TXC Brochure version 2 - Taylor Machine Works

TXC Brochure version 2 - Taylor Machine Works

TXC Brochure version 2 - Taylor Machine Works

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

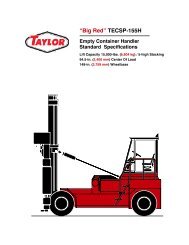

††Truck is shown with available options.Many options are available on <strong>TXC</strong>-976.PRODUCT LINEWHEELBASE & CAPACITIES<strong>TXC</strong>-976236-in. (5,994 mm) WheelbaseRated At 97-in. (2,464 mm) Center Of Load80,000-lbs. (36,288 kg) / 2-high Stacking75,000-lbs. (34,020 kg) / 6-high StackingRated At 106-in. (2,692 mm) Center Of Load75,000-lbs. (34,020 kg) / 2-high Stacking70,000-lbs. (31,752 kg) / 6-high Stacking6-HIGH9FT.-6IN.CONTAINERSLOADED CONTAINER HANDLER

All welded steel chassisdesign for superior strengthThe largest width over tiresin the industry (203”).This allows for greater lateralstability than any of thecompetition.Anti-slip steps and handrails for 3-point mounting anddismounting. (meets new proposed ANSI B56.1 standard)One step mounting to access daily checks and fills.

New Hydraulic System Benefits:Reduces fuel consumption thus increasing savingsAids in the management of engine horsepowerReduces hydraulic system operating temperatureFaster and more accurate hydraulic responseGreater control of hydraulic functionsHydraulic TankLarge 200-gallon capacity hydraulic tank has aspin-on tank breathers, dual wire-mesh strainers,and a full flow, 10-micron, return line filters witha replaceable elements in the tank. Bolt-on tankfor easy removal and cleaning. One step access.Variable Displacement Pump SystemHydraulic system utilizes a converter driven variabledisplacement pumps. Controls valves are separate,stacked and spool type. The tilt lock valve preventsmast drift and reduces torsional stress. Hydraulic oilis cooled through an air/oil cooler remote mountedunder the cab.Brake SystemThe internal force-cooled, wet disc, servicebrakes are oil-actuated and utilize a pedal tocombine transmission declutch and brakes.The parking brake control is mounted on theinstrument panel. The driveline brake is springapplied for parking and oil actuated off.America’s First6-High 9’-6”Mast StyleLoaded ContainerHandler

ENGINE• Tier Certified Cummins turbocharged engine(see specification sheet for engine detail)• 335 gross brake horsepower at 2100 rpm• 1235 ft-lbs of torque at 1400 rpm• Electronic diagnostics on enginewith fault code history for easydiagnostics and repair• Built-in emergencyshutdown system forengine and transmission• All service and dailychecks can bemade easily fromthe runningboards• High capacitycharge air, enginecoolant andtransmissioncooling system• 240-gallon fuel tank capacityfor longer run times between fillsCoolerThe deaeration tank, with asight gauge for checkingcoolant level, providesoptimum engine cooling.Charge air systemFuel/WaterSeparatorFanHigh performance, 12-blade,fan draws air through thecoils more effectively toensure cooler operationwith less dirt and debris.Alternator12 volt with 160 ampTransmission FilterShroudClose fitting fan shroudinsures maximum air flowthrough coolers.Fuel Filter

Drivetrain Features:Tier compliant Cummins turbocharged335 HP engineThree-speed fully reversing, modulated,heavy-duty, Powershift transmission withdeclutch and electric shift controlFingertip full hydrostatic steeringCooling system with wide fin spacing toreduce dirt buildup and provide optimumengine coolingSteer AxleThe high stability, wide stance outboard planetary driveaxle utilizes a hypoid ring gear and pinion. Proven, forcecooled, wet disc brakes. Axle mounted spring-on, oil-offparking brake with brake saver system does not allowoperator to drive through parking brakes. Ten-bar frictiontype rims for easy mounting and dismounting.Engine has a remote mounted fuel coolerunder the cabSteer AxleSingle hydraulic cylinder design with tapered wheel andkingpin bearings is fully sealed and never needs adjusting.Greaseable heavy trunnion mounts with replaceablebearings. Through bolt cylinder mounting. Simple, proven,durable design with links directly to spindle.Electrical SystemThe unit has a 12-volt electrical system. Standardequipment includes a key-type anti-restart ignitionsystem, two 220-amp/hour batteries, 160-ampalternator, main battery disconnect switch and thermalreset circuit breakers. Battery box with a hinged lid iseasily accessible from the ground.Transmission - Dana TC-40The Dana TC-40, three-speed, fully reversing, modulated,Heavy-duty, Powershift transmission has electric declutchand brakes behind the declutch feature as well as anelectric shift control with automatic Powershift control. Theintegrally built torque converter has constant-mesh gearsets actuated by hydraulic clutch packs. The filler pipedipstick and large, heavy-duty oil filter are easilyaccessible. Separate air-to-oil cooler.

Shown with optionalhydraulic pile slopeChain suspended, openframe attachmentfor easier maintenanceExpandable frames to handlecontainers from 20’ to 53’ in lengthTwistlock interlock systemensures correct locking procedureForward activated alarm6-high 9 ft.-6 in. container stacking51 ft.- 6 in. 2-stage telescopic mastDesigned to lift all types of containers andworks with all North American rail cars6-HIGH9FT.-6IN.CONTAINERSDual element air cleanerwith restriction indicatorLarge capacity fuel andhydraulic tanks240-gallon fuel200-gallon hydraulicWidest stance over drive axle in the industrywith proven, force-cooled, wet disc brakes Axlemounted spring-on, oil-off parking brakeAnti-slip steps and railingfor 3-point mounting and dismounting

Carriage mounted slider beam designreduces stress to the attachmentAttachment mounted work lightsfor improved safety and visibilityHeavy-duty lift cylindershave chrome plated rods andself-aligning packingOverhead rear work lights forimproved safety and visibilityHigh mounted tilt cylindersLess rail twisting than lowmount tilt cylinder designs forgreater mast stabilityExcellent visibilityand tinted glassthroughout cabExtra large, shock absorbing andcenter mounted cabwith the most interior cab room in theindustry for more operator comfort andan optional trainer seat is availableTilting cab for optimalviewing of containerwhile stacking 5 and 6 highReverse activated alarmTier compliant Cummins 335HP turbocharged engineWing design doors for easyaccess to engine compartmentRugged high strength, all weldedsteel chassis and frameHeavy-duty, industrial steer axleSimple, proven, durable design singlesteer cylinder with sealed taperedroller bearings throughout and widertrack for greater lateral stabilityServiceable from running boardsEasily accessible batteries

One of the most spacious all steel cabs inthe industry as well as great features10-deg. hydraulically tilted cab<strong>Taylor</strong> Integrated Control System (TICS)Two doors with sliding glassExcellent visibility forward and rearOne circulation fanEasily replaceable glassFront and rear windshield wipersFront windshield washerDoor hold-back latches with trip handlesPanoramic rearview mirrors inside andconvex mirrors outsideCloth air-ride suspension seat40,000 BTU heaterElectric horn rated at 118 DbaDome lightTinted glassSound insulationFloor matsKey-switch actuated amberstrobe lightPremium vinyl or clothadjustable air suspensionseat with arm rests, orangeseat belt, and OPS(operator presence switches)(Rotation 15°- left - 20° - right)Two brake pedalsleft – brakes and inchingright – brakes onlyJoystick control withindividual fingertip hydraulicand electronic controls forsmooth precise control

Fingertip, full hydrostaticsteeringSealed column-mountedelectric roll shiftNeutral LockFingertip, tilt steeringParking break controlEmergency Kill SwitchReset circuit breakers - instead of fusesSerial PortHinge down instrument panelTICS<strong>Taylor</strong> Integrated Control SystemUsing J1939 CANbus TechnologyElectronic diagnosticswith fault code historyfor fast problemidentification.Electronic diagnosticswith built-in shutdownsystem for engine andtransmission.Standard EquipmentNote: Components are subject to change without notice.Tier compliant Cummins Electronic Turbocharged, Charge-Air-After-Cooled (Air to Air) Diesel Engine • 240 Gallon Capacity Heavy Gauge Steel Fuel Tankw/Lockable Fuel Cap and Strainer • 2-Stage Dry-type Air Cleaner w/Safety Element, Restriction Indicator • 12-Volt Electrical System w/160 Amp Alternator •Reset Circuit Breakers • Key-type Anti-restart Ignition System • Tilt Steering • Dual 220 Amp-Hour Batteries • 118dba Electric Horn • Keyswitch-actuatedAmber Strobe Light • Reverse-actuated Backup Alarm • Forward Alarm • Rear View Mirrors • Powershift Transmission - 3-Speed Fully Reversing Modulated,w/Declutch and Electric Shift Control w/ Automatic Powershift Control • Single Hydraulic Cylinder Designed Steer Axle • Wide Stance Outboard PlanetaryDrive Axle with Hypoid Ring Gear and Pinion w/ Wet Disc Brakes • Transmission Mounted, Spring Applied, Oil Actuated Off Parking Brake w/ Brake SaverSystem • Fingertip Full Hydrostatic Steer-On-Demand Steering System • Multi-function Joystick Controls • Center Mount, 2-Door Elevated Operator CabShock Mounted w/Skyview Window • Cloth Covered Air Ride Seat w/Arm Rest and Anti-cinch Orange Operator Restraint • Large 200-gallon capacityHydraulic Tank • Spin-on Tank Breathers with Dual Wire Mesh Strainers and Full Flow 10-Micron Return Filters • ULTRA-VU 2-Stage Mast Standard 51’-6”Lift on <strong>TXC</strong>-976 • Greaseable Mast and Carriage Main Rollers w/ Shielded, Tapered Roller Bearings and Chain Rollers w/ Shielded Tapered Roller BearingsHandles ISO containers 8’ to 8’-6” wide, 8’ to 9’-6” high and 20’ to 53’ long • Twistlock interlock system ensures correct locking procedure • ± 24” side shiftTwistlock work lights and in-cab signal lights • ± 5° hydraulic slewing • 9-in. reach on <strong>TXC</strong>-976 • 3° non-powered pile slope standard • ± 4° degrees hydraulicpile slope optional • See specification sheets for tire information • Support data supplied upon delivery

Carriage MountedSlider Beam51ft.-6in. 2 stage telescopic mastfor 6-high 9ft.-6in. stackingHeavy-DutyCarriage AssemblyOpen FrameI-Beam AttachmentProven mast, carriageand attachment designExpandable frames tohandle containers from20’ to 53’ in lengthBolt-on cap mounting for mastTimken tapered roller bearingsand cast nylon side thrust padsOverhead in cab attachment signal lights

Shown with optionalhydraulic pile slopeChain SuspendedAttachmentPile SlopeSlewingAttachmentFour-point top pick loaded container attachment.Rated Capacity 80,000-lbs.Handles ISO containers 8’ to 8’-6” wide, 8’ to 9’-6”high and 20’ to 53’ long.Twistlock interlock system ensure correct lockingprocedure.Twistlock work lights and overhead in-cab signallights.± 24” side shift.± 5° hydraulic slewing.9-in. reach.3° non-powered pile slope standard.± 4° hydraulic pile slope optional.Mast / CarriageThe 51.5ft ULTRA-VU mast is a telescopic,nested-channel mast with two multiple leaf liftchains and is constructed of high-strengthsteel for minimum weight. Two lifting eyesand bolt-on caps permit safe, easy removal.Carriage side wear pads are adjustable tocompensate for wear.All rollers can be lubricated.The self-aligning, bearing mounted, liftcylinders have chrome plated rods and selfadjustingpacking.ISO, WTP and Side Pin Attachmentis available as an option.America’s First6-High 9’-6”Mast StyleLoaded ContainerHandler

With a complete fabrication shop andwarehouse serving as the master distributioncenter for genuine TAYLOR ® parts, theOperations and Distribution Center of SuddenService, Inc. ® is located at 103 Industrial Park Roadin Philadelphia, Mississippi.The master parts depot ships genuine TAYLOR ® partsnationwide and is a key component in the Sudden Service,Inc. ® dealer network.Warranty - 12 month or 2,000 hours parts andlabor. Optional warranties are available.<strong>Taylor</strong> <strong>Machine</strong> <strong>Works</strong>, Inc.650 North Church Ave.Louisville, MS 39339-2022Phone: (662) 773-3421Fax: (662) 773-9146taylorbigred.comSudden Service, Inc.Corporate Headquarters649 North Church Ave.Louisville, MS 39339-2022Phone: (662) 773-8056Fax: (662) 773-9160DisclaimerBecause of our ongoing commitment to product quality and innovation, we reservethe right, at any time, to discontinue or change specifications, prices, designs,features, models or equipment without incurring obligation.Preliminary 2/28/08