Refrigeration Lubricant Selection for Industrial Systems - Mobil ...

Refrigeration Lubricant Selection for Industrial Systems - Mobil ...

Refrigeration Lubricant Selection for Industrial Systems - Mobil ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

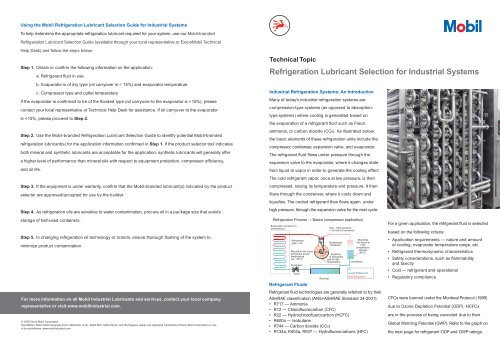

Using the <strong>Mobil</strong> <strong>Refrigeration</strong> <strong>Lubricant</strong> <strong>Selection</strong> Guide <strong>for</strong> <strong>Industrial</strong> <strong>Systems</strong>To help determine the appropriate refrigeration lubricant required <strong>for</strong> your system, use our <strong>Mobil</strong>-branded<strong>Refrigeration</strong> <strong>Lubricant</strong> <strong>Selection</strong> Guide (available through your local representative or Exxon<strong>Mobil</strong> TechnicalHelp Desk) and follow the steps below:Step 1. Obtain or confi rm the following in<strong>for</strong>mation on the application:a. Refrigerant fl uid in useb. Evaporator is of dry type (oil carryover is < 15%) and evaporator temperaturec. Compressor type and outlet temperatureIf the evaporator is confi rmed to be of the fl ooded type (oil carryover to the evaporator is >15%), pleasecontact your local representative or Technical Help Desk <strong>for</strong> assistance. If oil carryover to the evaporatoris

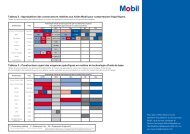

Compatibility of <strong>Lubricant</strong> with Refrigerant Fluid• Miscibility (important at the evaporator portion of theChart A<strong>Mobil</strong> EAL Arctic 46 and Refrigerant R-410a• <strong>Lubricant</strong> TechnologiesFor each refrigerant type, the table below showsrefrigeration circuit):compatible lubricant technology choices and availableGenerally large refrigerant systems, particularly those<strong>Mobil</strong>-branded refrigeration product lines.using ammonia as a refrigerant, are equipped with oilseparators. In these systems, it is desirable to use aRefrigerantType<strong>Lubricant</strong>Technology<strong>Mobil</strong>-brandedProducts Line(s)Ozone depletion potential (ODP) contrasted to global warming potential (GWP) <strong>for</strong>key single-compound refrigerants. CFCs generally have high ODP and GWP. HCFCsgenerally have much lower ODP and GWP. HFCs offer near-zero ODP, but some havecomparatively high GWPs.<strong>Selection</strong> of <strong>Refrigeration</strong> <strong>Lubricant</strong>sFrom a technical standpoint, the lubricant selected <strong>for</strong>a refrigeration system must• be suitable <strong>for</strong> lubricating the type of compressorused in the refrigeration system• have the appropriate miscibility and solubilitycharacteristics with the refrigerant fl uid<strong>Refrigeration</strong> Compressor LubricationThree types of compressors are predominantly usedin industrial refrigeration systems:• Reciprocating compressors — the oil lubricatescylinders, connecting rods, and journal and thrustbearings; and maintains good sealing in compressingthe refrigerant• Screw compressors — the oil lubricates the screw(s)lubricant that is immiscible or has low miscibility withthe refrigerant fl uid. With systems not equipped withoil-separation capability, the lubricant carried over fromthe compressor into the evaporator must be sufficientlymiscible with the refrigerant at the evaporator temperatureso that the refrigerant fl uid–lubricant blend remains inone phase after expansion in the evaporator and at asuffi ciently low viscosity to travel through to thecompressor. If the lubricant separates in the evaporatordue to poor miscibility with the refrigerant fl uid, or theblend viscosity is high, fl uid is likely to get trapped inthe evaporator and adversely affect the system’s coolingcapacity and effi ciency.Miscibility curves are used to ensure that the lubricantselected matches miscibility requirements <strong>for</strong> theapplication. Miscibility charts are specific to lubricantrefrigerantcombinations and are read based on theevaporator temperature and the percentage of oil carriedover into the evaporator <strong>for</strong> the application in question.For typical industrial systems, oil carryover is 15% or less.Viscosity/Pressure/Temperature curves (VPT curves),shown in Chart B, are used <strong>for</strong> this purpose and arespecific to lubricant-refrigerant combinations. Theviscosity of the lubricant-refrigerant blend at thetemperature and pressure of the compressor outletis read from the chart and validated against thebuilder-recommended optimum viscosity to lubricatethe compressor.Chart B<strong>Mobil</strong> EAL Arctic 22 with R-134aCFC and HCFCMineral NaphthenicMineral ParaffinicPolyalphaolefin(PAO)Alkylbenzene (AB)<strong>Mobil</strong> <strong>Industrial</strong> <strong>Lubricant</strong>s Applications ExpertiseCopies of miscibility and VPT curves <strong>for</strong> <strong>Mobil</strong>-brandedrefrigeration oils and various refrigerant fl uids areavailable from our Technical Help Desk. A selectionguide is also available to help you and your salesrepresentative make the right choice of lubricants<strong>for</strong> your particular applications.<strong>Mobil</strong> Gargoyle Arctic<strong>Mobil</strong> Gargoyle ArcticSHC 200<strong>Mobil</strong> Zerice SHFC Polyol Ester (POE) <strong>Mobil</strong> EAL ArcticAmmoniaCarbon Dioxide(CO2)HydrocarbonMineral NaphthenicMineral ParaffinicPAO/ABPAOEstersPolyalkylene Glycol(PAG)PAGMineral Naphthenic<strong>Mobil</strong> Gargoyle Arctic<strong>Mobil</strong> Gargoyle ArcticSHC NH68<strong>Mobil</strong> Gargoyle ArcticSHC 200<strong>Mobil</strong> Gargoyle Arctic(except in dry screw units), and sliding and thrustAt the evaporator temperature and expected oil carryoverConclusionbearings; maintains good sealing; and cools downpercentage <strong>for</strong> the application, the lubricant-refrigerantThe selection of a high-quality refrigeration lubricant iscompressed gasblend must remain in one phase. For example, as showndriven by the type of compressor, application parameters,• Centrifugal compressors — the oil lubricates sliding,in Chart A, <strong>Mobil</strong> EAL Arctic 46 is suitable <strong>for</strong> use withand, most important, the refrigerant fluid. We offer a wideantifriction, and thrust bearings as well as shaft packingrefrigerant R-410a at evaporator temperatures betweenrange of synthetic and mineral oil–based refrigeration oilsand multipliers gears; provides proper sealing; and in-40ºC and +57ºC at 15% expected oil carryover.that are equipment-builder approved, and suitable <strong>for</strong> amany cases cools the compressor parts• Solubility (important at the compressor portion of thebroad range of industrial refrigeration applications.Scroll or rotary vane compressors are also used insome refrigeration systems.refrigeration circuit):Another important consideration <strong>for</strong> proper lubricantselection is to ensure that the viscosity of the lubricant, after(continued on back page)absorption of gaseous refrigerant at the high compressortemperature, is sufficient <strong>for</strong> effective lubrication ofthe compressor.