REMCO Total Preventive Maintenance and ... - Morris Group, Inc.

REMCO Total Preventive Maintenance and ... - Morris Group, Inc.

REMCO Total Preventive Maintenance and ... - Morris Group, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

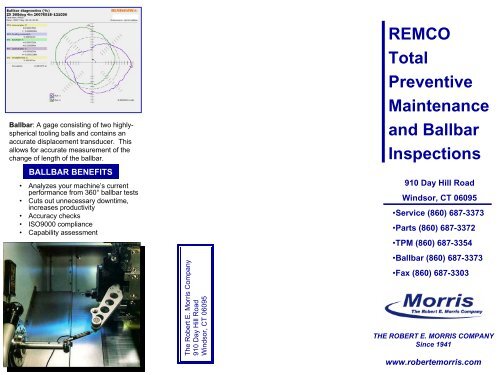

Ballbar: A gage consisting of two highlysphericaltooling balls <strong>and</strong> contains anaccurate displacement transducer. Thisallows for accurate measurement of thechange of length of the ballbar.BALLBAR BENEFITS• Analyzes your machine’s currentperformance from 360° ballbar tests• Cuts out unnecessary downtime,increases productivity• Accuracy checks• ISO9000 compliance• Capability assessment<strong>REMCO</strong><strong>Total</strong><strong>Preventive</strong><strong>Maintenance</strong><strong>and</strong> BallbarInspections910 Day Hill RoadWindsor, CT 06095•Service (860) 687-3373•Parts (860) 687-3372•TPM (860) 687-3354The Robert E. <strong>Morris</strong> Company910 Day Hill RoadWindsor, CT 06095•Ballbar (860) 687-3373•Fax (860) 687-3303THE ROBERT E. MORRIS COMPANYSince 1941www.robertemorris.com

Why <strong>Total</strong> <strong>Preventive</strong><strong>Maintenance</strong>?• Our Factory Trained Field ServiceEngineers are strategically locatedthroughout the Northeast.• Say “NO” to downtime <strong>and</strong> longercycle times.• Designed to keep your equipmentworking at optimum efficiency, our<strong>Total</strong> <strong>Preventive</strong> <strong>Maintenance</strong>Program protects the sizeableinvestment you’ve made.• Our Engineers are experts atdiagnosing problems before theyhappen.• Engineers from The Robert E.<strong>Morris</strong> Company are pro-active. We’llkeep your electronics, motors,pumps, hydraulics, lubrication, axismovement, spindle, tool changefunctions <strong>and</strong> alignments all finallytuned. You'll benefit by maintaininghigh levels of precision, repeatability<strong>and</strong> achieving longer machine life.• You’ll gain an intimate knowledge ofyour machines. We review problemareas with you as service is beingperformed.• We can usually acquire neededparts the next business day <strong>and</strong>make needed repairs. This will ensureyour production <strong>and</strong> quality levels areat their highest while avoiding costlydowntime <strong>and</strong> higher repair costs.• Any repairs made as a result of ourfindings will be invoiced at a reducedrate when you sign up for thisexclusive program.Your CNC equipment is a sizeableinvestment. To generate the largestreturn possible, these machines mustbe producing at their utmostcapability. A poorly maintainedmachine will produce longer cycletimes; more scrap parts, <strong>and</strong>ultimately, DOWN TIME!The best way to insure the highestreturns on your investment isRegular <strong>Maintenance</strong>! Justchanging the oils <strong>and</strong> filters is notenough to keep productivity at itshighest levels.Once the <strong>Total</strong> Productive<strong>Maintenance</strong> is completed youwill receive an in-depth report<strong>and</strong> our recommendations as tohow to achieve higher qualityproductivity. The documentationgoes above <strong>and</strong> beyond anyrequirements needed for ISO9001 certification. We will alsoassist in any way we can duringthe certification process.Please Contact Us!The Robert E. <strong>Morris</strong> Company