Expansion Joints Brochure - Flex-Hose Co Inc

Expansion Joints Brochure - Flex-Hose Co Inc

Expansion Joints Brochure - Flex-Hose Co Inc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

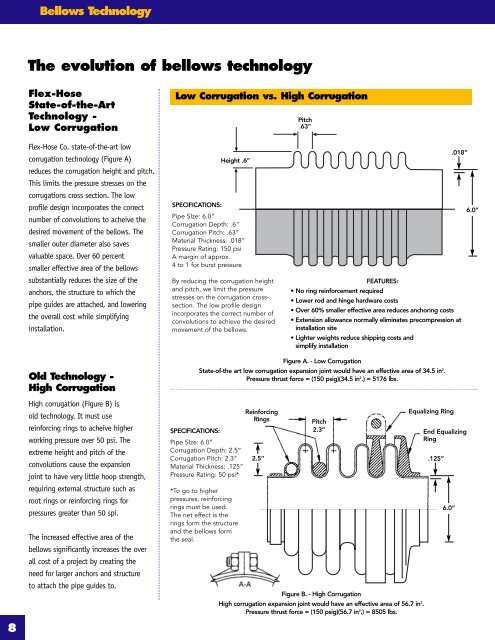

Bellows Technology1.877.METAL EJ • www.flexhose.comThe evolution of bellows technologyBellows Design Basics<strong>Flex</strong>-<strong>Hose</strong>State-of-the-ArtTechnology -Low <strong>Co</strong>rrugation<strong>Flex</strong>-<strong>Hose</strong> <strong>Co</strong>. state-of-the-art lowcorrugation technology (Figure A)reduces the corrugation height and pitch.Low <strong>Co</strong>rrugation vs. High <strong>Co</strong>rrugationHeight .6”Pitch.63”.018”<strong>Flex</strong>-<strong>Hose</strong> <strong>Co</strong>. metal expansion jointsare designed for a wide range ofservice conditions. They consist of aflexible bellows element, appropriate endfittings to match adjoining pipe fittingsand schedule. The bellows is a flexibleseal design to contain the media, absorbLimit RodBellowsFlow LinerThis limits the pressure stresses on thecorrugations cross section. The lowprofile design incorporates the correctnumber of convolutions to acheive thedesired movement of the bellows. Thesmaller outer diameter also savesvaluable space. Over 60 percentsmaller effective area of the bellowssubstantially reduces the size of theanchors, the structure to which thepipe guides are attached, and loweringthe overall cost while simplifyinginstallation.Old Technology -High <strong>Co</strong>rrugationHigh corrugation (Figure B) isold technology. It must usereinforcing rings to acheive higherworking pressure over 50 psi. Theextreme height and pitch of theconvolutions cause the expansionjoint to have very little hoop strength,requiring external structure such asroot rings or reinforcing rings forpressures greater than 50 spi.The increased effective area of thebellows significantly increases the overall cost of a project by creating theneed for larger anchors and structureto attach the pipe guides to.SPECIFICATIONS:Pipe SIze: 6.0”<strong>Co</strong>rrugation Depth: .6”<strong>Co</strong>rrugation Pitch: .63”Material Thickness: .018”Pressure Rating: 150 psiA margin of approx.4 to 1 for burst pressureBy reducing the corrugation heightand pitch, we limit the pressurestresses on the corrugation crosssection.The low profile designincorporates the correct number ofconvolutions to achieve the desiredmovement of the bellows.SPECIFICATIONS:Figure A. - Low <strong>Co</strong>rrugationState-of-the art low corrugation expansion joint would have an effective area of 34.5 in 2 .Pressure thrust force = (150 psig)(34.5 in 2 .) = 5176 lbs.Pipe SIze: 6.0”<strong>Co</strong>rrugation Depth: 2.5”<strong>Co</strong>rrugation Pitch: 2.3”Material Thickness: .125”Pressure Rating: 50 psi**To go to higherpressures, reinforcingrings must be used.The net effect is therings form the structureand the bellows formthe seal.ReinforcingRings2.5”FEATURES:• No ring reinforcement required• Lower rod and hinge hardware costs• Over 60% smaller effective area reduces anchoring costs• Extension allowance normally eliminates precompression atinstallation site• Lighter weights reduce shipping costs andsimplify installationPitch2.3”Figure B. - High <strong>Co</strong>rrugationHigh corrugation expansion joint would have an effective area of 56.7 in 2 .Pressure thrust force = (150 psig)(56.7 in 2 .) = 8505 lbs.Equalizing RingEnd EqualizingRing.125”6.0”6.0”thermal movement, and pressures ofthe system.The bellows are manufactured fromthin-walled tubing to form a corrugatedcylinder. The corrugations are commonlyreferred to as convolutions and add thestructure necessary for the bellows materialto contain system pressure.The bellows design incorporates thethickness and convolution geometry thatmeets the capacity of the adjoining pipe tocontain system pressure at the specifieddesign temperature.<strong>Flex</strong>ibility of the bellows is acheivedthrough the convolution profile andpitch as multiple convolutions arerequired to provide the expectedexpansion and contraction of thepiping system.Accessories<strong>Co</strong>vers<strong>Expansion</strong> joints require careful handlingand must be protected from any impact,weld spatter, etc. Before insulating anexpansion joint, care must be taken thatforeign material is not trapped in thecorrugations impeding its movements.It is suitable to install a metal cover overthe flanges and then wrap the insulationaround it.Flow LinersFlow liners are installed in the inlet bore ofthe expansion joint to protect the bellowsfrom erosion damage due to abrasive mediaor resonant vibration caused by turbulentflow or excessive velocities.Tie RodsTie Rods are devices with the primaryfunction to restrain the bellows pressurethrust. It should be pointed out that whentie rods are furnished on expansion jointssubject to external axial movement, theywill only restrain the pressure thrust in theevent of an anchor failure. During normaloperation the anchor or adjacentequipment will be subjected to thepressure thrust forces.Limit RodsLimit Rods are devices with the primaryfunction of restricting the bellows movementrange. The limit rods are designed to preventbellows over-extension or over-compressionwhile restraining the full pressure thrust inthe event of a main anchor failure.<strong>Co</strong>ntrol RodsEnd FittingExternal<strong>Co</strong>ver/Shroud<strong>Co</strong>ntrol Rods are devices attached to theexpansion joint with the primary functionof distributing movement between the twobellows of a universal joint. <strong>Co</strong>ntrol rodsare not designed to restrain bellowspressure thrust.8 9