H A R V E S T E R

H A R V E S T E R

H A R V E S T E R

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

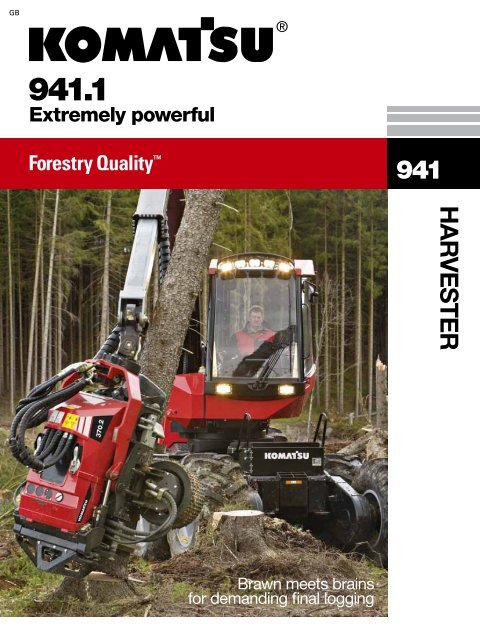

GB941.1Extremely powerful941HARVESTERBrawn meets brainsfor demanding final logging

941.1The Komatsu 941.1 is the new version of the largest Komatsu harvester. Thisis a giant specially adapted to handle demanding logging in really thick forests, andthe advantages are apparent in both the whole and the parts. Here are a few of thehighlights:Engine controlOptimum engine control andminimal energy losses for low fuelconsumption.ReliabilitySturdy chassis, hydraulics, andmechanical components andsystems provide high reliability andlong service life.Raw powerThe heavy-duty boom andharvesting head are proportionedto take on large diameter stems indifficult and demanding conditions.

Work environmentExtremely high-performance workenvironment with the roomiest cabon the market offering excellentvisibility at all times.Control and information systemBrand new MaxiXplorer control and information system,infinitely more powerful, faster, and easier to use than itspredecessor.

Easily-accessible inspectionpoints concentrated in strategiclocations to facilitate maintenanceand servicing.Big, sTrong,and noW even excepTionally BrighT.Information systemBrand new MaxiXplorer controland information system, infinitelymore powerful, faster, and easierto use than its predecessor.ErgonomicsSuperb ergonomics, highproductivity, and reliable operationmake any shift easy and enjoyable.Incredibly large, incredibly powerful – andnow even incredibly bright – for evengreater profits from heavy final logging.That’s the impressive résumé of the newKomatsu 941.1, the latest version of thebiggest rubber-tired harvester in theKomatsu lineup.And the biggest news is MaxiXplorer – abrand new Windows-based computersystem with many times more powerfuland more intuitive than its predecessor.You’ll notice the improvements ineverything from faster and more exactlength measurement and crosscuttingto easier pricelist editing. And, naturally,An optimizedcombination ofstrength andflexibility for highproductivity andprofitability.The uniqueboom positionbeside the caboptimizes visibilityand minimizesneck and backdiscomfort.

941.1increased computing power ultimatelymeans optimized productivity and timbervalue.MaxiXplorer is part of the 941.1’sextremely high-performance workenvironment. The cab includes, full-circleslewing with standing room that is themost spacious on the market. And it goeswithout saying that comfort and visibilityare on a par, enabling you to maintainmaximum productivity even when workinglong days and shifts.Much of the 941’s muscle comes fromits powerful turbo-diesel engine. Maximumtorque is reached at a low engine speed,guaranteeing high-level performance fromstart to finish. The effective fuel injectionsystem ensures immediate engineresponse when you increase the workload.All this engine power is combined withremarkably low fuel consumption.Strength and flexibility also characterizethe 941.1’s boom, which, despite itshuge size, is surprisingly quick and easyto maneuver. The same is true of theharvesting head, which is extremelypowerful yet surprisingly quick and easyto meneuver. The overall sturdy designmakes the Komatsu 941 impressivelyreliable and easy to service. The end resultis a superbly hardened, productive, andsmart profit-making machine. Whetheryou’re an operator, or an owner, choosingthe Komatsu 941.1 will help you harvestmore profitability from thick forests.Cab and boom levelingand stabilizercoupling for superiorstability and groundcontact.The largest cabon the market,providingoptimum visibility,comfort, andergonomics.

Technical specifications17° 17°22° 20°38206501825 2200A8075Wheel options and machine width (A) with different tiresTireWidth (mm/inches)6WD (front) 650/65 x 26.5 2,980/9’9”750/55 x 26.5 3,180/ 10’5”TireWidth (mm/inches)6WD (rear) 700/70 x 34 2,990/9’10”NB: Stated dimensions are nominal and may vary due to manufacturing tolerances.WeightCurb weight:from 23,500 kg (25.9 tons)Power (kW)2101901701501301101300125012001150110010501000950230225220215210Torque (Nm)SFC (g/kWh)System pressure:Working pressure, boom:Hydraulic oil tank:Miscellaneous:Frame/axlesAxle, front:Axle, rear:280 bar (4,060 PSI)CRH24: 260 bar (3,770 PSI)approx. 235 l (62 gal)Pressure filter for hydrost. circuit. Return oil filtersfor hydrost. drive and hydraulics. Hydraulicoil level warning. Hydraulic booster to comp.pump regulation.Bogie. Differential with mechanical differentiallock.Swing axle with hub reduction. Diff. with mechanicaldifferential lock. Hydraulic stabilizeroverride with leveling.205EngineStroke volume:Power, max.:Torque:Fuel tank:1000 1200 1400 1600 1800 2000Speed (rpm)84 CTA. 6-cylinder, turbo with Commonrail.Tier 3.8.4 l (2.2 gal)210 kW DIN (285 hp) at 1,600 rpm1,300 Nm (959 lbf-ft) at 1,500 rpmapprox. 550 l (145.3 gal)Brake systemDriving brake/Working brake:Parking brake:Braking performance:Fully-hydraulic multi-disc brakes. Hydraulicaccumulator charging valve.Multi-disc brakes in an oil bath. Automaticallyengaged when working.Spring-action brake with electrohydrauliccontrol. Emergency brake.Conforms to ISO 11169:1993 and VVFS2003:27.Power transmissionHydrostatic-mechanical, controlled by MaxiXplorer.Transfer gearbox with 2 positions. Disengageablefront-wheel drive.Differential locks:Driving speed:Traction force:Mechanical electro-hydraulic control.0-25 km/h (0-15.5 mph)190 kN (42,700 lbf)BoomModel: CRH 24, 10 m CRH 24, 8 mReach: 10 m (33’) 8.1 m (26’)Lifting torque, gross: 273 kNm (201,300 lbf-ft)Slewing torque, gross: 51 kNm (37,600 lbf-ft)Rated power, telesc., gross: 41 kN (30,240 lbf-ft)Head: 370.2 370EHydraulic systemFlow:Single-circuit load-sensing/high-low balancedconstant pressure, variable piston pump346 l/min at 1,650 rpm (0-91 gal)SteeringLever steering:Hydraulic articulated joint.Load-sensing (LS) proportional steering fromboom controls/rocker

941.1Steering angle:Available options:Electrical systemVoltage:Battery capacity:Generator:LightsAvailable options:+/- 40° Electrical end limit damping.Load-sensing proportional powerassistedsteering.24 V2 x 170 Ah2 x 100 AMore than 30 lux in work area. Halogen cab,boom, and reversing lights.Xenon lights on cab and boom. Roof-mountedwork lights, Halogen or Xenon.ErgonomicsAutolev – fully-automatic cab and boomleveling. Comfort-enhancing leveling. Cabcoupled to stabilizer. Boom and cab onhorizontal, rotating platform. Hydraulicstabilization when maneuvering.Horizontal leveling: Longitudinal 20°/22° and lateral 17°Rotation: 315°Available options: Slew damping. Boom damping.CabSafety-tested. Leveling. Thermal and acousticinsulation.Safety: Conforms to ROPS ISO 8082, FOPS ISO 8083,and OPS ISO 8084.Seat:Windshields:Heating/ventilation:Noise level:Vibrations:Miscellaneous:Available options:Choice of ergonomically designed seat for individualadjustment of the seat cushion, back andlumbar support, arm rests, and control panels.Forward side windows of 15 mm (0.6”) safetyglass.Heating and cooling unit ACC. Filtered intake airwith allergen filter.As per ISO standard.As per ISO standard.Manual tilt. Multi-position safety lock. Electricalkit for com-radio and telephone (12 V).Windshield wiper and washer on front and roofwindows.Sun blinds. Swivel seat. Electrically-controlledplatform under the cab. Radio with MP3 playerand USB-port. Air-ventilated KAB seat or airventilatedBeGe seat with head rest. Microfilter.Control and information systemMaxiHarvesterIntegrated system for machine and headcontrol. Operator-specific settings for head,boom, and machine functions. Cross-cuttinginformation and machine status display.Production registration. Administrative tools.PCProcessor, clock speed: 1,4 GhzInternal memory: 1 GB RAMHard drive, size:40 GBColor screen:12”, anti-reflection glassDVD player:OptionUSB ports:8, one of which on the side for easy accessSerial ports: 2Operating system: Windows XP ProKeyboard with trackball: IncludedAvailable options: A4 printer. GPS antenna. Production reports.Harvesting headKomatsu 370.2 Komatsu 370EWeight: fr. 1,470 kg (3,240 lb) fr. 1,600 kg (3,527 lb)Felling/cutting diameter: 700 mm (27.5”) 700 mm (27.5”)Feed speed: 0-5 m/s (0-16.4 ft/s) 0-5 m/s (0-16.4 ft/s)Feed force, gross: 28.2-30.7 kN. 21-30.8 kN.(6,340-6,900 lbf) (4,720-6,924 lbf)Opening, upper knives, max.: 640 mm (25.2”) 640 mm (25.2”)Roller opening, max.: 600 mm (23.6”) 600 mm (23.6”)Rotator:Roller slewing with hydraulic motor.Control and info. system: MaxiXplorerDocumentationAvailable optionsNotesOperating and starting instructions in paperformat.Instruction manual and spare parts catalogueon CD.Sprinkler system. Semi-automatic, Water-basedfire extinguishing. Conforms to RUS 127.Hand-held extinguishers. 2 x 6 kg (13 lb) ABE-3powder extinguishersInstruction manual in paper format(also electronic in Maxi)Spare parts catalogue in paper format (alsoelectronic in Maxi)Diesel heater 9.1 kW including timer andhydraulic oil heater.Stump treatment equipmentBiodegradable hydraulic oilService laddersToolbox with toolsRearview camera as standard (in EES countriesin compliance with EU Directive 2006/42/EU).Platform at side of cab and ladder on left sideof rear frame as standard (in EES countries incompliance with EU Directive 2006/42/EU).Belt guard for flat belt as standard (in EEScountries in compliance with EU Directive2006/42/EU).The specification describes possible equipment,which can be standard or optional.Weights are based on the standard specificationof the featured equipment. Specificationsand designs are subject to change withoutnotice.

941.1Why choose a komaTsu harvesTer?High productivity, low operating costs, innovative technology, superb operator environment – these arejust some of the features that make Komatsu forestry machines some of the best in the world. Behind allthis is a highly-focused strategy to continually build upon the advantages of owning a Komatsu harvester.A strategy based on the following principal ideas.ErgonomicsYour forestry equipment and its mobile work environmentis critical to an operators ability to maximize productionwithout fatigue and is a key factor for success. This is animportant reference point used in developing the uniqueegronomic designs of Komatsu harvesters. Automaticleveling cabs, side mounted booms and large operatorcompartments work together to keep the harvesting headcentered in the operators field of vision.EconomyThe ambition to maximize profitability is one of the mostimportant forces driving the development of Komatsuharvesters. Each small improvement that increasesproductivity and reliability, reduces costs, or saves timeis of interest. Tangible and quantifiable examples fromtoday’s Komatsu harvesters include energy-efficientengines, highly efficient hydraulics, fast heads, andunsurpassed productivity.ProductivityMore work in less time – a comment we often hearfrom contractors who switch from competing brands toKomatsu. There are many reasons, large and small. Themost important include extremely high-performanceoperator environments, great maneuverability, effectiveheads, powerful control and information systems, andlarge work areas from stationary positions.Customer SupportFast and competent service bears directly on forestrymachine performance and economy An extensive servicenetwork provides the Komatsu owner with a sense ofsecurity. Well-trained technicians provide additionalassurance, as they are Komatsu experts. Anotherbenefit is ProSelect, our special line of accessoriesand consumables. The range is based on a selection ofitems that are all of the highest quality and designed forboth Komatsu and other brands of professional forestmachinery.EnvironmentForests are an essential and fragile element of the globalecology. Consequently, every new Komatsu product, andall its component parts, is considered from both shorttermand long-term environmental perspectives. Thishas resulted in real environmental improvements such ashighly-effective exhaust emission control and low, evenlydistributedground pressure in Komatsu harvesters.Environmental considerations also permeate our broadrange of accessories and consumables, such as in ourspecial, rapidly biodegradable oils.Global ExperienceKomatsu harvesters are found the world over.Consequently, they are designed to deliver optimumprofitability regardless of conditions. The samefundamental concept is applied to our global service anddealer network that provides support to thousands ofKomatsu owners on a daily basis.Komatsu Forest ABwww.komatsuforest.comk941_1_b_gb_110101 • TR Reklambyrå / Ågrenshuset