June 2011 | petrofac.com - Petrofac Emirates

June 2011 | petrofac.com - Petrofac Emirates

June 2011 | petrofac.com - Petrofac Emirates

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>June</strong> <strong>2011</strong> | <strong>petrofac</strong>.<strong>com</strong>

<strong>June</strong> <strong>2011</strong><br />

in this issue<br />

<strong>Petrofac</strong>ts is designed and published by<br />

<strong>Petrofac</strong> on a quarterly basis. To provide<br />

<strong>com</strong>ment or contributions please contact:<br />

2<br />

06<br />

Integrated Energy Services<br />

Andy Inglis articulates the strategy for his new division,<br />

Integrated Energy Services<br />

Corporate Communications<br />

Hazel Meldrum/Claire Baxter<br />

editor@<strong>petrofac</strong>.<strong>com</strong><br />

Engineering & Construction<br />

Engineering & Construction Ventures<br />

Engineering Services<br />

Kaye Krause-Whiteing<br />

kaye.krause-whiteing@<strong>petrofac</strong>.<strong>com</strong><br />

Offshore Engineering & Operations<br />

Jilly Powell<br />

jilly.powell@<strong>petrofac</strong>.<strong>com</strong><br />

Training Services<br />

Pamela Campbell<br />

pamela.campbell@<strong>petrofac</strong>.<strong>com</strong><br />

Production Solutions<br />

Energy Developments<br />

Elinor Geary<br />

elinor.geary@<strong>petrofac</strong>.<strong>com</strong><br />

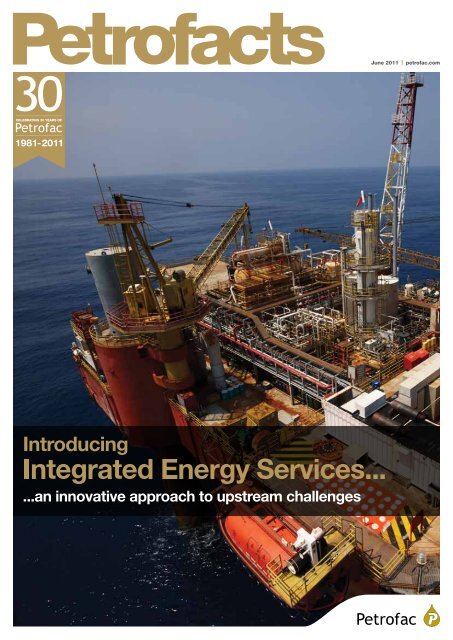

Cover image<br />

Cendor, MOPU, Malasyia.<br />

Photograph by Sam Robinson<br />

22<br />

glossary of abbreviations<br />

E&C E&CV EPC ERSC FEED FDP<br />

Engineering<br />

& Construction<br />

Engineering<br />

& Construction<br />

Ventures<br />

Engineering,<br />

Procurement,<br />

and Construction<br />

Emergency Response<br />

Service Centre<br />

Front end engineering<br />

and design<br />

Field development<br />

planning<br />

FPF HSSEIA IOC JV LSTK LTI<br />

Floating production Health, safety, security, International oil Joint venture Lump-sum turnkey Lost Time Incident<br />

facility<br />

environment and<br />

integrity assurance<br />

<strong>com</strong>pany<br />

MOPU NOC OE&O OPITO UKCS<br />

Mobile Offshore<br />

Production Unit<br />

National oil <strong>com</strong>pany Offshore Engineering<br />

& Operations<br />

29<br />

Sajaa transition success<br />

Contract highlights and engineering opportunities<br />

New freefall<br />

lifeboat training<br />

facility launched<br />

in Aberdeen<br />

Signifying our <strong>com</strong>mitment to<br />

continued investment in the UKCS<br />

Offshore Petroleum<br />

Industry Training<br />

Organisation<br />

United Kingdom<br />

Continental Shelf

10<br />

Floating production<br />

business acquires<br />

second FPSO<br />

Maarten Van Aller provides details on the<br />

acquisition and unveils the team’s longterm<br />

strategy<br />

08<br />

Country focus: Iraq<br />

<strong>petrofac</strong>.<strong>com</strong><br />

<strong>Petrofac</strong> awarded contract for Majnoon Field developments<br />

on behalf of Shell<br />

Part of <strong>Petrofac</strong>’s efforts to establish a strong presence on the ground to<br />

embed and develop the business in-country<br />

13<br />

Office expansion<br />

New offices support growth in Malaysia and Sharjah<br />

16<br />

Qatar Petroleum<br />

We check progress one year on<br />

25<br />

Tapping into our technical<br />

specialists<br />

<strong>Petrofac</strong>ts talks to Ros Thorogood, principal heat transfer<br />

engineer for <strong>Petrofac</strong>’s Engineering Services business<br />

30<br />

<strong>Petrofac</strong>’s journey<br />

As <strong>Petrofac</strong> celebrates its 30th anniversary, two of our<br />

longest serving employees share their thoughts on the<br />

journey so far<br />

3

<strong>June</strong> <strong>2011</strong><br />

WelCoMe to the <strong>June</strong> <strong>2011</strong><br />

eDition of PetrofaCts.<br />

in this issue We launCh our<br />

neW Division, integrateD<br />

energy serviCes.<br />

integrated energy services has been<br />

formed within <strong>Petrofac</strong> to deliver the<br />

existing group services for upstream and<br />

infrastructure assets, on an integrated<br />

basis in order to capture more value for<br />

our customers and shareholders.<br />

4

<strong>petrofac</strong>.<strong>com</strong><br />

Integrated Energy Services will be led by Andy Inglis as chief executive and<br />

will <strong>com</strong>prise of three of our seven business units: Energy Developments,<br />

Production Solutions and Training Services. We are excited about the<br />

creation of this new division and believe it will play an important part in<br />

<strong>Petrofac</strong>’s future growth. To find out why, please turn to page 6 to read<br />

the full interview with Andy.<br />

For further detail on our Integrated Energy Services, please visit our<br />

website on or after 14 <strong>June</strong> to download our Capital Markets presentation:<br />

www.<strong>petrofac</strong>.<strong>com</strong>/presentations.html<br />

Our preliminary results for the year ended 31 December 2010<br />

were released on 7 March. I am pleased to say that 2010 was another<br />

exceptional year for <strong>Petrofac</strong> and our results were excellent: revenue<br />

increased by 19%, we achieved a growth of 58% in net profit (26% on a<br />

like-for-like basis, excluding the gain on the EnQuest demerger) and our<br />

order intake resulted in a backlog of US$11.7 billion.<br />

We have also started <strong>2011</strong> well. During the first half of this year we<br />

secured an order intake of US$2 billion, with major new awards in Algeria,<br />

Iraq and Malaysia. Our backlog, as at the end of April, was US$12.3<br />

billion, giving us outstanding revenue visibility for the current year and<br />

beyond.<br />

We are now half way through the year and I am pleased with<br />

the achievements our group has made so far. While we continue to<br />

develop new business opportunities, with such a large project backlog,<br />

understandably our focus has been on contract execution. We have<br />

made good operational progress on many recent major contracts<br />

awards, including the Laggan Tormore gas plant on Shetland and<br />

the Duty Holder contract for the operation of the Sajaa gas plant on<br />

behalf of the Government of Sharjah. In Turkmenistan, we have made a<br />

positive start on the second phase of the South Yoloten project following<br />

<strong>com</strong>pletion of the first phase in late 2010, and have <strong>com</strong>menced early<br />

onsite construction works.<br />

The second phase of the Cendor development, offshore Peninsular<br />

Malaysia, is also advancing well and more details of this project can be<br />

found on page 17.<br />

In Iraq, we recently announced a US$240 million contract to deliver<br />

early production facilities on the Majnoon field for Shell. We expect to bid<br />

on a number of other projects in the country over the <strong>com</strong>ing months and<br />

details on our presence in the country can be found on page 8.<br />

In May, I visited our Training Services business in Aberdeen to<br />

launch its new freefall lifeboat training facility. This was an excellent<br />

event demonstrating that the investment we have made underlines<br />

the importance we place on the continued development of our training<br />

business. It also restates Aberdeen as the strategic centre for the<br />

development of <strong>Petrofac</strong>’s operations in the North Sea.<br />

At the group’s AGM in May we wel<strong>com</strong>ed Norman Murray as our new<br />

Non-executive Chairman. Norman succeeds Rodney Chase who led our<br />

Board successfully for six years, taking us from a privately held <strong>com</strong>pany<br />

to a constituent of the FTSE100. I would like to take this opportunity<br />

to thank Rodney for his significant contribution; he has left our Board in<br />

excellent shape for Norman’s future stewardship. Together with my Board<br />

colleagues, I am looking forward to working with Norman as we continue<br />

on our growth journey.<br />

As I mentioned in our last edition of <strong>Petrofac</strong>ts, <strong>2011</strong> marks our 30th<br />

year in business. Having joined <strong>Petrofac</strong> in 1991 along with Maroun<br />

Semaan, we are both marking our 20th anniversary with the group this<br />

year. In this, and in future editions, we are profiling some of the employees<br />

who have also been with <strong>Petrofac</strong> for 20 years and the first of our longserving<br />

employees are recognised on page 30.<br />

The theme of our 2010 Annual Report & Accounts “We’ve <strong>com</strong>e a long<br />

way, but the journey is just beginning” is very apt as we look back on three<br />

decades of history while staying focused on our future development and<br />

prospects. <strong>2011</strong> is already proving to be a successful year for the group,<br />

and personally I remain excited about the next stage of our journey.<br />

I hope you enjoy this issue.<br />

Ayman Asfari<br />

Group Chief Executive<br />

5

<strong>June</strong> <strong>2011</strong><br />

Cover story<br />

In January, <strong>Petrofac</strong> appointed Andy Inglis as chief executive of Energy<br />

Developments and Production Solutions. <strong>Petrofac</strong>ts caught up with Andy as<br />

he was preparing to articulate the strategy for his new division, Integrated<br />

Energy Services, for the first time at a Capital Markets event for investors<br />

and analysts in <strong>June</strong>.<br />

6<br />

Andy, is the provision of integrated<br />

services a move away from <strong>Petrofac</strong>’s<br />

core strategy?<br />

No it’s not. For three decades <strong>Petrofac</strong>’s<br />

entrepreneurial flair and customer focus<br />

has brought it success by continually<br />

staying one step ahead of the market,<br />

anticipating customer requirements<br />

and responding to them. Our strategy<br />

– which has been both successful and<br />

consistent – is focused on expanding<br />

our current services into new regions<br />

and sectors, and leveraging our core<br />

<strong>com</strong>petencies to improve the return<br />

we get for our scarcest resource – our<br />

people.<br />

So, while we are not changing the<br />

core elements of the <strong>Petrofac</strong> strategy,<br />

we do intend to bring a new impetus<br />

and focus with the creation of Integrated<br />

Energy Services.<br />

Can you explain the concept of integrated services?<br />

<strong>Petrofac</strong> has been on a journey for more than ten years to add<br />

<strong>com</strong>petence beyond our core engineering & construction<br />

capability, including: asset management, maintenance and<br />

operations, training, Brownfield engineering, well management and<br />

production engineering. Our focus now is to deliver this existing<br />

service capability on an integrated basis; capturing more value by<br />

doing so. While Energy Developments and Production Solutions<br />

are considered more capital intensive than other parts of the group,<br />

with a history of investments, we regard capital deployment as just<br />

another part of our overall service offering.<br />

I think this is an area that has caused confusion about <strong>Petrofac</strong><br />

in the past. For me it’s quite simple really, we are a service <strong>com</strong>pany<br />

with a highly differentiated offering, which can include the provision<br />

of capital if it is required. We are definitely not trying to build an E&P<br />

<strong>com</strong>pany inside <strong>Petrofac</strong> nor do we have any requirement to own<br />

hydrocarbon assets.<br />

What sort of projects will Integrated Energy Services<br />

undertake?<br />

<strong>Petrofac</strong> has established a track record for leading the development<br />

of, and subsequently operating, a wide range of integrated<br />

Greenfield and Brownfield projects both with and without an equity<br />

position. There is a growing desire by our national oil <strong>com</strong>pany<br />

(NOC) customers to retain the title to, and a degree of control over,<br />

their oil & gas reserves. However, they still need human resource<br />

and capability to deliver their projects. Integrated Energy Services’<br />

role within <strong>Petrofac</strong> is to <strong>com</strong>bine all of these skills and capabilities<br />

into a clear service offering which will enable resource holders to<br />

contract with us to maximise the value of their assets without us<br />

necessarily owning a stake in their reserves.<br />

Our new division is an important part of <strong>Petrofac</strong>’s growth<br />

story. With clarity of purpose, and an enhanced delivery model and<br />

organisation, we can pursue and deliver repeatable and scalable<br />

business for the group.

Where is the opportunity for IES and how will we create value?<br />

Forecasts of world oil production show that NOCs will drive global<br />

oil production capacity in the future. Many of the fields that are<br />

under their control are small and, though they are of low <strong>com</strong>plexity,<br />

they are unlikely to be a priority for either the NOCs or the IOCs.<br />

So it is this market - discovered, low risk reserves - that Integrated<br />

Energy Services is going to focus on. Our key advantage is that we<br />

are ahead of the <strong>com</strong>petition with few service <strong>com</strong>panies operating<br />

in this space. While small by NOC or IOC standards these fields<br />

represent substantial projects for <strong>Petrofac</strong>.<br />

The opportunity set is large so we will approach this market in<br />

a focused way, prioritising geographies where we have established<br />

relationships and operations, while leaving some capacity for new<br />

country entry.<br />

We will continue to deploy a variety of <strong>com</strong>mercial models which<br />

reflect the individual needs of each customer. It is our expectation<br />

that the traditional production sharing contract (PSC), where we<br />

enter into an equity model with <strong>com</strong>modity exposure (such as our<br />

Cendor project in Malaysia) will increasingly represent a smaller<br />

part of our portfolio. As such, our direct exposure to the <strong>com</strong>modity<br />

price will also reduce.<br />

Instead we expect to see an increase in production enhancement<br />

contracts (PECs). Like the Brownfield Ticleni contract for Petrom in<br />

Romania, where we are paid on a tariff basis for each additional unit<br />

of production above a certain threshold and have no <strong>com</strong>modity<br />

exposure. And, in risk service contracts (RSCs), where we will<br />

deploy development capital with low exposure to <strong>com</strong>modity<br />

prices and reservoir performance, such as our existing Greenfield<br />

project in Malaysia, Berantai.<br />

Training Services is the third business stream within Integrated<br />

Energy Services, how does it fit with the other two?<br />

Our strategy is to focus on supporting resource holders, primarily<br />

NOCs, to develop and manage their assets. The one thing that is<br />

core to all our NOC customers is their need to create capability<br />

within their own workforce. Through a well constructed training<br />

and <strong>com</strong>petence development programme our customers can<br />

attain global standards in <strong>com</strong>petency with local capability; making<br />

Training Services a key <strong>com</strong>ponent of our integrated offer.<br />

“On a personal level, I am very<br />

excited by the opportunity to<br />

fundamentally change the way<br />

in which business is done in the<br />

upstream sector of the oil & gas<br />

industry. That’s a hugely exciting<br />

agenda and has the potential to<br />

create significant future growth.”<br />

<strong>petrofac</strong>.<strong>com</strong><br />

Are you making organisational changes in support of this new<br />

strategy?<br />

We are making some changes to support our strategy and delivery<br />

model. The organisational structure for Integrated Energy Services<br />

is built around the three business units: Developments (Greenfield<br />

developments), Production Solutions (Brownfield developments)<br />

and Training Services. We will develop a single business opportunity<br />

pipeline for both Developments and Production Solutions so that<br />

the deployment of resources and capital can be optimised. These<br />

business units will be supported by a single, consolidated business<br />

support function covering Commercial/Legal, Finance, HR and<br />

Technical. We will also benefit from a strengthened technical<br />

core that fosters learning from project to project, an improved<br />

risk management approach developed from our existing value<br />

assurance process and a stronger focus on building capability,<br />

which is really our only growth constraint. What we won’t change<br />

is the ethos of accountability and ownership for projects that has<br />

characterised the ‘<strong>Petrofac</strong> way’ for some 30 years.<br />

Andy, a lot of progress has been made in a very short time<br />

period, what do you think are going to be the most exciting<br />

and challenging aspects of this new division, and for <strong>Petrofac</strong><br />

generally?<br />

On a personal level, I am very excited by the opportunity to<br />

fundamentally change the way in which business is done in the<br />

upstream sector of the oil & gas industry. That’s a hugely exciting<br />

agenda and has the potential to create significant future growth.<br />

One of the key challenges for us will be to continue to attract<br />

and retain the talented people we need to grow our business, as we<br />

are certainly not going to be constrained by lack of opportunities.<br />

<strong>Petrofac</strong> is celebrating its 30th anniversary this year, and we all<br />

acknowledge that the group has been on a tremendous journey,<br />

but as we pass this milestone we recognise that in many ways the<br />

journey is just beginning again, and I am both proud and excited to<br />

be a part of this next chapter.<br />

For more information on Integrated Energy Services, you can watch a webcast of<br />

the Capital Markets event, available online at www.<strong>petrofac</strong>.<strong>com</strong>/presentations.<br />

html from 14 <strong>June</strong> <strong>2011</strong>.<br />

7

<strong>June</strong> <strong>2011</strong><br />

exPansion into neW geograPhies<br />

COUnTRy FOCUS: IRAQ<br />

Iraq is an emerging and exciting market and being so close to <strong>Petrofac</strong>’s<br />

large operational centre in Sharjah, is geographically well placed for the<br />

business to execute almost any scope of work. Our initial strategic planning<br />

for this market <strong>com</strong>menced a long time ago, when a dedicated ‘task force’<br />

was put in place. This team undertook detailed planning and preparatory<br />

work, in particular dedicating a great deal of time and effort in building<br />

relationships with an entire cross section of potential new stakeholders.<br />

Left to right: Mr. Ahmed Al Husseini, foreigner <strong>com</strong>panies administration<br />

department, SOC; Mr. Mehdi Badi, Majnoon JMC chairman, SOC; Mr Ole<br />

Myklestad, Majnoon general manager, Shell Iraq Petroleum Development BV;<br />

Mr Diego Perez-Claramunt, <strong>com</strong>munications manager, Shell Iraq Petroleum<br />

Development BV; Mr Malik Noori, <strong>com</strong>munity liaison manager, Shell Iraq Petroleum<br />

Development BV; Mr David Lufkin, group head of business development, <strong>Petrofac</strong><br />

8<br />

In the middle of 2010 <strong>Petrofac</strong> began to establish its operations in Iraq and<br />

it was a great moment, in March this year, when our E&C business was<br />

able to announce its award with Shell Iraq Petroleum Development BV for<br />

developments in the Majnoon Field, Southern Iraq. Majnoon is a super-giant<br />

oil field around 60 km from Basra and is one of Iraq’s largest fields with proven<br />

reserves of an estimated 12.8 billion barrels of oil although the estimate for<br />

potential reserves is significantly higher than this.<br />

The Majnoon project, with a value in excess of US$240 million, will <strong>com</strong>prise<br />

engineering, procurement, fabrication and construction management services<br />

for the development of a new early production system <strong>com</strong>prising two trains<br />

each with capacity for 50,000 barrels of oil per day, along with upgrading of<br />

existing Brownfield facilities. Work on the project began in mid-2010 and is<br />

expected to <strong>com</strong>plete during the fourth quarter of 2012.<br />

Ayman Asfari, <strong>Petrofac</strong> group chief executive, said: “Majnoon is one of<br />

Iraq’s largest developments and we are delighted to be working with Shell<br />

to assist them with unlocking the field’s potential. Iraq’s geographic location,<br />

adjacent to many of our existing areas of operation, made it a natural market for<br />

the group as we continue to broaden our geographic footprint.”<br />

Subramanian Sarma, managing director, <strong>Petrofac</strong> Engineering &<br />

Construction added: “Prior to beginning work with Shell in Iraq last year, we<br />

had spent many months preparing in order to achieve a sufficient level of<br />

readiness across several aspects of our business operations. All of our activities<br />

are underpinned by our strong <strong>com</strong>mitment to safety, quality and integrity and<br />

alongside Shell and the local <strong>com</strong>munity, we are working to deliver this project<br />

to the standards our customers and stakeholders expect from us.<br />

“As we go to press with <strong>Petrofac</strong>ts, <strong>Petrofac</strong>’s operations in Iraq, aside<br />

from the Majnoon project execution team, already has a general manager<br />

in place with a mandate from the executive management team to develop a<br />

substantial group base in Southern Iraq and to build up a core team of local<br />

employees. This is part of <strong>Petrofac</strong>’s efforts to establish a strong presence on<br />

the ground which is essential to embed and develop the business in-country<br />

in a sustainable manner for the long-term benefit of the local economy, whilst<br />

concurrently aligning with our business objectives.”<br />

12.8 billion barrels<br />

Proven oil reserves of the Majnoon oil field, although<br />

estimated potential reserves may be significantly higher<br />

US$240+ million<br />

Value of the Majnoon project<br />

100,000<br />

Number of barrels of oil per day that the production<br />

system will have the capacity to process

EngInEErIng SErvIcES EnTErS Uganda<br />

When independent oil & gas <strong>com</strong>panies Tullow Oil and Heritage Oil announced findings of<br />

a multi-billion barrel basin potential in the remote area of the Albertine Graben in Uganda in<br />

2006, the country - originally reliant on its agricultural industry and without a large skilled oil<br />

& gas workforce - was thrown into the spotlight and was on the verge of an economic boom.<br />

To help realise the potential of the discovery,<br />

<strong>Petrofac</strong> Engineering Services (PES) was<br />

appointed by Heritage Oil to undertake a fourweek<br />

study to verify the concept design on the<br />

Kingfisher development. Tullow Oil, originally<br />

a partner, went on to purchase Heritage Oil’s<br />

Ugandan assets.<br />

As the customer’s level of confidence<br />

regarding <strong>Petrofac</strong>’s ability to deliver integrated<br />

services increased, the project was extended to a<br />

sixty-five man FEED project, engaging the support<br />

of <strong>Petrofac</strong>’s Offshore Engineering & Operations<br />

and Training Services business units. During this<br />

period <strong>Petrofac</strong> was able to provide added value<br />

to the project by reducing electricity consumption<br />

at the central processing plant by 25%. <strong>Petrofac</strong><br />

used its expertise to propose modifications for<br />

the operating conditions so that the storage<br />

and transportation of the oil would be safer. The<br />

sensitive environment where the field is located<br />

was highly regarded and <strong>Petrofac</strong> proposed<br />

alternative technologies to conventional elevated<br />

flares to reduce visual impact.<br />

PES received positive feedback from both<br />

customers with regards to its ability to deliver a<br />

high quality project, on time and below budget.<br />

The high level of trust between the customers<br />

and <strong>Petrofac</strong> also meant that no customer teams<br />

were present to monitor the work carried out by<br />

<strong>Petrofac</strong>.<br />

Usman Darr, project manager and director<br />

of consultancy and integrity, said: “Our first<br />

experience in Uganda has been a positive<br />

one; acting as both a consultant and engineer<br />

contractor, we were able to develop strong<br />

relationships with Heritage and Tullow. It was<br />

important that we provided a flexible service so<br />

that we could respond to any strategic change<br />

our customers wished to implement. Heritage<br />

and Tullow both operated with high standards,<br />

and I have no doubt their activities will have a<br />

positive effect on the region.”<br />

If the resource is exploited in a prudent manner,<br />

the two billion barrels of oil could <strong>com</strong>mence a<br />

drive towards industrialisation. Annual revenues<br />

of US$2 billion and annual savings of US$600<br />

million spent on importing petroleum products<br />

into Uganda ought to generate a fiscal surplus.<br />

OE&O DEVELOPS ITS MARINE<br />

SERVICES CAPAbILITy<br />

OE&O has increased its in-house capabilities with the introduction<br />

of a marine services team focused on delivering marine consultancy<br />

services to the global oil & gas industry.<br />

The team of seven, headed up by Mark Jubb, manager, was previously<br />

employed by Promarine, an Aberdeen-based marine consultancy and<br />

part of the Seabrokers Group. The team transferred to <strong>Petrofac</strong> in<br />

February <strong>2011</strong> and has continued to service previous contracts whilst<br />

also getting involved in OE&O projects with specific marine requirements.<br />

The new team provides a range of services including, but not limited<br />

to, marine vessel audits, dynamic positioning services, independent third<br />

party verification, support to emergency response and rescue vessels<br />

and <strong>com</strong>plete marine assurance packages for vessels engaged in<br />

offshore operations.<br />

Andrew Ferguson, director, marine operations, OE&O explains how<br />

these services are already in use within the business: “Mark’s team<br />

previously worked for <strong>Petrofac</strong> on a range of projects but as our marine<br />

requirements increase and our floating production business expands,<br />

the need for an in-house team has be<strong>com</strong>e more apparent. The marine<br />

<strong>petrofac</strong>.<strong>com</strong><br />

neW serviCes<br />

services team is already providing small-scale consultancy services to<br />

current <strong>Petrofac</strong> projects such as Laggan Tormore and SEPAT but the<br />

aim is to grow the business by supporting the wider <strong>Petrofac</strong> group and<br />

by increasing the number of external customers we work with.”<br />

Mark Jubb continues: “The Laggan Tormore and SEPAT projects are<br />

exciting ones to be involved in and are excellent examples of how inhouse<br />

marine services capabilities were quickly and efficiently mobilised<br />

to the benefit of the overall project. We’re also providing consultancy<br />

services on a floating, storage and offloading (FSO) facility and rig<br />

placement and on the installation of a mooring system for one particular<br />

project and we are evaluating what solutions we can provide to support<br />

other projects within the <strong>Petrofac</strong> group.”<br />

More details on OE&O’s marine services capability can be found on the<br />

<strong>Petrofac</strong> website or by contacting Mark Jubb at mark.jubb@<strong>petrofac</strong>.<strong>com</strong><br />

or on +44 7500 709792.<br />

9

<strong>June</strong> <strong>2011</strong><br />

business foCus<br />

FlOaTInG PROdUCTIOn bUSInESS and<br />

aCqUISITIOn OF EaST FORTUnE FPSO<br />

Name<br />

Maarten Van Aller<br />

Title<br />

Chief operating<br />

officer for floating<br />

production<br />

Location<br />

London<br />

“This is the first conversion of an FPSO for<br />

<strong>Petrofac</strong> but we have recruited an excellent and<br />

experienced team of individuals to undertake<br />

the work and I have every confidence in them.”<br />

10<br />

Maarten Van Aller joined <strong>Petrofac</strong><br />

Energy Developments in late 2009<br />

with the objective of leading the newly<br />

established Floating Production service<br />

line. 18 months on, the business<br />

has grown organically to around 15<br />

full-time employees, <strong>com</strong>pleted the<br />

acquisition of two vessels and has<br />

secured its first deployment. Van<br />

Aller speaks to <strong>Petrofac</strong>ts about<br />

the fleet’s most recent addition and<br />

shares more about the long-term<br />

Floating Production strategy.<br />

Maarten, you recently acquired your fleet’s second<br />

vessel. How did this acquisition <strong>com</strong>e about and<br />

what plans do you have for the vessel?<br />

We <strong>com</strong>pleted the acquisition of the East Fortune floating<br />

production storage and offloading (FPSO) vessel in March.<br />

When we initially identified the East Fortune as a potential<br />

acquisition target, we didn’t have a specific deployment<br />

opportunity in mind, but as soon as we carried out our due<br />

diligence and saw that the vessel was such a high quality<br />

candidate and available for an attractive price, we realised<br />

that we simply couldn’t pass up the opportunity to acquire<br />

it.<br />

Working closely with our business development<br />

colleagues in Energy Developments, we were then able<br />

to tap into their networks and relationships with key<br />

upstream players to seek out deployment opportunities for<br />

the vessel. It was at this stage that we learned about the<br />

Berantai opportunity and started to think about how the<br />

vessel could be used as part of a fast track development<br />

of the field. On 31 January, <strong>Petrofac</strong> announced that it had<br />

teamed up with local <strong>com</strong>panies Sapura Energy Ventures<br />

and Kencana Petroleum, to sign a risk service contract<br />

to lead the development of the Berantai field on behalf of<br />

PETRONAS, the Malaysian National Oil Company. Our<br />

field development programme outlined that the use of the<br />

East Fortune would play an important part in facilitating<br />

the fast track development of the field. <strong>Petrofac</strong> and its<br />

partners will share ownership of the vessel which ensures<br />

all parties are perfectly aligned when it <strong>com</strong>es to making<br />

key decisions and meeting project deadlines.<br />

Where is the East Fortune now?<br />

The East Fortune sailed into the Keppel Shipyard in<br />

Singapore on 22 March to undergo substantial upgrade<br />

and modification works to ensure suitability for the<br />

Berantai deployment. The conversion will include the<br />

design and build of new topsides followed by integration<br />

and <strong>com</strong>missioning of the vessel before sailing out to the<br />

field, which is targeted for the last quarter of this year.<br />

This is the first conversion of an FPSO for <strong>Petrofac</strong><br />

but we have recruited an excellent and experienced team<br />

of individuals to undertake the work and I have every<br />

confidence in them.

<strong>petrofac</strong>.<strong>com</strong><br />

How does Floating Production’s approach to acquisition<br />

and deployment differ from that of a typical contractor?<br />

Firstly, through our Energy Developments networks we<br />

are able to achieve better visibility of potential deployment<br />

opportunities and through its established relationships we can<br />

gain access to key resource holders more easily and quickly<br />

than our <strong>com</strong>petitors.<br />

Secondly, our in-house subsurface capability allows us to<br />

mitigate risk by better understanding the reservoir ahead of<br />

deployment. And finally, through Energy Developments we<br />

have the ability to deploy the FPSO as part of a <strong>com</strong>plete<br />

integrated development for a field: this remains our key<br />

differentiator.<br />

The Floating Production business stream operates as part<br />

of the integrated services offering embodied within our Energy<br />

Developments upstream activities: it’s the ideal way of bringing<br />

a facilities provider and an Operator together to enable fast<br />

track developments with an attractive FPSO deployment.<br />

What are the short and medium-term plans for the<br />

Floating Production business?<br />

We have a number of goals in the short-term: firstly we aim to<br />

have secured a deployment for the FPF1 floating production<br />

facility before the end of <strong>2011</strong>. The vessel is currently along the<br />

quayside in Newcastle and we are closely engaged with two<br />

North Sea Operators, as well as one international, with a view<br />

to deploying the vessel.<br />

We are also in negotiations to acquire a third vessel, which<br />

we hope to <strong>com</strong>plete by the third quarter of this year. In the<br />

medium-term, we will work hand in hand with our business<br />

development colleagues in Energy Developments to identify<br />

new opportunities for a <strong>com</strong>bined field development/floating<br />

facilities offering; and so that we are prepared to respond as<br />

opportunities emerge, we will continue to look for speculative<br />

purchases that represent good value, as we have done with the<br />

FPF1 and East Fortune.<br />

What’s next for your team?<br />

I have a fantastic team of individuals, all of whom work<br />

extremely hard. We’re in business start-up mode: trying<br />

to build an organisation that has key <strong>com</strong>petencies as an<br />

FPSO provider. We’re in the process of recruiting more staff<br />

and we have just relocated the technical team to <strong>Petrofac</strong>’s<br />

Woking office: from this leadership team we will continue to<br />

work with our Enginering Services and Offshore Engineering &<br />

Operations business units to deliver our projects.<br />

As we move into the execution phase on Berantai and<br />

continue to seek our next acquisition and deployment targets,<br />

the next few months promise to be extremely busy but also<br />

very exciting for all those involved in Floating Production.<br />

11

<strong>June</strong> <strong>2011</strong><br />

Crisis ManageMent<br />

12<br />

PETROFAC ACHIEVES<br />

SECOND bUSINESS<br />

CONTINUITy STANDARD<br />

<strong>Petrofac</strong> OE&O’s Aberdeen-based business<br />

has be<strong>com</strong>e the first amongst its peer<br />

group to meet the rigorous standards set<br />

by business Continuity Standard bS 25999.<br />

The business follows in the footsteps of<br />

<strong>Petrofac</strong> Engineering Services which in<br />

2009 was the first oil & gas <strong>com</strong>pany in the<br />

UK to achieve certification.<br />

OE&O’s business continuity plans, which were driven, developed<br />

and tested over a three-year period by representatives from<br />

across OE&O’s business, were certified by an independent<br />

auditor assigned by Lloyd’s Register Quality Assurance (LRQA),<br />

the globally recognised certification body. The plans will support<br />

OE&O’s Bridge View site in the event of a disruption such as a<br />

flood, fire or loss of power and are designed to help the business<br />

to quickly ensure the safety of its personnel and to maintain critical<br />

business operations including Duty Holder support to offshore<br />

installations. The standard is difficult to achieve, reflected by the<br />

fact few oil & gas <strong>com</strong>panies have it, making this certification<br />

particularly significant as OE&O is now able to provide a level of<br />

<strong>com</strong>fort and assurance to customers that its <strong>com</strong>petitors cannot.<br />

Bill Dunnett, managing director, <strong>Petrofac</strong> OE&O <strong>com</strong>mented:<br />

“We’ve worked hard to implement a business continuity<br />

management system that, first and foremost, considers the<br />

safety and security of our people, whilst ensuring our ability to<br />

maintain critical business at a time of disruption.”<br />

He continued: “This certification will demonstrate to our<br />

customers that we have robust and tested plans in place to<br />

maintain ‘business as usual’ levels of service delivery at all<br />

times. To be recognised by LRQA through certification is a great<br />

achievement.”<br />

As part of a programme of work taking place across the<br />

<strong>Petrofac</strong> group, other locations are also working towards<br />

achieving certification of their current plans including <strong>Petrofac</strong><br />

Training Services’ Emergency Response Service Centre<br />

(ERSC), based at Marine House, and <strong>Petrofac</strong> Engineering &<br />

Construction, based in Sharjah, both of which are hoping to<br />

achieve the standard this year.<br />

Major regional and<br />

national emergency<br />

response exercises for<br />

Training Services’ crisis<br />

management team<br />

In February, <strong>Petrofac</strong> Training Services’<br />

crisis management team helped co-ordinate<br />

‘Exercise Glass’, a major exercise to test<br />

emergency response procedures in the event<br />

of a large scale incident in the UK North Sea.<br />

Sponsored by Shell, the exercise was initiated by Grampian Police<br />

in association with Emergency Preparedness Offshore Liaison<br />

(EPOL) Group. Formed in 1995, EPOL is an industry driven member<br />

group that allows oil & gas <strong>com</strong>panies in Aberdeen to share good<br />

practice and address emergency planning and response issues in<br />

relation to offshore safety.<br />

The exercise, which is normally held every five years under the<br />

auspices of EPOL Group, centered around a fictional gas release<br />

and subsequent explosion on the Shell Shearwater platform.<br />

Training Services’ crisis management team managed the evacuee<br />

reception exercise which involved the evacuation of injured and<br />

evacuated crew members to shore.<br />

Shell, RBG, ESS, PSN, Grampian Police, the Maritime and<br />

Coastguard Agency (MCA), NHS Scotland and the Strategic Coordination<br />

Group, which acts as a conduit to Scottish and UK<br />

government bodies, were just some of the participants in the<br />

exercise on the day. EPOL Group member <strong>com</strong>panies who were<br />

not participating in the exercise were invited to attend as observers<br />

at the various emergency response rooms (ERRs) set up throughout<br />

sites in Aberdeen. In addition to the establishment of multiple ERRs,<br />

the exercise also supported a full scale evacuation reception centre,<br />

a mock hospital and a press conference.<br />

Many of the participants <strong>com</strong>mented that the experience “felt<br />

very real” and emergency services stated that it was probably the<br />

largest joint industry-agency exercise run in a decade. <strong>Petrofac</strong><br />

Training Services managed the exercise planning team, directing<br />

staff, friends and relative role players, media role players and mock<br />

hospital role players at each of the sites used during the exercise.<br />

The post exercise debrief summarised that: “Exercise Glass<br />

helped many oil & gas <strong>com</strong>panies and emergency services agencies<br />

in improving their preparedness in jointly responding to a large scale<br />

incident offshore.”<br />

In May, Traning Services’ crisis management team was involved<br />

in another major national exercise, this time in association with the<br />

Department of Energy and Climate Change (DECC) and the MCA.<br />

The two day National Contingency Plan (NCP) Exercise ‘Sula’<br />

looked to address the response capability to an oil spill in the UK<br />

Continental Shelf (UKCS) and to demonstrate how the UK would<br />

react to a spill similar to that seen in the Gulf of Mexico in 2010. The<br />

crisis management team provided assistance in the development,<br />

delivery and observation of the exercise.<br />

Trevor Riley, emergency response and crisis manager<br />

<strong>com</strong>mented: “<strong>Petrofac</strong> Training Services’ crisis management<br />

team worked with the exercise directors and Oil & Gas UK to<br />

ensure successful delivery of the exercise. We were involved in the<br />

previous national exercise (‘Unicorn’) held in 2008 and we used this<br />

knowledge to shape our input in the process for this year’s exercise.”

SHARJAH bUSINESS<br />

TO bUILD NEW<br />

OFFICE TOWER<br />

Jean Chidiac, vice president administration and recruitment explains<br />

the latest expansion plans for <strong>Petrofac</strong> in the Middle East: “During<br />

2010, our Sharjah Engineering & Construction business <strong>com</strong>pleted<br />

another successful year marked by record growth in manpower. This<br />

was reflected in the recruitment of 1,700 new employees of which 600<br />

have joined the Sharjah offices. To facilitate this rapid development, we<br />

are currently expanding our Sharjah operations by building a new tower<br />

engineered to be interconnected to the existing Al Khan building. When<br />

<strong>com</strong>plete, we will be able to consolidate 4,000 employees between the<br />

two facilities with enhanced <strong>com</strong>munication and efficiencies.”<br />

Pierre Chalhoub, project manager for the new building project in<br />

Sharjah <strong>com</strong>mented: “When <strong>com</strong>plete the office will <strong>com</strong>prise six<br />

parking floors, a spacious main entrance and large cafeteria along with<br />

17 office floors and one floor for training and conferences, providing<br />

<strong>Petrofac</strong> with an additional 20,000 square metres of office space and<br />

seating for around 1,700 persons. The new office facility has been<br />

designed to ac<strong>com</strong>modate project task force teams and customers<br />

whilst the existing Al-Khan building will ac<strong>com</strong>modate technical and<br />

support disciplines.”<br />

ExPANDING IN MALAySIA<br />

Group chief executive, Ayman Asfari, opening <strong>Petrofac</strong> E&C’s new Asia Pacific office,<br />

ac<strong>com</strong>panied by Murugan Pitchai, senior vice president and general manager for the<br />

operation, and other members of the team<br />

In March, <strong>Petrofac</strong> opened a brand new<br />

Engineering & Construction office in Malaysia,<br />

<strong>Petrofac</strong> E&C Sdn bhd, located in the Jalan Tun<br />

Razak region of Kuala Lumpur.<br />

Led by Murugan Pitchai, senior vice president and general manager and<br />

his team, the new regional execution centre will focus on developing the<br />

onshore and offshore markets for upstream and downstream opportunities<br />

in the region.<br />

The centre was inaugurated by <strong>Petrofac</strong>’s group chief executive, Ayman<br />

Asfari in March and is already executing two projects for PETRONAS<br />

offshore Peninsular Malaysia: development of the Berantai field and<br />

development of the SEPAT offshore early production system.<br />

<strong>petrofac</strong>.<strong>com</strong><br />

neW offiCes<br />

A visual impression<br />

of what the finished<br />

building will look like<br />

OFFSHORE CONTRACT AWARDED by<br />

PETRONAS IN MALAySIA<br />

Following the announcement of the SEPAT offshore early production system<br />

project in February <strong>Petrofac</strong>ts we are pleased to present a visual from the<br />

recent official contract signing ceremony. Being delivered on the East coast<br />

of Peninsular Malaysia, the contract is valued at approximately US$280<br />

million and the project team is anticipating first oil before the end of <strong>2011</strong>.<br />

Officials from PETRONAS and <strong>Petrofac</strong> were present for the event.<br />

Left to right: Marwan Chedid, managing director, E&CV; Datuk Abdullah Karim,<br />

president of PETRONAS Carigali; Murugan Pitchai, senior vice president and general<br />

manager <strong>Petrofac</strong> E&C Sdn Bhd, and Mr. Tn. Hj Jabar Mohamed, head of development<br />

and production of PETRONAS Carigali<br />

13

<strong>June</strong> <strong>2011</strong><br />

living our values<br />

14<br />

STAND OUT FROM THE CROWD<br />

EVE Award entry extended to Thursday 30 <strong>June</strong><br />

As we prepare to go to press with <strong>Petrofac</strong>ts we are still receiving enquiries about<br />

the EVE Awards, so in order to allow applicants enough time to review and submit<br />

their applications, the deadline for entry to <strong>Petrofac</strong>’s first group-wide employee<br />

awards programme, has been extended to Thursday 30 <strong>June</strong>.<br />

Name<br />

Hazel Meldrum<br />

Title<br />

Head of corporate<br />

<strong>com</strong>munications<br />

Location<br />

Aberdeen<br />

Talking to <strong>Petrofac</strong>ts, head of corporate<br />

<strong>com</strong>munications, and EVE Awards steering<br />

group member, Hazel Meldrum, explains<br />

why employees and teams who haven’t yet<br />

submitted an application, should do so:<br />

“The EVE Awards were launched this year<br />

in celebration of our 30th anniversary and with<br />

the aim of recognising those individuals and<br />

teams within <strong>Petrofac</strong> who have contributed to<br />

our success to date.<br />

“You only need to read some of the stories<br />

within <strong>Petrofac</strong>ts to see that we have many<br />

potential EVE Awards applicants amongst us<br />

and we do want these people to take part.<br />

The programme provides an opportunity<br />

for employees to be recognised for their<br />

achievements and contributions. In addition<br />

to being recognised as an EVE Award winner<br />

throughout the year, finalists will be invited to<br />

attend a special prize giving ceremony at the<br />

group’s annual leadership event at the end of<br />

the year – something which I am sure will prove<br />

to be a great experience in itself.<br />

a wORd FROM ThE JUdGES...<br />

Representatives from the EVE award judging panels<br />

explain just what they are looking for in an applicant<br />

Group judge:<br />

Maroun Semaan, group chief operating officer<br />

“<strong>Petrofac</strong> is a very special place for all of<br />

us and in my 20 years with the business<br />

I have witnessed, on many occasions,<br />

the extraordinary lengths to which our<br />

employees go to fulfil and exceed their<br />

duties through their exceptional efforts<br />

and team work. Our winners and indeed<br />

all those who participate will be able to<br />

demonstrate these unique qualities in<br />

living up to our values.”<br />

Middle East, Africa and Caspian judge:<br />

Peter Collings, human resources director, Engineering<br />

& Construction Ventures<br />

“Applicants should have a cognisance<br />

and understanding of the importance of<br />

organisational values and how they can<br />

contribute to our <strong>com</strong>petitive advantage.”<br />

“I suspect there are many people who are<br />

too modest to submit an application form,<br />

but my advice is not to be shy about your<br />

achievements, take advantage of the deadline<br />

extension and submit an application. Also, we<br />

would like to remind all line managers across<br />

the group to encourage their star performers<br />

and those dedicated beyond the call of duty,<br />

to apply.<br />

“So far the applications represent a broad<br />

spectrum of the group, but they only represent<br />

a small percentage of our total population.<br />

With so many talented and capable people in<br />

<strong>Petrofac</strong>, I am sure there are more to <strong>com</strong>e.”<br />

EVE Award applications can be submitted<br />

against any of the <strong>com</strong>pany’s core values.<br />

Employees who are interested in applying for<br />

an award should email eveawards@<strong>petrofac</strong>.<br />

<strong>com</strong> for further information and application<br />

forms.<br />

India and Asia Pacific judge:<br />

Anil borkar, vice president, Engineering Services<br />

“I am looking for an award applicant<br />

who not only promotes the <strong>Petrofac</strong><br />

values but is also creative and innovative<br />

while practicing them. He or she should<br />

demonstrate that the values are a way of<br />

life, rather than something which is driven<br />

by management.”<br />

UK, Europe and United States judge:<br />

Mike Cannavina, senior vice president and general<br />

manager, Engineering Services<br />

“I am looking for applicants who<br />

demonstrate that they have really<br />

gone the extra mile for <strong>Petrofac</strong>, done<br />

something outstanding and have taken<br />

their efforts to the next level, exceeding<br />

what would be expected, and above all a<br />

good team player.”

Name<br />

Marcelo Cardoso<br />

Title<br />

Group head of<br />

<strong>com</strong>pliance<br />

Location<br />

London<br />

Career history<br />

Marcelo graduated with<br />

a Masters in Law and<br />

has an MBA from the<br />

University of Chicago.<br />

He practiced Law in<br />

Brazil and in the United<br />

States for a number of<br />

years before embarking<br />

on a 15 year career<br />

with BP, most latterly<br />

undertaking the role of<br />

Compliance Manager for<br />

the Upstream division.<br />

In the modern world, business success relies on far<br />

more than technical know-how or service capability.<br />

business ethics, above all, provide the foundations for<br />

sustainable business success. This is why being ethical<br />

at all times is one of <strong>Petrofac</strong>’s long held core values.<br />

Following his appointment as group head of <strong>com</strong>pliance, <strong>Petrofac</strong>ts spoke<br />

to Marcelo Cardoso about the role of <strong>com</strong>pliance within <strong>Petrofac</strong> and the<br />

introduction of our group standard for the prevention of bribery and corruption.<br />

Wel<strong>com</strong>e to <strong>Petrofac</strong>. Can you tell us about your role?<br />

Compliance is not a new area of focus for <strong>Petrofac</strong>. The introduction of our Code<br />

of Business Conduct (the Code) in 2006 set out the behaviours that we expect our<br />

employees, suppliers, contractors and agents to <strong>com</strong>ply with when undertaking<br />

business for and with <strong>Petrofac</strong>.<br />

Since the Code’s introduction, employee numbers have almost tripled to around<br />

14,000. The creation of a dedicated <strong>com</strong>pliance function signifies the group’s<br />

<strong>com</strong>mitment to ensuring that as we grow, we continue to cultivate a culture of<br />

<strong>com</strong>pliance and a genuine <strong>com</strong>mitment to the Code.<br />

My role involves supporting our business units and working with them to promote<br />

awareness and understanding of <strong>com</strong>pliance in line with ever evolving global laws<br />

and regulations, the Code and relevant standards – this is absolutely fundamental<br />

to sustaining business success. After all, <strong>Petrofac</strong> is a <strong>com</strong>pany that others want to<br />

work for and do business with, not only because we are technically very strong and<br />

<strong>com</strong>mercially astute, but because we are a trusted partner.<br />

What will your focus for this year be?<br />

Increasingly, our customers will ask for proof of our <strong>com</strong>mitment to <strong>com</strong>pliance –<br />

they want to know how we are mitigating <strong>com</strong>pliance risks in their value chain. We<br />

must do the same within our own value chain.<br />

This year we will assess our existing <strong>com</strong>pliance framework and introduce a fitfor-purpose<br />

<strong>com</strong>pliance programme which ensures that our employees, contractors<br />

and partners are aware that they each have a responsibility, at an individual level,<br />

for understanding and maintaining the standards outlined in both the Code and our<br />

newly created anti bribery and corruption standard and its principles.<br />

The standard, which is one part of a robust mitigation process, was developed<br />

in November last year. We now need to roll it out across the group in conjunction<br />

with other tools that we will implement to support the Code and relevant standards.<br />

What exactly is the standard for the prevention of bribery and corruption?<br />

The standard reflects what we believe is required for a <strong>com</strong>pany like ours to mitigate<br />

the risk of bribery in the places we operate in. Designed to foster transparency in all<br />

of our transactions, the standard reinforces the fact that we will not provide undue<br />

incentives to third parties – public or private - in order to secure business, nor will<br />

we receive such payments and incentives in return for the award of our business to<br />

third parties. It covers, for example, the exchange of gifts and entertainment, the<br />

need for due diligence of third parties and how we engage in <strong>com</strong>munity services.<br />

When people think of bribery they may be forgiven for thinking of big brown<br />

envelopes full of cash. However, bribery has be<strong>com</strong>e much more sophisticated and<br />

it might not always be immediately apparent whether or not a transaction could be<br />

interpreted as involving bribery and corruption. The standard’s ten principles very<br />

clearly outline our stance on bribery and corruption, and provide guidance to ensure<br />

that we protect the Company, protect ourselves and fulfil the principles expressed in<br />

our Code of Business Conduct.<br />

What is next and where can we find out more?<br />

In order to make the <strong>com</strong>pliance programme a success, it must involve each business<br />

unit and their respective leadership teams, who will be responsible for helping<br />

spread the message and mitigating the risks associated with non-<strong>com</strong>pliance.<br />

Communication and training are essential parts of a <strong>com</strong>pliance programme<br />

so we will support this process by further developing existing tools, as well as<br />

distributing other training and support materials.<br />

In the mean time, all <strong>Petrofac</strong> employees and contractors should familiarise<br />

themselves with the standard and its ten principles, full details of which can be<br />

found on PetroNet.<br />

<strong>petrofac</strong>.<strong>com</strong><br />

CorPorate uPDate<br />

Did you know...<br />

Only eight countries<br />

in the world<br />

allow facilitation<br />

payments – neither<br />

the UK or UaE are<br />

included in this<br />

group<br />

regulators are<br />

increasingly<br />

pursuing <strong>com</strong>panies<br />

and individuals<br />

accused of bribery<br />

The UK Bribery act<br />

<strong>com</strong>es into force on<br />

1 July <strong>2011</strong><br />

15

<strong>June</strong> <strong>2011</strong><br />

ProJeCt uPDates<br />

Progress With Qatar PetroleuM<br />

ONE yEAR ON<br />

<strong>Petrofac</strong> was awarded a contract for the Gas Sweetening Facility (GSF) at Mesaieed<br />

and Dukhan by Qatar Petroleum (QP) in March 2010. The project involves engineering,<br />

procurement, installation and <strong>com</strong>missioning of gas sweetening facilities at both<br />

locations, <strong>com</strong>prising a sulphur recovery upgrade at NGL-3 in Mesaieed and an<br />

acid gas recovery plant at Arab-D in Dukhan. As the project celebrates its first<br />

anniversary, <strong>Petrofac</strong>ts catches up with project director, Zeid Dandashi, to understand<br />

how the project is progressing and any developments since the initial award.<br />

Name<br />

Zeid Dandashi<br />

Title<br />

Project director<br />

Location<br />

Sharjah<br />

How has the project progressed one year on?<br />

The project is moving ahead well with more than 68% of the engineering<br />

<strong>com</strong>pleted, major equipment ordered, and construction activities<br />

<strong>com</strong>menced, with overall project progress at 19%.<br />

The project is technically very <strong>com</strong>plex; can you tell us more about<br />

this?<br />

The GSF project consists of two independent projects involving two different<br />

licensors: Worley Parsons (UK) for the Sulphur Recovery Unit (SRU) and<br />

Prosernat (France) for the Acid Gas Recovery Unit (AGRU). Additionally,<br />

we have engaged renowned international sulphur experts Black and Veatch<br />

for support during the engineering and procurement phases. We also<br />

have separate engineering and construction teams dedicated to the SRU<br />

and AGRU respectively with an overarching core team in place to ensure<br />

that areas of <strong>com</strong>monality and synergy between the two projects are fully<br />

optimised.<br />

What is the peak manpower reached so far on the project? Will this<br />

increase further before project <strong>com</strong>pletion?<br />

The current manpower count is over 2,000 and this will continue to increase<br />

as construction activities increase. The anticipated peak manpower,<br />

including direct and indirect labour will be around 3,500.<br />

What has the safety record been so far? Have you implemented any<br />

specific HSE initiatives to increase the level of HSE awareness on site?<br />

So far, the project has achieved more than two million man-hours without<br />

LTI. In addition to the weekly safety toolbox talks and other regular training<br />

and induction initiatives, the presence of highly toxic gas, such as hydrogen<br />

sulphide, in the facility requires additional levels of safety training.<br />

16<br />

There has been some recent training of engineers for Qatar<br />

Petroleum. Can you please give us some more details on this?<br />

QP requested <strong>Petrofac</strong> to provide training for some of its local assistant<br />

engineers. 11 assistant engineers spent around eight months in our Sharjah<br />

office, working alongside <strong>Petrofac</strong> engineers under the guidance of a<br />

dedicated mentor.<br />

The objective of the training was to provide hands-on experience<br />

to the assistant engineers during the design engineering phase of the<br />

project. Each assistant engineer had a designated coach from <strong>Petrofac</strong><br />

and a programme of detailed training modules to be <strong>com</strong>pleted during the<br />

training period. In addition, the assistant engineers attended all engineering<br />

review sessions and were provided with opportunities to work with multiple<br />

disciplines in order to maximise their learning during this critical stage of<br />

the project.<br />

It is extremely rewarding for all of us to have received very positive<br />

feedback from both QP senior management and project management<br />

teams as well as the assistant engineers.<br />

This is not the first large EPC project that <strong>Petrofac</strong> has<br />

<strong>com</strong>pleted for Qatar Petroleum. How do you see the<br />

relationship with Qatar Petroleum building from this project?<br />

Our immediate operational focus remains on delivering this project<br />

successfully and meeting our customer’s expectations. Over the years we<br />

have enjoyed a strong relationship with our colleagues in QP and naturally<br />

it would be our endeavour to continue the relationship, not only during this<br />

project, but for the many future projects to be executed in Qatar, which is<br />

one of our core markets.

FAST TRACK DEVELOPMENT CONTINUES FOR<br />

PHASE 2 OF THE CENDOR DEVELOPMENT<br />

On 4 August 2010 the <strong>Petrofac</strong> team in Malaysia celebrated its 20 millionth barrel of<br />

oil from the Cendor field, just under four years since achieving first oil. Following<br />

this milestone, the team submitted a field development plan (FDP) for a second<br />

phase of development which will see production levels rise from the current<br />

level of approximately 12,000 barrels of oil per day (bopd) to 35,000 bopd.<br />

Having received FDP approval from PETRONAS in November 2010, the team is<br />

now pressing ahead with the execution phase. <strong>Petrofac</strong>ts catches up with Ceri<br />

Wilding, project manager for Phase 2 of the development, to find out more.<br />

Name<br />

Ceri Wilding<br />

Title<br />

Cendor Phase 2<br />

project manager<br />

Location<br />

Kuala Lumpur<br />

“As outlined in the FDP for the second phase of development and<br />

as a result of increased confidence in the Cendor field reserves,<br />

the existing mobile offshore production unit (MOPU) and floating<br />

storage and offloading (FSO) facilities will be replaced by two new<br />

wellhead platforms and a single floating, production, storage and<br />

offloading facility (FPSO)”, explains Wilding.<br />

Kencana HL, a Malaysian contractor, was awarded the<br />

engineering, procurement and construction (EPC) contract to build<br />

the unmanned wellhead platforms; and TL Offshore, a subsidiary of<br />

SapuraCrest was awarded the contract for installing the platforms.<br />

“Both Kencana and SapuraCrest are <strong>Petrofac</strong>’s co-venturers in<br />

one of our other projects in Malaysia: the Berantai development.<br />

We therefore know the teams well and have been able to move<br />

the project forward at a good pace”, <strong>com</strong>mented Wilding. In<br />

order to facilitate an early start to construction activities, steel was<br />

purchased by <strong>Petrofac</strong> through a PETRONAS ‘frame’ agreement.<br />

Wilding explains: “By making the most of our established<br />

relationships with local <strong>com</strong>panies we were able to speed up many<br />

of the typically lengthy processes adding to a faster development<br />

than would otherwise have been achievable.<br />

“In March we awarded an engineering, procurement,<br />

construction and installation (EPCI) contract for the FPSO to MISC<br />

Berhad. The FPSO will be owned by MISC and leased to <strong>Petrofac</strong><br />

for a ten-year term, with provisions for extension if required. The<br />

FPSO will have an off take capacity of 600,000 barrels and will<br />

provide ac<strong>com</strong>modation for 70 personnel, who will also operate<br />

and maintain the wellhead platforms. The FPSO will be converted<br />

from an existing tanker, the MT Onozo, by Malaysia Marine and<br />

Heavy Engineering (MMHE), in its shipyard in Johor Bahru. The MT<br />

Onozo has been purchased by MISC and delivered to the shipyard,<br />

in preparation for an early start to tanker conversion activities,”<br />

added Wilding.<br />

“The FPSO will undergo extensive modifications with<br />

approximately 6,200 tonnes of topside facilities to be installed,<br />

including power generation, water injection, gas injection and<br />

gas lift facilities. Each of the two wellhead platforms will deliver<br />

untreated crude through two flexible flow lines and dynamic risers<br />

to the FPSO. Water injection and gas injection will be provided<br />

from the FPSO to the platforms via carbon steel pipelines. Remote<br />

control of the wellhead platforms from the FPSO will be facilitated<br />

by fiber optic subsea control cables. The wellhead platforms are<br />

due to be installed mid-2012 to facilitate an early start to drilling<br />

while the FPSO is scheduled to be installed and <strong>com</strong>missioned by<br />

mid-2013.”<br />

The installation of the phase 2 facilities will not only allow much<br />

more efficient oil recovery from the Cendor reservoir but will also<br />

enable the infrastructure to allow future fast-track developments to<br />

be brought on-stream in a cost effective way. Wilding concluded:<br />

“The investment of nearly US$1 billion in the further development<br />

of the Cendor field represents another significant milestone in<br />

maximizing shareholder value from our Malaysian assets and<br />

further develops our relationship with PETRONAS, our joint venture<br />

partners and contractors.”<br />

<strong>petrofac</strong>.<strong>com</strong><br />

17

<strong>June</strong> <strong>2011</strong><br />

hsseia<br />

Name<br />

Chris Allen<br />

Title<br />

Group director,<br />

HSSEIA<br />

Location<br />

Aberdeen<br />

18<br />

SAFETy AND INTEGRITy;<br />

IN FOCUS<br />

Following the release of <strong>Petrofac</strong>’s 2010 Annual Report and Accounts, in which the<br />

group’s safety performance for the year is reported, Chris Allen, group director of<br />

HSSEIA looks back on the past year and updates us on his plans to maintain strong<br />

focus on asset integrity management and the relaunch of Horizon Zero.<br />

LOOKING bACK AT 2010<br />

In 2010 we concentrated our efforts in two areas; the first<br />

being to ensure the technical integrity of the plants we<br />

design, build and operate; and secondly the prevention of<br />

occupational safety risks to avoid personal injury – within<br />

both areas, a lot of important work was undertaken.<br />

We improved the metrics used to measure and report<br />

asset integrity performance for all our operating sites,<br />

and reinforced the importance of robust asset integrity<br />

management by developing a group-wide asset integrity<br />

standard.<br />

Following recent events in the Gulf of Mexico, we<br />

undertook reviews to confirm that our operations are<br />

protected against major incidents and that we have effective<br />

emergency response arrangements in place.<br />

We also acted to strengthen our security resources,<br />

policies and procedures, in order to ensure we keep all our<br />

staff safe, particularly in areas subject to political uncertainty<br />

or civil unrest.<br />

VEHICLE SAFETy<br />

In 2010 the importance of vehicle safety on site was<br />

highlighted when an accident involving a forklift truck,<br />

sadly resulted in a fatality at our El Merk project in Algeria.<br />

The incident was investigated fully and the results of the<br />

investigation were reviewed at our quarterly group Incident<br />

Review Board, which is a senior level review attended by all<br />

business unit managing directors, to make sure that lessons<br />

learned from any significant incident are effectively shared.<br />

The circumstances were also separately reviewed by the<br />

executive management team.<br />

Notwithstanding this deeply regrettable accident,<br />

our safety performance last year – which we measure<br />

in accordance with the Occupational Safety and Health<br />

Administration rules – was maintained at a similar level to<br />

2009. Our recordable incident frequency rate was 0.18 per<br />

200,000 man-hours and our lost time injury rate was 0.026.<br />

These figures <strong>com</strong>pare well with the rest of our industry, but<br />

as the El Merk accident showed, we can never relax our<br />

efforts to keep people safe.<br />

Nowhere is that more true than with driving. Safe driving is<br />

one of <strong>Petrofac</strong>’s eight ‘golden rules of safety’ and provided<br />

the focus for a group-wide employee campaign. Last year<br />

our vehicles travelled more than 77 million km between<br />

locations or on project sites, which is equivalent to driving<br />

almost 2,000 times around the globe.<br />

77 million<br />

Number of kilometres <strong>Petrofac</strong> vehicles travelled<br />

between locations or on project sites in 2010<br />

MAINTAINING FOCUS ON ASSET INTEGRITy<br />

This year preventing the risk of major accidents will continue<br />

to be our top priority.<br />

Assuring technical integrity in everything we design,<br />

build, maintain and operate is key to protecting the safety<br />

of our people, the success of our projects and the value we<br />

have built up in our business. Our recent safety seminar was<br />

based around this theme, and in particular looked at the role<br />

our leadership team plays in managing asset integrity and<br />

identifying and controlling major incident hazards during<br />

design, construction, <strong>com</strong>missioning and operation. Our<br />

aim here is to ensure that consistent processes for integrity<br />

management are used across the group as part of our<br />

integrated service offering to customers.<br />

ACHIEVING HORIZON ZERO<br />

In line with efforts to avoid personal injury, this year we are<br />

relaunching our Horizon Zero safety initiative, pushing it to<br />

the next level.<br />

Throughout our industry, we encourage good leadership<br />

and safe behaviours, and we spend significant time and<br />

money on safety and integrity management, but we do still<br />

experience system failures, injuries and near misses. Horizon<br />

Zero, which was first introduced in 2005, reflects our aim<br />

to reach a day when we experience none of these within<br />

<strong>Petrofac</strong>.<br />

We have built on the original Horizon Zero strategy in<br />

order to reflect the needs of a much larger, more diverse<br />

<strong>Petrofac</strong> group.<br />

As part of this Horizon Zero has a new look, which is<br />

starting to be rolled out as the umbrella under which all new<br />

and existing safety campaigns and initiatives will sit. This<br />

will help us maintain consistency and improve sharing and<br />

learning across the group.<br />

A key <strong>com</strong>ponent of Horizon Zero is our eight ‘golden<br />

rules of safety’, and we continue to focus on these rules as<br />

the Company grows. It is worth remembering that the golden<br />

rules originate from a study of fatal accidents in our industry,<br />

which concluded that the vast majority of fatal and serious<br />

accidents could have been prevented if these few simple<br />

rules had been in place and followed.<br />

A variety of support materials are being prepared under<br />

the Horizon Zero banner to support local initiatives and there<br />

will be a drive to collect existing good ideas from across the<br />

group in order to share them more widely.<br />

I encourage everyone to participate fully and help to<br />

move us closer to our goal of zero incidents.<br />

If you have any examples of safety related<br />

literature which should be<strong>com</strong>e part of<br />

Horizon Zero, please send details to<br />

horizon.zero@<strong>petrofac</strong>.<strong>com</strong>

Centrica’s Kittiwake platform, for which <strong>Petrofac</strong><br />

Offshore Engineering & Operations is Duty<br />

Holder, has been <strong>com</strong>mended by the Health<br />

& Safety Executive (HSE) for the work being<br />

carried out by the platform’s offshore safety<br />

representatives.<br />

<strong>petrofac</strong>.<strong>com</strong><br />

OE&O SUCCESS AT THE UK OIL &<br />