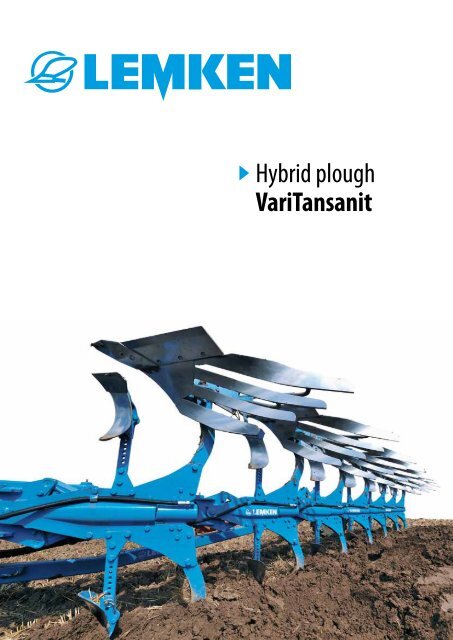

Hybrid plough VariTansanit - Lemken

Hybrid plough VariTansanit - Lemken

Hybrid plough VariTansanit - Lemken

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2Relaxed and safe at work

Increased safetyThe weight transfer to the tractorrear axle and the beneficial centre ofgravity lead to increased stability andenable safer headland turns even onhillsides.<strong>Hybrid</strong> <strong>plough</strong> withadjustable top linkLEMKEN’s <strong>VariTansanit</strong> hybrid <strong>plough</strong>comes with 6 or 7 furrows and isequipped with an adjustable top linkand a load-sense line. Reacting to soilconditions, the <strong>plough</strong> transfersweight from the land wheel to thetractor rear axle in order to improvetraction and minimise wheel slip.Plough comparison3m, 6-furrow <strong>plough</strong>s, 22 cm <strong>plough</strong>ing depthConsistent work quality at lower costsSource: DLG Test 03/07Unit Average wheel slip Average forward speed<strong>VariTansanit</strong> hybrid reversible<strong>plough</strong>, full oil pressure on top link11.9 % 5.8kphVariOpal mounted reversible<strong>plough</strong>16.8 % 5kphVariDiamant semi-mountedreversible <strong>plough</strong>23 % 3.8kphOn mounted <strong>plough</strong>s, the tractor’sthree-point draft control ensuresoptimum draft on the <strong>plough</strong>. Ploughswith 6 or 7 furrows are mostly towedin a semi-mounted configuration torelieve stress on the top and lowerlinks and to account for the tractor’slift capacity and load rating.However, since the connection betweenthe semi-mounted unit and the threepointhitch prevents any transfer ofload from the <strong>plough</strong> to the tractor,optimum traction can only beachieved with a heavier tractor.Compared to semi-mounted <strong>plough</strong>sof similar dimensions, the <strong>VariTansanit</strong>is expressly suited for smaller-sizedtractors, achieving the same level ofperformance at lower running costs.3

Optiquick forprecise <strong>plough</strong>adjustmentZMPZZMPZAdjusting front-furrow width and pulling pointThe <strong>VariTansanit</strong> includes LEMKEN’sproven Optiquick fuel-saving system.••When setting the front-furrowwidth the tractor may still besubject to lateral forces from the<strong>plough</strong>. This happens when thepulling line does not intersect withthe centre (M) of the tractor rearaxle.••The inner turnbuckle eliminates anyside draft by directing the pullingline across the rear axle centre (M).In this process, the front-furrowwidth does not change eventhough the pulling point has beenre-adjusted.ZMPZZMPZAdapt to different working widthsThe front furrow and the optimumpulling point are automaticallyadapted whenever you decide tochange your working width.••No matter which working width,the pull line will always cross therear axle centre.4

No side draftwhatever theworking widthOptiquick adjustment centreAll Optiquick pivots have hard-wearingbushings, hardened pins and lubricationpoints.••This ensures a high level of stabilityand a long service life.••Instead of an external turnbuckle,the <strong>VariTansanit</strong> uses a combinationof hydraulic frame swivel actionand front-furrow adjustment tocompensate for lateral forces.Hydraulic furrow widthThe <strong>VariTansanit</strong> comes standard witha hydraulic working width adjustment.• • Optiquick eliminates side draft at allworking widths.••With an adjustment range of 25 to55cm per body, it meets all requirementsfor arable farmers.5

Trend-setting<strong>plough</strong> technologyReduced operator fatigueThe electronic <strong>Hybrid</strong>Control system isused to set, control and monitor allmain <strong>plough</strong> functions.••The required traction and ballastingvalues can be chosen using the dialon the terminal.••The electro-hydraulic controllerssense all variations in pressure viathe load-sensing line and ensurethe pressure value set on the terminalis maintained throughout.••The standard headland managementsystem automates lifting and turningsequences at the headland.••Turnover of the <strong>plough</strong> is fullyautomatic and is started using thejoystick.••The electro-hydraulic setting forpitch and front-furrow width allowscomfortable and precise adjustmentsfrom the tractor seat.6

ISOBUS technology and CCI 200 terminalISOBUS technology has been a majoradvancement to the <strong>VariTansanit</strong>hybrid <strong>plough</strong> functions. Togetherwith the CCI 200 terminal, it supportsa variety of functions.••The terminal’s working screenoffers an overview of the mainfunctions and relevant settings,such as top link pressure, workingwidth or front furrow.••Main functions on the workingscreen can be selected directly bythe operator, for example to increase/decreasethe top link pressureor to enable/disable top linksensing.••Functions such as the pressuresetting can be entered by simplytouching the screen surface andentering numerical values insteadof using the dial.••The user-friendly joystick box is anoptional accessory. Up to threejoysticks can be easily allocated tofunctions including turnover, soilengagement and more. The joystickbox is mounted in the tractor cabwithin easy reach of the operator.7

Durable, solid and precise engineeringGrooved cap nutFixed mainbearing pinPloughframeScrewed ontension bushingLubricating pointScrewed onexpansionflange bushingPivot pointsVario swivel bracketsFrame platesThe pivot for each swivel bracket ismounted adjacent to the <strong>plough</strong> mainbeam.••This reduces strain on the pivotsand other components.••All pivot points have hard-wearingbushings, hardened pins and lubricationpoints ensuring maximumrigidity and a long service life.The Vario swivel bracket main bearingpin has tension bushings and is lockedagainst rotation with the frame plates.••The Vario swivel bracket also hascrimped flange bushings.••The two lubricated overlappingbushings for working width adjustmentensure long component lifeeven in the toughest of conditions.Each component can be replaced ifworn.The frame plates supporting theswivel brackets and the main link arebolted to the frame.••This gives enormous strength,increased durability and a highdegree of engineering precision.8

Hydromatic Auto-Reset Overload Safety DeviceThe conceptThree-dimensionalattachmentUpwards and sidewaysmovementOn conventional overload devicesbased on a four-point attachment,the entire <strong>plough</strong> body will be out ofbalance when having to trip sidewaysand upwards at the same time.••This is because the body disengagesfrom three of its attachment points,which leaves only one point for themechanical or hydraulic reset todraw it back into position.The significant advantage of theHydromatic system is its solid connectionto the three-dimensional attachmentin any <strong>plough</strong> body position.••Each body is retained to the frameand cannot unlatch.••The innovative Hydromatic hydraulicoverload device will trip sideways andupwards at the same time, even whenhitting lateral obstacles.With up to 38cm of upward traveland 20cm of sideways travel, the<strong>VariTansanit</strong> has sufficient trippingcapacity to provide continuouslytrouble-free work.••High trip forces, which are adjustablefrom the tractor seat, ensure thesystem combines quality <strong>plough</strong>ingwith efficient <strong>plough</strong> protection.••As a further benefit, the systemdoes without any lubrication pointsand is completely maintenance-free.9

Reliable and costefficienton all soilsDuraMaxx - the perfect <strong>plough</strong> bodyThe DuraMaxx body is a radical newconcept increasing service life by anenormous 75% whilst reducing set-uptime by up to 80%!••All DuraMaxx components aremanufactured from much hardersteel than before. The material isno longer weakened by drillingand punching holes in it.••Mouldboards and slats are fullysupported by the frog. They are nolonger a load-bearing part of the<strong>plough</strong> body so their sole functionis to turn over the soil.••This means they can wear out to ahigher degree without the risk ofsnapping due to soil forces.10

Quick changes withouttoolsDuraMaxx <strong>plough</strong> bodies are designedfor quick and tool-less changing ofmouldboards, slats and shins.••The shin is held in place by a lynchpin, which is simply removed todetach the shin. The shin, in turn,holds the mouldboard or slats inplace. Once the shin comes off, themouldboard or slats slide forwardsand can be removed without theneed of tools.••Also the share point is attached witha single bolt only, which enablesmuch quicker changing than onconventional systems.Body assemblyThe DuraMaxx <strong>plough</strong> body is availablewith mouldboards or slats.••The mouldboard and the slats areattached with no more than threehooks.••On slatted bodies, the clearancebetween the slats and their supporthas been greatly increased. The supportis aligned with the slats, whichreduces the possibility of blockagesfrom soil getting stuck in the slats.DuraMaxx <strong>Hybrid</strong> forsticky soilsThe DuraMaxx <strong>plough</strong> body can alsobe configured with plastic slats. Theyare ideal for use on extremely stickysoils and in soil conditions with littlepressure on the mouldboard.••The best sliding properties areachieved by using plastic slats at thetop and bottom areas of the <strong>plough</strong>body, which are most susceptible toadhesion.••Therefore, the DuraMaxx bodyworks without any adhesion issueseven in extreme conditions.11

Ready for adverse conditionsFlat stalkAngle adjustmentTool boxFitting the frog onto a flat stalkprevents the skimmer from beingtwisted.••All types of share and mouldboardcan be easily exchanged, thanks tothe frog being common to allskimmer types.••For <strong>plough</strong>ing without skimmers,just remove two bolts to completelydisassemble the skimmer arm.Both the <strong>VariTansanit</strong> and the<strong>VariTansanit</strong> T are optionally availablewith an individual quick-adjustmentsystem for the skimmer angle.••This allows further fine-tuning oftrash burial where required.Maintenance of all LEMKEN <strong>plough</strong>sis easy thanks to the toolbox whichholds tools, shear bolts and othersmall parts within easy reach of theoperator.D1 D0 M3M230 20 10 0 cm 30 20 10 0 cm 30 20 10 0 cm30 20 10 0 cmSkimmersSkimmers of different share lengthsensure trouble-free <strong>plough</strong>ing even inabundant surface trash.••The special shape of the sharesminimises wear and increasestheir service life, while creating anoutstanding soil flow.••The special shape of the mouldboardseparates the organic matter andneatly incorporates it into theground.••Plastic mouldboards are available forsticky soil conditions and soils exertinglittle pressure on the skimmer.Trash boardsThe trash boards are fitted directly tothe mouldboards and are fully adjustable.••They enable blockage-free workand clean incorporation even onextreme surface residue.••For sticky soils, trash boards are alsoavailable in plastic.12

1234 5Disc coultersThe plain disc coulters feature sidemouldings to provide a positive driveeven when breaking up high amountsof organic material.••Their depth is adjusted by verticallypivoting the coulter arm fixed by abolt in a splined bracket.••Disc coulters are available in a varietyof sizes and mounting positions:- 500 mm, adjacent to skimmer (1)- 500 mm, in front of skimmer (2)- 450/500 mm, spring-loaded (3)- 590 mm, adjacent to skimmer (4)- Serrated-type coulters optionallyavailable in all diameters (5)••The smooth bearings run alongsidethe un<strong>plough</strong>ed land and aredouble-sealed against dirt ingress.13

Support and transport wheelEasy AdjustmentAt the front of the <strong>plough</strong>, the workingdepth is controlled hydraulically bythe linkage, whereas the hydraulicallyadjusted land wheel controls <strong>plough</strong>ingdepth at the rear.A simple locking pin with an accuratelyadjustable scale serves as the mechanicalstop.Transport safetyFor quick and safe transport, the<strong>VariTansanit</strong> is rotated into centreposition, while the land wheel is hydraulicallylocked and the supporteddrawbar is hydraulically unlatched.The <strong>VariTansanit</strong> can be safely pulledby the tractor and the system efficientlyrelieves mechanical strain on thetractor and the <strong>plough</strong>.Technical dataModelNumberoffurrowsWorking widthper furrow[approx. cm]Interbodyclearance[cm]Weight[approx.kg]Frame[mm]Underframeclearance[cm]Dimensionof leg[mm]Tractor powerfrom - up toHPkWwith double cutting shearbolt overload safety device<strong>VariTansanit</strong> 8 6 N 105 6 30 - 55 105 2,437 140 x 140 x 10 85 80 x 30 140 - 205 103 - 151<strong>VariTansanit</strong> 8 6+1 N 105 6+1 30 - 55 105 2,736 140 x 140 x 10 85 80 x 30 140 - 230 103 - 169with additional hydraulic overload safety device Hydromatic<strong>VariTansanit</strong> 8 T 6 L 105 6 30 - 55 105 2,845 140 x 140 x 10 85 80 x 30 140 - 205 103 - 151<strong>VariTansanit</strong> 8 T 6+1 L 105 6+1 30 - 55 105 3,212 140 x 140 x 10 85 80 x 30 140 - 230 103 - 169All statements, measurements and weights given represent standards subject to continuous further development and aretherefore not binding. The weights given always refer to standard equipped implements. We reserve the right to changespecifications14

Service decidesWhen you have bought a machine from LEMKEN, thewell known, almost proverbial LEMKEN service starts. 17customer-oriented factory branches and outdoor storageareas in Germany as well as our own sales companies andimporters in more than 40 countries, and a strong dealernetwork, ensure that machines and spare parts are suppliedquickly. If a part is not in stock, it can be deliveredto the customer within 24 hours via the LEMKEN logisticscentre which is manned round-the-clock 365 days a year.Knowledge from the LEMKEN specialistWell trained customer service technicians are available tofarmers, contractors and trade, who are using machineryfor the first time, as well as for professional maintenanceand repairs. Thanks to regular training courses, LEMKENcustomer service is always up to date with the latestLEMKEN technology.Original spare parts fromLEMKENLEMKEN wearing parts are designed for a maximum servicelife. High-quality materials, the latest production methods,and an intensive quality control ensure a long service life.Therefore, all original spare parts bear a unique identificationwith the registered LEMKEN trademark. Original spare partscan be ordered at any time online on the Internet via theLEMKEN information and ordering system.15

As professional crop production specialists,LEMKEN is one of the leading companies inEurope, with over 1,100 employees worldwide,achieving sales revenues of more than EUR 270m. Originally founded in 1780 as a blacksmith’sforge, the family company produces highqualityand high-performance farm machineryfor soil cultivation, sowing and plant protectionat its German headquarters in Alpen andat its two other production sites in Foehrenand Meppen. 70 percent of the approximately15,000 machines per year are exported.LEMKEN in Alpen/GermanyMounted <strong>plough</strong>s <strong>Hybrid</strong> <strong>plough</strong>s Semi-mounted <strong>plough</strong>s Furrow presses Front pressesCompact combinations Seedbed combinations Power harrows Compact disc harrows CultivatorsSubsoilers Seed drills Drill combinations Mounted field sprayers Trailed field sprayersLEMKEN GmbH & Co. KGWeseler Straße 546519 AlpenTelefon +49 2802 81 0Telefax +49 2802 81 220lemken@lemken.comwww.lemken.comYour LEMKEN dealer:LEMKEN 06/12 . 175 0194/en