Technical Sheet (PDF Format) - M Barnwell Services Ltd

Technical Sheet (PDF Format) - M Barnwell Services Ltd

Technical Sheet (PDF Format) - M Barnwell Services Ltd

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

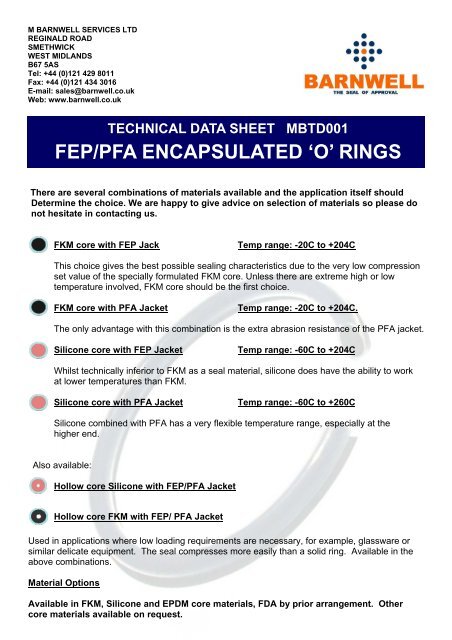

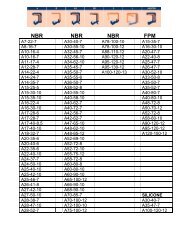

M BARNWELL SERVICES LTDREGINALD ROADSMETHWICKWEST MIDLANDSB67 5ASTel: +44 (0)121 429 8011Fax: +44 (0)121 434 3016E-mail: sales@barnwell.co.ukWeb: www.barnwell.co.ukTECHNICAL DATA SHEET MBTD001FEP/PFA ENCAPSULATED ‘O’ RINGSThere are several combinations of materials available and the application itself shouldDetermine the choice. We are happy to give advice on selection of materials so please donot hesitate in contacting us.FKM core with FEP Jack Temp range: -20C to +204CThis choice gives the best possible sealing characteristics due to the very low compressionset value of the specially formulated FKM core. Unless there are extreme high or lowtemperature involved, FKM core should be the first choice.FKM core with PFA JacketTemp range: -20C to +204C.The only advantage with this combination is the extra abrasion resistance of the PFA jacket.Silicone core with FEP Jacket Temp range: -60C to +204CWhilst technically inferior to FKM as a seal material, silicone does have the ability to workat lower temperatures than FKM.Silicone core with PFA Jacket Temp range: -60C to +260CSilicone combined with PFA has a very flexible temperature range, especially at thehigher end.Also available:Hollow core Silicone with FEP/PFA JacketHollow core FKM with FEP/ PFA JacketUsed in applications where low loading requirements are necessary, for example, glassware orsimilar delicate equipment. The seal compresses more easily than a solid ring. Available in theabove combinations.Material OptionsAvailable in FKM, Silicone and EPDM core materials, FDA by prior arrangement. Othercore materials available on request.

M BARNWELL SERVICES LTDREGINALD ROADSMETHWICKWEST MIDLANDSB67 5ASTel: +44 (0)121 429 8011Fax: +44 (0)121 434 3016E-mail: sales@barnwell.co.ukWeb: www.barnwell.co.ukSize RangeAs well as the standard ranges such as AS568, AS871, BS1806, BS4518,DIN and JIS B2401, we can supply a full range of metric and imperial crosssections and diameters. Whilst there is no upper limit to the inside diameteravailable, there is a lower limit and the following table shows how small wecan supply these rings.w d1 Solid Core d1 Hollow CoreViton Silicone Viton Silicone1.60 5.00 5.00 N/A N/A1.78 5.28 5.28 N/A 8.002.00 6.80 6.80 10.00 10.002.40 7.40 7.40 12.00 12.002.50 7.40 7.40 12.00 12.002.62 7.60 7.60 16.00 16.003.00 12.00 12.00 20.00 20.003.40 12.50 12.50 23.00 23.003.53 13.00 13.00 24.00 24.003.60 13.00 13.00 24.00 24.004.00 14.00 14.00 28.00 28.004.25 14.50 14.50 32.00 32.004.50 15.00 15.00 35.00 35.005.00 20.00 20.00 42.00 42.005.34 22.00 22.00 48.00 48.005.50 23.00 23.00 50.00 50.005.70 24.00 24.00 60.00 60.006.00 27.00 27.00 75.00 75.006.35 38.00 38.00 90.00 90.006.50 45.00 45.00 95.00 95.006.99 48.00 48.00 100.00 100.008.00 72.00 72.00 150.00 150.008.40 76.00 76.00 160.00 160.009.00 95.00 95.00 175.00 175.009.52 105.00 105.00 200.00 200.0010.00 110.00 110.00 230.00 230.0010.50 112.00 112.00 240.00 240.0011.10 115.00 115.00 250.00 250.0012.00 120.00 120.00 300.00 300.0012.70 130.00 130.00 350.00 350.0014.00 180.00 180.00 390.00 390.0014.30 180.00 180.00 390.00 390.0015.00 250.00 250.00 400.00 400.0015.90 280.00 280.00 450.00 450.0018.00 325.00 325.00 475.00 475.0019.05 350.00 350.00 500.00 500.0020.63 400.00 400.00 550.00 550.0025.40 425.00 425.00 600.00 600.0030.00 475.00 475.00 750.00 700.0032.00 500.00 500.00 850.00 750.00Other cross sections may be possible by special manufacture depending onthe volume, apply for price. Do not stretch small inside diameter rings whenfitting as this results in breakage of the core.Cross section and inner diameter tolerancesThe cross sectional and inside diameter tolerances of this type ofsealing ring differ to those of conventional moulded ’O’ Rings.When produced in medium to larger sizes, the cross section staysquite rounded in profile, but in smaller sizes a degree of ovality(a/r) may occur, due to the jacket material memory giving agreater axial height than radial width.w d1 to d1 w +/- d1 > w +/-1.60 5.00 - 10.00 0.12 0.101.78 5.28 - 12.00 0.12 0.102.00 6.80 - 15.00 0.12 0.102.40 7.40 - 17.00 0.15 0.122.50 7.40 - 17.00 0.15 0.122.62 7.60 - 18.00 0.15 0.123.00 12.00 - 20.00 0.20 0.153.40 12.50 - 22.50 0.20 0.153.53 13.00 - 25.00 0.20 0.153.60 13.00 - 25.00 0.20 0.154.00 14.00 - 30.00 0.30 0.254.25 14.50 - 35.00 0.30 0.254.50 15.00 - 40.00 0.30 0.255.00 20.00 - 45.00 0.30 0.255.34 22.00 - 50.00 0.30 0.255.50 23.00 - 52.00 0.30 0.255.70 24.00 - 54.00 0.30 0.256.00 27.00 - 56.00 0.35 0.306.35 40.00 - 58.00 0.35 0.306.50 45.00 - 59.00 0.35 0.306.99 50.00 - 60.00 0.35 0.308.00 75.00 - 90.00 0.45 0.408.40 76.00 - 100.00 0.45 0.409.00 95.00 - 125.00 0.45 0.409.52 105.00 - 150.00 0.45 0.4010.00 110.00 - 170.00 0.60 0.5010.50 112.00 - 180.00 0.60 0.5011.10 115.00 - 200.00 0.60 0.5012.00 120.00 - 250.00 0.60 0.5012.70 130.00 - 300.00 0.60 0.5014.00 180.00 - 300.00 0.60 0.5014.30 180.00 - 400.00 0.75 0.6015.00 250.00 - 450.00 0.75 0.6015.90 280.00 - 500.00 0.85 0.7018.00 325.00 - 700.00 1.00 0.8019.05 350.00 - 750.00 1.00 0.8020.63 400.00 - 875.00 1.00 0.9025.40 425.00 - 1000.00 1.25 0.9030.00 475.00 - 1250.00 1.50 1.2032.00 500.00 - 1500.00 1.75 1.50Due to the temperature sensitivity of FEP, ‘O’ Ringsare produced and controlled to conform withDIN 7715 M2F.larger d1 leaves w equally roundd1wd1tol5.0mm thro 16.0mm +/- 0.2016.0mm thro 25.0mm +/- 0.2525.1mm thro 40.0mm +/- 0.3540.1mm thro 63.0mm +/- 0.4063.1mm thro 100.0mm +/- 0.50100.1mm thro 160.0mm +/- 0.70smaller d1 leaves w ovalaThereafter, the tolerance will be +/- 0.5% of the nominalinside diameter of the ring.Example : inside diameter of 310.0mmrTolerance = +/- 1.55mm (0.5%)