Centralloy® G 4859 - Schmidt+Clemens

Centralloy® G 4859 - Schmidt+Clemens

Centralloy® G 4859 - Schmidt+Clemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

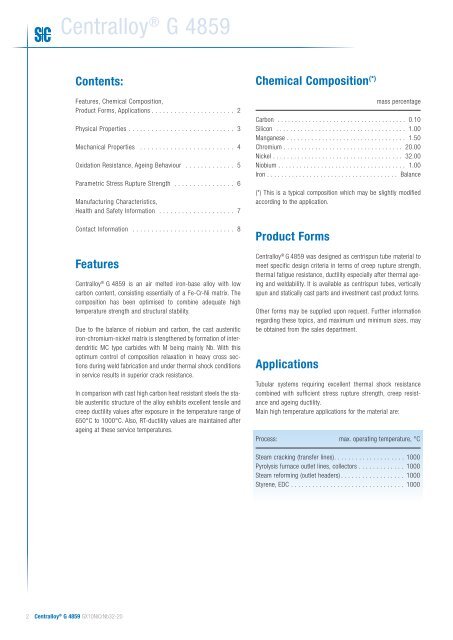

Centralloy ® G <strong>4859</strong>Contents:Features, Chemical Composition,Product Forms, Applications ...................... 2Physical Properties . ........................... 3Mechanical Properties ......................... 4Oxidation Resistance, Ageing Behaviour ............. 5Parametric Stress Rupture Strength ................ 6Manufacturing Characteristics,Health and Safety Information .................... 7Contact Information ........................... 8FeaturesCentralloy ® G <strong>4859</strong> is an air melted iron-base alloy with lowcarbon content, consisting essentially of a Fe-Cr-Ni matrix. Thecomposition has been optimised to combine adequate hightemperature strength and structural stability.Due to the balance of niobium and carbon, the cast austeniticiron-chromium-nickel matrix is stengthened by formation of interdendriticMC type carbides with M being mainly Nb. With thisoptimum control of composition relaxation in heavy cross sectionsduring weld fabrication and under thermal shock conditionsin service results in superior crack resistance.In comparison with cast high carbon heat resistant steels the stableaustenitic structure of the alloy exhibits excellent tensile andcreep ductility values after exposure in the temperature range of650°C to 1000°C. Also, RT-ductility values are maintained afterageing at these service temperatures.Chemical Composition (*) mass percentageCarbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10Silicon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.00Manganese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.50Chromium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.00Nickel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.00Niobium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.00Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Balance(*) This is a typical composition which may be slightly modifiedaccording to the application.Product FormsCentralloy ® G <strong>4859</strong> was designed as centrispun tube material tomeet specific design criteria in terms of creep rupture strength,thermal fatigue resistance, ductility especially after thermal ageingand weldability. It is available as centrispun tubes, verticallyspun and statically cast parts and investment cast product forms.Other forms may be supplied upon request. Further informationregarding these topics, and maximum und minimum sizes, maybe obtained from the sales department.ApplicationsTubular systems requiring excellent thermal shock resistancecombined with sufficient stress rupture strength, creep resistanceand ageing ductility.Main high temperature applications for the material are:Process: max. operating temperature, °CSteam cracking (transfer lines) ....................1000Pyrolysis furnace outlet lines, collectors ............. 1000Steam reforming (outlet headers) .................. 1000Styrene, EDC ................................ 10002Centralloy ® G <strong>4859</strong> GX10NiCrNb32-20