Mathematics for Management Science Notes 05

Mathematics for Management Science Notes 05

Mathematics for Management Science Notes 05

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Mathematics</strong> <strong>for</strong> <strong>Management</strong> <strong>Science</strong> <strong>Notes</strong> <strong>05</strong><br />

prepared by Professor Jenny Baglivo<br />

© Jenny A. Baglivo 2002. All rights reserved.<br />

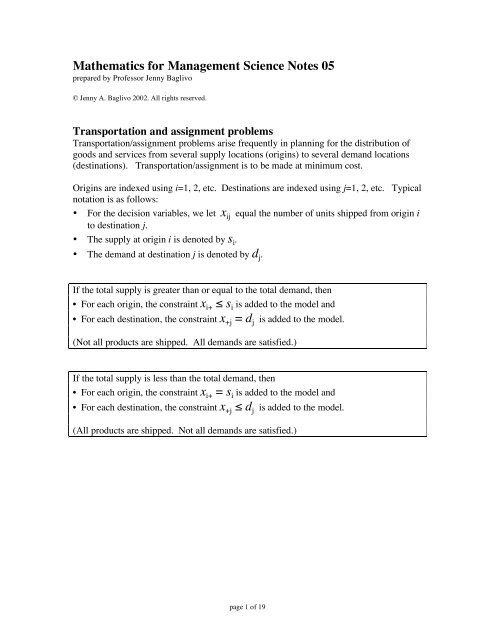

Transportation and assignment problems<br />

Transportation/assignment problems arise frequently in planning <strong>for</strong> the distribution of<br />

goods and services from several supply locations (origins) to several demand locations<br />

(destinations). Transportation/assignment is to be made at minimum cost.<br />

Origins are indexed using i=1, 2, etc. Destinations are indexed using j=1, 2, etc. Typical<br />

notation is as follows:<br />

• For the decision variables, we let x ij equal the number of units shipped from origin i<br />

to destination j.<br />

• The supply at origin i is denoted by s i .<br />

• The demand at destination j is denoted by d j .<br />

If the total supply is greater than or equal to the total demand, then<br />

• For each origin, the constraint x i+ ≤ s i is added to the model and<br />

• For each destination, the constraint x +j = d j is added to the model.<br />

(Not all products are shipped. All demands are satisfied.)<br />

If the total supply is less than the total demand, then<br />

• For each origin, the constraint x i+ = s i is added to the model and<br />

• For each destination, the constraint x +j ≤ d j is added to the model.<br />

(All products are shipped. Not all demands are satisfied.)<br />

page 1 of 19

Exercise 1:<br />

Tropicsun is a leading grower and distributor of fresh citrus products with three large<br />

citrus groves scattered around central Florida in the cities of Mt. Dora, Eustis, and<br />

Clermont. Tropicsun currently has 275,000 bushels of citrus at the grove in Mt. Dora,<br />

400,000 bushels at the grove in Eustis, and 300,000 at the grove in Clermont.<br />

Tropicsun has citrus processing plants in Ocala, Orlando, and Lessburg with processing<br />

capacities to handle 200,000, 600,000, and 225,000 bushels, respectively. Tropicsun<br />

contracts with a local trucking company to transport its fruit from the groves to the<br />

processing plants. The trucking company charges a flat rate <strong>for</strong> every mile that each<br />

bushel of fruit must be transported. Each mile a bushel of fruit travels is known as a<br />

bushel-mile. The following table summarizes the distances (in miles) between the groves<br />

and processing plants:<br />

to Ocala to Orlando to Leesburg<br />

from Mt. Dora 21 50 40<br />

from Eustis 35 30 22<br />

from Clermont 55 20 25<br />

Tropicsun wants to determine how many bushels to ship from each grove to each<br />

processing plant in order to minimize the total number of bushel-miles.<br />

Note: The problem can be visualized using a transportation network, where each source and<br />

destination is represented as a node, and each route from source to destination as a link.<br />

Mt Dora<br />

page 2 of 19<br />

Ocala<br />

Eustis Orlando<br />

Clermont<br />

Leesburg

• Define the decision variables precisely<br />

• Completely specify the LP model<br />

page 3 of 19

• Clearly state the optimal solution.<br />

• How would the total cost change if Leesburg could only process 200,000 bushels?<br />

• Interpret the reduced cost <strong>for</strong> shipping from Eustis to Ocala.<br />

page 4 of 19

Exercise 1 solution sheet:<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

A B C D E F G H<br />

Tropicsun<br />

Distance (miles)<br />

to Ocala to Orlando to Leesburg Supply:<br />

from Mt. Dora 21 50 40 275000<br />

from Eustis 35 30 22 400000<br />

from Clermont 55 20 25 300000<br />

M O D E L<br />

Capacity: 200000 600000 225000<br />

Minimize Total<br />

B u s h e l - M i l e s 24000000<br />

Decision Variables<br />

to Ocala to Orlando to Leesburg L H S R H S<br />

from Mt. Dora 200000 0 75000 275000 = 275000<br />

from Eustis 0 250000 150000 400000 = 400000<br />

from Clermont 0 300000 0 300000 = 300000<br />

L H S 200000 550000 225000<br />

Sensitivity and <strong>for</strong>mulas sheets:<br />

Adjustable Cells<br />

F i n a l Reduced O b j e c t i v e A l l o w a b l e A l l o w a b l e<br />

C e l l N a m e V a l u e C o s t C o e f f i c i e n t I n c r e a s e D e c r e a s e<br />

$B$18 from Mt. Dora to Ocala 200000 0 21 27 1E+30<br />

$C$18 from Mt. Dora to Orlando 0 2 50 1E+30 2<br />

$D$18 from Mt. Dora to Leesburg 75000 0 40 2 27<br />

$B$19 from Eustis to Ocala 0 32 35 1E+30 32<br />

$C$19 from Eustis to Orlando 250000 0 30 2 8<br />

$D$19 from Eustis to Leesburg 150000 0 22 8 2<br />

$B$20 from Clermont to Ocala 0 62 55 1E+30 62<br />

$C$20 from Clermont to Orlando 300000 0 20 13 1E+30<br />

$D$20 from Clermont to Leesburg 0 13 25 1E+30 13<br />

Constraints<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

F i n a l S h a d o w C o n s t r a i n t A l l o w a b l e A l l o w a b l e<br />

C e l l N a m e V a l u e P r i c e R.H. Side I n c r e a s e D e c r e a s e<br />

$F$18 from Mt. Dora LHS 275000 48 275000 50000 75000<br />

$F$19 from Eustis LHS 400000 30 400000 50000 250000<br />

$F$20 from Clermont LHS 300000 20 300000 50000 300000<br />

$B$22 LHS to Ocala 200000 -27 200000 75000 50000<br />

$C$22 LHS to Orlando 550000 0 600000 1E+30 50000<br />

$D$22 LHS to Leesburg 225000 - 8 225000 250000 50000<br />

A B C D E F G H<br />

T r o p i c s u n<br />

to Ocala<br />

Distance (miles)<br />

to Orlando to Leesburg Supply:<br />

from Mt. Dora 21 50 40 275000<br />

from Eustis 35 30 22 400000<br />

from Clermont 55 20 25 300000<br />

M O D E L<br />

Capacity: 200000 600000 225000<br />

Minimize Total<br />

B u s h e l - M i l e s =SUMPRODUCT(B5:D7,B18:D20)<br />

Decision Variables<br />

to Ocala to Orlando to Leesburg L H S R H S<br />

from Mt. Dora 0 0 0 =SUM(B18:D18) = =F5<br />

from Eustis 0 0 0 =SUM(B19:D19) = =F6<br />

from Clermont 0 0 0 =SUM(B20:D20) = =F7<br />

L H S =SUM(B18:B20) =SUM(C18:C20) =SUM(D18:D20)<br />

Assignment problems are special cases of transportation problems where s i = d j = 1.<br />

Exercise 2:<br />

Fowle Marketing Research Company has just received requests <strong>for</strong> market research<br />

studies from three new clients. The company faces the task of assigning a project leader<br />

to each client. Currently, four individuals have no other commitments and are available<br />

<strong>for</strong> the project leader assignments. Fowle’s management realizes, however, that the time<br />

required to complete each study will depend on the experience and ability of the project<br />

leader assigned. Estimated project completion times in days are given in the following<br />

table:<br />

Project Leader: Client 1 Client 2 Client 3<br />

1: Terry 10 15 9<br />

2: Carle 9 18 5<br />

3: McClymonds 6 14 3<br />

4: Higley 8 16 6<br />

The three projects have approximately the same priority, and the company wants to<br />

assign project leaders to minimize the total number of days required to complete all three<br />

projects. If a project leader is to be assigned to one client only, what assignments should<br />

be made?<br />

This problem could be solved by enumerating all 24 possible assignments of three of the<br />

four project leaders to the clients.<br />

page 7 of 19

• Define the decision variables precisely<br />

• Completely specify the LP model<br />

• Clearly state the optimal solution<br />

page 8 of 19

Solution and sensitivity sheets:<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

A B C D E F G H<br />

Fowle Marketing<br />

Completion Time (days)<br />

to Client 1 to Client 2 to Client 3<br />

Terry assigned 10 15 9<br />

Carle assigned 9 18 5<br />

McClymonds assigned 6 14 3<br />

Higley assigned 8 16 6<br />

M O D E L<br />

Minimize Total<br />

Completion Time: 26<br />

Decision Variables<br />

to Client 1 to Client 2 to Client 3 L H S R H S<br />

Terry assigned 0 1 0 1

Transshipment problems:<br />

Transshipment problems have the same basic goals as transportation problems (in<br />

particular, there is a need to ship goods from origins to destinations at minimum cost),<br />

but<br />

• Goods may travel from a source through an intermediate location (known as a<br />

transshipment node) to a destination,<br />

• Some destinations may also serve as transshipment points to other destinations,<br />

• etcetera.<br />

The locations (sources, destinations, and transshipment points) are visualized as nodes in<br />

a network, and are numbered consecutively. If nodes i and j are connected by a direct<br />

route in the network (a link), then the decision variable x ij is used to represent the number<br />

of items shipped from node i to node j. For example, if a company has<br />

1. two plants (sources),<br />

2. a warehouse (serving as a pure transshipment point), and<br />

3. two retail outlets (destinations),<br />

a transportation network could look like the following:<br />

1: Plant 1 4: Outlet 1<br />

2: Plant 2 5: Outlet 2<br />

3: Warehouse<br />

The links correspond to (i, j) equal to (1,3), (1,4), (1,5), (2,3), (2,4), (2,5), (3,4), (3,5).<br />

page 10 of 19

For each node in the network, there is a flow constraint, where the left and right hand<br />

sides are as follows:<br />

(1) LHS = OUTFLOW – INFLOW<br />

(2) RHS = supply with a plus sign or demand with a negative sign or zero if it is a<br />

pure transshipment node.<br />

The outflow corresponds to the number of units leaving a given node. The inflow<br />

corresponds to the number of units entering a given node.<br />

You can use the same relational symbol ( = , ≤ , ≥ ) <strong>for</strong> all flow constraints:<br />

Total Supply = Total Demand LHS = RHS<br />

Total Supply > Total Demand LHS ≤ RHS<br />

Total Supply < Total Demand LHS ≥ RHS<br />

Exercise 3:<br />

A company has two plants (at nodes 1 and 2), one regional warehouse (at node 3), and<br />

two retail outlets (at nodes 4 and 5). In the next production cycle:<br />

1. Plants 1 and 2 can produce 400 and 600 units of product, respectively,<br />

2. Outlets 1 and 2 have a demand <strong>for</strong> 750 and 250 units of product, respectively, and<br />

3. The costs <strong>for</strong> shipping each unit of the product are as follows:<br />

From1 to 3 $4 From 2 to 4 $9<br />

From 1 to 4 $10 From 2 to 5 $6<br />

From 1 to 5 $8 From 3 to 4 $2<br />

From 2 to 3 $4 From 3 to 5 $3<br />

At most 500 units can be shipped between the warehouse and the outlet at node 4.<br />

The company wants to determine the least costly way to ship the units.<br />

page 11 of 19

• Construct the transshipment network, including supplies and demands (with appropriate signs),<br />

and costs along each route.<br />

• Define the decision variables precisely<br />

• Completely specify the LP model<br />

page 12 of 19

• Clearly state the optimal solution<br />

• Interpret the shadow price and range of feasibility <strong>for</strong> the last constraint.<br />

page 13 of 19

Exercise 3 solution sheet:<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

A B C D E F<br />

Company with<br />

W a r e h o u s e<br />

Supply(+)/<br />

Nodes: Demand(-)<br />

1: Plant 1 400 Warehouse Max<br />

2: Plant 2 600 to Outlet 1: 500<br />

3: Whs 0<br />

4: Outlet 1 -750<br />

5: Outlet 2 -250<br />

D e c i s i o n<br />

V a r i a b l e s :<br />

Unit Cost #Units<br />

1 to 3 4 400<br />

1 to 4 10 0<br />

1 to 5 8 0<br />

2 to 3 4 100<br />

2 to 4 9 250<br />

2 to 5 6 250<br />

3 to 4 2 500<br />

3 to 5 3 0<br />

M i n i m i z e<br />

Total Cost: 6750<br />

Subject to<br />

Outflow Inflow L H S R H S<br />

Node 1 flow 400 400 = 400<br />

Node 2 flow 600 600 = 600<br />

Node 3 flow 500 500 0 = 0<br />

Node 4 flow 750 -750 = -750<br />

Node 5 flow 250 -250 = -250<br />

Whs to Outlet 1 500

Sensitivity and <strong>for</strong>mulas sheets:<br />

Adjustable Cells<br />

F i n a l Reduced O b j e c t i v e A l l o w a b l e A l l o w a b l e<br />

C e l l N a m e V a l u e C o s t C o e f f i c i e n t I n c r e a s e D e c r e a s e<br />

$D$14 1 to 3 #Units 400 0 4 1 1E+30<br />

$D$15 1 to 4 #Units 0 1 10 1E+30 1<br />

$D$16 1 to 5 #Units 0 2 8 1E+30 2<br />

$D$17 2 to 3 #Units 100 0 4 3 1<br />

$D$18 2 to 4 #Units 250 0 9 1 3<br />

$D$19 2 to 5 #Units 250 0 6 1 1E+30<br />

$D$20 3 to 4 #Units 500 0 2 3 1E+30<br />

$D$21 3 to 5 #Units 0 1 3 1E+30 1<br />

Constraints<br />

F i n a l S h a d o w C o n s t r a i n t A l l o w a b l e A l l o w a b l e<br />

C e l l N a m e V a l u e P r i c e R.H. Side I n c r e a s e D e c r e a s e<br />

$D$28 Node 1 flow LHS 400 0 400 100 0<br />

$D$29 Node 2 flow LHS 600 0 600 0 1E+30<br />

$D$30 Node 3 flow LHS 0 - 4 0 100 0<br />

$D$31 Node 4 flow LHS -750 - 9 -750 250 0<br />

$D$32 Node 5 flow LHS -250 - 6 -250 250 0<br />

$D$34 Whs to Outlet 1 LHS 500 - 3 500 0 100<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

A B C D E F<br />

Company with<br />

W a r e h o u s e<br />

Supply(+)/<br />

Nodes: Demand(-)<br />

1: Plant 1 400 Warehouse Max<br />

2: Plant 2 600 to Outlet 1: 500<br />

3: Whs 0<br />

4: Outlet 1 -750<br />

5: Outlet 2 -250<br />

D e c i s i o n<br />

V a r i a b l e s :<br />

Unit Cost #Units<br />

1 to 3 4 400<br />

1 to 4 10 0<br />

1 to 5 8 0<br />

2 to 3 4 100<br />

2 to 4 9 250<br />

2 to 5 6 250<br />

3 to 4 2 500<br />

3 to 5 3 0<br />

M i n i m i z e<br />

Total Cost: =SUMPRODUCT(B14:B21,D14:D21)<br />

Subject to<br />

Outflow Inflow L H S R H S<br />

Node 1 flow =SUM(D14:D16) =B28-C28 = =B5<br />

Node 2 flow =SUM(D17:D19) =B29-C29 = =B6<br />

Node 3 flow =SUM(D20:D21) =D14+D17 =B30-C30 = =B7<br />

Node 4 flow =D15+D18+D20 =B31-C31 = =B8<br />

Node 5 flow =D16+D19+D21 =B32-C32 = =B9<br />

Whs to Outlet 1 =D20

Exercise 4:<br />

The Bavarian Motor Company (BMC) manufactures expensive luxury cars in Hamburg,<br />

Germany, and exports cars to sell in the United States. The exported cars are shipped from<br />

Hamburg to ports in Newark, New Jersey, and Jacksonville, Florida. From these ports, the<br />

cars are transported by rail or truck to distributors located in Boston, Columbus, Atlanta,<br />

Richmond, and Mobile.<br />

1. There are 200 cars in Newark and 300 in Jacksonville.<br />

2. The numbers of cars needed in Boston, Columbus, Richmond, Atlanta, and Mobile are<br />

100, 60, 80, 170, and 70, respectively.<br />

3. Per car shipping costs are as follows (see the graph <strong>for</strong> numbering):<br />

From 1 to 2 $30 From 5 to 6 $35<br />

From 1 to 4 $40 From 6 to 5 $25<br />

From 2 to 3 $50 From 7 to 4 $50<br />

From 3 to 5 $35 From 7 to 5 $45<br />

From 5 to 3 $40 From 7 to 6 $50<br />

From 5 to 4 $30<br />

BMC would like to determine the least costly way of transporting the cars from the ports<br />

to the locations where they are needed.<br />

• Complete the following transshipment network by filling in the supplies and demands (with<br />

appropriate signs) and the unit costs along each link.<br />

2: Boston<br />

3: Columbus 1: Newark<br />

5: Atlanta 4: Richmond<br />

6: Mobile 7: Jacksonville<br />

page 16 of 19

• Define the decision variables precisely<br />

• Completely specify the LP model<br />

page 17 of 19

• Clearly state the optimal solution.<br />

• Interpret the shadow price of the first constraint, and its range of feasibility.<br />

page 18 of 19

Exercise 4 solution and sensitivity reports:<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

A B C D E F<br />

Bavarian<br />

Motor Works<br />

Supply(+)/ Decision<br />

Demand(-) V a r i a b l e s :<br />

City 1 200 Unit Cost: #Cars<br />

City 2 -100 1 to 2 30 120<br />

City 3 -60 1 to 4 40 80<br />

City 4 -80 2 to 3 50 20<br />

City 5 -170 3 to 5 35 0<br />

City 6 -70 5 to 3 40 40<br />

City 7 300 5 to 4 30 0<br />

5 to 6 35 0<br />

6 to 5 25 0<br />

7 to 4 50 0<br />

7 to 5 45 210<br />

7 to 6 50 70<br />

M i n i m i z e<br />

Total Cost: 22350<br />

Subject to<br />

Outflow Inflow L H S R H S<br />

City 1 flow 200 200