Spring Issue 2 - Knox Box

Spring Issue 2 - Knox Box

Spring Issue 2 - Knox Box

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

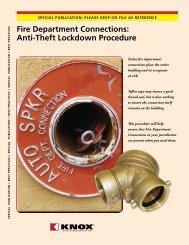

Storz: What’s in a Name?In parts of the worldit is called a Stortz fitting.In the U.S. it is mostcommonly spelled Storz.Regardless how you spell it,a Storz connection is the generally acceptedcoupling used on all large diameter firesupply hose and a growing number of firehydrants and fire department connections.How did it come into existence? What arethe practical uses?Historical BackgroundThe concept of a fast action couplingwas the late 1800s brainchild of Germaninventor Carl Storz. A Storz couplingis essentially a variation of a hoseconnection. It is quick, reliable, and hasseen service in American fire departmentson large diameter fire hose for decades.It is also used as the auxiliary FDC intaketo supplement fire sprinkler systems orother fire protection applications like foamdeluge systems. It is generally used in 4inch and 5 inch sizes in America, but isavailable in Europe in a variety of sizes forapplications other than fire fighting. NFPA1963 Standard for Fire Hose Connectionsdefines the requirements for 4 inch and 5inch non-threaded connections. It definesthem as: “A coupling or adaptor in whichmating is achieved with locks or camsbut without the use of screw threads.”Compared to a conventional connectionthat has a threaded male and femalescrew connection at either end that canbe attached in only one direction (withoutthe use of an adaptor), a Storz connectionis a two-way universal coupling that can bejoined to another Storz coupling end. CarlStorz patented his design in Switzerlandin 1890 and submitted it to the U.S.Patent Office in 1893. It soon became astandard for fire hydrants throughout muchof Europe. While it saw wide spread usagein Europe in the early 20th century, ittook almost one hundred years before theconcept was embraced and implemented inthe United States. In 2007, all major U.S.hydrant manufacturers offer Storz as anoriginal equipment option.A detail of the original Storz fitting illustrationsubmitted to the U.S. Patent Office in 1893 byCarl Storz.Regulating StandardsThere are essentially two recognizedstandards that impact the construction,and application of Storz Connections;NFPA 1963 and DIN (Deutsches Institutfür Normung, or the German Institute forStandardization). While NFPA 1963 is thegenerally accepted Standard in Americaand addresses/sets all pertinent acceptancestandards, the original DIN Standardshave long been the benchmark for Storzapplication and construction acceptance inthe rest of the world. In some cases theDIN Standards are higher. Since Storz wasa German invention and it has enjoyedover a century of actual usage, the DINStandards do merit considerable respectand consideration. An example is DIN14303 and 1725 standards that specificallystate that any aluminum used in a Storzapplication must be ‘forged’ (hammered,machined, and formed like a Blacksmithmight do) and not ‘cast’ (heated until itis liquefied, then poured or ‘cast’ into amold). The DIN standard goes on to statethat in the interest of firefighter safety,any cast aluminum connection componentsmust be reserved for non-fire fightingapplications and suggest these productsbe used for agricultural purposes. Thisshould be something local jurisdictionsand contractors take into account whensetting acceptance criteria for theircommunity. It is interesting to note thatthe top U.S. component suppliers including<strong>Knox</strong> Company’s StorzLok use only forgedand/or machined materials on all Storzproducts.Tactical BenefitsThe impact is evident in several ways.Storz connections typically connect moreeasily and more positively. Things weredifferent in the days prior to Storz andlarge diameter hose when fire departmentsused multiple sections of 2½” hose. Oncea supply line was laid between the firehydrant and the engine, many times adistance of hundreds of feet, a firefighter,after flushing, connecting the hose, andturning on the hydrant, would have to walkthe entire lay with a couple of spannerwrenches in hand and tighten eachconnection along the way. Depending onthe length of the lay and the number ofconnections that needed to be tightened,this could take a significant amount oftime. With Storz connections, the firefighterstill has to make that walk, but less time isneeded to walk/inspect the hose, gettingthe firefighter back to the engine andavailable to fight the fire. Another tacticalbenefit is that there is not as much needto have engines with different hose laysfor either supply or attack evolutions. Thishas made it easier for individual enginesto be more self-sufficient, allowing firedepartments to spread out more withsingle engine stations, compared to multienginestations, potentially lowering initial