CAFOs Uncovered - Union of Concerned Scientists

CAFOs Uncovered - Union of Concerned Scientists

CAFOs Uncovered - Union of Concerned Scientists

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

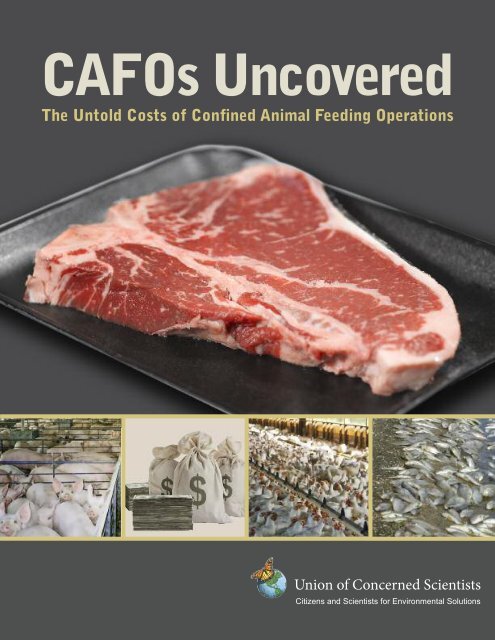

<strong>CAFOs</strong> <strong>Uncovered</strong>The Untold Costs <strong>of</strong> ConfinedAnimal Feeding OperationsDoug Gurian-ShermanU N I O N O F C O N C E R N E D S C I E N T I S T SA P R I L 2 0 0 8

ii <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>© 2008 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>All rights reservedDoug Gurian-Sherman is a senior scientist in the<strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong> (UCS) Food andEnvironment Program.e <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong> is the leadingscience-based nonpr<strong>of</strong>it working for a healthyenvironment and a safer world.e goal <strong>of</strong> the UCS Food and EnvironmentProgram is a food system that encouragesinnovative and environmentally sustainable waysto produce high-quality, safe, and affordable food,while ensuring that citizens have a voice in howtheir food is grown.More information about the <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong><strong>Scientists</strong> and the Food and Environment Programis available on the UCS website at www.ucsusa.org.e full text <strong>of</strong> this report is available online(in PDF format) at www.ucsusa.org or may beobtained from:UCS PublicationsTwo Brattle SquareCambridge, MA 02238-9105Or, email pubs@ucsusa.org or call (617) 547-5552.COVER PHOTOS:David Michalak, www.huntingtoncreative.com(steak), Farmsanctuary.org (pigs),istockphoto (money), Farmsanctuary.org (chickens) ,Rick Dove, www.doveimaging.com andwww.neuseriver.com (fish)DESIGN: Penny Michalak (designmz.com)Printed on recycled paper using soy-based inks

iv <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>F I G U R E S A N D T A B L E SFigures1. U.S. Hog Inventory on the Largest Farms 142. Number <strong>of</strong> U.S. Hog Operations and Hog Inventory 153. Federal EQIP Funding for 2006 434. Counties Eligible for EQIP Subsidies in Georgia’s Poultry Litter Transfer Program, 2006 445. Average Atmospheric Ammonium Ion Concentration, 1985–2002 456. Wet Deposition <strong>of</strong> Ammonium Nitrogen, 2002 457. Wet Deposition <strong>of</strong> Ammonia and Nitrate Nitrogen, 2002 468. Geographic Concentration <strong>of</strong> Hog Production, 1997–2002 469. Geographic Concentration <strong>of</strong> Dairy Cows, 1997–2002 4710. Geographic Concentration <strong>of</strong> Broiler Production, 1997–2002 4711. CAFO Manure Lagoon 4812. Environmental Danger <strong>of</strong> <strong>CAFOs</strong> 4813. CAFO Manure Pile 4814. CAFO Manure Lagoon 4815. Unsanitary Conditions in Cattle CAFO 4916. Alternative Cattle Production 4917. Crowding in Chicken CAFO 4918. Alternative Poultry Production 4919. Crowding in Hog CAFO 5020. Hog Hoop Barn 5021. Alternative Pork Production 50TablesES-1. CAFO Costs Underwritten by U.S. Taxpayers 61. Number <strong>of</strong> Livestock Operations by Size, 1982–1997 162. Number <strong>of</strong> Animals by Operation Size, 1982–1997 163. Percent <strong>of</strong> Livestock Production under Contract by Sector 214. Percent <strong>of</strong> Animals Slaughtered in Large Plants 225. Indirect Subsidies to the CAFO Industry, 1997–2005 346. Comparison <strong>of</strong> Subsidies for <strong>CAFOs</strong> and Diversified Farms 35

<strong>CAFOs</strong> <strong>Uncovered</strong>vA C K N O W L E D G M E N T Sis report was made possible through the financialsupport <strong>of</strong> e Cedar Tree Foundation, e DeerCreek Foundation, e Educational Foundation <strong>of</strong>America, e David B. Gold Foundation, Newman’sOwn Foundation, and UCS members.e report was greatly informed by Dr. Silvia Secchi<strong>of</strong> Southern Illinois University, who provided insightson economic matters concerning the livestockindustry and also reviewed parts <strong>of</strong> the text. Wewere similarly fortunate to receive research contributionsand perspectives from Elanor Starmer <strong>of</strong> theGlobal Development and Environment Institute(GDAE) at Tus University. We also thank Dr. KateClancy for her helpful thoughts and suggestions.We are grateful for the reviews provided byDr. Mark Honeyman <strong>of</strong> Iowa State University,Dr. Michael Mallin <strong>of</strong> the University <strong>of</strong> North Carolina,Dr. William Weida <strong>of</strong> Colorado College andthe Global Resource Action Center for the Environment(GRACE), and Timothy A. Wise <strong>of</strong> the GDAEat Tus University. Each <strong>of</strong>fered invaluable commentsthat greatly improved the report, but we mustnote that their willingness to review the materialdoes not necessarily imply an endorsement <strong>of</strong> thereport or its conclusions and recommendations.Here at the <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>, a greatdeal <strong>of</strong> appreciation is due to Margaret Mellon,without whose patience, counsel, and many contributionsthis report would not have been possible.anks are also due to Stanback interns ElizabethWillets and Pei Yen for research contributions, JaneRissler and Heather Sisan for logistical and otherhelp, and Julie MacCartee for research assistance.We would also like to thank Bryan Wadsworth forcopyediting, Heather Tuttle for coordinating printproduction, and Penny Michalak for designand layout.

<strong>CAFOs</strong> <strong>Uncovered</strong> 1EXECUTIVE SUMMARYThe livestock industry (including poultry) is vitalto our national economy, supplying meat, milk,eggs, and other animal products and providingmeaningful employment in rural communities. Untilrecently, food animal production was integrated withcrop production in a balanced way that was generallybeneficial to farmers and society as a whole. Butlivestock production has undergone a transformationin which a small number <strong>of</strong> very large <strong>CAFOs</strong>(confined animal feeding operations) predominate.ese <strong>CAFOs</strong> have imposed significant—but largelyunaccounted for—costs on taxpayers and communitiesthroughout the United States.<strong>CAFOs</strong> are characterized by large numbers <strong>of</strong>animals crowded into a confined space—an unnaturaland unhealthy condition that concentrates toomuch manure in too small an area. Many <strong>of</strong> thecostly problems caused by <strong>CAFOs</strong> can be attributedto the storage and disposal <strong>of</strong> this manure and theoveruse <strong>of</strong> antibiotics in livestock to stave <strong>of</strong>f disease.e predominance <strong>of</strong> <strong>CAFOs</strong> is not the inevitableresult <strong>of</strong> market forces; it has been fosteredby misguided public policy. Alternative productionmethods can be economically efficient and technologicallysophisticated, and can deliver abundant animalproducts while avoiding most <strong>of</strong> the problemscaused by <strong>CAFOs</strong>. However, these alternatives are ata competitive disadvantage because <strong>CAFOs</strong> have reducedtheir costs through subsidies that come at thepublic’s expense, including (until very recently) lowcostfeed. <strong>CAFOs</strong> have also benefited from taxpayersupportedpollution cleanup programs andtechnological “fixes” that may be counterproductive,such as the overuse <strong>of</strong> antibiotics. And by shiingthe risks <strong>of</strong> their production methods onto the public,<strong>CAFOs</strong> avoid the costs <strong>of</strong> the harm they cause.In addition, the fact that the meat processing industryis dominated by a few large and economicallypowerful companies makes it difficult for alternativeproducers to slaughter their animals and get theirproducts to market. is excessive market concentrationis facilitated by lax enforcement <strong>of</strong> laws intendedto prevent anti-competitive practices.By describing several <strong>of</strong> the subsidies and otheroen hidden costs <strong>of</strong> <strong>CAFOs</strong> that are imposed onsociety (referred to as externalized costs or “externalities”),this report attempts to clarify the realprice we pay—and can no longer afford—for thisharmful system. ese externalities are associatedwith the damage caused by water and air pollution(along with cleanup and prevention), the costsborne by rural communities (e.g., lower propertyvalues), and the costs associated with excessive antibioticuse (e.g., harder-to-treat human diseases).Subsidies have included payments to grain farmersthat historically supported unrealistically low animalfeed prices, and payments to <strong>CAFOs</strong> to preventwater pollution.e United States can do better. In fact, there isa new and growing movement among U.S. farmersto produce food efficiently by working with naturerather than against it. More and more meat anddairy farmers are successfully shiing away frommassive, overcrowded <strong>CAFOs</strong> in favor <strong>of</strong> modernproduction practices. We <strong>of</strong>fer a number <strong>of</strong> policyrecommendations that would level the playing fieldfor these smart, sophisticated alternatives by reducingCAFO subsidies and requiring <strong>CAFOs</strong> to pay afair share <strong>of</strong> their costs.

2 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong><strong>CAFOs</strong>—Too Big for Our Own GoodMost <strong>of</strong> the problems caused by <strong>CAFOs</strong> result fromtheir excessive size and crowded conditions. <strong>CAFOs</strong>contain at least 1,000 large animals such as beefcows, or tens <strong>of</strong> thousands <strong>of</strong> smaller animals suchas chickens, and many are much larger—with tens<strong>of</strong> thousands <strong>of</strong> beef cows or hogs, and hundreds <strong>of</strong>thousands <strong>of</strong> chickens.e problems that arise from excessive size anddensity (e.g., air and water pollution from manure,overuse <strong>of</strong> antibiotics) are exacerbated by the paralleltrend <strong>of</strong> geographic concentration, whereby<strong>CAFOs</strong> for particular types <strong>of</strong> livestock have becomeconcentrated in certain parts <strong>of</strong> the country.For example, large numbers <strong>of</strong> swine <strong>CAFOs</strong> arenow located in Iowa and North Carolina, dairy<strong>CAFOs</strong> in California, and broiler chicken <strong>CAFOs</strong> inArkansas and Georgia.We need to be concerned about these excessivelylarge feeding operations because they have becomethe predominant means <strong>of</strong> producing meatand dairy products in this country over the past fewdecades. Although they comprise only about 5 percent<strong>of</strong> all U.S. animal operations, <strong>CAFOs</strong> now producemore than 50 percent <strong>of</strong> our food animals.ey also produce about 65 percent <strong>of</strong> the manurefrom U.S. animal operations, or about 300 milliontons per year—more than double the amount generatedby this country’s entire human population. Forthe purposes <strong>of</strong> this report, there are approximately9,900 U.S. <strong>CAFOs</strong> producing hogs, dairy cows, beefcows, broiler chickens, or laying hens.Better Options Exist<strong>CAFOs</strong> do not represent the only way <strong>of</strong> ensuringthe availability <strong>of</strong> food at reasonable prices. Recentstudies by the U.S. Department <strong>of</strong> Agriculture(USDA) show that almost 40 percent <strong>of</strong> mediumsizedanimal feeding operations are about as costeffectiveas the average large hog CAFO, and manyother studies have provided similar results.Medium-sized and smaller operations also avoid orreduce many <strong>of</strong> the external costs that stemfrom <strong>CAFOs</strong>.If <strong>CAFOs</strong> are not appreciably more efficientthan small and mid-sized operations, why are theysupplanting smaller farms? e answers lie largelyin farm policies that have favored large operations.<strong>CAFOs</strong> have relied on cheap inputs (water, energy,and especially feed) to support the high animal densitiesthat <strong>of</strong>fset these operations’ high fixed costs(such as buildings). Feed accounts for about 60 percent<strong>of</strong> the costs <strong>of</strong> producing hogs and chickensand is also an important cost for dairy and beefcows, and federal policies have encouraged the production<strong>of</strong> inexpensive grain that benefits <strong>CAFOs</strong>.Perhaps even more important has been the concentration<strong>of</strong> market power in the processing industryupon which animal farmers depend. isconcentration allows meat processors to exert considerableeconomic control over livestock producers,oen in the form <strong>of</strong> production contracts andanimal ownership. e resulting “captive supply”can limit market access for independent smallerproducers, since the large majority <strong>of</strong> livestock areeither owned by processors or acquired under contract—andprocessors typically do not contract withsmaller producers. Federal government watchdogshave stated that the agency responsible for ensuringthat markets function properly for smaller producersis not up to the task.Hoop barns and smart pasture operationsAlthough there is evidence that confinement operationssmaller than <strong>CAFOs</strong> can be cost-effective andproduce ample animal products, studies also suggestthat sophisticated alternative means <strong>of</strong> producinganimal products hold even greater promise. For example,hog hoop barns, which are healthier for theanimals and much smaller than <strong>CAFOs</strong>, can producecomparable or even higher pr<strong>of</strong>its per unit atclose to the same price.Research in Iowa (the major hog-producingstate) has also found that raising hogs on pasturemay produce animals at a lower cost than <strong>CAFOs</strong>.Other studies have shown that “smart” pasture oper-

4 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong><strong>of</strong> raw manure into streams and estuaries and killingmillions <strong>of</strong> fish. Smaller but more numerous spillscause substantial losses as well.Remediation <strong>of</strong> the leaching under dairy andhog <strong>CAFOs</strong> in Kansas has been projected to costtaxpayers $56 million—and Kansas is not one <strong>of</strong> thecountry’s top dairy- or hog-producing states. Basedon these data, a rough estimate <strong>of</strong> the total cost <strong>of</strong>cleaning up the soil under U.S. hog and dairy<strong>CAFOs</strong> could approach $4.1 billion.The two primary pollutants from manure, nitrogenand phosphorus, can cause eutrophication(the proliferation and subsequent death <strong>of</strong> aquaticplant life that robs freshwater and marine environments<strong>of</strong> the oxygen that fish and many otheraquatic organisms need to survive). For example,run<strong>of</strong>f and leaching from animal sources including<strong>CAFOs</strong> is believed to contribute about 15 percent<strong>of</strong> the nutrient pollution that reaches the Gulf <strong>of</strong>Mexico, where a large “dead zone”—devoid <strong>of</strong> fishand commercially important seafood such asshrimp—has developed. CAFO manure also contributesto similar dead zones in the ChesapeakeBay (another important source <strong>of</strong> fish and shellfish)and other important estuaries along the EastCoast. The Chesapeake Bay’s blue crab industry,which had a dockside value <strong>of</strong> about $52 million in2002, has declined drastically in recent years alongwith other important catches such as striped bass,partly due to the decline in water quality caused inpart by <strong>CAFOs</strong>.Although it is difficult to account for all <strong>of</strong> thesocial benefits (such as fisheries and drinkingwater) lost due to CAFO pollution, it is reasonableto assume the losses are substantial. One indirectway <strong>of</strong> estimating such costs is to calculate the cost<strong>of</strong> preventing some or all <strong>of</strong> the pollution causedby <strong>CAFOs</strong>. The USDA, for example, has determinedhow much it would cost to transport manureto enough crop fields or pastures to complywith new Clean Water Act rules governing the distribution<strong>of</strong> manure on fields. Based on a nitrogenlimitedstandard and realistic estimates <strong>of</strong> the rateat which farms will accept manure, the annual cost<strong>of</strong> adequate manure distribution in the ChesapeakeBay region alone would total $134 million per year.Using a phosphorus-limited standard and an unrealisticallyhigh manure acceptance rate, the costwould be $153 million annually. Considering thatnet returns for the animal industry in this regionamount to $313 million, compliance with suchstandards could comprise between 43 and 49 percent<strong>of</strong> net returns.Air pollution from manureAirborne ammonia is a respiratory irritant and cancombine with other air pollutants to form fine particulatematter that can cause respiratory disease.And because ammonia is also re-deposited onto theground, mostly within the region from which itoriginates, ammonia nitrogen deposited on soilsthat have evolved under low-nitrogen conditionsmay reduce biodiversity and find its way into watersources. Ammonium ion deposition also contributesto the acidification <strong>of</strong> some forest soils.Animal agriculture is the major contributor <strong>of</strong>ammonia to the atmosphere, and the substantialmajority <strong>of</strong> this ammonia likely comes from confinementoperations, since manure deposited bylivestock on pasture contributes proportionatelymuch less ammonia to the atmosphere than manurefrom <strong>CAFOs</strong>. Up to 70 percent <strong>of</strong> the nitrogen inCAFO manure can be lost to the atmosphere dependingon manure storage and field applicationmeasures. Over the past several decades, theamount <strong>of</strong> airborne ammonia deposition in manyareas <strong>of</strong> the United States with large numbers <strong>of</strong><strong>CAFOs</strong> has been rising dramatically, and may oenexceed the capacity <strong>of</strong> forests and other environmentsto utilize it without harm.e USDA has estimated the total U.S. cost <strong>of</strong>controlling air and water pollution through manuredistribution onto farmland—in quantities that complywith the Clean Water Act—at $1.16 billion peryear under high manure acceptance rates. However,the standard applied in this calculation would onlyreduce airborne ammonia pollution from <strong>CAFOs</strong> byabout 40 percent. And if lower, more realistic ma-

<strong>CAFOs</strong> <strong>Uncovered</strong> 5nure acceptance rates were used, the manure wouldhave to be transported unacceptable distances.erefore, proper manure disposal from <strong>CAFOs</strong> atcurrent farmer acceptance rates would in all likelihoodexceed these values considerably.Harm to rural communities<strong>CAFOs</strong> are sited in rural communities that bear thebrunt <strong>of</strong> the harm caused by <strong>CAFOs</strong>. is harm includesthe frequent presence <strong>of</strong> foul odors and watercontaminated by nitrogen and pathogens, as wellas higher rates <strong>of</strong> respiratory and other diseasescompared with rural areas that are not locatednear <strong>CAFOs</strong>.One study determined that each CAFO in Missourihas lowered property values in its surroundingcommunities by an average total <strong>of</strong> $2.68 million. Itis not possible to accurately extrapolate this valuenationally due to the many differences between localities,but as a very rough indication <strong>of</strong> the magnitude<strong>of</strong> these costs, multiplying by 9,900 (the totalnumber <strong>of</strong> U.S. <strong>CAFOs</strong> as defined for this report)would yield a loss <strong>of</strong> about $26 billion.Antibiotic-resistant pathogensEstimates have suggested that considerably greateramounts <strong>of</strong> antibiotics are used for livestock productionthan for the treatment <strong>of</strong> human disease inthe United States. e massive use <strong>of</strong> antibiotics in<strong>CAFOs</strong>, especially for non-therapeutic purposessuch as growth promotion, contributes to the development<strong>of</strong> antibiotic-resistant pathogens that aremore difficult to treat.Many <strong>of</strong> the bacteria found on livestock (such asSalmonella, Escherichia coli, and Campylobacter) cancause food-borne diseases in humans. Furthermore,recent evidence strongly suggests that some methicillin-resistantStaphylococcus aureus (MRSA) anduropathogenic E. coli infections may also be causedby animal sources. ese pathogens collectivelycause tens <strong>of</strong> millions <strong>of</strong> infections and many thousands<strong>of</strong> hospitalizations and deaths every year.e costs associated with Salmonella alone havebeen estimated at about $2.5 billion per year—about88 percent <strong>of</strong> which is related to premature deaths.Because an appreciable degree <strong>of</strong> antibiotic resistancein animal-associated pathogens is likely due tothe overuse <strong>of</strong> antibiotics in <strong>CAFOs</strong>, the resultingcosts are likely to be high. Eliminating the use <strong>of</strong> antibioticsfor growth promotion (the majority <strong>of</strong>which occurs on <strong>CAFOs</strong>) could cost <strong>CAFOs</strong>between $1.5 billion and $3 billion per year.Conclusions and Recommendationse costs we pay as a society to support <strong>CAFOs</strong>—inthe form <strong>of</strong> taxpayer subsidies, pollution, harm torural communities, and poorer public health—ismuch too high (Table ES-1, p. 6). For example, conservativeestimates <strong>of</strong> grain subsidies and manuredistribution alone suggest that <strong>CAFOs</strong> would haveincurred at least $5 billion in extra production costsper year if these expenses were not shied onto thepublic. e figure would undoubtedly be muchhigher if truly adequate manure distribution was required.Although we do not have good national datafor other costs quantified in Table ES-1, and somethat have not been quantified (such as water and energyuse and water purification costs), they couldamount to billions <strong>of</strong> dollars more per year.Technological solutions to specific CAFO problemshave been proposed, such as feed formulationsthat would reduce manure nitrogen, lagoon coversthat would reduce atmospheric ammonia, and “biogas”capture and production that would reducemethane emissions from manure, but these are onlypartial solutions and would generally add to the cost<strong>of</strong> production. None <strong>of</strong> these technologies solve antibioticresistance, loss <strong>of</strong> rural income, or theethical treatment <strong>of</strong> animals. By comparison, sophisticatedCAFO alternatives can provide plentifulanimal products at similar prices, but with muchfewer <strong>of</strong> the problems caused by <strong>CAFOs</strong>.e bottom line is that society is currently proppingup an undesirable form <strong>of</strong> animal agriculturewith enormous subsidies and a lack <strong>of</strong> accountabilityfor its externalized costs. Once we appreciate therole these subsidies—along with government

6 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>Table ES-1. CAFO Costs Underwritten by U.S. Taxpayers 1Cost <strong>of</strong> Pollution orPollution AvoidanceCost to Distribute andApply Manure to Fields $1.16 billion/year 2Reduction in Property Values $26 billion (total loss) 3Public Health Costs from Overuse<strong>of</strong> Antibiotics in Livestock $1.5 billion – $3.0 billion/year 4Remediation <strong>of</strong> Leakage fromManure Storage Facilities(Swine and Dairy) $4.1 billion (total cost) 5Cost <strong>of</strong> SubsidyGrain Subsidies for Livestock Feed $3.86 billion/year 6EQIP Subsidy $100 million – $125 million 71Numbers are rough estimates <strong>of</strong> current or recent costs and are presented only to indicate the magnitude <strong>of</strong> these costs. See the text for details.2SOURCE: Aillery et al. 2005.3SOURCE: Mubarak, Johnson, and Miller 1999. Extrapolation from Missouri data based on national CAFO numbers.4SOURCE: NRC 1999. Extrapolation based on U.S. population <strong>of</strong> 300 million.5SOURCE: Volland, Zupancic, and Chappelle 2003. Extrapolation from Kansas data based on national swine and dairy CAFO numbers.6SOURCE: Starmer 2007. Data averaged over the period 1996–2005.7SOURCE: NRCS 2003. Calculations based on NRCS projections for 2007 (yearly values increase from a low in 2002 to a high in 2007).policies—play in shaping the way our food animalsare raised, we can also see the environmental,health, and economic benefits to be gained fromredirecting agriculture toward smart pasture operationsand other desirable alternatives.Public policies that support <strong>CAFOs</strong> at the expense<strong>of</strong> such alternatives should be eliminated, andpolicies that support these alternatives should beimplemented. Needed actions include:• Strict and vigorous enforcement <strong>of</strong> antitrust andanti-competitive practice laws under the Packersand Stockyards Act (which cover captive supply,transparency <strong>of</strong> contracts, and access to openmarkets)• Strong enforcement <strong>of</strong> the Clean Water Act as itpertains to <strong>CAFOs</strong>, including improved oversightat the state level or the takeover <strong>of</strong> responsibilitiescurrently delegated to the states forapproving and monitoring and enforcement <strong>of</strong>National Pollution Discharge Elimination System(NPDES) permits; improvements could includemore inspectors and inspections, bettermonitoring <strong>of</strong> manure-handling practices, andmeasurement <strong>of</strong> pollution prevention practices• Development <strong>of</strong> new regulations under theClean Air Act that would reduce emissions <strong>of</strong>ammonia and other air pollutants from <strong>CAFOs</strong>,and ensure that CAFO operators cannot avoidsuch regulations by encouraging ammoniavolatilization• Continued monitoring and reporting <strong>of</strong> ammoniaand hydrogen sulfide emissions as requiredunder the Comprehensive Environmental Response,Compensation, and Liability Act(CERCLA, commonly referred to as the “Superfund”)and the Emergency Planning andCommunity Right-to-Know Act (EPCRA)• Replacement <strong>of</strong> farm bill commodity crop subsidieswith subsidies that strengthen conservationprograms and support prices when suppliesare high (rather than allowing prices to fallbelow the cost <strong>of</strong> production)• Reduction <strong>of</strong> the current $450,000 EQIP project capto levels appropriate to smaller farms, with a focuson support for sound animal farming practices• Revision <strong>of</strong> slaughterhouse regulations to facilitatelarger numbers <strong>of</strong> smaller processors, includingthe elimination <strong>of</strong> requirements not

<strong>CAFOs</strong> <strong>Uncovered</strong> 7appropriate to smaller facilities, combined withpublic health measures such as providing adequatenumbers <strong>of</strong> federal inspectors or empoweringand training state inspectors• Substantial funding for research to improvealternative animal production methods (especiallypasture-based) that are beneficial to the environment,public health, and rural communities

draw precise conclusions was beyond the scope <strong>of</strong>this report, but even when limited to the availablenational data, a glimpse <strong>of</strong> the large scale <strong>of</strong> <strong>CAFOs</strong>ubsidies is possible.Alternatives to <strong>CAFOs</strong> are many and diverse.ey include smaller feeding operations; pasturebasedcattle, swine, and poultry; and swine hoopbarns. Even these alternatives receive some subsidies;in particular, systems that use feed grain mayhave received some <strong>of</strong> the indirect grain subsidiesthat <strong>CAFOs</strong> have received. However, some alternativeshave not received these subsidies, and mosthave received proportionately less than <strong>CAFOs</strong>. Alternativesdo not receive several important directsubsidies (e.g., for manure transport), and they donot produce the degree <strong>of</strong> water pollution, air pollution,antibiotic-resistant organisms, health costs, orharm to rural communities that <strong>CAFOs</strong> do, thusgreatly reducing the costs the public must bear.Depriving <strong>CAFOs</strong> <strong>of</strong> their subsidies could helplevel the playing field, but would not necessarily ensurethe success <strong>of</strong> alternative systems. In manyways subsidies are appropriate in agriculture—providedthe public gets the desired benefits in returnfor its investment.<strong>CAFOs</strong> <strong>Uncovered</strong> 11

14 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>however, it can be prohibitively expensive to transportthe manure beyond a short distance. Disposalmay therefore be accomplished by pumping the liquefiedmanure onto nearby “sprayfields” (a practicethat can only distribute manure over a relativelyshort distance), or by trucking it a greater distance(which adds additional expense).e weight <strong>of</strong> CAFO manure is due to the mixing<strong>of</strong> urine and feces, which forms a slurry that ismostly liquid, and additional liquid is oen addedwhen manure is flushed with water into storage facilitiessuch as lagoons. Placing a large number <strong>of</strong>animals in a small space oen means that more manureis produced than can be properly disposed <strong>of</strong>on fields close to the CAFO.Other problems stem from the density <strong>of</strong> theanimals in individual operations. High-density confinementmeans that animals may be exposed totheir own manure, which is typically collectedwithin the stocking facilities, oen aer droppingthrough slatted floors. e manure can harbor andspread disease-causing organisms, and gases such asammonia and hydrogen sulfide emitted from themanure can be harmful to both animals and workers.<strong>CAFOs</strong> also release these harmful products intothe surrounding air and water, causing problems farbeyond the facility itself.Large manure storage facilities are oen requiredbecause the application <strong>of</strong> manure to fields isoen restricted to certain times <strong>of</strong> the year (e.g.,when the ground is not frozen). Such storage facilitiesraise additional environmental concerns. eycan overflow or collapse, sending unprocessed manureinto surface water, killing fish and contributingto degradation <strong>of</strong> the aquatic environment. Waterpollution can also occur due to leakage through theground under the storage facility, contaminatinggroundwater supplies such as wells and aquifers. Finally,these facilities also emit gases, especially ammonia,that cause air pollution and global warming.<strong>CAFOs</strong> Are Getting BiggerIt should be acknowledged that many <strong>CAFOs</strong> aremuch larger than the lower limit recognized by theEPA. is is illustrated for hog production in Figure 1,which shows the percent <strong>of</strong> hogs produced at operationslarger than 2,000 head and 5,000 head (doublethe minimum CAFO size) from 1994 to 2001(McBride and Key 2003). Over 50 percent <strong>of</strong> totalFigure 1. U.S. Hog Inventory on the Largest Farms80PERCENT OF TOTAL U.S. INVENTORY70605040302010+Operations with 2,000+ headOperations with 5,000+ head01994 1995 1996 1997 1998 1999 2000 2001Operations with 5,000+ head were not reported prior to 1996.SOURCE: McBride and Key 2003.

<strong>CAFOs</strong> <strong>Uncovered</strong> 15Figure 2. Number <strong>of</strong> U.S. Hog Operations and Hog Inventory250,0008075OPERATIONS200,000150,000100,00050,000OperationsInventory7065605550INVENTORY (MILLION OF HEAD)4501994 1995 1996 1997 1998 1999 2000 200140An operation is any place having one or more hogs on hand at any time during the year.SOURCE: McBride and Key 2003.hog production occurred on <strong>CAFOs</strong> with morethan 5,000 hogs by 2001. e average hog CAFOin the EPA’s southern seaboard region held morethan 12,000 head per year in 2004 (McBride andKey 2007).On the other hand, as illustrated in Figure 2, thetotal number <strong>of</strong> swine in the United States remainedabout the same over this time period, demonstratingthat increased size <strong>of</strong> operations was not requiredto supply the domestic demand for pork.Between 1994 and 2001, the number <strong>of</strong> hog operationsfell by more than 50 percent. Between 1982and 2006, the number <strong>of</strong> hog operations fell by afactor <strong>of</strong> almost 10, from just under 500,000 toabout 60,000 (NASS 2007).e total number <strong>of</strong> beef cattle produced in theUnited States has declined somewhat over the pastseveral decades, while broilers have increased dramatically.Between 1966 and 2006, the amount <strong>of</strong>broiler meat produced in the United States increasedby about 500 percent.e proportion <strong>of</strong> animals produced on <strong>CAFOs</strong>has increased greatly over the past several decades,and the geographic distribution <strong>of</strong> <strong>CAFOs</strong> has alsobecome more concentrated. Despite the fact thatmany smaller livestock operations remain, theirnumbers have been falling dramatically (Table 1,p. 16), 7 and <strong>CAFOs</strong> are now responsible forproducing much <strong>of</strong> the animal products soldin the United States.Table 2 (p. 16) shows the number <strong>of</strong> animalsraised by operations <strong>of</strong> different sizes in the UnitedStates. 8 e much greater size <strong>of</strong> animal operationsover 1,000 AU compared with smaller operationsmeans that even though there are many fewer largeoperations, they produce more animals than anyother size class as <strong>of</strong> 1997 (although medium-sizedoperations continue to produce a substantial number<strong>of</strong> animals). Large <strong>CAFOs</strong> clearly have been replacingother ways <strong>of</strong> raising livestock.Nevertheless, the fact that there are still manyoperations <strong>of</strong> small and medium size suggests that7 About 92 percent <strong>of</strong> all operations larger than 1,000 AU are confined operations (Kellogg et al. 2000).8 About 16 million AU are raised in <strong>CAFOs</strong>; therefore about 35 percent <strong>of</strong> all AU at large operations are unconfined. However, about 7.3 million AU on theselarge unconfined operations are in categories other than feedlot beef cows or dairy cows (Kellogg et al. 2000). e overwhelming majority <strong>of</strong> these are likely tobe cow-calf operations with animals on range or pasture, and virtually all beef calves over 500 lb. from these operations are eventually transferred to feedlot<strong>CAFOs</strong>. Excluding these cows, about 91 percent <strong>of</strong> all animals at operations larger than 1,000 AU are in confined operations, including virtually all large beefcattle- and swine-finishing operations, and virtually all chicken operations.

16 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>Table 1. Number <strong>of</strong> Livestock Operations by Size,* 1982–1997FarmSize Category1982 1987 1992 1997 Percent Change1982 to 1997Less Than 25 Total AU 660,425 577,488 496,206 474,335 -2825 to

<strong>CAFOs</strong> <strong>Uncovered</strong> 17tages against disadvantages such as the pollutioncaused by animal waste.To assess the efficiency <strong>of</strong> <strong>CAFOs</strong> we must firstchoose one <strong>of</strong> several possible definitions. Onemeasure <strong>of</strong> efficiency is costs per unit <strong>of</strong> production.ese costs typically include labor, materials, andenergy, but <strong>CAFOs</strong> also cause harm to the environmentand people that are “costs” to society.When such costs to the environment, publichealth, or rural communities are borne by societyrather than the producer they are termed “negativeexternalities” (or just “externalities” for the purposes<strong>of</strong> this report). If <strong>CAFOs</strong> were required to remediateor prevent the cost <strong>of</strong> these externalities, they wouldincur higher production costs and thus be consideredless efficient than they currently appear. In addition,<strong>CAFOs</strong> receive subsidies that help defraytheir production costs. Because these subsidies aretypically funded by taxes, society is paying to reduce<strong>CAFOs</strong>’ production costs in more ways than one.So, when examined in a broader societal context,suppositions about the higher economic efficiency<strong>of</strong> <strong>CAFOs</strong> can be seen as half-truths. eprimary purpose <strong>of</strong> this report is to examine some<strong>of</strong> the costs our society pays for <strong>CAFOs</strong> from an environmentaland public health perspective, and howsubsidies create an illusion <strong>of</strong> CAFO efficiency.e societal costs <strong>of</strong> pollution externalities andgrain subsidies—that is, costs for which CAFOowners have never been held accountable—are examinedprimarily in Chapters 2 and 3. But first, weconsider narrower aspects <strong>of</strong> efficiency that encompassthose costs CAFO owners have historically paid.Factors Contributing to CAFO GrowthSeveral key factors have driven CAFO expansion,one being the availability <strong>of</strong> cheap inputs (i.e., expensessuch as grain, water, and energy that havevariable costs). We consider the importance <strong>of</strong> lowcostgrain below.Another factor that will be briefly addressed inChapter 3 is technological change. is has takenthe form <strong>of</strong> developing breeds <strong>of</strong> livestock that bettersuit the CAFO environment and that facilitate highspeedprocessing, reliance on antibiotics to compensatefor conditions that favor disease, and feed formulationsthat allow animals to be produced in a way that meetsthe demands <strong>of</strong> <strong>CAFOs</strong>. ese changes and others haveoen been accomplished through taxpayer-supportedresearch at public universities.In addition, the ability <strong>of</strong> <strong>CAFOs</strong> to shi thecosts <strong>of</strong> their pollution onto the public in the form<strong>of</strong> externalities such as air and water pollution reducesthe apparent costs <strong>of</strong> production. e cost <strong>of</strong>these externalities is considered at greater length inChapter 3.In this chapter we will examine economic efficienciesand processor-related market control.Economic efficiencyEconomies <strong>of</strong> scale, which help larger operationsrun more efficiently by using production tools notreadily available to smaller operations, are oenoveremphasized in discussions <strong>of</strong> CAFO efficiency.Economies <strong>of</strong> scale do exist for <strong>CAFOs</strong> when costssuch as manure disposal are avoided, but are oensmall and reach optimum levels at an operation sizebelow that <strong>of</strong> large <strong>CAFOs</strong>.Much more important has been the availability<strong>of</strong> low-cost grain, which allows <strong>CAFOs</strong> to maintainlarge numbers <strong>of</strong> animals in a small space (becausethe grain can be brought to the animals rather thanhaving the animals forage for their food, as in pastures).Corn and soybeans, the primary feed grains,are high in easily digestible carbohydrates and proteincompared with forage. eir high nutritionalvalue per unit <strong>of</strong> weight allows large volumes <strong>of</strong>these grains to be shipped at relatively low expense, 9further facilitating the centralization <strong>of</strong> animal feedingoperations. For example, the ability to ship grainat low cost to the Mid-Atlantic, which lies outsidemajor corn- and soybean-growing regions, has facilitatedthe dramatic growth <strong>of</strong> <strong>CAFOs</strong> in North Carolina—nowthe second largest hog-producing stateand fourth largest producer <strong>of</strong> broilers.9 Soybeans are technically not grain, but for the sake <strong>of</strong> simplicity will be referred to as grain along with corn in this report (unless otherwise noted).

18 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>e high nutrient content <strong>of</strong> grain also gives it ahigh “conversion efficiency” compared with manyother feed sources. Conversion efficiency refers tothe amount <strong>of</strong> feed needed to produce a unit <strong>of</strong> animalproduct. Cattle, even though they evolved to eatforage, generally add weight somewhat faster andproduce more milk when fed grain rather than pastureor forage.Livestock also expend more energy to maintainbody temperature and mobility on pasture and otherCAFO alternatives, which contributes to lower conversionefficiency. Animals that are housed in temperature-controlledfacilities and have restricted mobilitycan devote more <strong>of</strong> their food consumption to gainingweight or producing eggs or milk. In other words, animalsin heated facilities are kept warm through theuse <strong>of</strong> fossil fuel energy rather than the metabolic energythey would otherwise expend.Beginning in the 1950s, the growth <strong>of</strong> broiler<strong>CAFOs</strong> applied pressure to other livestock sectors toadopt similar measures for increasing production andreducing costs. Chickens convert grain into meatmore efficiently than cattle or hogs: it typically takesabout 2.3 lb. <strong>of</strong> grain to produce a pound <strong>of</strong> chicken,but 5.9 lb. to produce a pound <strong>of</strong> pork and 13 lb. for apound <strong>of</strong> beef (Pimentel and Pimentel 2003), so evenaer adopting CAFO production methods, a grainbaseddiet for poultry maintains some advantagescompared with other types <strong>of</strong> livestock.Despite its advantages for weight gain, heavy dependenceon feed grain can only occur if it is lessexpensive than alternatives such as forage. is isbecause feed is a large part <strong>of</strong> <strong>CAFOs</strong>’ productioncosts—about 60 percent for hogs and broilers(Starmer, Witteman, and Wise 2006). As discussedat length in the following chapter, the low cost <strong>of</strong>grain in recent decades has been largely supportedby federal government policies that 1) provide taxpayersubsidies for cheap grain and 2) have eliminatedgrain supply controls, allowing prices to fall.Because feed comprises such a large expense for theCAFO industry, the cost to taxpayers for this subsidyis high.Low-cost inputs such as grain favor CAFO expansionwhen prices for animal products are low.is has generally been the case during the past severaldecades. Low-cost inputs spread the high fixedcosts <strong>of</strong> confinement infrastructure (such as thebuildings that contain the animals) over many units<strong>of</strong> production. <strong>CAFOs</strong> can compensate for lowpr<strong>of</strong>it margins per animal by producing large numbers<strong>of</strong> animals. By contrast, small and diversifiedproducers oen have relatively lower fixed costs andhigher variable costs, and may attempt to lowertheir costs by reducing production when prices arelow. In this way, <strong>CAFOs</strong> may expand at the expense<strong>of</strong> smaller operations.Another factor in CAFO efficiency is economies<strong>of</strong> scale. Hypothetically, a large facility may be ableto afford machinery that greatly improves productionefficiency because its cost is distributed over alarge amount <strong>of</strong> finished product (in this case,processed animals). A smaller facility could not takeadvantage <strong>of</strong> such efficiency because the cost <strong>of</strong> themachinery would be spread over too few products.Studies <strong>of</strong> this factor in the hog industry (e.g.,McBride and Key 2003) suggest that economies <strong>of</strong>scale exist, but are oen minimal for animal producerslarger than medium-sized AFOs or small<strong>CAFOs</strong>. erefore, economies <strong>of</strong> scale do not significantlyfavor <strong>CAFOs</strong> over medium-sized operations.A summary <strong>of</strong> several studies comparing theproduction costs <strong>of</strong> hog operations by size showedthat smaller and medium-sized hog farms had coststhat, compared with the largest farms, ranged fromthe same to 15 to 28 percent higher (Weida 2004a).For example, in one <strong>of</strong> the cited studies, three years’worth <strong>of</strong> data suggested that the optimal operationsize based on cost <strong>of</strong> production was 120 sows (producingabout 2,400 hogs per year). Typical costs inother studies were about 5 to 11 percent higher forthe smaller farms <strong>of</strong> 150 to 250 sows (producingabout 3,000 to 5,000 hogs per year) compared withoperations <strong>of</strong> 3,500 sows. Medium-sized AFOs weretypically more efficient than the smallest operations.Pr<strong>of</strong>its per hog for the best third <strong>of</strong> producers in another<strong>of</strong> the cited studies, regardless <strong>of</strong> operationsize, averaged about $10 per hog in 1999 dollars.Smaller to medium-sized independent hog producersspan a range <strong>of</strong> production efficiencies, and

<strong>CAFOs</strong> <strong>Uncovered</strong> 19the more efficient <strong>of</strong> these operations are cost-competitivewith larger <strong>CAFOs</strong> (Ikerd 2004; McBrideand Key 2003). ese more-efficient smaller, independentoperations produce hogs at about the samecost as the larger <strong>CAFOs</strong>. In a more recent study,costs for very large hog feeder-to-finish <strong>CAFOs</strong> averagedabout 9 percent less than medium-sized operations(500 to 1,999 head). However, 38 percent <strong>of</strong>medium-sized operations had costs below $40 perhundredweight (cwt), compared with 64 percent <strong>of</strong>very large <strong>CAFOs</strong>. A similar percentage <strong>of</strong> mediumsizedoperations, and about 16 percent <strong>of</strong> smallones, had the same or lower production costs thanthe average very large hog CAFO. Many mediumsizedoperations used production practices associatedwith higher efficiency, such as “all-in-all-out”production and “phase feeding” (McBride and Key2007). 10 ese data suggest that management skillsmay oen be more important than size in determiningefficiency, and that medium-sized and somesmall AFOs are capable <strong>of</strong> production as cost-effectiveas <strong>CAFOs</strong>—even without considering the externalities<strong>of</strong> manure that <strong>CAFOs</strong> impose in greateramounts than smaller operations. 11Comparisons based on scale are difficult whencomparing fundamentally different types <strong>of</strong> animalproduction. For example, such comparisons may beuseful when comparing <strong>CAFOs</strong> to smaller but otherwisesimilar AFOs. Various alternative livestockand poultry production methods, however, may differsubstantially from <strong>CAFOs</strong> in the technology,capital, and labor processes they employ, and theconsumer markets they target. In those cases, factorsother than scale may also be important in determiningefficiency or economic viability.For example, hog hoop barns that use deep beddingare generally a substantially less expensive alternativeto hog CAFO shelters. On the other hand,because hoop barns typically allow more space peranimal (especially if the hogs are provided with outdooraccess), fewer animals may be raised per unit<strong>of</strong> land. Bedding in hoop barns—typically smallgrainstraw or corn stalks—also adds expense, becausehog <strong>CAFOs</strong> typically have no bedding. Inaddition, feed conversion rates in Iowa (where moststudies <strong>of</strong> hoop barns have taken place) are somewhatlower in typically unheated hoop barns in winter(Kliebenstein et al. 2003). us, comparisonsbetween hoop barns and <strong>CAFOs</strong> based primarily onscale may not be appropriate to determine the financialviability <strong>of</strong> these alternative methods forraising hogs.Processor-driven market controlAnother major factor in the growing predominance<strong>of</strong> <strong>CAFOs</strong> is the integrated structure <strong>of</strong> the industry.Animal production and processing has become increasinglyintegrated and concentrated over the pastseveral decades. In particular, a few very large animalprocessors largely control the supply <strong>of</strong> animalsthrough ownership or contracting arrangements.And because <strong>of</strong> increasing functional integration,processors have gained considerable economicpower over producers, who depend on processors toslaughter their animals and distribute their products.In most cases, contracts (especially productioncontracts) have become the primary marketingarrangement between animal producers and processorsor packers (oen referred to as “integrators”).Industry concentration has risen substantiallyover the past several decades, to a point where itmay have a substantial impact on producers. An industryin which the market share <strong>of</strong> the four largestfirms (“four-firm concentration” or CR4) totalsmore than 40 percent is oen considered to threatenfree-market mechanisms by giving those firms too10All-in-all-out production keeps animals <strong>of</strong> the same age together in discrete batches, rather than mingling animals <strong>of</strong> different ages. Phase feeding matchesanimals’ diets to their specific life stage.11It has been observed that many operators <strong>of</strong> smaller and independent hog farms are older and preparing for retirement (McBride and Key 2003). eseolder owners may be less willing to invest in newer management approaches or make capital improvements that would improve efficiency. Younger or newerproducers, on the other hand, may be more attracted to CAFO production methods such as contract arrangements with processors for several reasons; reduction<strong>of</strong> risk has been suggested as one. Better availability <strong>of</strong> credit has also been associated with contract production, and because <strong>of</strong> the high capital expensesassociated with <strong>CAFOs</strong>, may be a significant motivating factor (MacDonald et al. 2004; Knoeber and urman 1995). Insufficient open-market options for independentproducers may be another reason.

20 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>much control over pricing and supply (Heffernan2000). e broiler chicken processing industry’sCR4 is 56 percent, the beef industry’s is 83.5 percent,and the hog industry’s is 64 percent, and eachhas been rising steadily for the past several decades.In 1990 these numbers were 44 percent, 72 percent,and 40 percent, respectively (Hendrickson and Heffernan2005). In 1987, the pork packers’ CR4 was 37percent, and the broiler processors’ was 35 percentin 1986—both below the 40 percent benchmark.e dairy processing industry is more complex thanother sectors, but is also undergoing increasing concentration(Hendrickson et al. 2001).Several <strong>of</strong> the largest companies, such as Cargill,ConAgra, Smithfield, and Tyson, have substantialholdings in several livestock sectors, and also ownlarge numbers <strong>of</strong> animals. For example, Smithfield isby far the largest owner <strong>of</strong> hogs in the country.Cargill and ConAgra are also grain suppliers (Hendricksonand Heffernan 2005). Growing ownershipby processors (called “captive supply”), a high percentage<strong>of</strong> production contracts, and shrinkingopen (or “spot”) markets have the potential to distortmarkets in favor <strong>of</strong> lower prices for producers.Despite this growing industry concentration,the federal authority charged with oversight <strong>of</strong> theprocessor industry, the USDA’s Grain Inspection,Packers and Stockyards Administration (GIPSA),has been strongly criticized for lax regulation <strong>of</strong>anti-competitive practices under the Packers andStockyards Act (PSA). In reports beginning in 2000,the Government Accountability Office (GAO, formerlythe General Accounting Office) and theUSDA’s Office <strong>of</strong> Inspector General (OIG) foundthat GIPSA lacked the organizational structure andprocesses needed to effectively monitor and enforcePSA provisions (GAO 2000). In particular, GIPSAdid not adequately involve attorneys from its Office<strong>of</strong> General Counsel in its investigations <strong>of</strong> potentialanti-competitive practice violations.Although GIPSA agreed to many <strong>of</strong> the recommendations<strong>of</strong> the GAO’s 2000 report, later investigationsby the GAO and OIG found that importantagreed-upon improvements had not been implemented(USDA 2006; GAO 2005), and lawyers hadnot been adequately integrated into GIPSA actions.e GAO noted that GIPSA senior managementthwarted investigations through delays and inaction,and that GIPSA <strong>of</strong>ficials had not adequatelyresponded to the GAO and OIG reports (GAO2006). e investigations <strong>of</strong> GIPSA oversight <strong>of</strong> theprocessor industry suggest that anti-competitivepractices against smaller and independent animalproducers are unlikely to be prevented under thecurrent system.e limited access <strong>of</strong> small and medium-sizedproducers to slaughterhouses is exacerbated byUSDA inspection requirements. With the exception<strong>of</strong> small chicken producers in many states that selldirectly to consumers, health inspections are necessaryfor marketing, and federal inspections are requiredfor sales across state lines. Access toregulator-approved facilities is therefore needed toensure broad market access. In other words, difficultyin gaining access to processors not only impedesproducers’ ability to slaughter their animals,but also may restrict their ability to market theirproducts. e resulting bottleneck between producerand consumer can reduce the viability <strong>of</strong> smaller andalternative producers even when their products maybe competitive based on production costs.Poultry processors, for example, have becomelarger and have built larger slaughterhouses. At thesame time, smaller processors and processing plantshave le the industry (Ollinger, MacDonald, andMadison 2005). e remaining large processorspreferentially contract with large producers (i.e.,<strong>CAFOs</strong>) and do not accept chickens or hogs fromindependent producers. is problem is exacerbatedby the need for slaughterhouses to be close to producersdue to the potential harm done to animalsduring transportation.Contracts are key features <strong>of</strong> the CAFO system.Broiler and egg production, the first types <strong>of</strong> animalproduction to develop <strong>CAFOs</strong>, were almost entirelydominated by contracting in 2001 (as shown inTable 3), with 88 percent <strong>of</strong> production under contract.Almost 61 percent <strong>of</strong> hogs were also produced

<strong>CAFOs</strong> <strong>Uncovered</strong> 21under contract in 2001, while only 31 percent wereproduced under contract from 1994 to 1995. Dairycontracts jumped from about 37 percent between1991 and 1993 to about 57 percent between 1994and 1995. Beef cattle were the only animals consideredin this report <strong>of</strong> which less than half (21 percent)were produced under contract (MacDonaldet al. 2004).Furthermore, only the largest producers typicallyuse contracts. For example, 65 percent <strong>of</strong> thelargest hog producers ($1 million production valueor greater) were under contract in 2001, while onlyabout 8 percent <strong>of</strong> small hog farms (less than$250,000 production value) used contracts. Evenmore dramatically, 92 percent <strong>of</strong> the total value <strong>of</strong>hog production was produced under contract thatyear (MacDonald et al. 2004).The role <strong>of</strong> integrators in contract processingProcessors are oen referred to as integrators becausethey combine the production and processingaspects <strong>of</strong> the industry through animal ownershipor contracts. Integrators have preferences about thesize <strong>of</strong> livestock producers with which they contract,so their decisions may have an important bearingon producer size.As noted above, most livestock are producedunder contractual arrangements with large integrators.erefore, access to processors for slaughterand distribution <strong>of</strong> animal products may oen dependon the producers’ ability to enter into contractswith processors. Because processors favorcontracts with large feeding operations, smaller oralternative animal producers can have difficulty processingand marketing their products, even if theyproduce these products at competitive prices. Andbecause the large majority <strong>of</strong> animals and productsare processed under contract, independent producersmay have difficulty in finding processors thatwill buy their products (or buy them at a fair price).Probably most important, however, is the need<strong>of</strong> large processing plants to operate near full capacityto realize economies <strong>of</strong> scale (MacDonald et al.2000). is encourages the use <strong>of</strong> contracts withlarge suppliers and captured supply, which canensure processing at full capacity.In the case <strong>of</strong> hog and beef processors,economies <strong>of</strong> scale at the largest processing plantsprovide only about a 3 to 5 percent cost savings forbeef and hog slaughter compared with plants onequartertheir size, and these savings are only realizedif the slaughterhouses run near full capacity.is favors processors that reduce their risk <strong>of</strong> operatingbelow capacity by contracting with <strong>CAFOs</strong>(MacDonald et al. 2000).Economies <strong>of</strong> scale are greater for poultry processing,and may be more directly associated withthe growth in large processing plants. e largestplants realized cost savings <strong>of</strong> about 8 percentcompared with smaller plants in 1992. erefore,Table 3. Percent <strong>of</strong> Livestock Production under Contract by SectorCommodity 1991–1993 1994–1995 1996–1997 1998–2000 2001Livestock 32.8 42.9 44.8 48.0 46.8Cattle na 19.0 17.0 24.3 20.9Hogs na 31.1 34.2 55.1 60.6Poultry and Eggs 88.7 84.6 84.0 88.8 88.1Dairy 36.8 56.7 58.2 53.6 53.1Other Livestock 0.2 9.3 4.9 10.9 9.3na=not availableData drawn from USDA Farm Costs and Returns Survey (1991–1995); USDA Agricultural Resource Management Survey (1996–2001)SOURCE: MacDonald et al. 2004.

22 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>economies <strong>of</strong> scale may explain a substantialamount <strong>of</strong> the consolidation in the poultry processingindustry (Ollinger, MacDonald, and Madison2000). Although economies <strong>of</strong> scale are less pronouncedfor swine processors, that sector seems tobe following a similar pattern.e increasing size <strong>of</strong> meat slaughtering operationshas occurred alongside the growth <strong>of</strong> <strong>CAFOs</strong>.is has led to the disappearance <strong>of</strong> smaller processorsthat might be more accessible to smaller producers(Ollinger, MacDonald, and Madison 2005).By 1992 large plants processed 88 percent <strong>of</strong> chickens(Ollinger, MacDonald, and Madison 2005), andas <strong>of</strong> 1997, four firms handled almost 80 percent <strong>of</strong>steer and heifer slaughter—twice as much as twodecades earlier. Large plants handled 38 percent <strong>of</strong>hog slaughter in 1977, but 88 percent by 1997(Table 4).With the increase in large processors and largeplants operating through contracts with producers,and a simultaneous decrease in smaller processors,it is becoming increasingly difficult for smaller independentand alternative producers to find slaughterhouseswilling to process their animals (Fanatico2003). is problem is exacerbated for specialty producersin niche markets such as pastured-raisedbeef, which require segregation <strong>of</strong> their productsfrom mainstream products.An alternative to contracts is open bidding (alsocalled a competitive or “spot” market), which wasthe common means for producers to sell to processorsprior to the predominance <strong>of</strong> contracting. Ascontracting has expanded, spot markets have becomemore restricted in many regions, which maylimit them as a marketing option for smaller producers(MacDonald et al. 2004). An added problemis that when spot markets become too small theymay no longer function efficiently, which can lowerprices for producers.Although cattle producers may be unhappy withspot market prices, the data show only modestlylower spot prices compared with contracts (MacDonaldet al. 2004). Nevertheless, because low prices foranimals may occur for both contract and spot marketsdue to the economic concentration <strong>of</strong> processorsand their ability to cross-subsidize different sectors <strong>of</strong>their business (Heffernan 2000), spot market pricesthat are only modestly lower than contracts do notnecessarily reflect fair pricing for producers.In summary, the evidence suggests that severalfactors have influenced the expansion <strong>of</strong> <strong>CAFOs</strong>over the past several decades, including the availability<strong>of</strong> low-cost grain and coordination between<strong>CAFOs</strong> and large processors through contracts andownership. e ability <strong>of</strong> <strong>CAFOs</strong> to shi the costs <strong>of</strong>their pollution onto society has also been important,but is considered separately in Chapter 3.Economies <strong>of</strong> scale exist for some <strong>CAFOs</strong> but areoen modest, while many medium-sized AFOs areas efficient as the largest <strong>CAFOs</strong>.Table 4. Percent <strong>of</strong> Animals Slaughtered in Large PlantsSlaughter Classes and Size Cut<strong>of</strong>f*Report YearAll Cattle Steers/Heifers Cows/Bulls Hogs(

<strong>CAFOs</strong> <strong>Uncovered</strong> 23Are CAFO Alternatives Cost-effective?Smaller to medium-sized AFOs that are adequatelydistributed geographically may address some <strong>of</strong> theconcerns posed by <strong>CAFOs</strong>. But what about other alternativesthat may avoid more <strong>of</strong> the problems that<strong>CAFOs</strong> cause? Are these alternatives cost-effective?Although the following review is not intendedto be comprehensive, it shows that several <strong>of</strong> thebetter-researched alternatives can indeed competewith confinement operations. is is something <strong>of</strong> asurprise considering that the great majority <strong>of</strong> researchdollars have been devoted to improvingCAFO performance while largely neglecting alternativemethods. In fact, one <strong>of</strong> the oen-touted advantages<strong>of</strong> <strong>CAFOs</strong> is their ability to adopttechnological advances such as breeds that gainweight quickly—advances that are sometimes availableonly to large producers.e disparity in research effort also suggests thatthere may be substantial opportunities to improvethe efficiency <strong>of</strong> alternatives. is review is thereforeonly a snapshot <strong>of</strong> an evolving picture, and as suchprovides only a rough indication <strong>of</strong> the possibilities.Hog production alternativesSome <strong>of</strong> the best-studied alternatives to <strong>CAFOs</strong> involvehog production. One <strong>of</strong> these alternatives ishoop barns—open-ended structures with curvedro<strong>of</strong>s, in which hogs are allowed to “nest” in strawbedding. Hogs may also be raised on pasture.In one test, hogs raised in hoop barns in NorthDakota provided 6.63 percent higher net incomeper pig than conventional confinement. is testalso evaluated pasture-raised hogs and found thatthe net return was 4.07 percent higher than confinement(Landblom et al. 2001). ese results are alsosupported by Iowa Livestock Enterprise budgets calculatedfor confined and pasture-raised hogs for2003. at report determined the break-even sellingprice for pasture-raised hogs was $43.56/cwt, comparedwith $43.60/cwt for confined hogs (May, Edwards,and Lawrence 2003). Mid-gestation swineraised on alfalfa pasture, with only 40 percent <strong>of</strong>their diet from corn, gained weight and performedas well as swine fed an exclusively corn/soy diet(Honeyman and Roush 1999).Financial viability based on net returns (includingamortization <strong>of</strong> infrastructure and debt) hasbeen used to determine how well hoop barns comparewith confinement operations. Because hoopbarn production is more sensitive to different inputparameters than confinement, it will perform betteror worse than <strong>CAFOs</strong> under different circumstances.For example, in one test conducted in Iowaduring winter, when feed conversion efficiency ispoorer than for confinement systems, hoop barnsdo less well by comparison. In warmer months,when conversion efficiencies are comparable, hoopbarns oen do as well or better than confinementproduction (Honeyman and Harmon 2003;Kliebenstein et al. 2003).Poorer winter conversion efficiency, which resultsin a slightly poorer overall efficiency, meansthat the financial viability <strong>of</strong> hoop barns is likely tobe more sensitive to grain prices than <strong>CAFOs</strong>. Forinstance, hoop barns will do less well by comparisonparticularly when grain prices are high and thegrain must be purchased rather than raised on thefarm. is alternative is also more sensitive to returnson investment: hoop barns delivered a higherreturn at prices over $54/cwt, while confinementoperations delivered better returns at lower prices.In addition, slightly more labor (three to six minutesper pig) was needed for hoop barns, so net returns forconfinement hogs were about 20 percent higher inthis test.An additional consideration not evaluated inthese studies is the effect <strong>of</strong> geographic location oneconomic efficiency. For example, hoop barns mayperform better in locations where the climate ismilder than Iowa and the feed conversion ratios willthus be higher. On the other hand, because Iowa—the country’s top hog-producing state—is alsolocated in the country’s corn belt, its grain prices arelower than some other regions <strong>of</strong> the country. ismay favor production in hoop barns in Iowa even iffeed conversion efficiencies are lower than in statesthat have milder climates but little grain production.

26 <strong>Union</strong> <strong>of</strong> <strong>Concerned</strong> <strong>Scientists</strong>Impact on global warmingOne important externality <strong>of</strong> livestock productionis the emission <strong>of</strong> heat-trapping gases such asmethane. Cattle are a major source <strong>of</strong> methane,which is produced during both the fermentation <strong>of</strong>feed in the animal’s gut and the anaerobic fermentation<strong>of</strong> manure in CAFO lagoons and other manureholding structures.Cows that feed on pasture or forage producemore methane during digestion than grain-fed cows(Clemens and Ahlgrimm 2001). ough this may bereduced substantially by optimizing productivitythrough MIRG (DeRamus et al. 2003), it is not clearthat methane levels can be reduced to those <strong>of</strong>grain-fed cattle.Production <strong>of</strong> the heat-trapping gas nitrousoxide from the breakdown <strong>of</strong> fertilizer used to producegrain must also be weighed against the production<strong>of</strong> nitrous oxide from manure produced by<strong>CAFOs</strong> and their alternatives. erefore the net effecton global warming pollution from pasture- versusgrain-fed livestock is unclear (Liebig et al. 2005).It should be noted, however, that althoughmethane production may be about 125 percenthigher on pasture operations compared with<strong>CAFOs</strong> (Boody et al. 2005), the atmospheric impactwould likely be <strong>of</strong>fset by higher capture <strong>of</strong> carbondioxide (Russelle, Entz, and Franzluebbers 2007).e results <strong>of</strong> several studies suggest that perennialpasture may capture about 0.9 metric ton <strong>of</strong> carbondioxide per hectare per year, while commoditycrops in Minnesota—even when grown under conservationtillage—capture only one-third thatamount (Boody et al. 2005).On balance, it appears likely that alternativeproduction systems that reduce the size and geographicdensity <strong>of</strong> animal feeding operations havesubstantial benefits compared with <strong>CAFOs</strong>. It is notpossible at this time to determine whether lowerglobal warming pollution is one <strong>of</strong> those benefits,but alternative integrated animal and crop productionsystems will likely substantially reduce otherexternalities associated with <strong>CAFOs</strong>.Conclusionse small sample <strong>of</strong> studies discussed above cannotbe used to draw sharp conclusions about the productivity<strong>of</strong> alternative animal production methodscompared with <strong>CAFOs</strong>. Many variables can affectboth productivity and pr<strong>of</strong>itability, including managementcapability, geography (e.g., regional climate),and availability <strong>of</strong> processors and markets.Some important parameters also change over timeas research develops new innovations and breeds oras the prices <strong>of</strong> grain, energy, and other inputschange.Despite these data limitations, however, thisoverview <strong>of</strong> alternative animal production and historictrends related to animal feeding operations allowsus to draw some broad conclusions about<strong>CAFOs</strong> and alternative animal production methods.First, although <strong>CAFOs</strong> oen exhibit someminor economies <strong>of</strong> scale, superior managementmay oen be more important in determining productionefficiency in at least some sectors. Wellmanagedsmaller to medium-sized swineoperations, for example, are as economically efficientas large <strong>CAFOs</strong>. Alternative systems can oenproduce animal products cost-effectively, and at anet pr<strong>of</strong>it to producers.Second, the largest obstacle facing alternativesis not the inability to produce animals efficiently,but the effects <strong>of</strong> processor-related market power.Challenges in this regard (vertically coordinatedproduction contracts between <strong>CAFOs</strong> and processors,elimination <strong>of</strong> smaller processors, and shrinking<strong>of</strong> efficient spot markets in some areas) couldhamper smaller and alternative producers evenwhen they may otherwise produce animals in acost-effective and pr<strong>of</strong>itable manner.Finally, alternatives that integrate animal andcrop production can provide benefits to farms andsociety alike, in the form <strong>of</strong> higher pr<strong>of</strong>itability andreduced externalities. Linking manure to croppingsystems, for example, creates major economic, social,and environmental benefits for an entire

egion. Considering the relatively limited researchcurrently available on ways to improve alternativeanimal farming systems, further research is neededto expand these benefits.<strong>CAFOs</strong> <strong>Uncovered</strong> 27

<strong>CAFOs</strong> <strong>Uncovered</strong> 29C h a p t e r 2DIRECT AND INDIRECT SUBSIDIES TO <strong>CAFOs</strong>The price consumers pay for animal products atthe grocery store does not reflect all <strong>of</strong> the costssociety as a whole pays for these products. One <strong>of</strong>the important ways these costs are masked isthrough the provision <strong>of</strong> subsidies to <strong>CAFOs</strong>. Somesubsidies may go directly to <strong>CAFOs</strong>; others (socalledindirect or implicit subsidies) go to otherparts <strong>of</strong> the economy and are then passed on to<strong>CAFOs</strong>. ese indirect subsidies may easily go unnoticedby the general public, but are just as importantto <strong>CAFOs</strong> in facilitating their operation andgrowth. Where subsidies go to <strong>CAFOs</strong> preferentiallyover other production systems, they provide an especiallyimportant advantage.In this chapter, several types <strong>of</strong> subsidies thathave been given to the CAFO industry are examined.One particularly substantial indirect subsidyhas been payments made to commodity crop growers,largely for corn and soybeans, which is passedon to the CAFO industry in the form <strong>of</strong> artificiallylow feed grain prices. ese low prices have largelybeen the result <strong>of</strong> the elimination <strong>of</strong> grain supplycontrols that were intended to keep prices at a reasonablelevel. is and other changes in federal farmlegislation have allowed the price <strong>of</strong> feed grains todrop below the cost <strong>of</strong> production in many years. Inresponse, lawmakers have compensated grain growersfor most <strong>of</strong> the difference between their cost <strong>of</strong>production and low market prices. Such indirectcrop subsidies have amounted to a windfall <strong>of</strong> severalbillion dollars per year for the CAFO industry.e second type <strong>of</strong> subsidy examined in this reportis direct payments made to the CAFO industrythrough the federal Environmental Quality IncentivesProgram (EQIP), which provides about$100 million per year to <strong>CAFOs</strong> to reduce some <strong>of</strong>the environmental damage they cause. EQIP subsidies,like commodity crop subsidies, are ultimatelypaid for by taxpayers, and could become increasinglyimportant as pressure is applied to the industryto clean up its practices.Although the reduction <strong>of</strong> harm caused by<strong>CAFOs</strong> is desirable, EQIP payments raise legitimatequestions about whether the public should underwrite<strong>CAFOs</strong> in this way. is is especially importantwhen considered in the context <strong>of</strong> alternativeproduction systems that are efficient, cause fewerproblems, and have greater societal benefits.Subsidies are appropriate buffers for the agriculturalsector against the uncertainties <strong>of</strong> nature andprice dips due to overproduction, and they encourageconservation and technological innovation.However, it is essential that subsidies also encourageand support desirable agricultural practices.How Crop Subsidies Have Propped Up <strong>CAFOs</strong>Livestock raised in confinement eat an enormousamount <strong>of</strong> corn and soybeans. Grain and animalproduction (and their respective costs) are thereforeinseparable when evaluating CAFO production.Over the last 80 years or so, U.S. farm policy hassubsidized the production <strong>of</strong> commodity crops suchas corn and soybeans in a variety <strong>of</strong> ways; currently,some payments are made to commodity farmers regardless<strong>of</strong> market prices or production costs. Herewe examine whether these subsidies have contributedto the growth <strong>of</strong> <strong>CAFOs</strong>, which are the primaryusers <strong>of</strong> these crops.A majority <strong>of</strong> the two most widely cultivatedcrops in the United States, corn and soybeans, is fedto livestock. In 2007, corn was grown on about