O Rings - M Barnwell Services Ltd

O Rings - M Barnwell Services Ltd

O Rings - M Barnwell Services Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

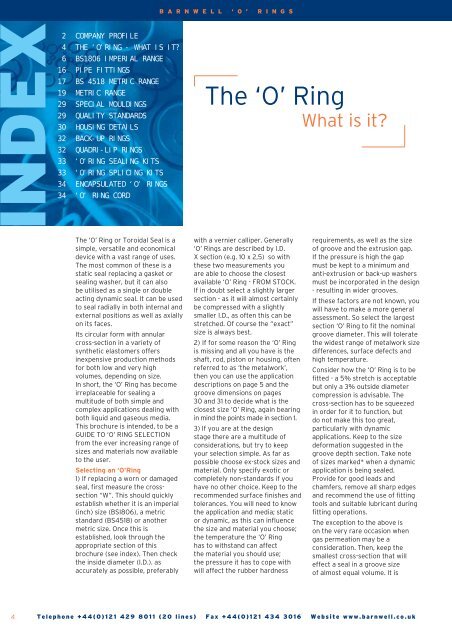

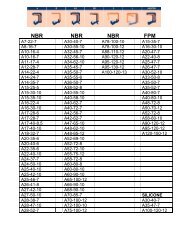

B A R N W E L L‘ O ’ R I N G SINDEX2 COMPANY PROFILE4 THE ‘O’RING - WHAT IS IT?6 BS1806 IMPERIAL RANGE16 PIPE FITTINGS17 BS 4518 METRIC RANGE19 METRIC RANGE29 SPECIAL MOULDINGS29 QUALITY STANDARDS30 HOUSING DETAILS32 BACK-UP RINGS32 QUADRI-LIP RINGS33 ‘O’RING SEALING KITS33 ‘O’RING SPLICING KITS34 ENCAPSULATED ‘O’ RINGS34 ‘O’ RING CORDThe ‘O’ RingWhat is it?The ‘O’ Ring or Toroidal Seal is asimple, versatile and economicaldevice with a vast range of uses.The most common of these is astatic seal replacing a gasket orsealing washer, but it can alsobe utilised as a single or doubleacting dynamic seal. It can be usedto seal radially in both internal andexternal positions as well as axiallyon its faces.Its circular form with annularcross-section in a variety ofsynthetic elastomers offersinexpensive production methodsfor both low and very highvolumes, depending on size.In short, the ‘O’ Ring has becomeirreplaceable for sealing amultitude of both simple andcomplex applications dealing withboth liquid and gaseous media.This brochure is intended, to be aGUIDE TO ‘O’ RING SELECTIONfrom the ever increasing range ofsizes and materials now availableto the user.Selecting an ‘O’Ring1) If replacing a worn or damagedseal, first measure the crosssection“W”. This should quicklyestablish whether it is an imperial(inch) size (BSI806), a metricstandard (BS4518) or anothermetric size. Once this isestablished, look through theappropriate section of thisbrochure (see index). Then checkthe inside diameter (I.D.). asaccurately as possible, preferablywith a vernier calliper. Generally‘O’ <strong>Rings</strong> are described by I.D.X section (e.g. 10 x 2,5) so withthese two measurements youare able to choose the closestavailable ‘O’ Ring - FROM STOCK.If in doubt select a slightly largersection - as it will almost certainlybe compressed with a slightlysmaller I.D., as often this can bestretched. Of course the “exact”size is always best.2) If for some reason the ‘O’ Ringis missing and all you have is theshaft, rod, piston or housing, oftenreferred to as ‘the metalwork’,then you can use the applicationdescriptions on page 5 and thegroove dimensions on pages30 and 31 to decide what is theclosest size ‘O’ Ring, again bearingin mind the points made in section 1.3) If you are at the designstage there are a multitude ofconsiderations, but try to keepyour selection simple. As far aspossible choose ex-stock sizes andmaterial. Only specify exotic orcompletely non-standards if youhave no other choice. Keep to therecommended surface finishes andtolerances. You will need to knowthe application and media; staticor dynamic, as this can influencethe size and material you choose;the temperature the ‘O’ Ringhas to withstand can affectthe material you should use;the pressure it has to cope withwill affect the rubber hardnessrequirements, as well as the sizeof groove and the extrusion gap.If the pressure is high the gapmust be kept to a minimum andanti-extrusion or back-up washersmust be incorporated in the design- resulting in wider grooves.If these factors are not known, youwill have to make a more generalassessment. So select the largestsection ‘O’ Ring to fit the nominalgroove diameter. This will toleratethe widest range of metalwork sizedifferences, surface defects andhigh temperature.Consider how the ‘O’ Ring is to befitted - a 5% stretch is acceptablebut only a 3% outside diametercompression is advisable. Thecross-section has to be squeezedin order for it to function, butdo not make this too great,particularly with dynamicapplications. Keep to the sizedeformation suggested in thegroove depth section. Take noteof sizes marked* when a dynamicapplication is being sealed.Provide for good leads andchamfers, remove all sharp edgesand recommend the use of fittingtools and suitable lubricant duringfitting operations.The exception to the above ison the very rare occasion whengas permeation may be aconsideration. Then, keep thesmallest cross-section that willeffect a seal in a groove sizeof almost equal volume. It is4Telephone +44(0)121 429 8011 (20 lines) Fax +44(0)121 434 3016 Website www.barnwell.co.uk