ELGEF Plus - Plastic Systems

ELGEF Plus - Plastic Systems

ELGEF Plus - Plastic Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

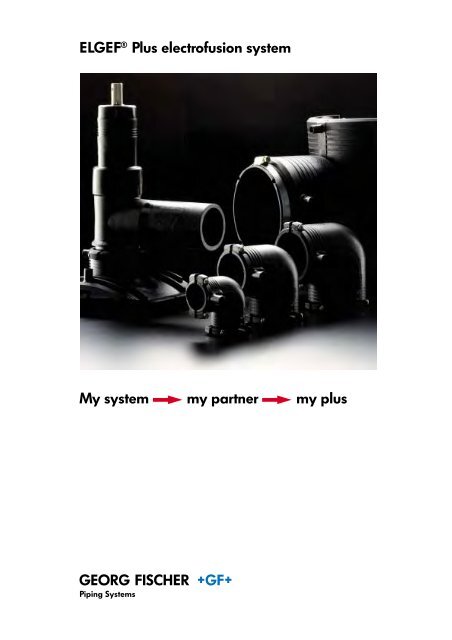

<strong>ELGEF</strong> ® <strong>Plus</strong> electrofusion system<br />

My system my partner my plus<br />

¥ ‡<br />

Piping <strong>Systems</strong>

<strong>ELGEF</strong> <strong>Plus</strong><br />

is the electrofusion<br />

system for pressurised<br />

piping systems from<br />

Georg Fischer.<br />

Convincing due to its<br />

pioneering modular<br />

concept.<br />

2<br />

<strong>ELGEF</strong> <strong>Plus</strong> showing the way<br />

So a decision has been made to use<br />

plastics for the piping system? Then<br />

without doubt our complete polyethylene<br />

system provides the perfect choice!<br />

Each single part has been developed to<br />

mix and match effectively and convincingly<br />

with all other system components.<br />

Whether for gas, water or other pressurised<br />

piping, above or below ground –<br />

<strong>ELGEF</strong> <strong>Plus</strong> is the exact answer.<br />

The unique versatility of our fittings and<br />

saddles has made us the worlds leading<br />

supplier of plastic piping systems.<br />

Our far-reaching and applications-led<br />

assortment of components includes, in<br />

addition to the modular electrofusion<br />

system, a comprehensive range of<br />

spigot end fittings. We provide marketoriented<br />

solutions utilising high quality<br />

products.<br />

¥ ‡

<strong>ELGEF</strong> <strong>Plus</strong> – the system with added value<br />

The strength of <strong>ELGEF</strong> <strong>Plus</strong> lays in its<br />

modular concept. Each individual fitting<br />

and saddle is made to match and when<br />

put together form reliable leak-proof<br />

connections.<br />

Outstanding customising possibilities<br />

with <strong>ELGEF</strong> <strong>Plus</strong> together with its wide<br />

flexibility produce convincing and<br />

decisive customer benefits.<br />

Many different end combinations can be<br />

devised using just a few products.<br />

¥ ‡<br />

Another hallmark of the <strong>ELGEF</strong> <strong>Plus</strong><br />

modular concept is its limited stock<br />

requirement.<br />

As only a small number of fittings and<br />

saddles constitute the system, warehouse<br />

costs are low. This attractive feature<br />

reflects most positively on associated<br />

expenses.<br />

If necessary, installation engineers can<br />

create their own tailor-made solutions<br />

on-site – quickly and with full flexibility.<br />

<strong>ELGEF</strong> <strong>Plus</strong><br />

Everything is made<br />

to match.<br />

3

<strong>ELGEF</strong> <strong>Plus</strong><br />

electrofusion couplers<br />

join all PE pressure<br />

pipes and spigot<br />

fittings quickly and<br />

reliably.<br />

A new design for electro-<br />

1 fusion couplers in the<br />

medium size ranges<br />

Electrofusion couplers<br />

2 for large diameter<br />

pipes<br />

Electrofusion couplers<br />

3<br />

with integrated clamps<br />

for sizes up to d63 mm<br />

4<br />

<strong>ELGEF</strong> <strong>Plus</strong> electrofusion coupler the safe conn<br />

1<br />

Your system<br />

<strong>ELGEF</strong> <strong>Plus</strong> electrofusion couplers are<br />

available in the size range from d20 to<br />

d500 mm.<br />

Couplers are grouped into various size<br />

ranges. In this way, individual requirements<br />

can be satisfied according to size<br />

considerations.<br />

In the smaller sizes a coupler is available<br />

which especially fulfils service line conditions.<br />

Couplers up to d63 mm can be<br />

easily matched with all Georg Fischer<br />

threaded transition adapters.<br />

The pipe-in-pipe technology used for<br />

large couplers compensates for large<br />

differences in pipe outside diameter<br />

tolerances. The possible large clearance<br />

fit permits an easy assembly and can<br />

accommodate the pipe ovality often<br />

found in practice.<br />

The optimised use of material during<br />

the manufacture of the couplers has a<br />

decisive and important environmental<br />

advantage.

ection<br />

2<br />

What is gained!<br />

A covered coil winding design prevents<br />

any contact between medium and resistance<br />

wire. Therefore, the entire piping<br />

system has identical surface properties<br />

throughout. The coupler design concept<br />

provides an installation-friendly assembly.<br />

Large inside diameter, easy-to-hold<br />

form as well as integrated clamps. Latest<br />

requirements have been closely considered<br />

when planning each size range.<br />

An even distribution of thermal penetration<br />

over the entire fusion zone is assured<br />

by the dynamic pitch technology of the<br />

heating coil.<br />

3<br />

Your benefits<br />

Easy assembly due to the tapered socket mouth<br />

Each electrofusion socket has a smooth inside<br />

surface with a protected resistance wire permitting<br />

a thorough and simple removal of possible<br />

on-site contamination<br />

The dynamic pitch of the heating coil results in<br />

optimum joint quality<br />

Clear identification with large and easily understandable<br />

product marking<br />

Large and effective fusion area for full safety<br />

Integrated clamps up to d63 mm for fast and<br />

safe jointing<br />

Removable centre stop up to d¢60 mm – a coupler<br />

for all applications<br />

5

<strong>ELGEF</strong> electrofusion<br />

fittings convincingly<br />

satisfy all demands<br />

with their attractive<br />

practical advantages<br />

and ease-of-assembly.<br />

They can be used<br />

without any reservation<br />

together with any<br />

other <strong>ELGEF</strong> <strong>Plus</strong><br />

modular product.<br />

6<br />

<strong>ELGEF</strong> <strong>Plus</strong> electrofusion fittings<br />

2<br />

Your system<br />

The electrofusion fitting programme is<br />

unique for two reasons. Firstly, due to<br />

the complete range of elbows, tees,<br />

reducers and end caps extending from<br />

d20 to d250 mm. Secondly, because<br />

of the unlimited possibilities offered<br />

when combining such fittings in the sizes<br />

d20 to d63 mm with modular transition<br />

adapters. On top of this, the harmonised<br />

design of the complete range of fittings<br />

easily meets the demanding requirements<br />

of the user.<br />

1<br />

3<br />

the attractive<br />

Directional control<br />

The advantages of using electrofusion<br />

fittings are now offered up to d250 mm.<br />

From the wrapping directly onto the<br />

prepared pipe end. One fitting, one joint<br />

and the direction can be reset. On-site<br />

cleaning becomes unnecessary due to<br />

the care and attention taken during<br />

manufacture and the sealed packaging<br />

used for all fittings.<br />

A complete installation in the sizes<br />

between d20 and d63 mm can be easily<br />

pre-assembled without any difficulty<br />

using the integrated clamps. The jointing<br />

procedure is then completed when everything<br />

is in its final position. The threaded<br />

adapters are screwed into position<br />

and then the direction chosen using the<br />

fitting. This is a crucial advantage in<br />

difficult conditions.<br />

¥ ‡

partner<br />

Your benefits<br />

Single source supplier – complete range<br />

even up to the very largest dimensions<br />

Extensive variety of combination possibilities<br />

and ease-of-assembly with the<br />

modular transition adapters<br />

Easy user-friendly pre-assembly due to<br />

integrated clamps up to d63 mm<br />

Highly automated manufacturing and<br />

process technology for flawless products<br />

Tees may be connected using couplers<br />

or reducers<br />

¥ ‡<br />

1<br />

2<br />

3<br />

Design of small and medium size<br />

ranges<br />

Upon request supplied in kit form.<br />

The third electrofusion outlet<br />

90° elbow as an example of extensive<br />

assortment<br />

7

<strong>ELGEF</strong> <strong>Plus</strong> branch fitting<br />

<strong>ELGEF</strong> <strong>Plus</strong> branch<br />

fitting – the userfriendly<br />

solution for<br />

new installations<br />

or network extensions<br />

in gas and water<br />

distribution systems.<br />

For non-pressure<br />

applications – simply<br />

use a normal drill.<br />

1<br />

2<br />

1 Cutter<br />

2<br />

3<br />

8<br />

Different connection<br />

possibilities<br />

Tapping tool<br />

Sub-assemblies<br />

4 can be easily<br />

prepared in advance<br />

Branch fittings<br />

5 for user-friendly<br />

solutions<br />

6<br />

Unlimited possibilities<br />

The <strong>ELGEF</strong> <strong>Plus</strong> branch fitting offers a<br />

user-friendly solution for new installations<br />

or network extensions.<br />

Whether new installation, subsequent<br />

tie-in of mains or service line, hydrant<br />

connection, rehabilitation or repair<br />

work – our branch fittings are faster and<br />

easier to use than standard tees.<br />

Branch fittings provide considerable<br />

savings with respect to material<br />

and overall costs.<br />

3<br />

Why is this?<br />

To begin with coiled pipes are laid without<br />

any disruption. Then the branch<br />

fitting is mounted and the connection for<br />

the non-pressure or pressurised pipe<br />

completed. At the same time, the electrofusion<br />

outlet simplifies the workload<br />

considerably. As a result, the system<br />

offers maximum flexibility and economyof-use.<br />

Naturally, all of this has a minimising<br />

effect on total time consumed as<br />

well as final costs.<br />

Save time and money –<br />

with <strong>ELGEF</strong> <strong>Plus</strong> branch fittings.<br />

Tooling<br />

The tapping tool is suitable for working<br />

pressures of up to 16 bar water or<br />

10 bar gas.<br />

The various flange or sleeve adapters for<br />

spigot ends produce a flexible, modular<br />

tool for polyethylene piping systems.<br />

The extensive range of adapters and<br />

cutters enables the tapping tool to be<br />

used on steel as well as cast-iron pipes<br />

and also with standard cutters.<br />

¥ ‡

5<br />

Your benefits<br />

Branch fittings can be installed and tapped through<br />

under live mains conditions. In other words, the main<br />

line must not be shut-down or by-passed as when using<br />

tees<br />

Less fittings required resulting in savings with material<br />

costs<br />

Minimal installation costs due to easy and fast working<br />

practices<br />

Conventional tapping procedures, the use of existing<br />

tooling is possible<br />

Integrated clamp for the branch outlet<br />

¥ ‡<br />

4<br />

the flexible solution<br />

6<br />

9

<strong>ELGEF</strong> <strong>Plus</strong> modular<br />

saddles offer the ideal<br />

connection for all<br />

purposes.<br />

Greater possibilities,<br />

increased flexibility, less<br />

stock – a contradiction?<br />

Not with the <strong>ELGEF</strong> <strong>Plus</strong><br />

modular system.<br />

10<br />

<strong>ELGEF</strong> <strong>Plus</strong> Saddles the convincing variations<br />

Your system<br />

<strong>ELGEF</strong> <strong>Plus</strong> modular saddles comprise a<br />

complete product package – tapping<br />

saddles, tapping saddles with Gas-Stop,<br />

under-pressure tapping valves, stop-off<br />

saddles, repair saddles and spigot<br />

saddles. A complete modular system.<br />

There is also the branch fitting – also<br />

termed saddle – as the active heart of<br />

our modular system. All requirements are<br />

covered with just a few components.<br />

Your application<br />

When extending or replacing existing<br />

distribution networks maximum flexibility<br />

can be assured with the use of our<br />

<strong>ELGEF</strong> <strong>Plus</strong> modular saddles.<br />

The saddles can be used equally well<br />

for water distribution networks up to 16<br />

bar or for gas distribution purposes up<br />

to 10 bar working pressure as well as for<br />

1<br />

a large variety of industrial applications.<br />

A complete saddle connection can be<br />

completed at full working pressure or<br />

under non-pressure conditions.<br />

¥ ‡

All saddle sizes from d40 to d250 mm are supplied with bottom<br />

saddle to ease assembly.<br />

1<br />

The branch saddle as heart<br />

of the modular system<br />

Your benefits<br />

Complete system contains limited parts<br />

Reduced stock volume with savings of up to 50%<br />

360° rotation of outlet permits infinitely variable<br />

positioning and wide freedom of movement during<br />

assembly<br />

Vertical or horizontal fixation possible – exactly as site<br />

conditions dictate<br />

Easy, flexible and fast attachment, therefore, substantially<br />

lower costs<br />

¥ ‡ 11

The <strong>ELGEF</strong> <strong>Plus</strong> transition<br />

range offers many<br />

practical solutions with<br />

just a few components.<br />

<strong>ELGEF</strong> <strong>Plus</strong> transition adapters<br />

Your system<br />

The unique <strong>ELGEF</strong> <strong>Plus</strong> modular range of<br />

transition fittings permits wide product<br />

utilisation but is, nevertheless, limited to<br />

just a few component parts:<br />

Transition couplers, 45° and 90° transition<br />

elbows, transition tees and transition<br />

reducers. All bodies are available either<br />

in brass or stainless steel with male or<br />

female threads and also with a loose<br />

collar. Therefore, one can pre-decide<br />

which fitting and transition should taken<br />

from stock and be combined together<br />

for particular on-site applications.<br />

Of course, each individual fitting and<br />

transition combination is available as<br />

a separate kit.<br />

12 ¥ ‡<br />

1<br />

the unlimited c

onnections<br />

2<br />

Your application<br />

All components that enable a transition<br />

from metal to polyethylene pipes to<br />

be made form a very important part of<br />

any gas and water distribution network.<br />

They are frequently used as tie-ins for<br />

polyethylene piping in existing systems.<br />

Also for repair work. Additionally, water<br />

meters can also be installed in an uncomplicated<br />

and reliable manner using<br />

such transitions.<br />

The <strong>ELGEF</strong> <strong>Plus</strong> rotating transition enable<br />

pumps and metal flow control valves to<br />

be connected easily and without complication<br />

to fixed line components even<br />

under difficult on-site conditions.<br />

¥ ‡<br />

Your benefits<br />

Modular concept – diverse – only a few parts<br />

Matching, fully interchangeable fittings and<br />

transitions<br />

Low costs due to minimised stock volume<br />

Brass and stainless steel transition adapters are<br />

available<br />

Rotating transition adapters provide easy<br />

installation<br />

1<br />

Transition coupler<br />

Transition fittings<br />

2 (90° and 45° elbows,<br />

90° tees and reducers)<br />

13

The range of MSA<br />

control units offers<br />

ideal on-site technology<br />

for all installers,<br />

utilities or system<br />

operators.<br />

Our MSA control units<br />

offer comprehensive<br />

solutions from joint<br />

data recording to the<br />

highly-sophisticated<br />

Pipe-Win-Weld computing<br />

software.<br />

14<br />

2<br />

3<br />

MSA fusion control units the reliable partners<br />

1<br />

Your MSA control units<br />

Complex demands with respect to<br />

today’s electrofusion technology for gas<br />

and water distribution networks are<br />

entirely fulfilled by MSA control units.<br />

These units are valued because of their<br />

user-friendliness, easy handling and<br />

especially their performance. For each<br />

application, whether MSA 200, 250,<br />

300, 350 or 400, one can choose exactly<br />

which unit is needed – no more, no less.<br />

Robust cast aluminium housing, close<br />

attention to quality during manufacture,<br />

careful selection of components, low<br />

overall weight and latest technology –<br />

are offered by all of these control units.<br />

Your application<br />

MSA 200: A 40 volt version which is<br />

limited to just what is absolutely necessary.<br />

Manual input of fusion time. An<br />

ideal unit for price-conscious companies.<br />

MSA 250: This control unit is a complete<br />

all-rounder. Fusion data input either<br />

by barcode reader pen or, as an alternative,<br />

manually. The menu guide is<br />

straight forward and language-free.<br />

The in-built high frequency transformer<br />

reaches top output even at poor generator<br />

performance levels. Simple and<br />

strong. The 11.5 kg light-weight partner<br />

for daily use.<br />

MSA 300: In addition to the functions of<br />

the MSA 250, this unit contains a 24<br />

language menu guide. This reliable control<br />

unit is in daily use from China to<br />

Chile. It bridges-over on-site multi-cultural<br />

language barriers and oversees each<br />

joint safely and reliably. The unit indicates<br />

status and any possible faults as<br />

a visible text and supports an efficient<br />

work flow on site.<br />

MSA 350: The unit with a fusion data<br />

recording option. In gas distribution<br />

circles, fusion data recording forms an<br />

important milestone towards successful<br />

co-operation between installer and net-

4<br />

work operator. In addition to the functions<br />

of the MSA 300, the MSA 350 has<br />

a memory storage capability for 800<br />

fusion records. The Pipe-Win-Weld<br />

software provides active support for the<br />

evaluation of all data and with the configuration<br />

of the unit. Barcodes can be<br />

created to control procedures, limit operator<br />

access and allocate individual<br />

order numbers on the retrievable data.<br />

A choice can also be made to pre-set<br />

and optimise all process functions either<br />

on-site or beforehand in the comfort of<br />

an office.<br />

MSA 400: This unit combines all the<br />

features of the MSA 350 but also<br />

provides full traceability for all associated<br />

pipeline components. In the future,<br />

traceability of on-site process procedures<br />

and all components will play an<br />

important part in the cooperation between<br />

manufacturer, installer and operator.<br />

Regulations will also cover the limitation<br />

of unit usage to qualified personnel,<br />

require continuous data recording<br />

and management as well as more innovative<br />

solutions in control unit technology.<br />

Already the MSA 400 electrofusion<br />

control unit with traceability function, in<br />

co-operation with the matching Pipe-<br />

Win-Weld operational software, provides<br />

a complete solution for the management<br />

of these tasks. Configure all<br />

operating procedures according to individual<br />

wishes and achieve highest levels<br />

of safety for the distribution network.<br />

Your benefits<br />

Top quality electronic components<br />

Multi-purpose solutions.<br />

1 Back row: MSA 200 and<br />

MSA 250<br />

Front row: MSA 300, 350, 400<br />

Maximum performance also by fluctuating<br />

generator performance<br />

Low weight and easy handling<br />

2<br />

3<br />

4<br />

5<br />

6<br />

5<br />

6<br />

Complete management of<br />

traceability and process data<br />

Create individual barcodes<br />

Data processing via interface<br />

or data carrier<br />

Perfect sorting and filtering<br />

of data with Pipe-Win-Weld<br />

Easy addition of supplementary<br />

data<br />

24 languages (MSA 200, 250 without menu languages)<br />

Individual solutions and concepts<br />

In-series jointing possible<br />

15

1<br />

Georg Fischer spigot<br />

fittings provide a<br />

natural extension to the<br />

<strong>ELGEF</strong> <strong>Plus</strong> electrofusion<br />

programme.<br />

Proven technology with<br />

a broad and diversified<br />

range.<br />

16<br />

Spigot fittings the proven technology<br />

Your system<br />

The extensive spigot fitting range from<br />

Georg Fischer is the natural complement<br />

to the <strong>ELGEF</strong> <strong>Plus</strong> electrofusion programme.<br />

Elbows, tees, reducers, end caps<br />

and flange adapters in the sizes from<br />

d20 to d500 mm are all available.<br />

These spigot fittings can be easily combined<br />

with <strong>ELGEF</strong> <strong>Plus</strong> electrofusion<br />

couplers or fittings. Thereby, the fittings<br />

illustrate their pronounced diversity.<br />

The variety and range are attractive for<br />

those important applications. Additionally,<br />

reducers and reduced outlets can<br />

prove irreplaceable under difficult<br />

conditions.<br />

So much is certain<br />

The well-known and well-proven<br />

spigot fitting is, as before, technically<br />

up-to-date.<br />

Decades of injection moulding experience<br />

in combination with latest processing<br />

technology place our products<br />

at the peak of quality.<br />

The exclusive use of high-grade PE ¢00<br />

material assures an efficient utilisation<br />

3<br />

even under demanding conditions.<br />

Wallthicknesses in SDR 1¢ and from<br />

d90 mm also in SDR ¢7/¢7.6 provide<br />

sufficient scope for detailed network<br />

design.<br />

¥ ‡

2<br />

¥ ‡<br />

Your benefits<br />

Wide assortment of fittings and sizes<br />

High quality manufacturing<br />

Wide range with<br />

1 respect to diameter<br />

and outlet<br />

For example, end<br />

2 caps extend from d20<br />

to d500 mm<br />

3<br />

Typical fitting types<br />

Full compatibility with existing piping from PE 63, PE 80 and PE ¢00<br />

Long spigot end versions are suitable for both electrofusion and butt fusion jointing –<br />

assuring on-site flexibility<br />

Individually wrapped in PE foil to protect against on-site contamination<br />

17

We do more for our customers!<br />

High level technical<br />

production methods<br />

produce decisive<br />

benefits.<br />

Highest standards of<br />

quality are therefore<br />

fulfilled.<br />

Our production facilities are<br />

ISO 900¢ certified<br />

Environment management<br />

implies the professional treatment<br />

of environmental issues.<br />

A certification to ISO ¢400¢<br />

is just the start. Continual selfevaluation<br />

and improvement<br />

is a further obligation.<br />

18<br />

Modern production techniques and<br />

highest quality levels<br />

Create satisfying customer-focused<br />

benefits. The acknowledged target of<br />

Georg Fischer.<br />

How can we achieve this?<br />

Our sophisticated and highly technical<br />

production methods assure top levels of<br />

quality. In all respects. It also greatly<br />

simplifies logistics. Any possible product<br />

contamination is avoided. Additionally,<br />

the fully-automatic manufacturing process<br />

completely eliminates inadvertent<br />

faults. The high quality level is under<br />

constant supervision.<br />

Just-in-time delivery and, last but not<br />

least, a good price are additional<br />

benefits of the fully automatic manufacturing<br />

process.<br />

Local presence and advice –<br />

worldwide.<br />

Competent practice-related operator<br />

training and close customer support are<br />

important success factors. In addition to<br />

top grade products, we offer a first class<br />

customer-focused service. Georg Fischer<br />

are very active on a global basis with<br />

sales organisations in 24 different countries<br />

and production locations in North<br />

America, Asia as well as Europe. We are<br />

represented in a further 40 countries<br />

through well-trained distributors and<br />

partners. Therefore, from the planning<br />

stage to realisation a close and intensive<br />

customer support is assured by our local<br />

specialists.<br />

And this throughout the world.<br />

1<br />

Competent training<br />

Our intensive training courses give the<br />

user a chance to receive the knowledge<br />

and skills required for all piping system<br />

products. For example, we offer such<br />

courses in our Training Centre in Schaffhausen.<br />

The courses can also be implemented<br />

in one of our sales companies or<br />

on the premises of one of our partners<br />

or distributors based around the world.<br />

Request full details of our comprehensive<br />

training programmes.<br />

2<br />

¥ ‡

www.piping.georgfischer.com<br />

Visit our Internet web-site 24 hours<br />

around the clock and download the<br />

latest informative up-date from Georg<br />

Fischer. The current status of an order<br />

or additional information about product<br />

availability can also be obtained at<br />

the same time.<br />

¥ ‡<br />

3<br />

Your plus <strong>ELGEF</strong> <strong>Plus</strong><br />

Customising – tailor-made solutions<br />

for our customers<br />

Georg Fischer provides permanent solutions<br />

to practice-related problems. Special<br />

customer-oriented solutions as well<br />

as diverse tailor-made products trimmed<br />

to particular needs can also be realised.<br />

Single sourcing<br />

We can provide the most versatile product<br />

packages. Our sales companies<br />

and distributors will be pleased to assist.<br />

A worldwide market support is assured.<br />

Your benefits<br />

State-of-the-art technology<br />

Technically advanced production methods<br />

Full traceability of all PE components in accordance<br />

with ISO 12 176<br />

Continuously supervised high-grade product quality<br />

Global presence<br />

Tailor-made customer-focused solutions<br />

Product packages – all from one supplier<br />

Georg Fischer provides attractive benefits!<br />

1<br />

2<br />

3<br />

Worldwide advisory<br />

service<br />

In-house training,<br />

worldwide<br />

On-line information<br />

19

The technical data are not<br />

binding. They are not<br />

warranted characteristics and<br />

are subject to change. Please<br />

consult our General Conditions<br />

of Supply.<br />

Global presence<br />

¥ ‡<br />

Piping <strong>Systems</strong><br />

A Georg Fischer Rohrleitungssysteme GmbH, Sandgasse 16, 3130 Herzogenburg, Tel. +43(0)2782/856 43-0, Fax +43(0)2782/856 64, e-mail: office@georgfischer.at<br />

AUS George Fischer Pty Ltd, 186–190 Kingsgrove Road, Kingsgrove NSW 2008, Tel. +61(0)2/95 54 39 77, Fax +61(0)2/95 02 25 61<br />

B/L Georg Fischer NV/SA, Digue du Canal 109-¢¢¢ — Vaartdijk 109-¢¢¢, 1070 Bruxelles/Brüssel, Tél. +32(0)2/556 40 20, Fax +32(0)2/524 34 26<br />

e-mail: info.be@be.piping.georgfischer.com<br />

BR George Fischer Ltda, Av. das Nações Unidas 21689, 04795-100 São Paulo, Brasil, Tel. +55(0)11/5687 1311, Fax +55(0)11/5687 6009<br />

CH Georg Fischer Rohrleitungssysteme (Schweiz) AG, Amsler-Laffon-Strasse ¢, Postfach, 8201 Schaffhausen, Tel. +41(0)52 631 30 26, Fax +41(0)52 631 28 97<br />

e-mail: info@rohrleitungssysteme.georgfischer.ch<br />

CHINA Chinaust <strong>Plastic</strong>s Corp. Ltd., Songlin Dian, Zhuo Zhou City, Hebei Province, P.R. China, 07276¢, Tel. +86 3¢2 395 2000, Fax +86 3¢2 395 2222<br />

e-mail: info@chinaust.com<br />

D Georg Fischer GmbH, Daimlerstraße 6, 73095 Albershausen, Tel. +49(0)7161/302-0, Fax +49(0)7161/30 2 259<br />

e-mail: info@georgfischer.de, Internet: http://www.rls.georgfischer.de<br />

DK/IS Georg Fischer A/S, Rugvænget 30, 2630 Taastrup, Tel. +45 70 22 19 75, Fax +45 70 22 19 76<br />

e-mail: info@dk.piping.georgfischer.com, Internet: http://www.georgfischer.dk<br />

E Georg Fischer S.A., Alcalá, 85, 2 a , 28009 Madrid, Tel. +34(0)9¢/781 98 90, Fax +34(0)9¢/426 08 23<br />

e-mail: info@georgfischer.es<br />

F George Fischer S.A., 105–1¢3, rue Charles Michels, 93208 Saint-Denis Cedex 1, Tél. +33(0)1/49 22 ¢3 4¢, Fax +33(0)¢/49 22 ¢3 00, e-mail: info@georgefischer.fr<br />

GB George Fischer Sales Limited, Paradise Way, Coventry, CV2 2ST, Tel. +44(0)2476/535 535, Fax +44(0)2476/530 450<br />

e-mail: info@georgefischer.co.uk, Internet: http://www.georgefischer.co.uk<br />

George Fischer Castings Ltd, Norse Road, Bedford MK41 7QN, Tel. +44(0)¢234/355 291, Fax +44(0)¢234/328 570<br />

GR Georg Fischer S.p.A., Athens Branch, 101, 3rd September Str., 10434 Athen, Tel. +30(0)1/882 0491, Fax +30(0)1/881 0291, e-mail: info@piping-georgfischer.gr<br />

I Georg Fischer S.p.A., Via Sondrio 1, 20063 Cernusco S/N (MI), Tel. +3902/921 861, Fax +3902/921 407 85-6, e-mail: office@piping.georgfischer.it<br />

Alprene S.r.l., Via Bonazzi, 32, Castel Maggiore, 40013 Bologna, Tel. +39051/63 24 211, Fax +39051/63 24 213, e-mail: info@alprene.georgfischer.it<br />

N Georg Fischer AS, Rudsletta 97, ¢35¢ Rud, Tel. +47(0)67 18 29 00, Fax +47(0)67 13 92 92, Internet: http://www.georgfischer.no<br />

NL Georg Fischer N.V., Postbus 35-8160, 8161 PA Epe, Tel. +31(0)578/678222, Fax +31(0)578/621768<br />

e-mail: info.vgnl@nl.piping.georgfischer.com, Internet: http://www.georgfischer.nl<br />

Georg Fischer WAGA N.V., Lange Veenteweg 19, Postbus 290, 8160 AG Epe, Tel. +31(0)578/678378, Fax +31(0)578/620848<br />

e-mail: info@waga.georgfischer.com, Internet: http://www.waga.georgfischer.com<br />

PL Georg Fischer Sp. z o.o., ul. Radiowa 1A, 01-485 Warszawa, Tel. +48(0)22/638 91 39, Fax +48(0)22/638 00 94<br />

S/FIN Georg Fischer AB, Box 113, 12523 Älvsjö-Stockholm, Tel. +46(0)8/506 77 500, Fax +46(0)8/749 23 70, e-mail: info@georgfischer.se, Internet: http://www.georgfischer.se<br />

SGP George Fischer Pte Ltd, ¢5 Kaki Bukit Road 2, KB Warehouse Complex, 4¢7 845 Singapore, Tel. +65(0)67 47 06 ¢¢, Fax +65(0)67 47 05 77, e-mail: info@georgefischer.com.sg<br />

USA George Fischer Inc., 2882 Dow Avenue, Tustin, CA 92780-7258, Tel. +1(714) 731 88 00, Toll Free 800/854 40 90, Fax +1(714) 73¢ 62 01<br />

e-mail: info@us.piping.georgefischer.com, Internet: http://www.us.piping.georgefischer.com<br />

Export Georg Fischer Wavin AG, Ebnatstrasse ÝÝÝ, Postfach, CH-8201 Schaffhausen, Tel. +41(0)52 631 38 41, Fax +41(0)52 631 28 14<br />

e-mail: info@piping.georgfischer.com, Internet: http://www.piping.georgfischer.com<br />

Fi 5676/4c (7.03) © Georg Fischer Wavin AG, CH-8201 Schaffhausen/Schweiz, 2002 Printed in Switzerland