, and specifically engineered for high bidirectionalsealing performance and prolonged service life ofvalves. Its resistance to high or low temperature, creep orcompression, abrasion and corrosion is all outstanding. As anoption, KITZ SWELLESS ® ball seats principally made of PFAare recommended specifically for monomer service. Thisepoch-making new seat maximizes resistance to thepermeation of monomer into its molecular structure (generallyknown as a “swelling” problem) which causes seat deformationand seriously affects shut-off function of valves in styrene andbutadiene monomer service.Simplified actuator mountingFor 150/300 SCTDZ/UTDZM and SCTA/UTAM Series ballvalves, ISO 5211 actuator mounting pad is integrally providedfor uniformly simplified mounting of any actuators provided withvalve mounting flanges designed to ISO 5211 dimensionalrequirement. 150UTBM Series ball valves are provided withKITZ standard integral actuator mounting pad.Easy maintenanceSplit body design for KITZ SCTDZ/UTDZM Series provides theconvenience of very easy maintenance critically required forprocess plants. Body inserts of uni-body, end entry design forKITZ 150/300 SCTA/UTAM Series are threaded into the valvebody with provision of unthreading for valve disassembly incase of maintenance operation.12

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignKITZ 150/300 SCTA/UTAM SeriesReduced Port, Uni-body, End Entry <strong>Ball</strong> <strong>Valves</strong>This is an illustrated cross-section of a typical KITZ uni-bodyfloating type reduced port ball valve to exhibit the basic designconcept. The actual design of a valve may be slightly differentfrom this illustration, depending on its size and pressure class.Key lock plateStopper pinLow emissionstem packingAntistatic deviceThrust washerBlowout-proofstem collarHYPATITE ® PTFEball seat with cavitypressure reliefprovisionStem head(Double “D” designparallel to flowpassage)Gland nutBellevillespring washerfor live loadingIntegral ISO 5211Actuator mountingpadStem bearingEmission-freePTFE primarygasketFlexible graphitesecondary gasket(Fire safe type only)Precisionmachined ballBody insertMetal-to-metalfiresafe contactBody1 1 /2˝ KITZ 150SCTAExtensive safety considerationsKITZ ball valves are designed with extensive safety considerationsfor users. Blow-out proof stems, provision of lockingdevices and prevention of misalignment of lever handlesprovide safe handling in the field and trouble-free operation inthe plant. Antistatic devices, firesafe seal design and cavitypressure relief features all assure the economic benefits ofsmooth, steady plant operation. KITZ advancements in lowemission design features contribute to the global battle againstfugitive emissions while greatly reducing costs caused byproduct loss.For sour serviceHardness of body, body cap/insert, ball and stem materialof KITZ Class 150/300 steel ball valves are controlledby appropriate heat treatment and conformed to thehardness requirements in NACE MR0175, as standard.In addition to the above, following requirements are optionallyavailable.-Bolting for valves exposed to sour environment.-NACE requirements for Class 600 and higher steel ballvalves.Please contact KITZ for those requirements.13

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignSeven Safety Considerationsfor KITZ 150/300 SCTDZ/UTDZM 150UTBM and 150/300 SCTA/UTAM Series <strong>Ball</strong> <strong>Valves</strong>1. Double “D” stem head design provides mountingof the lever handle always in parallel to the flowpassage. Misaligment of the handle is thusprevented. (Fig. 1)Flow directionAntistaticdevicesStemStem CollarBody2. The lower end of the stem is designed with anintegral collar to be blowout-proof. It also functionsas the backseat for assured stem sealing.(Fig. 2)3. An antistatic feature is provided to ensureelectrical continuity between ball, stem, and body.(Fig. 2)Top of stemHandle<strong>Ball</strong>Fig. 1 Fig. 24. Facility for mounting a locking device for preventionof accidental valve operation is provided.5. Plant fires are a serious concern for soft-seatedball valves because of possible fluid leakage andconsequent increase of the fire magnitude causedby deterioration of resilient sealing materials.SeatBodyBodyMetal-to-metalcontactKITZ ball valves are engineered for firesafety andsuccessfully fire tested to minimize both externaland internal fluid leakage after plant fires. Theyhave post-fire metal-to-metal contact of all sealingareas such as:Fig. 3 (Before fire)PackingBearingFig. 4 (After fire)Metal-to-metalcontact Contact between ball and valve shell(Fig. 3 & 4) Contact between stem and valve shell(Fig. 5 & 6) Valve shell coupling flanges of split body design(Fig. 7 & 8) Contact between valve body and insert of unibodydesign (Fig. 9)StemWasherGasketThe problem of external fluid leakage is moreserious than internal leakage through the valvebore because of the fear of fueling the fire. Toprevent this, KITZ ball valves may be ordered withflexible graphite packing and gaskets, whichare extremely heat resistant, and not affected bythe fire.Fig. 5 (Before fire)<strong>Ball</strong>Fig. 6 (After fire)<strong>Ball</strong>6. The surface of stem and stuffing box, and interfaceclearance of stem-to-gland, stem-to-body andgland-to-stuffing box are precision controlled onmachining and assembly for low emission service.A Belleville spring washer is employed for liveloading on gland packing rings, to minimize needof gland retightening for low emission service.7. A provision of cavity pressure relief is incorporatedinto precision engineered KITZ HYPATITE ®PTFE ball seats for the ultimate safety. Refer toPage15 for details.GasketFig. 7 (Before fire)Flexible graphitegasket for superfiresafeprovisionEmission-freePTFE primarygasketMetal-to-metalcontactFig. 8 (After fire)As the primary body seal, emissionfree PTFE gasket is alwaysprovided. Flexible graphite gasketmay be additionally employed asthe secondary body seal for superfiresafeprovision.Fig. 9 (Uni-body insert)14

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignIntegral Actuator Mounting PadsKITZ 150/300 SCTDZ/UTDZM series and 150/300SCTA/UTAM series ball valves are furnished with anintegral actuator mounting pad designed and factorydrilledaccording to ISO 5211 specification. Thiseasily and uniformly enable mouthing of any actuatorsprovided with ISO 5211 valve mounting flanges.Mounting pad and stem head dimension alsoconforms to CAPI ADDS 2.02.Actuatormounting padActuator mounting padActuatormounting padNote: Customers are requested to prepare mountingbrackets and connectors for the actuators chosenfor their valve automation. Actuators can bemounted on KITZ ball valves without disassembly ofvalve glands.Split body designUni-body designHYPATITE ® PTFE <strong>Ball</strong> SeatsKITZ ball valves are furnished, as the manufacturer’sstandard, with HYPATITE ® PTFE ball seats made ofdenatured PTFE, a molecularly reinforced PTFEcopolymer, and specially engineered for highperformance which include: Wide service temperature range of 29C (20F)through 270C (518F) SCTDZ/UTDZM Series,260C (500F) UTB and SCTA/UTAM Series.This is for standard valve design and materials used formedium to high temperature services. The lower temperaturerange can be extended down to 196C (321F)by means of extended bonnet design and special lowtemperature service materials. High chemical resistance is comparable to virginPTFE. Monomer permeability is lower than other PTFEmaterials. Resistance against compression and creeping (cold flow) ishigher than other PTFE materials to guarantee long life cycle. Specific gravity and friction coefficient are equal to those ofvirgin PTFE for smooth valve operation. Purity of processed products is guaranteed as highly asvirgin PTFE. Resiliency is as high as other PTFE materials for bubble-tightsealing performance.notchFrontgroovenotchRearA typical HYPATITE ® PTFE seat used for 4" KITZ 150SCTDZ ball valves.FILLTITE ® <strong>Ball</strong> SeatsHighest heat resistance amond PTFE based materials. Service temperature range: 29℃ to 300℃ Trim symbol: 1HCavity Pressure ReliefSome line fluid is usually left trapped inside the ball-body cavity.This fluid can expand under the influence of high ambient or linetemperature. An abnormal increase of such cavity pressure maysometimes damage the valve seats or balls, unless the valvehas an adequate cavity pressure relief provision. Trunnionmounted ball valves generally provide perfect protection fromthis problem. Refer to KITZ Cat. No. E-202 for technical detailsof KITZ trunnion mounted ball valves.In case of floating ball valves, however, their rather simpleseating principle requires some special protection fromexcessive cavity pressure rise when highly volatile liquid inservice is subject to frequent and large temperature variation,while the valve is not frequently operated. KITZ 150/300SCTDZ/UTDZM and 150/300 SCTA/UTAM Series ball valvesoffer self-relieving of excessive cavity pressure as a standardfeature engineered in HYPATITE ® PTFE ball seats.Other general solutions for floating ball valves includeemployment of automatic pressure relief valves or drillingpressure equalization holes on the ball. If the requirement ofautomatic cavity pressure relief is as critical as in chlorineservice, be sure to contact KITZ Corporation or its distributors fortechnical advice.This capability is influenced by many variables including: fluidcharacteristics, variations in pressure, temperature and thermalcycles.15

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignKITZ <strong>Ball</strong> Seat MaterialsThe following seat materials are available.Virgin PTFEHYPATITE ® PTFE Carbon filled PTFE FILLTITE ® GraphiteMetalPEEKGlass fiber filled PTFE with MoS2Nylon with MoS2FILLTITE ® is a specially reinforced ball seat, made by using more carbon based fillers into PTFE than conventional carbon filled PTFE, whichgreatly improves heat and abrasion resistance. The material shows excellent operability, durability, chemical resistance and sealing performanceat a high temperature of 300. In addition, the ball seat is replaceable with the most of our conventional ball seats, so it also has the costadvantage.270Uni-body design26016

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150/300 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesAntistatic deviceBlowout-proof stemFire test certification (API 607, ISO 10497)Stem head conform with CAPI ADDS2.02 dimensionHigh performance HYPATITE ® PTFE ball seatsActuator mounting pad to ISO 5211Conform to NACE MR0175 for hardness of body, body cap, stem and ball.Page 7 for Pressure-Temperature RatingsPage 42 for Construction and MaterialsPage 39 for Dimension of Actuator Mounting Pad150SCTDZ300SCTDZDimensions of 150SCTDZ Valve operator1 /2´´8´´: Lever operation6´´8´´: Optional gear operation10: Standard gear operationOptionsFlexible graphite packing and gasket(See Page 14 and 40) <strong>Ball</strong> and stem to CF8M (316)Dimensions of 300SCTDZ Valve operator1 /2´´8´´: Lever operation6´´8´´: Optional gear operationOptionsFlexible graphite packing and gasket(See Page 14 and 42) <strong>Ball</strong> and stem to CF8M (316)Gear Operation Worm gear operators may be mounted on KITZball valves at your option for the smoothestvalve operation. Electric or pneumatic actuatorsare also optionally available. Contact KITZdistributors for appropriate choice and sizing ofvalve actuators.17

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150/300 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesFILLTITE ® ball seats. Temperature range: –29℃ to 300℃Antistatic deviceBlowout-proof stemFire test certification (API 607, ISO 10497)Stem head conform with CAPI ADDS2.02 dimensionsActuator mounting pad to ISO 5211Conform to NACE MR0175 for hardness of body, body cap, stem and ballPage 7 for Pressure-Temperature Ratings150SCTDZ1H300SCTDZ1HDimensions of 150SCTDZ1H Valve operator1 /2´´4´´: Lever operation5´´10´´: Standard gear operationDimensions of 300SCTDZ1H Valve operator1 /2´´3´´: Lever operation4´´8´´: Standard gear operationOptions <strong>Ball</strong> and stem to CF8M (316)Gear Operation Electric or pneumatic actuators are alsooptionally available.Contact KITZ distributors for appropriatechoice and sizing of valve actuators.18

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 600/1500 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesAntistatic deviceBlowout-proof stemFire test certification (API 607)Double “D” stem head<strong>Ball</strong> seats: Reinforced PTFE with MoS2 for Class 600Nylon with MoS2 for Class 1500Page 9 for Pressure-Temperature RatingsPage 47 and 49 for Construction and Materials600SCTB1500SCTBDimensions of 600SCTB Valve operatorLever operationOptionsFlexible graphite packing and flexiblegraphite spiral wound gasket(See Page 14 and 47) <strong>Ball</strong> and stem to 316Dimensions of 1500SCTB Valve operatorLever operationOptionsFlexible graphite packing and flexiblegraphite spiral wound gasket(See Page 14 and 49) <strong>Ball</strong> and stem to 31620

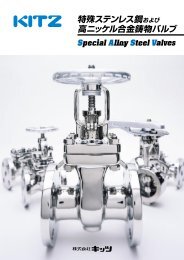

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150/300 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesAntistatic deviceBlowout-proof stemFire test certification (API 607, ISO 10497)Stem head conform with CAPI ADDS 2.02 dimensionsHigh performance HYPATITE ® PTFE ball seatsActuator mounting pad to ISO 5211Conform to NACE MR0175 for hardness of body, body cap, stem and ball.Page 7 for Pressure-Temperature RatingsPage 44 for Construction and MaterialsPage 39 for Dimension of Actuator Mounting Pad150UTDZM300UTDZMDimensions of 150UTDZM Valve operator1 /2´´8´´: Lever operation5´´8´´: Optional gear operation10´´: Standard gear operationOptionFlexible graphite packing and gasket(See Page 14 and 44)Dimensions of 300UTDZM Valve operator1 /2´´8´´: Lever operation6´´8´´: Optional gear operationOptionFlexible graphite packing and gasket(See Page 14 and 44)Gear Operation Worm gear operators may be mounted on KITZball valves at your option for the smoothestvalve operation. Electric or pneumatic actuatorsare also optionally available. Contact KITZdistributors for appropriate choice and sizing ofvalve actuators.21

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150/300 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesFILLTITE ® ball seats. Temperature range: –29℃ to 300℃Antistatic deviceBlowout-proof stemFire test certification (API 607, ISO 10497)Stem head conform with CAPI ADDS2.02 dimensionsActuator mounting pad to ISO 5211Conform to NACE MR0175 for hardness of body, body cap, stem and ballPage 7 for Pressure-Temperature Ratings150UTDZ1H300UTDZ1HDimensions of 150UTDZ1HGear Operation22 Dimensions of 300UTDZ1H Valve operator1 /2´´4´´: Lever operation5´´10´´: Standard gear operationValve operator1 /2´´3´´: Lever operation4´´8´´: Standard gear operationOptions <strong>Ball</strong> and stem to CF8M (316)Electric or pneumatic actuators are alsooptionally available.Contact KITZ distributors for appropriatechoice and sizing of valve actuators.

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesAntistatic deviceBlowout-proof stemDouble “D” stem headHigh performance HYPATITE ® PTFE ball seatsPage 8 for Pressure-Temperature RatingsPage 45 for Construction and Materials150UTBMDimensions of 150UTBM Valve operator1 /2´´8´´: Lever operation5´´8´´: Optional gear operation10´´: Standard gear operationGear Operation Worm gear operators may be mounted on KITZball valves at your option for the smoothestvalve operation. Electric or pneumatic actuatorsare also optionally available. Contact KITZdistributors for appropriate choice and sizing ofvalve actuators.23

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150/300 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Uni-body, End entry designFeaturesAntistatic deviceBlowout-proof stemFire test certification (API 607)Double “D” stem headHigh performance HYPATITE ® PTFE ball seatsActuator mounting pad to ISO 5211Conform to NACE MR0175 for hardness of body, body insert, stem and ball.Page 8 for Pressure-Temperature RatingsPage 46 for Construction and MaterialsPage 40 and 41 for Dimension of Actuator Mounting Pad150UTAM300UTAMDimensions of 150UTAM Valve operator1 /2´´10´´: Lever operation6´´10´´: Optional gear operationOptionFlexible graphite packing and gasket(See Page 14 and 44)Dimensions of 300UTAM Valve operator1 /2´´10´´: Lever operation6´´10´´: Optional gear operationOptionFlexible graphite packing and gasket(See Page 14 and 44)Gear Operation Worm gear operators may be mounted on KITZball valves at your option for the smoothestvalve operation. Electric or pneumatic actuatorsare also optionally available. Contact KITZdistributors for appropriate choice and sizing ofvalve actuators.24

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 600/1500 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesAntistatic deviceBlowout-proof stemDouble “D” stem head<strong>Ball</strong> seats: Reinforced PTFE with MoS2 for Class 600Nylon with MoS2 for Class 1500Page 9 for Pressure-Temperature RatingsPage 46 and 48 for Construction and Materials600UTBM1500UTBMDimensions of 600UTBM Valve operatorLever operationDimensions of 1500UTBM Valve operatorLever operation25

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150 Low Temperature Service <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesExtended bonnet for assured stem seal and freezing prevention.Bolted bonnet with body seal gasket.Protection of stem alignment by means of two bearings built on top and bottom of stem extension.Page 9 for Pressure-Temperature RatingsLowest working temperature: 104150UTDZXLG-150UTDZXLValve operator1 /2´´4´´: Lever operation5´´10´´: Gear operationRefer to Page 42 for the basic construction and materials.Dimensions of 150UTDZXLStandard materials Dimensions of G-150UTDZXL ® CF8M are available26

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 300 Low Temperature Service <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designFeaturesExtended bonnet for assured stem seal and freezing prevention.Bolted bonnet with body seal gasket.Protection of stem alignment by means of two bearings built on top and bottom of stem extension.Page 9 for Pressure-Temperature Ratings.Lowest working temperature: 104300UTDZXLG-300UTDZXLValve operator1 /2´´3´´: Lever operation4´´ 8´´ : Gear operationRefer to Page 42 for the basic construction and materials.Dimensions of 300UTDZXLStandard materials Dimensions of G-300UTDZXL ® CF8M are availableValve size 1 1 /4´´ and 5´´ are available27

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150 Stainless <strong>Steel</strong> 3-way <strong>Ball</strong> <strong>Valves</strong>Full port, 2-seated or 4-seated, Split body, Side entry designFeaturesUsed for diverting or mixing process mediaOne 3-way valve can replace several other valves plus theassociated piping piecesAntistatic deviceBlowout-proof stemDouble “D” stem headHigh performance HYPATITE ® PTFE ball seatsActuator mounting pad to KITZ standard150UTB 2L/2T: Page 7 for Pressure-Temperature Ratings (See UTB Series)150UTB 4LA/4TA: Page 9 for Pressure-Temperature Ratings150UTB2L (L-port, 2-seated)150UTB2T (T-port, 2-seated)L-portC150UTB4LA (L-port, 4-seated)150UTB4TA (T-port, 4-seated)L-portCABABForm 1CForm 1CABABForm 2Form 2T-portCT-portCAForm 1CBAForm 1CBABABForm 2CForm 2CABABForm 3Form 3CABForm 4Dimensions of 150UTB2LM/2TM Dimensions of 150UTB4LAM/4TAM150UTR 2LM/2TM 150UTR 4LAM/4TAM28Valve operator1´´6´´: Lever operation6´´: Optional gear operationNoteJIS 10K type is also available.Valve operator1 /2´´8´´: Lever operation5´´8´´: Optional gear operationNoteJIS 10K type is also available.

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150 Stainless <strong>Steel</strong> Pocketless <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designPage 8 for Pressure-Temperature RatingsFeaturesUnique filled cavity providesexcellent resistance to media buildup and/or stagnation between seatsAntistatic deviceBlowout-proof stemDouble “D” stem headHigh performance HYPATITE ®PTFE ball seatsActuator mounting pad to KITZstandard150UTBPMValve operator1 /2´´8´´: Lever operation5´´8´´: Optional gear operationDimensions Class 150 Stainless <strong>Steel</strong> Jacketed <strong>Ball</strong> <strong>Valves</strong>Full portPage 8 for Pressure-Temperature RatingsFeaturesFully jacketed to maintain mediatemperatureAntistatic deviceDouble “D” stem headHigh performance HYPATITE ®PTFE ball seatsActuator mounting pad to KITZstandard150UTBJMValve operator1 /2´´6´´: Lever operation6´´: Optional gear operationNoteMaximum allowable pressure is 1.37MPa(199psi) at 260 (500).JIS 10K type is also available.Dimensions 150UTRJM29

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 150 Stainless <strong>Steel</strong> Tank <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designPage 8 for Pressure-Temperature RatingsFeaturesDirect mounting to tank bottomChurning media evenlyAntistatic deviceBlowout-proof stemDouble “D” stem headHigh performance HYPATITE ®PTFE ball seatsActuator mounting pad to KITZstandard150UTBTMValve operator1´´6´´: Lever operationNoteMaximum allowable temperature is 200(392).Class 300 and JIS 10K/20K types are alsoavailable.Dimensions 10K Stainless <strong>Steel</strong> PFA Lined <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry designPage 9 for Pressure-Temperature RatingsFeaturesHighly corrosion-resistant PFA liningFine lining without a pinholeHighly heat-resistant PFANo additives or paints are includedDouble “D” stem headHigh performance HYPATITE ®PTFE ball seatsActuator mounting pad to KITZstandard10UTBLNValve operator1 /2´´4´´: Lever operationNoteClass 150 type is also available.Dimensions 30

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignType 600 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Reduced port, Uni-body design, Threaded endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemChoice of threaded ends:Rc threads to BS 21 (Fig. SCTK)NPT threads to ASME B1.20.1(Fig. AKSCTK)SCTKStandard materials 1 304 for 1 /2´´ & larger2 304 for 3 /4´´ & largerEnd-to-end dimensions: KITZ standardDimensions Valve operatorLever operationT-type handle as option ( 3 /4´´ & larger only)Type 1500/2000 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Split body design, Threaded endsPage 11 for Pressure-Temperature RatingsFeaturesBlowout-proof stemAPI 607 firesafe type as optionNPT threaded ends toASME B1.20.1AKSCTHZMStandard materials ® API 607 firesafe flexible graphite is optionallyavailable.End-to-end dimensions: KITZ standardDimensions Valve operatorLever operation with latch lockOval handle as option31

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignType 1500/2000 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Welded body design, Threaded endsPage 11 for Pressure-Temperature RatingsFeaturesBlowout-proof stemAPI 607 firesafe type as optionNPT threaded ends toASME B1.20.1AKSCTHWZMStandard materials ® API 607 firesafe flexible graphite is optionallyavailable.End-to-end dimensions: KITZ standardDimensions Valve operatorLever operation with latch lockOval handle as optionClass 800 and Type 3000 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Welded body design, Threaded endsPage 10 for Pressure-Temperature RatingsFeaturesAntistatic deviceBlowout-proof stemFire test certification(800 SCTK only) Choice of threaded ends:Rc threads to BS 21(Fig. 800/3000 SCTK)NPT threads to ASME B1.20.1(Fig. AK800/3000 SCTK)Note1. Class 800 ball valves are designed to BS 5351.2. Type 3000 ball valves are designed to KITZstandard for servicing water, oil and gaseousfluid under the maximum working pressure of3000psi.800/3000 SCTKStandard materials Polychloro-Trifluoro-Ethylene.Dimensions Valve operatorLever operationOptionFlexible graphite packing and gasket.32

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignClass 800 and Type 3000 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Split body design, Socket welding endsPage 10 for Pressure-Temperature RatingsFeaturesAntistatic deviceBlowout-proof stemSocket welding ends toASME B16.11AW800/3000 SCTKStandard materialsNote1. Class 800 ball valves are designed to BS 5351.2. Type 3000 ball valves are designed to KITZstandard for servicing water, oil and gaseousfluid under the maximum working pressure of3000psi. Polychloro-Trifluoro-Ethylene.End-to-end dimensions: KITZ standardDimensions Valve operatorLever operationType 1000 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Three-piece body design, Threaded or socket welding endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemSwing-away body for maintenanceeaseChoice of threaded ends:Rc threads to BS 21 (Fig. SC3TZF)NPT threads to ASME B1.20.1(Fig. AKSC3TZF)Socket welding ends to BS 5351(Fig. SWSC3TZF)Socket welding ends toASME B16.11 (Fig. AWSC3TZF)SC3TZFStandard materials ® End-to-end dimensions: KITZ standardDimensions Valve operatorLever operationOval handle as optionNoteUse SC3TZ for size 2´´.33

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignType 1000 Carbon <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Three-piece body design, Threaded or socket welding endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemSwing-away body for maintenanceeaseChoice of threaded ends:Rc threads to BS 21 (Fig. SC3TZ)NPT threads to ASME B1.20.1(Fig. AKSC3TZ)Socket welding ends to BS 5351(Fig. SWSC3TZ)Socket welding ends toASME B16.11 (Fig. AWSC3TZ)SC3TZStandard materials ® End-to-end dimensions: KITZ standardDimensions Valve operatorLever operationOval handle as optionNoteUse SC3TZF for sizes 1 /4´´ & 3 /8´´.Type 600 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Reduced port, Uni-body design, Threaded endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemChoice of threaded ends:Rc threads to BS 21 (Fig. UTKM)NPT threads to ASME B1.20.1(Fig. AKUTKM)UTKMStandard materialsEnd-to-end dimensions: KITZ standardDimensions Valve operatorLever operationT-type handle as option34

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignType 800 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Split body design, Threaded endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemChoice of threaded ends:Rc threads to BS 21 (Fig. UTHM)NPT threads to ASME B1.20.1(Fig. AKUTHM)UTHMStandard materials End-to-end dimensions: KITZ standardDimensions Valve operatorLever operationType 1000 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body design, Threaded endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemChoice of threaded ends:Rc threads to BS 21 (Fig. UTFM)NPT threads to ASME B1.20.1(Fig. AKUTFM)UTFMStandard materials ® End-to-end dimensions: KITZ standardDimensions Valve operatorLever operation35

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignType 1500/2000 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Split body design, Threaded endsPage 11 for Pressure-Temperature RatingsFeaturesBlowout-proof stemAPI 607 firesafe type as optionNPT threads to ASME B1.20.1AKUTHZMStandard materials ® API 607 firesafe flexible graphite is optionallyavailable.End-to-end dimensions: KITZ standardDimensions Valve operatorLever operation with latch lockOval handle as optionType 1500/2000 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, Welded body design, Threaded endsPage 11 for Pressure-Temperature RatingsFeaturesBlowout-proof stemAPI 607 firesafe type as optionNPT threads to ASME B1.20.1AKUTHWZMStandard materials ® API 607 firesafe flexible graphite is optionallyavailable.End-to-end dimensions: KITZ standardDimensions Valve operatorLever operation with latch lockOval handle as option36

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignType 1000 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, 3-pce body design, Threaded or socket welding endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemSwing-away body for maintenanceeaseChoice of threaded ends:Rc threads to BS 21 (Fig. U3TZFM)NPT threads to ASME B1.20.1(Fig. AKU3TZFM)Socket welding ends to BS 5351(Fig. SWU3TZFM)Socket welding ends toASME B16.11 (Fig. AWU3TZFM)U3TZFMStandard materials ® End-to-end dimensions: KITZ standardDimensions Valve operatorLever operationOval handle as optionNoteUse U3TZM for size 2´´.Type 1000 Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Regular port, 3-pce body design, Threaded or socket welding endsPage 10 for Pressure-Temperature RatingsFeaturesBlowout-proof stemSwing-away body for maintenanceeaseChoice of threaded ends:Rc threads to BS 21 (Fig. U3TZM)NPT threads to ASME B1.20.1(Fig. AKU3TZM)Socket welding ends to BS 5351(Fig. SWU3TZM)Socket welding ends toASME B16.11 (Fig. AWU3TZM)U3TZMStandard materials ® End-to-end dimensions: KITZ standardDimensions Valve operatorLever operationOval handle as optionNoteUse U3TZFM for sizes 1 /4´´ & 3 /8´´.37

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignType 800 Stainless <strong>Steel</strong> 3-way <strong>Ball</strong> <strong>Valves</strong>Regular port, 4-seated, Split body, Threaded endsPage 10 for Pressure-Temperature RatingsL-port and T-portRc threads to BS 21L-portUTH4LM (L-port)UTH4TM (T-port)Standard materialsCCAAForm 1Form 2T-portCCForm 1CBBAAForm 2CBB ® ABForm 3 Form 4ABThis drawing shows L-port design.End-to-end dimensions: KITZ standardDimensions Valve operatorLever operationClass 150, 10K Stainless <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>Full port, Split body, Side entry design, Threaded endsPage 11 for Pressure-Temperature RatingsChoice of threaded ends:Rc threads to BS 21(Fig. 150UTM)NPT threads to ASME B1.20.1(Fig. AK150UTM)AK150UTM, 10UTMStandard materials End-to-end dimensions: KITZ standardWall thickness: ASME B16.34 Class 150Dimensions Valve operatorLever operationNoteJIS 10K type is also available.38

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignDimensions of ISO 5211 Actuator Mounting Padfor Class 150 / 300 Full Port, Split Body, Side Entry Design <strong>Ball</strong> <strong>Valves</strong>DimensionsClassNominalsize(in.)KITZ product codes:(1) 150UTDZ (2) 150SCTDZ(3) 300UTDZ -0.05-0.10A(4) 300SCTDZ(5) 150UTDZXL(6) 300UTDZXL-0.1-0.2B-0.1-0.2E0.2FGKLNote: Dimension of stem head are in accordance with CAPI ADDS 2.02,but the maximum specified dimension in CAPI ADDS 2.02 is “F14”.For NPS 8 and 10, mounting pads are F16/ISO 5211.dM threadTISO 5211FlangeType39

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignDimensions of ISO 5211 Actuator Mounting Padfor Class 150 / 300 Regular Port, Uni-body, End Entry Design <strong>Ball</strong> <strong>Valves</strong>´´´´DimensionsClassNominalsize(in.)0.020.06A0.10.2B0.10.2EE10.2FG H K L L1M threaddUNC thread M1TT1T2ISO 5211flange type UNC threads optionally available.40

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignDimensions of ISO 5211 Actuator Mounting Padfor Class 150 / 300 Regular Port, Uni-body, End Entry Design <strong>Ball</strong> <strong>Valves</strong> ´´´´´´DimensionsClassNominalsize(in.)0.020.07A0.10.2B0.10.2EE10.2FG H K L L1M threaddUNC thread T T1 T2ISO 5211flange type UNC threads optionally available.41

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and Materials ® ® 1 A352 Gr. LCC low-temperature service materials are optionally available.2 CF8M or Type 316 is optionally available for balls & stems.3 Class 150: Bar type handle used for size 6´´ & 8´´.Class 300: Bar type handle used for size 4´´ to 8´´.4 Up to size 1´´.5 A276 Type 304 or equal.6 A276 Type 316 or equal.7 Trim 1H (150/300 SCTDZ 1H)All part numbers are corresponding with thoseshown in valve assembly drawings.Standard material configuration can beapplied to sour service.Illustration shows Size 4 design.42

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and Materials Standard material configuration can beapplied to sour service. ® 1 A352 low-temperature service materials are optionally available.2 CF8M or Type 316 is optionally available for balls & stems.3 Bar type handles are used for 6and larger.4 A276 Type 304 or equal.5 A276 Type 316 or equal.All part numbers are correspondingwith those shown in valveassembly drawings.Illustration shows Size 1 1 /2˝ design.43

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and Materials ® ® 1 CF8M or Type 316 is optionally available for balls & stems.2 Class 150: Bar type handle used for size 6´´ & 8´´.Class 300: Bar type handle used for size 4´´ to 8´´.3 Up to size 11/4´´.4 A276 Type 304 or equal.5 A276 Type 316 or equal.6 Trim 1H (150/300 UTDZ 1H)All part numbers are corresponding with thoseshown in valve assembly drawings.Standard material configuration can beapplied to sour service.Illustration shows Size 4 design.44

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and MaterialsStandard material configuration can beapplied to sour service. ® 1 Bar type handles are used for 6and 8. Worm gear operations are used for 10.2 Packing washers are used only for 1 smaller.3 A276 Type 304 or equal.4 A276 Type 316 or equal.All part numbers are corresponding with those shown in valve assembly drawings.Illustration shows Size 4 design.45

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and Materials 1 Bar type handles are used for 6and larger.2 A276 Type 304 or equal.3 A276 Type 316 or equal.All part numbers are correspondingwith those shown in valveassembly drawings. ® Standard material configuration can beapplied to sour service.Illustration shows Size 1 1 /2˝ design.46

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and Materials 1 A350 low-temperature service materials are optionally available.2 Type 316 and other stainless steels are optionally available for ball & stem.3 These parts are used only for super-firesafe provision.4 A276 Type 304 or equal.5 A276 Type 316 or equal.All part numbers are corresponding with those shown invalve assembly drawings.An optional material configuration isavailable for sour service.Illustration shows Size 1 1 /2 design.47

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and MaterialsStandard material configuration can beapplied to sour service. 1 This parts are used only for super-firesafe provision.2 Other stainless steel are optionally available.3 A276 Type 304 or equal.4 A276 Type 316 or equal.All part numbers are corresponding with those shown in valve assembly drawings.Refer to the illustration on Page 45.48

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and Materials1 A352 low-temperature service materials are optionally available.2 Type 316 is optionally available for ball & stem.3 These parts are used only for super-firesafe provision.4 A276 Type 304 or equal.5 A276 Type 316 or equal.All part numbers are correspondingwith those shownin valve assemblydrawings. An optional material configuration isavailable for sour service.49

KITZ <strong>Steel</strong> <strong>Ball</strong> <strong>Valves</strong>, Floating <strong>Ball</strong> DesignConstruction and Materials Standard material configuration can beapplied to sour service. 1 These parts are used only for super-firesafe provision.2 Other stainless steel are optionally available.3 A276 Type 304 or equal.4 A276 Type 316 or equal.All part numbers are corresponding with those shown in valve assembly drawings.Refer to the illustration on Page 47.50

Technical InformationGeneral PrecautionsFlow Characteristics<strong>Steel</strong> Pipe Flanges51

Technical InformationGeneral Precautions for Trouble-free Operation of Soft-seated <strong>Ball</strong> <strong>Valves</strong>1. Excessive Cavity PressureRefer to Page 15. Very important2. High-Temperature and High-Pressure ServiceThe pressure-temperature ratings published by manufacturersare usually considered an appropriate guide to themaximum temperature and pressure that such ball valvesmay withstand. KITZ recommends, however, reference tothe valve distributor or manufacturer for an assurance ofsuitability when ball valves are to be subjected to the followingconditions:a: Floating ball valves are left closed for a long period of timeunder high temperature or high differential pressure.b: Floating ball valves are operated frequently for long periodof time under high temperature or high differential pressure.c: Floating ball valves are subjected to frequent change ofthe line pressure or service temperature.3. Liquids with High VelocityWhen ball valves must be operated frequently on liquids withvery high velocity, a check should be made with the valvedistributor or manufacturer for appropriate advice to minimizethe possibility of seat deformation, especially whenthey are highly pressurized on high-temperature lines.4. Valve SelectionBe sure to select a valve with design specifications whichmeet the pressure and temperature conditions required.Take special care to select the valve to be used for the fluidcontaining abrasives, since the high molecular materialsemployed in the seats could suffer degradation.5. Valve MountingBefore mounting the valve, the pipe bore should be checkedto confirm that no weld spatter, scale or rust particles remaininside. For mounting flanged valves, diagonally locatedflange bolts should be tightened evenly.6. Degree of Valve Opening<strong>Ball</strong> valves should basically be considered as ON/OFFvalves only and care should be taken to ensure that they arefully closed or open. Opening ball valves partially will resultin seat erosion and cause seat leakage. Pipelines thatrequire the use of ball valves for throttling service should bedesigned in consideration of the amount of the seat leakagewhich may occur in its fully closed position. Note that ballvalves should be stored in a fully open position.7. Valve ActuationThree types of pneumatic valve actuator (KITZ HAS-Series,KITZ B-Series, F-Series) are available for our factorymounting. Also KITZ “KELMO” electric actuators areavailable. Electric actuators or pneumatic actuators of anyother specified brands are also available for our factorymounting.In case of user’s mounting their own actuators on KITZ ballvalves, however, all users are recommended to contactKITZ or its authorized distributors for adequate technicaladvice, because any improper sizing of actuators may causeserious problems in the field. It must be carefully noted thatthe actual value of the operating torque of any given valvemay vary, depending on the service conditions listed below:(1) Fluida. Kind of fluidb. Line pressurec. Line temperatured. Fluid volume(2) Ambient temperature(3) Opening/closing degree(4) Type of actuator(5) Frequency and pattern of change of line pressure(6) Frequency and pattern of change of line and ambienttemperatures8. Valve DisassemblyThe line fiuid should be completely removed from the internalof the valves before they are dismantled from the pipeline formaintenance.Even after the line fluid has been discharged through thepipeline, some fluid is always trapped inside the body andbody cavity (the room surrounded by the body, ball and twoseats).Be sure to completely discharge the pressure trapped in thebody cavity, before valve disassembly.Inspection and WarrantyEach KITZ ball valve is subjected to 100% in-house inspectiondesignated by API 598 or BS 6755 Part 1. This includeshydrostatic shall tests and pneumatic low-pressure seat test.Manufacturer’s material certificates and test reports areavailable upon request. Each KITZ ball valve is guaranteedfor 12 months after placement in service, but not exceeding18 months after shipment from KITZ factories.52

Technical InformationFlow CharacteristicsOne of the best advantages of ball valves is that every flowper any given bore size is larger than other types of valves.Fluid is much less disturbed by eddy currents or pulsation.To obtain the figure of flow per valve opening, simplymultiply the flow rate (%) given here by the correspondingvalue given in the table of Pressure Loss vs. Flow Rate.Flow rate ()100806040Valve opening vs. flow rate20045Opening degree90Pressure Loss vs. Flow RateFull port valveskPa6.91 /2˝ 3 /4˝ 1˝ 1 /2˝ 2˝ 2 1 /2˝ 3˝ 4˝ 5˝ 6˝ 8˝ 10˝psi1.0Pressure loss0.690.010.069 0.011.0 10100 1000 10000 100000Flow in gallons per minute (gpm)Reduced port valveskPa6.91 /2˝ 3/4˝ 1˝ 1 1 /2˝ 2˝ 3˝ 4˝ 6˝ 8˝ 10˝psi1.0Pressure loss0.690.010.069 0.011.0 110 100 1000 10000Flow in gallons per minute (gpm)Schedule 40 steelpipe (10m)kPa6.91 /2˝ 3 /4˝ 1˝ 1 /4˝1 /2˝ 2˝ 2 1 /2˝ 3˝ 4˝ 5˝ 6˝ 8˝ 10˝ 12˝ 16˝18˝ psi1.020˝24˝Pressure loss0.690.010.069 0.011.0 10100 1000 10000 100000Flow in gallons per minute (gpm)53

Technical Information<strong>Steel</strong> Pipe FlangeshtgASME B16.5-1996Class 150 RF, Class 300 RFCDClass 150 steel pipe flange dimensions Class 300 steel pipe flange dimensions 54

Technical Information<strong>Steel</strong> Pipe FlangeshtgCClass 600 RFClass 600 steel pipe flange dimensionsD 55

Technical Information<strong>Steel</strong> Pipe FlangeshthtClass 1500 RFClass 1500 steel pipe flange dimensions ASME B16.47-1996 (Series A)Class 150 steel pipe flange dimensionsClass 300 steel pipe flange dimensionsgCDClass 600 to 1500 Class 150, 300gCD Class 600 steel pipe flange dimensions 56

NOTEIf any products designated as strategic material in the Foreign Exchange and Foreign TradeLaw, Cabinet Order Concerning Control of Export Trade, Cabinet Order Concerning Control ofForeign Exchange and other related laws and ordinances (“Foreign Exchange Laws”) areexported to any foreign country or countries, an export license issued by the JapaneseGovernment will be required under the Foreign Exchange Laws.Further, there may be cases where an export license issued by the government of the UnitedStates or other country will be required under the applicable export-related laws andordinances in such relevant countries.The contract shall become effective subject to that a relevant export license is obtained fromthe Japanese Government.57

E-205= 111112ITP