The top ten factors in kraft pulp yield - The Kraft Pulping Course

The top ten factors in kraft pulp yield - The Kraft Pulping Course

The top ten factors in kraft pulp yield - The Kraft Pulping Course

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mart<strong>in</strong> MacLeod<br />

<strong>The</strong> <strong>top</strong> <strong>ten</strong> <strong>factors</strong> <strong>in</strong> <strong>kraft</strong> <strong>pulp</strong> <strong>yield</strong><br />

AbstrAct<br />

<strong>Kraft</strong> <strong>pulp</strong> <strong>yield</strong> depends on a plethora of <strong>factors</strong>:<br />

the nature of the wood and the quality<br />

of the chips, the cook<strong>in</strong>g recipe (especially<br />

the key <strong>in</strong>dependent variables – alkali charge,<br />

sulphidity, temperature, and kappa target),<br />

the <strong>pulp</strong><strong>in</strong>g equipment, and so on. Here, the<br />

<strong>factors</strong> have been assembled <strong>in</strong>to a “<strong>top</strong> <strong>ten</strong>”<br />

list, and are assessed <strong>in</strong> terms of relative<br />

importance, po<strong>ten</strong>tial to <strong>in</strong>fluence <strong>yield</strong> values,<br />

and contribution to practical knowledge<br />

of how <strong>pulp</strong> <strong>yield</strong>s can be improved. the <strong>ten</strong><br />

<strong>factors</strong> can be re-ordered at will, to rank the<br />

magnitude of the <strong>yield</strong> changes they can produce,<br />

for example, or to see which <strong>factors</strong><br />

have the highest po<strong>ten</strong>tial for <strong>yield</strong> improvement<br />

at modest cost.<br />

What are the pr<strong>in</strong>cipal <strong>factors</strong><br />

affect<strong>in</strong>g <strong>pulp</strong> <strong>yield</strong>s <strong>in</strong> <strong>kraft</strong> mills? How<br />

comprehensive is our understand<strong>in</strong>g of<br />

them? Are there practical ways to use exist<strong>in</strong>g<br />

knowledge to improve <strong>yield</strong>s?<br />

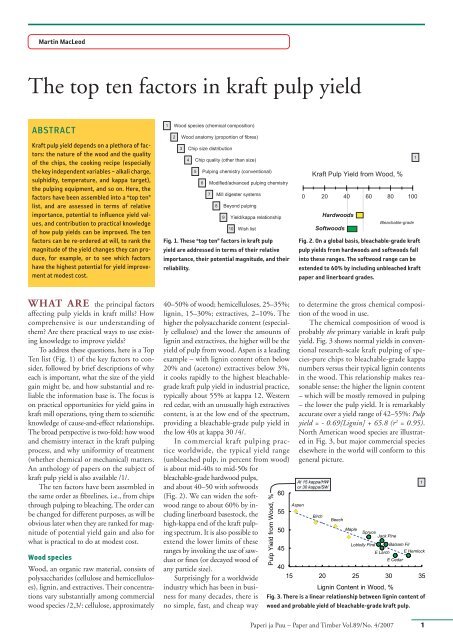

To address these questions, here is a Top<br />

Ten list (Fig. 1) of the key <strong>factors</strong> to consider,<br />

followed by brief descriptions of why<br />

each is important, what the size of the <strong>yield</strong><br />

ga<strong>in</strong> might be, and how substantial and reliable<br />

the <strong>in</strong>formation base is. <strong>The</strong> focus is<br />

on practical opportunities for <strong>yield</strong> ga<strong>in</strong>s <strong>in</strong><br />

<strong>kraft</strong> mill operations, ty<strong>in</strong>g them to scientific<br />

knowledge of cause-and-effect relationships.<br />

<strong>The</strong> broad perspective is two-fold: how wood<br />

and chemistry <strong>in</strong>teract <strong>in</strong> the <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g<br />

process, and why uniformity of treatment<br />

(whether chemical or mechanical) matters.<br />

An anthology of papers on the subject of<br />

<strong>kraft</strong> <strong>pulp</strong> <strong>yield</strong> is also available /1/.<br />

<strong>The</strong> <strong>ten</strong> <strong>factors</strong> have been assembled <strong>in</strong><br />

the same order as fibrel<strong>in</strong>es, i.e., from chips<br />

through <strong>pulp</strong><strong>in</strong>g to bleach<strong>in</strong>g. <strong>The</strong> order can<br />

be changed for different purposes, as will be<br />

obvious later when they are ranked for magnitude<br />

of po<strong>ten</strong>tial <strong>yield</strong> ga<strong>in</strong> and also for<br />

what is practical to do at modest cost.<br />

Wood species<br />

Wood, an organic raw material, consists of<br />

polysaccharides (cellulose and hemicelluloses),<br />

lign<strong>in</strong>, and extractives. <strong>The</strong>ir concentrations<br />

vary substantially among commercial<br />

wood species /2,3/: cellulose, approximately<br />

1 Wood<br />

species<br />

( chemical<br />

composition)<br />

2 Wood<br />

anatomy<br />

( proportion<br />

of<br />

fibres)<br />

3 Chip<br />

size<br />

distribution<br />

4 Chip<br />

quality<br />

( other<br />

than<br />

size)<br />

5 Pulp<strong>in</strong>g<br />

chemistry<br />

( conventional)<br />

6 Modified/<br />

advanced<br />

<strong>pulp</strong><strong>in</strong>g<br />

chemistry<br />

7 Mill<br />

digester<br />

systems<br />

8 Beyond<br />

<strong>pulp</strong><strong>in</strong>g<br />

9 Yield/<br />

kappa<br />

relationship<br />

10 Wish<br />

list<br />

Fig. 1. <strong>The</strong>se “<strong>top</strong> <strong>ten</strong>” <strong>factors</strong> <strong>in</strong> <strong>kraft</strong> <strong>pulp</strong><br />

<strong>yield</strong> are addressed <strong>in</strong> terms of their relative<br />

importance, their po<strong>ten</strong>tial magnitude, and their<br />

reliability.<br />

40–50% of wood; hemicelluloses, 25–35%;<br />

lign<strong>in</strong>, 15–30%; extractives, 2–10%. <strong>The</strong><br />

higher the polysaccharide con<strong>ten</strong>t (especially<br />

cellulose) and the lower the amounts of<br />

lign<strong>in</strong> and extractives, the higher will be the<br />

<strong>yield</strong> of <strong>pulp</strong> from wood. Aspen is a lead<strong>in</strong>g<br />

example – with lign<strong>in</strong> con<strong>ten</strong>t of<strong>ten</strong> below<br />

20% and (acetone) extractives below 3%,<br />

it cooks rapidly to the highest bleachablegrade<br />

<strong>kraft</strong> <strong>pulp</strong> <strong>yield</strong> <strong>in</strong> <strong>in</strong>dustrial practice,<br />

typically about 55% at kappa 12. Western<br />

red cedar, with an unusually high extractives<br />

con<strong>ten</strong>t, is at the low end of the spectrum,<br />

provid<strong>in</strong>g a bleachable-grade <strong>pulp</strong> <strong>yield</strong> <strong>in</strong><br />

the low 40s at kappa 30 /4/.<br />

In commercial <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g practice<br />

worldwide, the typical <strong>yield</strong> range<br />

(unbleached <strong>pulp</strong>, <strong>in</strong> percent from wood)<br />

is about mid-40s to mid-50s for<br />

bleachable-grade hardwood <strong>pulp</strong>s,<br />

and about 40–50 with softwoods<br />

(Fig. 2). We can widen the softwood<br />

range to about 60% by <strong>in</strong>clud<strong>in</strong>g<br />

l<strong>in</strong>erboard basestock, the<br />

high-kappa end of the <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g<br />

spectrum. It is also possible to<br />

ex<strong>ten</strong>d the lower limits of these<br />

ranges by <strong>in</strong>vok<strong>in</strong>g the use of sawdust<br />

or f<strong>in</strong>es (or decayed wood of<br />

any particle size).<br />

Surpris<strong>in</strong>gly for a worldwide<br />

<strong>in</strong>dustry which has been <strong>in</strong> bus<strong>in</strong>ess<br />

for many decades, there is<br />

no simple, fast, and cheap way<br />

Pulp Yield from Wood, %<br />

60<br />

55<br />

50<br />

45<br />

40<br />

15<br />

0<br />

<strong>Kraft</strong><br />

20<br />

Pulp<br />

Yie<br />

40<br />

Hardwoods<br />

Softwoods<br />

from<br />

Wood,<br />

%<br />

to determ<strong>in</strong>e the gross chemical composition<br />

of the wood <strong>in</strong> use.<br />

<strong>The</strong> chemical composition of wood is<br />

probably the primary variable <strong>in</strong> <strong>kraft</strong> <strong>pulp</strong><br />

<strong>yield</strong>. Fig. 3 shows normal <strong>yield</strong>s <strong>in</strong> conventional<br />

research-scale <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g of species-pure<br />

chips to bleachable-grade kappa<br />

numbers versus their typical lign<strong>in</strong> con<strong>ten</strong>ts<br />

<strong>in</strong> the wood. This relationship makes reasonable<br />

sense: the higher the lign<strong>in</strong> con<strong>ten</strong>t<br />

– which will be mostly removed <strong>in</strong> <strong>pulp</strong><strong>in</strong>g<br />

– the lower the <strong>pulp</strong> <strong>yield</strong>. It is remarkably<br />

accurate over a <strong>yield</strong> range of 42–55%: Pulp<br />

<strong>yield</strong> = - 0.69[Lign<strong>in</strong>] + 65.8 (r 2 = 0.95).<br />

North American wood species are illustrated<br />

<strong>in</strong> Fig. 3, but major commercial species<br />

elsewhere <strong>in</strong> the world will conform to this<br />

general picture.<br />

Paperi ja Puu – Paper and Timber Vol.89/No. 4/2007<br />

ld<br />

60<br />

80<br />

100<br />

Bleachable-grade<br />

Fig. 2. On a global basis, bleachable-grade <strong>kraft</strong><br />

<strong>pulp</strong> <strong>yield</strong>s from hardwoods and softwoods fall<br />

<strong>in</strong>to these ranges. <strong>The</strong> softwood range can be<br />

ex<strong>ten</strong>ded to 60% by <strong>in</strong>clud<strong>in</strong>g unbleached <strong>kraft</strong><br />

paper and l<strong>in</strong>erboard grades.<br />

At<br />

15<br />

kappa/<br />

HW<br />

or<br />

30<br />

kappa/<br />

SW<br />

Aspen<br />

Birch<br />

20<br />

Beech<br />

Maple<br />

Spruce<br />

Jack<br />

P<strong>in</strong>e<br />

Loblolly<br />

P<strong>in</strong>e<br />

Balsam<br />

Fir<br />

E Larch<br />

E Cedar<br />

E Hemlock<br />

25<br />

30<br />

1<br />

1<br />

35<br />

Lign<strong>in</strong><br />

Con<strong>ten</strong>t<br />

<strong>in</strong><br />

Wood,<br />

%<br />

Fig. 3. <strong>The</strong>re is a l<strong>in</strong>ear relationship between lign<strong>in</strong> con<strong>ten</strong>t of<br />

wood and probable <strong>yield</strong> of bleachable-grade <strong>kraft</strong> <strong>pulp</strong>.

Wood anatomy<br />

<strong>The</strong> physical nature of wood also plays an<br />

important role <strong>in</strong> <strong>yield</strong>. Large differences<br />

exist among wood species, especially <strong>in</strong><br />

percentage of “fibres” (the preferred cell<br />

type for papermak<strong>in</strong>g) versus that of less<br />

desirable cells (e.g., ray parenchyma <strong>in</strong> softwoods,<br />

vessel elements <strong>in</strong> hardwoods) /5/.<br />

This is compounded by large ranges <strong>in</strong> the<br />

pr<strong>in</strong>cipal wood fibre dimensions: length,<br />

diameter, and cell wall thickness /6/. For<br />

example, loblolly p<strong>in</strong>e <strong>kraft</strong> <strong>pulp</strong> fibres<br />

can be five times longer than sugar maple<br />

fibres. Further, there are dimensional differences<br />

between earlywood and latewood,<br />

and between juvenile and mature wood. Of<br />

all of these, only fibre length distribution<br />

is rout<strong>in</strong>ely measured <strong>in</strong> the <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g<br />

world.<br />

From a papermaker’s perspective, a more<br />

appropriate concept might be the <strong>yield</strong> of<br />

papermak<strong>in</strong>g fibres from wood. In this sense,<br />

different wood species offer very different<br />

po<strong>ten</strong>tial <strong>yield</strong>s. If only long, narrow fibres<br />

are sought, for example, then softwoods<br />

have a large advantage over hardwoods, <strong>in</strong><br />

which wood anatomy is much more diverse<br />

(Fig. 4). But by acknowledg<strong>in</strong>g that hardwoods<br />

<strong>in</strong>evitably conta<strong>in</strong> significant<br />

amounts of vessel elements, we can add<br />

them back s<strong>in</strong>ce they are part of the <strong>pulp</strong><br />

<strong>yield</strong>, br<strong>in</strong>g<strong>in</strong>g the hardwood cases much<br />

closer to the softwood ones. Still, there is<br />

a substantial amount of cell material <strong>in</strong> all<br />

woods that is not ideal from a papermak<strong>in</strong>g<br />

standpo<strong>in</strong>t.<br />

We can generalize with the follow<strong>in</strong>g<br />

observations:<br />

• <strong>The</strong> higher the percentage of long, narrow<br />

fibres (as opposed to any other cell<br />

types) <strong>in</strong> the wood raw material, the<br />

more uniform will be the <strong>pulp</strong><strong>in</strong>g, en-<br />

Papermak<strong>in</strong>g<br />

0<br />

20<br />

Fibres<br />

only<br />

Sweetgum<br />

Fibres,<br />

% of<br />

wood<br />

40<br />

Aspen<br />

60<br />

White<br />

birch<br />

80<br />

c<br />

Spruces<br />

D Fir,<br />

P<strong>in</strong>es<br />

Fibres<br />

and<br />

vessel<br />

elements<br />

on<strong>ten</strong>t<br />

100<br />

Fig. 4. If <strong>yield</strong> is def<strong>in</strong>ed on the basis of suitable<br />

papermak<strong>in</strong>g fibres, softwoods have an<br />

advantage due to wood anatomy. Whether vessel<br />

elements are considered “suitable” makes a<br />

large difference <strong>in</strong> the hardwood results.<br />

Paperi ja Puu – Paper and Timber Vol.89/No. 4/2007<br />

2<br />

hanc<strong>in</strong>g the <strong>yield</strong> of <strong>pulp</strong> which is ideal<br />

for papermak<strong>in</strong>g.<br />

• <strong>The</strong> greater the range of wood cell types,<br />

the wider will be the dimensional ranges<br />

of length, width, and cell wall thickness<br />

<strong>in</strong> the raw material before <strong>pulp</strong><strong>in</strong>g, and<br />

hence <strong>in</strong> the <strong>kraft</strong> <strong>pulp</strong> which is produced.<br />

• <strong>The</strong> anatomy of hardwoods is much more<br />

complex and – <strong>in</strong> some papermak<strong>in</strong>g<br />

ways – adverse than that of softwoods.<br />

Chip size distribution<br />

In chip size, two th<strong>in</strong>gs are clear – thickness<br />

is the pr<strong>in</strong>cipal dimension of concern<br />

<strong>in</strong> <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g, and 2–8 mm thick chips<br />

are ideal /7/. Thickness distributions are<br />

rout<strong>in</strong>ely measured <strong>in</strong> chip classifiers, and<br />

modern chip thickness screen<strong>in</strong>g systems <strong>in</strong><br />

mills are capable of controll<strong>in</strong>g the thickness<br />

range reasonably well. Sadly, they of<strong>ten</strong><br />

don’t. Greater precision <strong>in</strong> chip mak<strong>in</strong>g<br />

would help, whether dur<strong>in</strong>g sawmill<strong>in</strong>g<br />

operations or <strong>in</strong> log chipp<strong>in</strong>g. Undersized<br />

“chips”, although they <strong>pulp</strong> rapidly, carry<br />

a substantial <strong>yield</strong> penalty. With oversized<br />

chips, the danger is <strong>in</strong> generat<strong>in</strong>g rejects,<br />

<strong>in</strong>herently a penalty <strong>in</strong> mills produc<strong>in</strong>g<br />

bleachable-grade <strong>pulp</strong> whether the rejects<br />

are re-processed or are removed from the<br />

fibrel<strong>in</strong>e. If small wood particles can go to<br />

a dedicated, separate production l<strong>in</strong>e, and<br />

overthick chips are processed mechanically<br />

to make them more amenable to <strong>pulp</strong><strong>in</strong>g,<br />

significant <strong>yield</strong> ga<strong>in</strong>s can be obta<strong>in</strong>ed when<br />

<strong>pulp</strong><strong>in</strong>g only the properly-sized chips, on the<br />

order of 1–2%.<br />

Fig. 5 illustrates two thickness distributions<br />

of same-species softwood chips on<br />

f<strong>in</strong>al delivery to two <strong>kraft</strong> digesters. <strong>The</strong><br />

mill on the left achieves excellent control<br />

from a chip thickness screen<strong>in</strong>g plant with<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Total<br />

Yield<br />

%<br />

< 2mm<br />

0.<br />

9<br />

Chip<br />

T<br />

2-8mm<br />

43.<br />

7<br />

45.<br />

8<br />

hickness,<br />

% of<br />

> 8mm<br />

1.<br />

2<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

total<br />

mass<br />

< 2mm<br />

5.<br />

7<br />

2-8mm<br />

33.<br />

1<br />

45.<br />

1<br />

disc screens and slicers. From pilot-plant<br />

<strong>pulp</strong><strong>in</strong>g, these chips gave 46% <strong>pulp</strong> <strong>yield</strong><br />

at 25 kappa when only the 2–8 mm fraction<br />

(conta<strong>in</strong><strong>in</strong>g 95% of the total mass) was<br />

cooked. Us<strong>in</strong>g mass fractions and reasonable<br />

assumptions to calculate the fractional <strong>yield</strong>s<br />

shown <strong>in</strong> Fig. 5, the actual total <strong>yield</strong> from<br />

this chip furnish was 45.8%.<br />

<strong>The</strong> older mill on the right had rudimentary<br />

chip screen<strong>in</strong>g and therefore a<br />

much broader thickness distribution. At<br />

25 kappa, the penalties with the undersized<br />

and oversized fractions were more serious,<br />

br<strong>in</strong>g<strong>in</strong>g the total <strong>yield</strong> down to 45.1%.<br />

Note that with significantly less 2–8 mm<br />

material present, its fractional <strong>yield</strong> was <strong>ten</strong><br />

percentage po<strong>in</strong>ts lower.<br />

A <strong>yield</strong> difference of 0.7% may seem<br />

rather small, but at a <strong>pulp</strong> production rate<br />

of 1000 tpd the older mill requires 12,000<br />

t more wood (on an oven-dry basis) annually.<br />

That can easily translate <strong>in</strong>to a cost<br />

<strong>in</strong>crease of a million dollars or more a year.<br />

<strong>The</strong> penalty will be worse when account<strong>in</strong>g<br />

for wasted volume <strong>in</strong> the digester occupied<br />

by overthick chips, higher alkali consumption,<br />

greater knotter rejects recycl<strong>in</strong>g costs,<br />

more shives go<strong>in</strong>g forward, less uniform<br />

<strong>pulp</strong>, and higher bleach<strong>in</strong>g costs.<br />

A chip thickness screen<strong>in</strong>g plant is a<br />

necessary part of a modern <strong>kraft</strong> <strong>pulp</strong> mill.<br />

But simply buy<strong>in</strong>g and <strong>in</strong>stall<strong>in</strong>g such a<br />

plant is not enough – it must also be ma<strong>in</strong>ta<strong>in</strong>ed,<br />

tested periodically, adjusted, and<br />

improved.<br />

Chip quality (other than chip size)<br />

Many <strong>yield</strong>-related considerations fall <strong>in</strong>to<br />

this category. In mixed-species chip furnishes,<br />

the proportions of the species, each<br />

with its own <strong>yield</strong> po<strong>ten</strong>tial, will affect overall<br />

<strong>pulp</strong> <strong>yield</strong>. Moisture con<strong>ten</strong>t can <strong>in</strong>fluence<br />

<strong>yield</strong> values if green wood<br />

(rather than dry wood) is the basis<br />

> 8mm<br />

6.<br />

3<br />

Yield<br />

= 0.<br />

7%<br />

= ~ 12,<br />

000<br />

t/<br />

y more<br />

wood<br />

= ~ $ 1.<br />

2 million/<br />

y<br />

Fig. 5. Maximiz<strong>in</strong>g the 2–8 mm fraction of a chip<br />

thickness distribution can significantly improve<br />

<strong>pulp</strong> <strong>yield</strong>.<br />

3<br />

for calculation; it can also affect the<br />

efficiency of <strong>pulp</strong><strong>in</strong>g if the “recipe”<br />

changes (e.g., an un<strong>in</strong><strong>ten</strong>tional<br />

change <strong>in</strong> alkali charge due to an unseen<br />

change <strong>in</strong> wood moisture might<br />

penalize <strong>pulp</strong> <strong>yield</strong>). Mechanical<br />

damage to wood fibres can make<br />

them more susceptible to chemical<br />

attack dur<strong>in</strong>g <strong>pulp</strong><strong>in</strong>g, lower<strong>in</strong>g<br />

<strong>yield</strong>. Biological decay, bark, or the<br />

presence of biological knots and<br />

overthick chips <strong>in</strong> chip furnishes all<br />

impair <strong>pulp</strong> <strong>yield</strong> relative to fresh,<br />

sound wood of suitable thickness<br />

Any of these <strong>factors</strong> may represent<br />

only a small <strong>yield</strong> penalty; together,<br />

they may reduce <strong>pulp</strong> <strong>yield</strong> by<br />

2–4%.

White<br />

Birch<br />

Screened Yield, %<br />

Components<br />

55<br />

53<br />

51<br />

49<br />

47<br />

45<br />

of<br />

Pulp<br />

Reference<br />

Chips<br />

Yie<br />

PS-AQ<br />

Process<br />

Chemistry<br />

ld<br />

+ 3.<br />

0<br />

+ 1.<br />

5<br />

KRAFT<br />

BASELINE<br />

( Hang<strong>in</strong>g<br />

baskets,<br />

mill<br />

chips)<br />

Ga<strong>in</strong><br />

53.<br />

8<br />

Wood Species<br />

+ 0.<br />

5 . 5<br />

53.<br />

3<br />

Pilot-Plant<br />

Pulp<strong>in</strong>g<br />

Best<br />

Mill<br />

Chips<br />

+ 1.<br />

5<br />

+ 0.<br />

5<br />

Fig. 6. Many aspects of chip quality and <strong>pulp</strong><strong>in</strong>g<br />

practice offer substantial <strong>yield</strong> benefits,<br />

<strong>in</strong>clud<strong>in</strong>g orig<strong>in</strong>al wood quality, removal of<br />

f<strong>in</strong>es and oversized particles, and uniformity of<br />

impregnation and cook<strong>in</strong>g.<br />

Total Yield, %<br />

60<br />

55<br />

50<br />

45<br />

Effect<br />

of<br />

Southern<br />

P<strong>in</strong>e<br />

Alk<br />

EA,<br />

%<br />

15.<br />

0<br />

17.<br />

5<br />

20.<br />

0<br />

ali<br />

20 40<br />

60<br />

80<br />

100<br />

120<br />

Kappa<br />

Number<br />

Charge<br />

on<br />

Pulp<br />

A comprehensive exam<strong>in</strong>ation of <strong>pulp</strong><br />

<strong>yield</strong> with respect to chip quality was part<br />

of hang<strong>in</strong>g basket experiments <strong>in</strong> a mill<br />

trial to implement Paprilox ® polysulphideanthraqu<strong>in</strong>one<br />

<strong>pulp</strong><strong>in</strong>g of hardwood <strong>in</strong><br />

conventional batch digesters at Domtar’s<br />

Espanola, ON, <strong>kraft</strong> mill /8/: Four aspects<br />

were measured (Fig. 6):<br />

• Reference Chips: <strong>The</strong> removal of all bark,<br />

knots, decayed wood, and heartwood<br />

provided ideal chips for <strong>kraft</strong> pilot-plant<br />

<strong>pulp</strong><strong>in</strong>g, account<strong>in</strong>g for a 3% <strong>yield</strong> advantage<br />

over the mill’s normal chips.<br />

<strong>The</strong> reference chips were made from the<br />

stemwood of middle-aged white birch<br />

logs of uniform growth chosen at the<br />

Espanola mill, and their thickness range<br />

was 2–6 mm.<br />

• Best Mill Chips: When only the 2–6 mm<br />

thick fraction of mill chips was used <strong>in</strong><br />

pilot-plant experiments, a 0.5% <strong>yield</strong><br />

ga<strong>in</strong> was measured relative to whole mill<br />

chips, whether <strong>in</strong> <strong>kraft</strong> or PS-AQ <strong>pulp</strong><strong>in</strong>g.<br />

<strong>The</strong> mill chips had an average thickness<br />

classification of 11% < 2 mm, 59%<br />

2-6 mm, and 30% >6 mm. Obviously,<br />

remov<strong>in</strong>g 41% of the raw material is<br />

51.<br />

8<br />

51.<br />

3<br />

48.<br />

3<br />

46.<br />

8<br />

Fig. 7. Alkali charge plays a major role <strong>in</strong> <strong>pulp</strong> <strong>yield</strong><br />

– the higher the charge, the lower the <strong>yield</strong>, due to<br />

<strong>in</strong>creased susceptibility of the polysaccharides to<br />

alkal<strong>in</strong>e degradation.<br />

Total Yield, %<br />

60<br />

55<br />

50<br />

45<br />

Y<br />

Mixed<br />

Hardwoods<br />

+ 5<br />

ield<br />

10 30<br />

50<br />

70<br />

90<br />

110<br />

Kappa<br />

Number<br />

4<br />

EA,<br />

%<br />

15.<br />

0<br />

17.<br />

5<br />

20.<br />

0<br />

5<br />

not a practical th<strong>in</strong>g to do,<br />

but decreas<strong>in</strong>g the overthick<br />

fraction substantially<br />

would help. S<strong>in</strong>ce the trial,<br />

chip thickness screen<strong>in</strong>g and<br />

overthick chip crush<strong>in</strong>g have<br />

been <strong>in</strong>stalled on the hardwood<br />

side at Espanola.<br />

• Pilot-Plant Pulp<strong>in</strong>g: Due<br />

to good chip pre-steam<strong>in</strong>g<br />

practice, ideal temperature<br />

control, and homogeneity of<br />

impregnation and cook<strong>in</strong>g<br />

<strong>in</strong> small research digesters,<br />

greater uniformity of <strong>pulp</strong><strong>in</strong>g<br />

resulted <strong>in</strong> a significant <strong>yield</strong><br />

advantage (1.5%) regardless<br />

of whether reference chips or<br />

mill chips were cooked.<br />

• Wood Species: Species<br />

analysis of basket <strong>pulp</strong>s from<br />

mill “birch” chips showed<br />

that they actually conta<strong>in</strong>ed<br />

24% maple on average.<br />

Tak<strong>in</strong>g maple as one-quarter<br />

of the mass, and assign<strong>in</strong>g<br />

this fraction a 2% <strong>yield</strong><br />

penalty from wood relative to<br />

white birch /4/, a 0.5% <strong>yield</strong><br />

deficit was calculated.<br />

Overall, the four <strong>factors</strong><br />

illustrated here added up to a<br />

po<strong>ten</strong>tial <strong>yield</strong> ga<strong>in</strong> of 5.5%,<br />

whether associated with the<br />

<strong>kraft</strong> basel<strong>in</strong>e <strong>yield</strong> or with<br />

the PS-AQ <strong>yield</strong>. Achiev<strong>in</strong>g best performance<br />

<strong>in</strong> all of these <strong>factors</strong> significantly improves<br />

<strong>pulp</strong> <strong>yield</strong>.<br />

Conventional <strong>pulp</strong><strong>in</strong>g chemistry<br />

Among the primary <strong>in</strong>dependent variables<br />

of <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g, high alkali charge, low<br />

sulfidity, high maximum temperature, and<br />

high lign<strong>in</strong> con<strong>ten</strong>t <strong>in</strong> the wood are the<br />

most dangerous for <strong>in</strong>ferior <strong>yield</strong>, po<strong>ten</strong>tially<br />

reduc<strong>in</strong>g the value by several percentage<br />

po<strong>in</strong>ts. By contrast, the higher the<br />

cellulose-to-hemicellulose ratio <strong>in</strong> the wood,<br />

the better. Lower extractives con<strong>ten</strong>t is also<br />

desirable. Liquor-to-wood ratio can affect<br />

<strong>yield</strong> <strong>in</strong> that it has a strong <strong>in</strong>fluence on<br />

<strong>pulp</strong><strong>in</strong>g rate, and therefore the time dur<strong>in</strong>g<br />

which the polysaccharides (especially<br />

hemicelluloses) are degraded by alkal<strong>in</strong>e<br />

attack. Hardwood lign<strong>in</strong> is chemically different<br />

from softwood lign<strong>in</strong>, and accounts<br />

for part of the reason why hardwoods of<strong>ten</strong><br />

have higher <strong>pulp</strong> <strong>yield</strong>s (and faster delignification<br />

rates).<br />

How the ma<strong>in</strong> <strong>in</strong>dependent variables of<br />

<strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g affect <strong>kraft</strong> <strong>pulp</strong> <strong>yield</strong> is clearly<br />

expla<strong>in</strong>ed <strong>in</strong> Kleppe’s classic paper “<strong>Kraft</strong><br />

Pulp<strong>in</strong>g” /9/. Higher alkali charge decreases<br />

<strong>pulp</strong> <strong>yield</strong> at a given kappa number, all other<br />

<strong>factors</strong> held constant, both with softwoods<br />

and hardwoods (Fig. 7). For every 1% <strong>in</strong>crease<br />

<strong>in</strong> effective alkali charge (NaOH basis)<br />

with softwoods, there is a 0.15% penalty<br />

<strong>in</strong> <strong>yield</strong>. <strong>The</strong> problem is three times worse<br />

with hardwoods, due ma<strong>in</strong>ly to the higher<br />

proportion of hemicelluloses (especially<br />

xylans) and their susceptibility to alkal<strong>in</strong>e<br />

attack.<br />

An <strong>in</strong>dependent example with <strong>kraft</strong><br />

<strong>pulp</strong><strong>in</strong>g of aspen to 15 kappa showed these<br />

results: total <strong>yield</strong> of 55.6% at 11% effective<br />

alkali, 54.4 % <strong>yield</strong> at 13.5% EA, and<br />

52.8% <strong>yield</strong> at 17% EA. Thus, an <strong>in</strong>crease<br />

of 6% effective alkali led to a <strong>yield</strong> loss of<br />

2.7%, just as predicted (i.e., 6 x 0.45%).<br />

Although not particularly important<br />

<strong>in</strong> <strong>in</strong>dustrial <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g (the majority of<br />

which is done at or above 30% sulphidity),<br />

how sulphidity affects <strong>yield</strong> is <strong>in</strong>formative.<br />

Aga<strong>in</strong> from Kleppe /9/, with birch (at a kappa<br />

target of 25), the <strong>yield</strong> plateau at 54%<br />

comes at 30% sulphidity. At 0% sulphidity,<br />

<strong>pulp</strong> <strong>yield</strong> is about 50% <strong>in</strong>stead, a deficit of<br />

4%; note that <strong>pulp</strong><strong>in</strong>g rate is much slower<br />

as well. With p<strong>in</strong>e at 55 kappa number, the<br />

51% <strong>pulp</strong> <strong>yield</strong> plateau is at ~40% sulphid-<br />

56<br />

54<br />

52<br />

50<br />

48<br />

Effect<br />

of<br />

0<br />

2h<br />

3h<br />

20<br />

Sulphi<br />

Paperi ja Puu – Paper and Timber Vol.89/No. 4/2007<br />

3h<br />

10<br />

Effect<br />

of<br />

Sulphidity<br />

T<br />

Total<br />

<strong>yield</strong>,<br />

%<br />

2h<br />

1h<br />

Difference<br />

<strong>in</strong><br />

TY,<br />

%<br />

Ascribed<br />

to<br />

chips<br />

Ascribed<br />

to<br />

EA<br />

30<br />

dity,<br />

%<br />

on<br />

Pulp<br />

Birch<br />

( kappa<br />

25)<br />

1h<br />

40<br />

P<strong>in</strong>e<br />

( kappa<br />

55)<br />

50<br />

Y<br />

emperature<br />

on<br />

Pulp<br />

ield<br />

Fig. 8. Sulphidity has a m<strong>in</strong>or effect, provid<strong>in</strong>g<br />

that it is at the plateau level of 30% or above<br />

(this is true for the majority of <strong>kraft</strong> mills).<br />

Y<br />

5<br />

ield<br />

Digester A Digester<br />

B<br />

45.<br />

4<br />

2.<br />

1<br />

- 0.<br />

3<br />

- 0.<br />

1<br />

Yield Loss<br />

due<br />

to<br />

Tmax,<br />

% 1.<br />

7<br />

43.<br />

3<br />

Fig. 9. Maximum temperature of cook<strong>in</strong>g has a<br />

major effect on <strong>pulp</strong> <strong>yield</strong> – although it speeds<br />

up the delignification rate, it accelerates<br />

polysaccharides degradation even more.<br />

5

ity. At 0% sulphidity, <strong>pulp</strong> <strong>yield</strong> is 48%, a<br />

deficit of 3%. Aga<strong>in</strong>, the <strong>pulp</strong><strong>in</strong>g rate decreases<br />

significantly with lower sulphidity.<br />

In both cases, then, <strong>pulp</strong> <strong>yield</strong> is directly<br />

related to sulphidity, but not <strong>in</strong> a l<strong>in</strong>ear<br />

manner. Sulphidity needs to be at or above<br />

30% for optimum <strong>yield</strong> and rate reasons.<br />

<strong>The</strong> maximum temperature of <strong>pulp</strong><strong>in</strong>g<br />

is also important for <strong>yield</strong>. In the case shown<br />

<strong>in</strong> Fig. 9, two chip furnishes from the same<br />

wood species were be<strong>in</strong>g delivered to two<br />

cont<strong>in</strong>uous digesters. <strong>The</strong>y were <strong>pulp</strong>ed <strong>in</strong><br />

a pilot-plant digester at process conditions<br />

taken from the two mill digesters (A: 18.5%<br />

effective alkali, 163°C maximum; B: 19.1%<br />

EA, 175°C max.). Case A had 86% 2-8 mm<br />

chips and 7% > 8 mm chips; Case B, 79%<br />

2–8 mm chips and 14% > 8 mm chips.<br />

<strong>The</strong> difference <strong>in</strong> total <strong>yield</strong> at kappa<br />

number 30 was 2.1%. When adjusted for<br />

the differences attributable to chip thickness<br />

distribution and applied effective alkali, the<br />

<strong>yield</strong> deficit due to the 12°C higher maximum<br />

temperature <strong>in</strong> Digester B was 1.7%.<br />

Modified <strong>pulp</strong><strong>in</strong>g chemistry<br />

<strong>The</strong> era of modified <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g (orig<strong>in</strong>ally<br />

called ex<strong>ten</strong>ded delignification) which<br />

began <strong>in</strong> the 1980s was founded on chemical<br />

pr<strong>in</strong>ciples <strong>in</strong><strong>ten</strong>ded to make <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g<br />

more selective for delignification over<br />

polysaccharide degradation. Comb<strong>in</strong>ed with<br />

appropriate changes <strong>in</strong> mill digesters, some<br />

<strong>yield</strong> benefits have accrued. Liquor displacement<br />

batch systems can improve <strong>yield</strong> over<br />

conventional batch systems (as measured by<br />

hang<strong>in</strong>g baskets) by 1–2% /10/. Cont<strong>in</strong>uous<br />

digesters with multiple white liquor <strong>in</strong>puts<br />

and black liquor extractions appear to offer<br />

a <strong>yield</strong> advantage – particularly with<br />

hardwoods – of up to 4% /11/. In general,<br />

however, evidence for a universal <strong>yield</strong> benefit<br />

with modified <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g equipment<br />

is scanty.<br />

Modify<strong>in</strong>g <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g with additives<br />

(e.g., anthraqu<strong>in</strong>one, or polysulfide,<br />

or both) can improve <strong>pulp</strong> <strong>yield</strong>s by about<br />

1–3%. <strong>The</strong> research knowledge is ex<strong>ten</strong>sive<br />

and deep /12/, and both additives have been<br />

used for the past 30 years <strong>in</strong> mills scattered<br />

around the world. An obvious advantage<br />

with AQ is that it can work <strong>in</strong> all types of<br />

<strong>kraft</strong> digesters – no equipment changes are<br />

required. To achieve maximum benefits with<br />

AQ, its strategy of use needs to be based<br />

on optimiz<strong>in</strong>g all the key <strong>factors</strong> <strong>in</strong> <strong>kraft</strong><br />

delignification, <strong>in</strong>clud<strong>in</strong>g alkali charge, sulphidity,<br />

and kappa target. Fig. 10 shows an<br />

example /13/.<br />

A recent implementation of PS-AQ<br />

<strong>pulp</strong><strong>in</strong>g of hardwoods demonstrated that<br />

the change from <strong>kraft</strong> resulted <strong>in</strong> a <strong>yield</strong> ga<strong>in</strong><br />

Paperi ja Puu – Paper and Timber Vol.89/No. 4/2007<br />

of about 2% whether measured by<br />

hang<strong>in</strong>g baskets <strong>in</strong> the mill or <strong>in</strong><br />

pilot-plant <strong>pulp</strong><strong>in</strong>g us<strong>in</strong>g the chips<br />

and cook<strong>in</strong>g liquors from the mill<br />

/8/ (see also Fig. 6).<br />

Occasionally, an astonish<strong>in</strong>g<br />

possibility emerges, such as alkali<br />

sulphite-AQ <strong>pulp</strong><strong>in</strong>g /14,15/.<br />

Although not <strong>in</strong> use <strong>in</strong>dustrially<br />

because of its slow delignification<br />

rate and complex chemical<br />

recovery issues, AS-AQ <strong>pulp</strong><strong>in</strong>g<br />

can provide <strong>yield</strong> ga<strong>in</strong>s of 5–10%<br />

(Fig. 11), depend<strong>in</strong>g on the scenario.<br />

No other <strong>in</strong>dustrially-feasible<br />

process chemistry change can<br />

do better.<br />

Mill digester systems<br />

Digester equipment considerations<br />

can have a big <strong>in</strong>fluence on<br />

<strong>yield</strong> <strong>in</strong> <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g. Especially<br />

important are the chip pre-steam<strong>in</strong>g<br />

and liquor impregnation steps.<br />

Advanced batch and cont<strong>in</strong>uous<br />

digesters do an effective job of chip<br />

pre-steam<strong>in</strong>g by provid<strong>in</strong>g enough<br />

contact time with atmospheric<br />

steam (15+ m<strong>in</strong>utes), but most digester<br />

systems have either no deliberate<br />

pre-steam<strong>in</strong>g or not enough,<br />

even when it is a comb<strong>in</strong>ation<br />

of atmospheric and low-pressure<br />

regimes. When air removal and<br />

Mixed<br />

SW<br />

water saturation of the <strong>in</strong>ner void spaces<br />

<strong>in</strong> wood chips are <strong>in</strong>adequate, the result is<br />

a less-than-perfect liquid environment for<br />

<strong>pulp</strong><strong>in</strong>g, lead<strong>in</strong>g to more heterogeneous<br />

delignification and <strong>in</strong>ferior <strong>yield</strong>.<br />

Good impregnation is always a key to<br />

good <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g. It needs to be long<br />

enough (usually 30+ m<strong>in</strong>utes) and at a low<br />

enough temperature (120° ± 5°C) to ensure<br />

that the liquid-phase chemistry is ready to<br />

beg<strong>in</strong> everywhere <strong>in</strong>side the chips when they<br />

are taken to delignification temperature. Fig.<br />

12 illustrates results from <strong>kraft</strong> pilot-plant<br />

experiments on two softwood sawdust furnishes<br />

from a mill operat<strong>in</strong>g M&D digesters<br />

/16/. <strong>The</strong> M&D operations were simulated<br />

by comb<strong>in</strong><strong>in</strong>g the sawdust and cook<strong>in</strong>g liquor<br />

<strong>in</strong> bombs and driv<strong>in</strong>g the temperature<br />

to 185°C as fast as possible (~ 10 m<strong>in</strong>utes).<br />

Even when start<strong>in</strong>g with t<strong>in</strong>y sawdust-sized<br />

wood particles, plenty of rejects were generated.<br />

But when we used conventional <strong>kraft</strong><br />

conditions designed for chips, <strong>in</strong>clud<strong>in</strong>g<br />

a 90-m<strong>in</strong>ute ramp of 1°C/m<strong>in</strong> to cook<strong>in</strong>g<br />

temperature for graceful impregnation,<br />

the rejects decreased by about two-thirds,<br />

mean<strong>in</strong>g that the screened <strong>pulp</strong> <strong>yield</strong> rose<br />

by 2%. This case shows that extreme im-<br />

Yie<br />

AA,<br />

%<br />

AQ,<br />

%<br />

H-factor<br />

ld<br />

Total Yield<br />

Yield,<br />

%<br />

Ga<strong>in</strong><br />

Yield<br />

Ga<strong>in</strong>,<br />

%<br />

with<br />

<strong>Kraft</strong><br />

basel<strong>in</strong>e<br />

30<br />

Kappa<br />

17.<br />

1<br />

0<br />

2350<br />

42.<br />

6<br />

0<br />

Anthraqu<strong>in</strong>one<br />

1 2<br />

Add<br />

AQ<br />

Reduce<br />

H<br />

Fig. 10. Optimal anthraqu<strong>in</strong>one’s effectiveness<br />

as a <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g additive depends on the<br />

strategy of use vis-à-vis other primary variables<br />

such as alkali charge and sulphidity.<br />

Yie<br />

ld<br />

Ga<strong>in</strong><br />

30<br />

17.<br />

1<br />

0.<br />

10<br />

2000<br />

43.<br />

5<br />

0.<br />

9<br />

with<br />

Alkal<strong>in</strong>e<br />

pregnation conditions can carry a significant<br />

<strong>yield</strong> penalty.<br />

Pilot-plant experiments have also shown<br />

that if chips are thoroughly pre-steamed and<br />

impregnation with white liquor is done with<br />

good temperature control, then bulk liquor<br />

circulation through the cook<strong>in</strong>g chip column<br />

<strong>in</strong>side a steam-jacketed 20L digester<br />

is not vital <strong>in</strong> produc<strong>in</strong>g <strong>kraft</strong> <strong>pulp</strong> of high<br />

<strong>yield</strong> and quality. Forced liquor circulation<br />

<strong>in</strong> mill digesters is a means to try to overcome<br />

temperature and chemical concentration<br />

gradients created dur<strong>in</strong>g fill<strong>in</strong>g and<br />

impregnation. It is no surprise that the best<br />

liquor displacement batch digesters have<br />

the lowest measured kappa variability <strong>in</strong>side<br />

them /10/.<br />

<strong>The</strong> era of modified <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g has<br />

fostered longer and slower delignification<br />

<strong>in</strong> cont<strong>in</strong>uous digesters and more effective<br />

impregnation <strong>in</strong> liquor displacement batch<br />

digesters. Both provide an <strong>in</strong>herent advantage<br />

<strong>in</strong> selectivity (although the ma<strong>in</strong> benefit<br />

seems to be better preservation of cellulose<br />

<strong>in</strong>tegrity).<br />

Together, all of these <strong>factors</strong> can improve<br />

<strong>pulp</strong> <strong>yield</strong>s by several percentage po<strong>in</strong>ts.<br />

3<br />

Add<br />

AQ<br />

Reduce<br />

AA<br />

30<br />

15.<br />

8<br />

0.<br />

10<br />

2350<br />

44.<br />

8<br />

2.<br />

2<br />

Sulphite-AQ<br />

S W HW<br />

Yield ga<strong>in</strong><br />

( brownstock)<br />

, %<br />

6 10*<br />

Kappa<br />

number<br />

+ 10<br />

+ 6<br />

Yield<br />

ga<strong>in</strong><br />

( bleached)<br />

, %<br />

Unbleached<br />

brightness<br />

5<br />

6<br />

ga<strong>in</strong>,<br />

% ISO<br />

Bleach<strong>in</strong>g<br />

chemical<br />

20<br />

35<br />

consumption<br />

<strong>in</strong>crease,<br />

% ~ 30<br />

~ 20<br />

* From<br />

aspen:<br />

total<br />

<strong>yield</strong><br />

of<br />

65%<br />

at<br />

kappa<br />

18<br />

a world<br />

record?<br />

Fig. 11. Alkal<strong>in</strong>e sulphite-AQ <strong>pulp</strong><strong>in</strong>g offers<br />

astound<strong>in</strong>g <strong>yield</strong> ga<strong>in</strong>s over <strong>kraft</strong>, but the<br />

process is burdened by slow a delignification<br />

rate and chemical recovery is complex.<br />

6<br />

6

Screen Rejects, %<br />

Pulp Yield, %<br />

Lower<br />

4.<br />

0<br />

3.<br />

5<br />

3.<br />

0<br />

2.<br />

5<br />

2.<br />

0<br />

1.<br />

5<br />

1.<br />

0<br />

0.<br />

5<br />

0<br />

50<br />

48<br />

46<br />

44<br />

42<br />

40<br />

10<br />

R<br />

<strong>Kraft</strong><br />

M&D<br />

Version<br />

ejects<br />

Yield beyond <strong>pulp</strong><strong>in</strong>g<br />

with<br />

Better<br />

Impregnation<br />

+ 2.<br />

0%<br />

SY<br />

A B<br />

Yield/<br />

Kappa<br />

<strong>Kraft</strong><br />

Conventional<br />

Version<br />

Relatio<br />

<strong>The</strong>oretical<br />

( lign<strong>in</strong><br />

only)<br />

LR<br />

for<br />

5 po<strong>in</strong>ts<br />

TY= 0.<br />

06kappa<br />

+ 45.<br />

2 r2=<br />

0.<br />

99<br />

Oxygen<br />

Delignification<br />

LR<br />

for<br />

highest<br />

5 po<strong>in</strong>ts<br />

TY= 0.<br />

09kappa<br />

+ 44.<br />

2 r2=<br />

0.<br />

99<br />

20<br />

<strong>Kraft</strong>-AQ<br />

M&D<br />

Version<br />

Fig. 12. Even with sawdust-sized wood particles,<br />

<strong>in</strong>ferior impregnation conditions lead to<br />

excessive rejects; good pre-steam<strong>in</strong>g and<br />

conventional impregnation significantly reduce<br />

rejects generation, translat<strong>in</strong>g it <strong>in</strong>to higher<br />

<strong>pulp</strong> <strong>yield</strong>.<br />

nship<br />

SW<br />

sawdust<br />

Beyond<br />

Three ma<strong>in</strong> considerations apply here: the<br />

chemical selectivity of oxygen delignification<br />

and chlor<strong>in</strong>e dioxide bleach<strong>in</strong>g, the uniformity<br />

of the fibrous <strong>pulp</strong> pass<strong>in</strong>g through<br />

the chemical operations, and any physical<br />

losses of fibres <strong>in</strong> the progression of operations<br />

along a fibrel<strong>in</strong>e.<br />

<strong>The</strong> <strong>yield</strong> losses accompany<strong>in</strong>g oxygen<br />

delignification and ECF bleach<strong>in</strong>g are much<br />

smaller than those <strong>in</strong> <strong>pulp</strong><strong>in</strong>g, offer<strong>in</strong>g less<br />

opportunity to improve <strong>yield</strong> substantially<br />

by process changes. But at<strong>ten</strong>tion is required<br />

to avoid unnecessary mechanical degradation<br />

of <strong>pulp</strong> fibres through these areas of a<br />

mill’s fibrel<strong>in</strong>e so as not to lose <strong>yield</strong> solely<br />

due to “leakage” of fibrous debris. Also,<br />

any recycles of unacceptable fibrous ma-<br />

7<br />

+ 1.<br />

8%<br />

SY<br />

<strong>Kraft</strong>-AQ<br />

Conventional<br />

Version<br />

Pulp<strong>in</strong>g<br />

<strong>Kraft</strong><br />

Pulp<strong>in</strong>g<br />

LR<br />

for<br />

highest<br />

4 po<strong>in</strong>ts<br />

TY= 0.<br />

23kappa<br />

+ 40.<br />

1 r2=<br />

0.<br />

99<br />

30<br />

Kappa<br />

Number<br />

Fig. 13. <strong>The</strong> <strong>yield</strong>/kappa l<strong>in</strong>es of <strong>kraft</strong><br />

<strong>pulp</strong><strong>in</strong>g, oxygen delignification, and ECF<br />

bleach<strong>in</strong>g have progressively lower slopes,<br />

hence greater selectivity for lign<strong>in</strong> removal<br />

over polysaccharide degradation. <strong>The</strong> <strong>kraft</strong><br />

<strong>pulp</strong><strong>in</strong>g and oxygen delignification l<strong>in</strong>es enter<br />

danger zones below about kappa 20 and 15,<br />

respectively.<br />

8<br />

40<br />

terials need to be m<strong>in</strong>imized<br />

– they are proof of <strong>in</strong>adequate<br />

upstream process conditions,<br />

they add to process<strong>in</strong>g costs,<br />

and they make the <strong>pulp</strong> less<br />

uniform. Common examples<br />

are knotter rejects (especially<br />

from biological knots) be<strong>in</strong>g<br />

recycled to digesters /17/, and<br />

f<strong>in</strong>al screen rejects be<strong>in</strong>g ref<strong>in</strong>ed<br />

and recycled <strong>in</strong> bleachable-grade<br />

mills.<br />

It is <strong>in</strong>structive to exam<strong>in</strong>e<br />

the <strong>yield</strong>/kappa relationships<br />

of <strong>pulp</strong><strong>in</strong>g, oxygen delignification,<br />

and ECF bleach<strong>in</strong>g<br />

together. Fig. 13 provides a<br />

generic softwood case.<br />

For <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g, the slope<br />

of a softwood l<strong>in</strong>e to ~30 kappa<br />

is 0.15 ± ~0.05; for hardwoods<br />

to ~15 kappa, the slope<br />

is the same. Both are straight<br />

l<strong>in</strong>es. With softwoods, the l<strong>in</strong>e<br />

represents the bulk delignification<br />

phase start<strong>in</strong>g from about<br />

100 kappa (the high-<strong>yield</strong> end<br />

of <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g), and is a fact<br />

which can’t be changed easily.<br />

<strong>The</strong> <strong>kraft</strong> case <strong>in</strong> Figure 13<br />

is for a softwood with a <strong>pulp</strong><br />

<strong>yield</strong> of 47% at kappa 30.<br />

With oxygen delignification,<br />

the slope is about 0.10,<br />

and ex<strong>ten</strong>ds down to perhaps kappa 15 before<br />

beg<strong>in</strong>n<strong>in</strong>g a steeper fall /18/. With f<strong>in</strong>al<br />

lign<strong>in</strong> removal, <strong>in</strong> theory the slope is about<br />

0.05; this is chemically close to what ECF<br />

bleach<strong>in</strong>g actually does. In all three cases,<br />

lower slope means better selectivity dur<strong>in</strong>g<br />

lign<strong>in</strong> removal, the right direction for <strong>yield</strong><br />

enhancement.<br />

Several aspects of <strong>yield</strong>/kappa relationships<br />

need to be remembered:<br />

• <strong>The</strong>re are non-l<strong>in</strong>ear consequences<br />

for <strong>yield</strong> when either<br />

<strong>pulp</strong><strong>in</strong>g or oxygen delignification<br />

is taken below its practical<br />

kappa limit where the<br />

selectivity for lign<strong>in</strong> removal<br />

is lost.<br />

• <strong>The</strong> <strong>yield</strong> gap widens <strong>in</strong> favour<br />

of oxygen delignification<br />

over <strong>pulp</strong><strong>in</strong>g as kappa<br />

number decreases.<br />

• Rais<strong>in</strong>g the kappa target of<br />

<strong>pulp</strong><strong>in</strong>g lifts the whole picture<br />

to higher <strong>yield</strong>, notwithstand<strong>in</strong>g<br />

the higher cost of<br />

remov<strong>in</strong>g residual lign<strong>in</strong> later<br />

<strong>in</strong> the process l<strong>in</strong>e.<br />

Pulp Yield, %<br />

50<br />

48<br />

46<br />

44<br />

42<br />

Yield/kappa relationship<br />

<strong>The</strong> typical <strong>yield</strong>/kappa relationship for <strong>kraft</strong><br />

<strong>pulp</strong><strong>in</strong>g (as illustrated <strong>in</strong> Fig. 13) requires<br />

some caveats. <strong>The</strong>re is, of course, a <strong>yield</strong> <strong>in</strong>tercept<br />

which is strongly related to wood species,<br />

chip size, and <strong>pulp</strong><strong>in</strong>g conditions. <strong>The</strong><br />

straight l<strong>in</strong>e represents the bulk delignification<br />

phase, which covers almost the whole<br />

kappa range of commercial <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g<br />

from high-kappa l<strong>in</strong>erboard base stock to<br />

bleachable-grades.<br />

Fig. 14 amplifies the mean<strong>in</strong>g of a specific<br />

<strong>yield</strong>/kappa relationship. This is a<br />

spruce/p<strong>in</strong>e/fir case <strong>in</strong> which pilot-plant<br />

<strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g of 2–8 mm thick chips was<br />

done at five H-<strong>factors</strong> (the highest one was<br />

duplicated). Because the fibre liberation<br />

po<strong>in</strong>t with softwoods is at about kappa 40,<br />

screened <strong>yield</strong> equals total <strong>yield</strong> at all but the<br />

highest kappa level. Three l<strong>in</strong>ear regressions<br />

can be calculated:<br />

• For all six total <strong>yield</strong> values, total <strong>yield</strong> =<br />

0.12(kappa) + 41.3 r 2 = 0.95<br />

• For the highest four <strong>yield</strong>s, total <strong>yield</strong> =<br />

0.11(kappa) + 42.0 r 2 = 0.94<br />

• For the lowest three <strong>yield</strong>s, total <strong>yield</strong> =<br />

0.22(kappa) + 38.9 r 2 = 0.98<br />

This demonstrates that where you s<strong>top</strong><br />

<strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g has a significant effect on <strong>pulp</strong><br />

<strong>yield</strong>. For bleachable grades, the idea is to<br />

aim for the end of the bulk delignification<br />

phase without fall<strong>in</strong>g <strong>in</strong>to the residual phase.<br />

Be<strong>in</strong>g seduced by ever lower kappa numbers<br />

prior to oxygen delignification or bleach<strong>in</strong>g<br />

has its price!<br />

With hardwoods, only bleachable-grade<br />

<strong>pulp</strong> is made, and the entire kappa range is<br />

about 12–18, so there is much less room<br />

for un<strong>in</strong><strong>ten</strong>tional over<strong>pulp</strong><strong>in</strong>g. <strong>The</strong> use of<br />

an excessive alkali charge is the greater risk.<br />

At the low-kappa end, the onset of the<br />

residual delignification phase will beg<strong>in</strong> to<br />

<strong>in</strong>crease the slope rapidly, sacrific<strong>in</strong>g <strong>yield</strong><br />

Slope<br />

of<br />

ield/<br />

Kappa<br />

L<strong>in</strong>e<br />

LR<br />

for<br />

highest<br />

4 po<strong>in</strong>ts<br />

TY= 0.<br />

11kappa<br />

+ 42.<br />

0 r2=<br />

0.<br />

94<br />

LR<br />

for<br />

lowest<br />

3 po<strong>in</strong>ts<br />

TY= 0.<br />

22kappa<br />

+ 38.<br />

9 r2=<br />

0.<br />

98<br />

Paperi ja Puu – Paper and Timber Vol.89/No. 4/2007<br />

Y<br />

Screened<br />

Yield<br />

LR<br />

for<br />

all<br />

6 TY<br />

po<strong>in</strong>ts<br />

TY= 0.<br />

12kappa<br />

+ 41.<br />

3 r2=<br />

0.<br />

95<br />

9<br />

Total<br />

Yield<br />

40<br />

15 25<br />

35<br />

45<br />

55<br />

Kappa<br />

Number<br />

Fig. 14. When a typical <strong>yield</strong>/kappa l<strong>in</strong>e for <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g of<br />

a softwood is separated <strong>in</strong>to parts, it becomes clear that<br />

seek<strong>in</strong>g kappa targets below the high 20s <strong>in</strong>evitably sacrifices<br />

<strong>yield</strong> by enter<strong>in</strong>g the residual delignification phase.

Lign<strong>in</strong>-free<br />

trees<br />

Extractives-free<br />

trees<br />

Hardwoods<br />

Fig. 15. Substantial <strong>yield</strong> improvements would<br />

come from all of these items. While the first<br />

three rema<strong>in</strong> <strong>in</strong>tractable, the last two are<br />

possible today.<br />

despite the further slow decrease <strong>in</strong> kappa<br />

number. Because the residual lign<strong>in</strong> is more<br />

resistant to delignification while the polysaccharides<br />

cont<strong>in</strong>ue to degrade, the selectivity<br />

of <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g becomes progressively worse<br />

– the slope of the l<strong>in</strong>e becomes steeper.<br />

This relationship is a crucial aspect of<br />

every <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g scenario, and it should<br />

be known for every mill operation. Of<strong>ten</strong>,<br />

that is not the case. To obta<strong>in</strong> accurate numbers,<br />

such <strong>in</strong>formation is determ<strong>in</strong>ed <strong>in</strong><br />

research-scale <strong>pulp</strong><strong>in</strong>g. It should be done<br />

rout<strong>in</strong>ely when any significant changes are<br />

made <strong>in</strong> chip furnishes and cook<strong>in</strong>g recipes,<br />

<strong>in</strong>clud<strong>in</strong>g any proposed use of <strong>pulp</strong><strong>in</strong>g<br />

additives.<br />

Wish list<br />

A Short<br />

with<br />

no<br />

vessel<br />

Wish<br />

List<br />

CTS<br />

plants<br />

which<br />

perform<br />

to<br />

( and<br />

receive<br />

regular<br />

audits)<br />

lements<br />

Although <strong>in</strong>dustrial <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g practice<br />

has changed slowly and <strong>in</strong>crementally over<br />

the years, it is always useful to imag<strong>in</strong>e how<br />

it could be made better, and by how much.<br />

Figure 15 lists some possibilities, from the<br />

far-fetched to the practical:<br />

• Lign<strong>in</strong>-free trees: In Factor 1, Fig. 3,<br />

the l<strong>in</strong>ear regression suggests that the<br />

lign<strong>in</strong>-free case has a Y-<strong>in</strong>tercept of 66%,<br />

e<br />

specifications<br />

Practical<br />

work<strong>in</strong>g<br />

knowledge<br />

of<br />

<strong>kraft</strong><br />

<strong>pulp</strong><strong>in</strong>g<br />

chemistry<br />

a qualification<br />

for<br />

digester<br />

operators<br />

Magnitude<br />

of<br />

Change<br />

Wood<br />

species<br />

SW<br />

to<br />

HW<br />

14%<br />

SW<br />

to<br />

SW<br />

8%<br />

HW<br />

to<br />

HW<br />

AS-AQ<br />

vs.<br />

conventional<br />

<strong>kraft</strong><br />

7%<br />

SW<br />

6%<br />

HW<br />

PS-AQ<br />

vs.<br />

conventional<br />

<strong>kraft</strong><br />

10%<br />

SW<br />

3%<br />

HW<br />

3%<br />

A dd<br />

oxygen<br />

delignification<br />

2%<br />

Improve<br />

impregnation<br />

a nd<br />

cook<strong>in</strong>g<br />

uniformity<br />

2%<br />

Paperi ja Puu – Paper and Timber Vol.89/No. 4/2007<br />

1<br />

10<br />

Factors<br />

Fig. 16. When ranked accord<strong>in</strong>g to magnitude of<br />

po<strong>ten</strong>tial <strong>yield</strong> ga<strong>in</strong>, the <strong>top</strong> <strong>ten</strong> <strong>factors</strong> emerge<br />

<strong>in</strong> this order. Very few options offer <strong>in</strong>dividual<br />

ga<strong>in</strong>s above 3%.<br />

6<br />

6<br />

8<br />

7<br />

2<br />

far higher than any <strong>kraft</strong> <strong>pulp</strong> <strong>yield</strong> currently<br />

obta<strong>in</strong>ed commercially.<br />

• Extractives-free trees: <strong>The</strong> same general<br />

argument applies. Because there is no<br />

great bus<strong>in</strong>ess <strong>in</strong> by-products from extractives<br />

any more, it would be nice to<br />

avoid deal<strong>in</strong>g with extractives at all.<br />

• Hardwoods without vessel elements:<br />

<strong>The</strong> wood would be denser, provid<strong>in</strong>g<br />

higher <strong>pulp</strong> <strong>yield</strong> per unit volume of<br />

digester space, and the <strong>pulp</strong> would be<br />

more uniform, allow<strong>in</strong>g improvements<br />

<strong>in</strong> stock ref<strong>in</strong><strong>in</strong>g, papermak<strong>in</strong>g, coat<strong>in</strong>g,<br />

and pr<strong>in</strong>t<strong>in</strong>g.<br />

• Chip thickness screen<strong>in</strong>g: Most CTS<br />

plants don’t come close to their orig<strong>in</strong>al<br />

specifications for segregat<strong>in</strong>g and<br />

controll<strong>in</strong>g chip dimensions, nor work<br />

consis<strong>ten</strong>tly well <strong>in</strong> cold-weather locations.<br />

Overthick chip process<strong>in</strong>g spans<br />

the range from very good to abysmal<br />

/17/.<br />

• Work<strong>in</strong>g knowledge: Tra<strong>in</strong><strong>in</strong>g of digester<br />

operators is not as good as it should be<br />

(especially <strong>in</strong> North America). <strong>The</strong>re<br />

is usually no certification of personal<br />

knowledge of the chemistry of <strong>pulp</strong><strong>in</strong>g,<br />

so digesters <strong>ten</strong>d to be treated foremost<br />

as mechanical entities. Is this satisfactory<br />

for the operation of chemically complex<br />

systems worth upwards of $100 million<br />

that produce <strong>ten</strong>s of billions of dollars<br />

worth of <strong>pulp</strong> per year? Standards are<br />

much stricter <strong>in</strong> many other l<strong>in</strong>es of<br />

work, <strong>in</strong>clud<strong>in</strong>g regular cont<strong>in</strong>u<strong>in</strong>g education<br />

plus re-test<strong>in</strong>g. Why not <strong>in</strong> our<br />

bus<strong>in</strong>ess?<br />

Hav<strong>in</strong>g assembled this Top Ten list for<br />

<strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g <strong>yield</strong>, it is possible to rank<br />

the <strong>factors</strong> <strong>in</strong> a variety of ways. Fig. 16 does<br />

this based on magnitude of <strong>yield</strong> ga<strong>in</strong>. For<br />

example, a bleachable-grade <strong>kraft</strong> sw<strong>in</strong>g<br />

mill could ga<strong>in</strong> 14% go<strong>in</strong>g from the lowest<br />

softwood <strong>yield</strong> to the highest hardwood one<br />

(Figs. 2 and 3). No mill has the wood basket<br />

to do this. But <strong>in</strong> the northern boreal forest<br />

zone, a 7–8% <strong>yield</strong> ga<strong>in</strong> is rout<strong>in</strong>e when<br />

go<strong>in</strong>g from spruces to aspen. <strong>The</strong> same<br />

is true <strong>in</strong> hardwood mills go<strong>in</strong>g from<br />

maples to aspen.<br />

Alkal<strong>in</strong>e sulphite-AQ <strong>pulp</strong><strong>in</strong>g has<br />

been done <strong>in</strong>dustrially, but only briefly<br />

and conf<strong>in</strong>ed to two mills. In the right<br />

circumstances, its use <strong>in</strong> l<strong>in</strong>erboard production<br />

could be <strong>in</strong>terest<strong>in</strong>g from a <strong>yield</strong><br />

perspective. Unfortunately, slow <strong>pulp</strong><strong>in</strong>g<br />

rate and complex chemical recovery are<br />

serious hurdles to overcome.<br />

Most of the opportunities <strong>in</strong> Fig. 16<br />

provide <strong>yield</strong> ga<strong>in</strong>s of 3% or less – not<br />

so excit<strong>in</strong>g, perhaps, but feasible and<br />

operat<strong>in</strong>g <strong>in</strong> some mills. In fact, there<br />

are a lot of opportunities which can deliver<br />

1–3% <strong>yield</strong> ga<strong>in</strong>s: additives such as<br />

anthraqu<strong>in</strong>one and polysulphide, mov<strong>in</strong>g<br />

to advanced modes of digester operation,<br />

oxygen delignification (especially with a<br />

higher kappa target after <strong>pulp</strong><strong>in</strong>g), and close<br />

at<strong>ten</strong>tion to the quality of chips be<strong>in</strong>g fed<br />

to a digester. It is also good to have a strong<br />

command of exist<strong>in</strong>g knowledge and apply<br />

it to the technical details of good <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g<br />

practice.<br />

Enhanced <strong>yield</strong>s can also come from better<br />

chip mak<strong>in</strong>g and dimensional control,<br />

improved pre-steam<strong>in</strong>g and impregnation<br />

practices, cook<strong>in</strong>g at lower temperatures<br />

for longer times wherever possible, m<strong>in</strong>imization<br />

of rejects from <strong>pulp</strong><strong>in</strong>g (and the<br />

re-process<strong>in</strong>g of them), efficient fibre spill<br />

collection, and tight process control of oxygen<br />

delignification and bleach<strong>in</strong>g. Research<br />

demonstrates that impressive, cumulative<br />

<strong>yield</strong> ga<strong>in</strong>s are possible.<br />

F<strong>in</strong>ally, Fig. 17 is an attempt at reality<br />

– what can you do <strong>in</strong> a <strong>kraft</strong> mill to improve<br />

<strong>pulp</strong> <strong>yield</strong> at modest cost with the equipment<br />

you have today? <strong>The</strong> items are listed<br />

<strong>in</strong> order of <strong>in</strong>creas<strong>in</strong>g cost:<br />

• Get out – and stay out – of the residual<br />

delignification phase.<br />

• Make your CTS plant perform to maximize<br />

the 2–8 (or 9 or 10) mm thick<br />

fraction. M<strong>in</strong>imize the f<strong>in</strong>es go<strong>in</strong>g to<br />

<strong>pulp</strong><strong>in</strong>g, and deal effectively with the<br />

(small) fraction of overthick material.<br />

Buy or make chips with a narrower distribution<br />

of thickness.<br />

• Push cont<strong>in</strong>ually to <strong>in</strong>crease your best<br />

species for <strong>yield</strong>. Know the real numbers<br />

by species from R&D work done<br />

on your wood sources.<br />

• Make sure that your alkali charge and<br />

maximum temperature of cook<strong>in</strong>g don’t<br />

creep too high, or your sulfidity too low.<br />

Process creep can occur over the long<br />

term, and current process targets may<br />

lose their connections to the orig<strong>in</strong>al<br />

reasons for change.<br />

Stay<br />

out<br />

of<br />

Get<br />

full<br />

p<br />

residual<br />

d<br />

elignification<br />

phase<br />

erformance<br />

from<br />

CTS<br />

Optimize<br />

for<br />

best<br />

Optimize<br />

<strong>pulp</strong><strong>in</strong>g<br />

Add<br />

AQ<br />

Improve<br />

Practical<br />

To<br />

Do<br />

At<br />

Modest<br />

Cost<br />

p<br />

pecies<br />

<strong>in</strong><br />

a<br />

s<br />

re-steam<strong>in</strong>g,<br />

p<br />

m<br />

lant<br />

ixture<br />

recipe<br />

for<br />

EA,<br />

S,<br />

Tmax<br />

impregnation<br />

regimes<br />

Factors<br />

Fig. 17. When ranked accord<strong>in</strong>g to what is practical<br />

to do at a modest cost, the <strong>top</strong> <strong>ten</strong> <strong>factors</strong> offer<br />

plenty of opportunities for improvement.<br />

1<br />

9<br />

3<br />

5<br />

6<br />

7<br />

2

• Anthraqu<strong>in</strong>one? It is probably the simplest<br />

quick fix for <strong>yield</strong> ga<strong>in</strong> if you can<br />

afford it. Don’t waste it by add<strong>in</strong>g too<br />

much, los<strong>in</strong>g some of it <strong>in</strong> an early black<br />

liquor extraction, or fail<strong>in</strong>g to recognize<br />

trade-offs with other primary <strong>factors</strong><br />

such as alkali charge, sulphidity, and<br />

kappa target.<br />

• Do anyth<strong>in</strong>g you can to improve chip<br />

pre-steam<strong>in</strong>g. Optimize impregnation<br />

by ensur<strong>in</strong>g that the <strong>in</strong>gredients you<br />

put <strong>in</strong> your digester are the best you can<br />

provide. Don’t exceed what the chemistry<br />

can actually do.<br />

• And if the opportunity comes, go to an<br />

advanced batch or cont<strong>in</strong>uous digester<br />

system and advanced oxygen delignification.<br />

Happy <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g!<br />

References<br />

1. <strong>Kraft</strong> Pulp Yield Anthology (CD-ROM), 100 published<br />

papers, 1990–2001, TAPPI, Atlanta, GA.<br />

2. Gullichsen, J.: Fiber L<strong>in</strong>e Operations, <strong>in</strong> Chemical<br />

Pulp<strong>in</strong>g, Volume 6A, Papermak<strong>in</strong>g Science and<br />

Technology, J. Gullichsen and H. Paulapuro, eds.,<br />

TAPPI/F<strong>in</strong>nish Paper Eng<strong>in</strong>eers’ Association, Atlanta/Hels<strong>in</strong>ki,<br />

1999, Chapter 2, p. A27–28.<br />

3. Process Variables, <strong>in</strong> Alkal<strong>in</strong>e Pulp<strong>in</strong>g, Volume 5,<br />

Pulp & Paper Manufacture Series, 3 rd edition,<br />

184x133mm<br />

Grace, T.M., Leopold, B., and Malcolm, E.W.,<br />

eds., Jo<strong>in</strong>t Textbook Committee of the Paper<br />

Industry, CPPA-TAPPI, Montreal/Atlanta, 1989,<br />

Chapter 5, p. 82.<br />

4. MacLeod, J.M.: <strong>Kraft</strong> Pulp<strong>in</strong>g: Connect<strong>in</strong>g <strong>The</strong>ory to<br />

Industrial Practice, Notes of PAPTAC <strong>Kraft</strong> Pulp<strong>in</strong>g<br />

<strong>Course</strong>, Session 1, Po<strong>in</strong>te-Claire, QC, October<br />

23–25, 2006 (Typical Yields of <strong>Kraft</strong> Pulps).<br />

5. Hakkila, P.: Structure and Properties of Wood and<br />

Woody Biomass, Volume 2, Papermak<strong>in</strong>g Science<br />

and Technology, J. Gullichsen and H. Paulapuro,<br />

eds., TAPPI/F<strong>in</strong>nish Paper Eng<strong>in</strong>eers’ Association,<br />

Atlanta/Hels<strong>in</strong>ki, 1998, Chapter 4, p.143.<br />

6. ibid., p.141–150.<br />

7. Process Variables, <strong>in</strong> Alkal<strong>in</strong>e Pulp<strong>in</strong>g, Volume 5,<br />

Pulp & Paper Manufacture Series, 3 rd edition,<br />

Grace, T.M., Leopold, B., and Malcolm, E.W.,<br />

eds., Jo<strong>in</strong>t Textbook Committee of the Paper<br />

Industry, CPPA-TAPPI, Montreal/Atlanta, 1989,<br />

Chapter 5, p. 90–96.<br />

8. MacLeod, J.M., Radiotis, T., Uloth, V.C., Munro,<br />

F.C., Tench, L.: Basket cases IV: Higher <strong>yield</strong> with<br />

Paprilox ® polysulphide-AQ <strong>pulp</strong><strong>in</strong>g of hardwoods,<br />

new Tappi J 1(8):3 (2002).<br />

9. Kleppe, P.J.: <strong>Kraft</strong> Pulp<strong>in</strong>g, Tappi J 53(1):35<br />

(1970).<br />

10. Tikka, P.O., Kovas<strong>in</strong>, K.K.: Displacement vs. conventional<br />

batch <strong>kraft</strong> <strong>pulp</strong><strong>in</strong>g: delignification<br />

patterns and <strong>pulp</strong> strength delivery, Paperi ja Puu<br />

72(8):773 (1990).<br />

11. Lebel, D.J.: Cont<strong>in</strong>uous Digester Operations,<br />

Notes of PAPTAC <strong>Kraft</strong> Pulp<strong>in</strong>g <strong>Course</strong>, Session<br />

3, Po<strong>in</strong>te-Claire, QC, October 23-25, 2006 (Lo-<br />

Solids ® Pulp<strong>in</strong>g).<br />

12. Anthraqu<strong>in</strong>one Pulp<strong>in</strong>g: a TAPPI PRESS Anthol-<br />

ogy of Published Papers, G. Goyal, ed., TAPPI,<br />

Atlanta, GA, 1997, 600 pages.<br />

13. MacLeod, J.M.: Improv<strong>in</strong>g <strong>kraft</strong> <strong>pulp</strong> <strong>yield</strong> with<br />

anthraqu<strong>in</strong>one and polysulphide: science and strategy,<br />

2002 <strong>Kraft</strong> Pulp Yield Workshop Prepr<strong>in</strong>ts,<br />

TAPPI, Atlanta, GA, Session 6, Paper 6-1.<br />

14. MacLeod, J.M.: Alkal<strong>in</strong>e Sulphite-Anthraqu<strong>in</strong>one<br />