Buell set up a large drawing board in the “barn ... - Whitehorse Gear

Buell set up a large drawing board in the “barn ... - Whitehorse Gear

Buell set up a large drawing board in the “barn ... - Whitehorse Gear

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

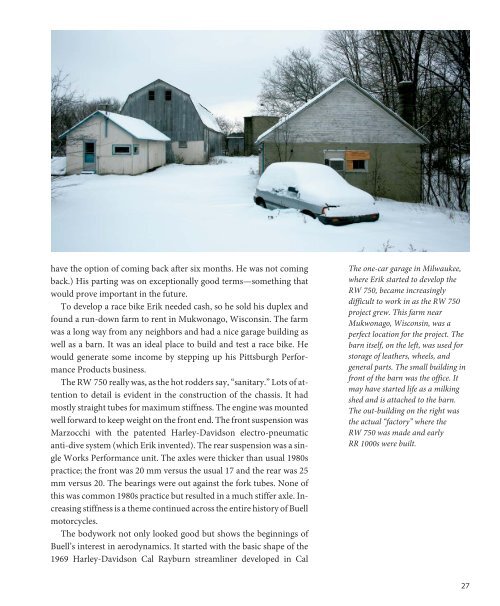

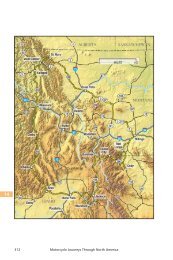

have <strong>the</strong> option of com<strong>in</strong>g back after six months. He was not com<strong>in</strong>gback.) His part<strong>in</strong>g was on exceptionally good terms—someth<strong>in</strong>g thatwould prove important <strong>in</strong> <strong>the</strong> future.To develop a race bike Erik needed cash, so he sold his d<strong>up</strong>lex andfound a run-down farm to rent <strong>in</strong> Mukwonago, Wiscons<strong>in</strong>. The farmwas a long way from any neighbors and had a nice garage build<strong>in</strong>g aswell as a barn. It was an ideal place to build and test a race bike. Hewould generate some <strong>in</strong>come by stepp<strong>in</strong>g <strong>up</strong> his Pittsburgh PerformanceProducts bus<strong>in</strong>ess.The RW 750 really was, as <strong>the</strong> hot rodders say, “sanitary.” Lots of attentionto detail is evident <strong>in</strong> <strong>the</strong> construction of <strong>the</strong> chassis. It hadmostly straight tubes for maximum stiffness. The eng<strong>in</strong>e was mountedwell forward to keep weight on <strong>the</strong> front end. The front suspension wasMarzocchi with <strong>the</strong> patented Harley-Davidson electro-pneumaticanti-dive system (which Erik <strong>in</strong>vented). The rear suspension was a s<strong>in</strong>gleWorks Performance unit. The axles were thicker than usual 1980spractice; <strong>the</strong> front was 20 mm versus <strong>the</strong> usual 17 and <strong>the</strong> rear was 25mm versus 20. The bear<strong>in</strong>gs were out aga<strong>in</strong>st <strong>the</strong> fork tubes. None ofthis was common 1980s practice but resulted <strong>in</strong> a much stiffer axle. Increas<strong>in</strong>gstiffness is a <strong>the</strong>me cont<strong>in</strong>ued across <strong>the</strong> entire history of <strong>Buell</strong>motorcycles.The bodywork not only looked good but shows <strong>the</strong> beg<strong>in</strong>n<strong>in</strong>gs of<strong>Buell</strong>’s <strong>in</strong>terest <strong>in</strong> aerodynamics. It started with <strong>the</strong> basic shape of <strong>the</strong>1969 Harley-Davidson Cal Rayburn streaml<strong>in</strong>er developed <strong>in</strong> CalThe one-car garage <strong>in</strong> Milwaukee,where Erik started to develop <strong>the</strong>RW 750, became <strong>in</strong>creas<strong>in</strong>glydifficult to work <strong>in</strong> as <strong>the</strong> RW 750project grew. This farm nearMukwonago, Wiscons<strong>in</strong>, was aperfect location for <strong>the</strong> project. Thebarn itself, on <strong>the</strong> left, was used forstorage of lea<strong>the</strong>rs, wheels, andgeneral parts. The small build<strong>in</strong>g <strong>in</strong>front of <strong>the</strong> barn was <strong>the</strong> office. Itmay have started life as a milk<strong>in</strong>gshed and is attached to <strong>the</strong> barn.The out-build<strong>in</strong>g on <strong>the</strong> right was<strong>the</strong> actual “factory” where <strong>the</strong>RW 750 was made and earlyRR 1000s were built.27