MMA DC welding machines - Ewm-sales.co.uk

MMA DC welding machines - Ewm-sales.co.uk

MMA DC welding machines - Ewm-sales.co.uk

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

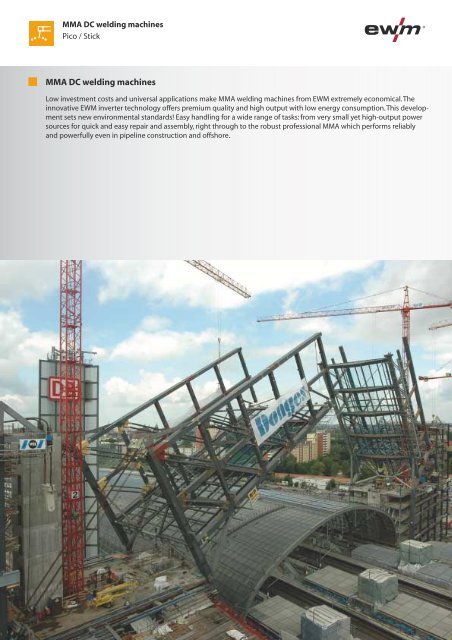

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong> / Stick<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Low investment <strong>co</strong>sts and universal applications make <strong>MMA</strong> <strong>welding</strong> <strong>machines</strong> from EWM extremely e<strong>co</strong>nomical. Theinnovative EWM inverter technology offers premium quality and high output with low energy <strong>co</strong>nsumption. This developmentsets new environmental standards! Easy handling for a wide range of tasks: from very small yet high-output powersources for quick and easy repair and assembly, right through to the robust professional <strong>MMA</strong> which performs reliablyand powerfully even in pipeline <strong>co</strong>nstruction and offshore.182EWM HIGHTEC WELDING GmbH Tel.: +49 2680 181-0, Fax: -244 www.ewm-group.<strong>co</strong>m PK 2009/2010 A3

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong> 162 / Pi<strong>co</strong> 180Light, robust and smallPi<strong>co</strong> 162Pi<strong>co</strong> 180The PICO 162 and 180, EWM's miniature powerhouses, are barely the sizeof a shoe box, yet they really pack a punch. In doing so, with up to 160and 180 amperes output, oustanding <strong>welding</strong> properties, large mainsvoltage ranges and the easiest of handling, these <strong>MMA</strong> specialists setnew standards in assembly. The universal all-rounder: The Pi<strong>co</strong> 162 MV(multi-volt variant) automatically detects the mains voltages of different<strong>co</strong>untries between 115 and 230 volts.HighlightsAntistick and Arcforce – weld like a professionalExtremely easy <strong>welding</strong>: The arc burns steadily without the electrode sticking orannealing.Perfect weld seams even with thick electrodesEven 4-millimetre electrodes are no problem for the Pi<strong>co</strong>. State-of-the-art invertertechnology with superb <strong>co</strong>ntrol dynamics provides a stable arc. This makes even jointingwith rutile or rutile-cellulose electrodes that are hard to weld effortless.Light, transportable and mobileEasily transportable to any work location. Very small and lightweight in a robust plasticcasing, this machine can easily be carried up ladders or over cramped scaffolding.100% suitable for <strong>co</strong>nstruction sitesPerfect for large <strong>co</strong>nstruction sites and very tough assembly work with mains supplyleads up to 50 metres or <strong>co</strong>nnected directly to a generator. High tolerance to mainsfluctuations ensures a perfect <strong>welding</strong> result.Reliable, safe, <strong>co</strong>st-effectiveAll electronic <strong>co</strong>mponents are particularly well protected against dust. The temperature-<strong>co</strong>ntrolledfan prevents unnecessary intake of dirt. An all-round low-maintenance,reliable and therefore <strong>co</strong>st-effective solution!Arcforce: tuning for all electrodesArcforce offers exceptional <strong>welding</strong> properties with all types of electrodes. No shortcircuits, even with rutile-cellulose electrodes.130EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong> 162 / Pi<strong>co</strong> 180Pi<strong>co</strong> 162: Insulating protective <strong>co</strong>verfor optimum protection of the machine intough <strong>co</strong>nditions. Light, robust and easy to retrofitby hand. Combined with an optional dirtfilter, you can protect your machine as best aspossible from dirt.Made-to-measure open circuit voltage – forworldwide useThe VRD (voltage reduction device) functionreduces the open circuit voltage to safe levels.This option meets regional requirements andstandards all over the world.Overvoltage protection.Accidental <strong>co</strong>nnection to 400 V mains voltagedoes not result in damage to the machineHotstart for exceptional qualityThe variable Hotstart function (adjustablecurrent and time) reliably ignites the electrodeand melts perfectly to ensure the best qualityeven at the start of the seam. This solutionmakes lack of fusion and <strong>co</strong>ld welds a thing ofthe past and significantly reduces excess weldmetal.Very <strong>co</strong>mfortable to carryStable and <strong>co</strong>mfortablecarrying strap, slender and<strong>co</strong>nvenient designModern, ergonomic casingThe front and rear sections ofthe machine are made of shockresistantplastic, with rounded<strong>co</strong>rners and edgesExtremely resilientSide panels made from powder<strong>co</strong>atedsheet aluminiumIntelligent casing designOptimised air <strong>co</strong>nduction forlong duty cycleOperating elementsParticularly robust, clear andprotected layoutSafe and reliableIntegrated temperature monitorsprotect against overloadEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244131

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong> 300 / Stick 350Compact, indestructible and versatilePi<strong>co</strong> 300Stick 350For tough, safe everyday operation on <strong>co</strong>nstruction sites and in assemblywork, the resilient <strong>MMA</strong> professional <strong>machines</strong> with metal casing offerthe perfect solution. Even on long mains leads or <strong>co</strong>nnected to a generator,the <strong>welding</strong> electrode ignites reliably. EWM inverter technology withdigital <strong>co</strong>ntrol ensures a stable arc, providing problem-free <strong>welding</strong> evenfor special electrodes. The CEL model versions are 100% safe for verticaldownwelds with cellulose electrodes.HighlightsIdeal for every <strong>co</strong>nstruction siteSlimline design and effortless transport with stable carrying bar – the perfect partnerfor almost any <strong>co</strong>nstruction site. Mains fluctuations are no problem for EWM powersources. Reliable <strong>welding</strong> even with weak mains supplies or extra-long cables. Wellthought-outventilation ensures long duty cycles and protects against dirt.Antistick and Arcforce – weld like a professionalExtremely easy <strong>welding</strong>: The arc burns steadily without the electrode sticking orannealing.Reliable ignition and excellent <strong>welding</strong> propertiesThe digital inverter technology ensures superb arc characteristics for all electrodetypes, a reliable, stable arc and an easily <strong>co</strong>ntrolled molten pool. The high open circuitvoltage and hotstart function guarantee reliable ignition for the long term.Hotstart for exceptional qualityThe variable Hotstart function (adjustable current and time) reliably ignites theelectrode and melts perfectly to ensure the best quality even at the start of the seam.This solution makes lack of fusion and <strong>co</strong>ld welds a thing of the past and significantlyreduces excess weld metal.Reliable, safe, <strong>co</strong>st-effectiveAll electronic <strong>co</strong>mponents are particularly well protected against dust. The temperature-<strong>co</strong>ntrolledfan prevents unnecessary intake of dirt. An all-round low-maintenance,reliable and therefore <strong>co</strong>st-effective solution!Arcforce: tuning for all electrodesArcforce offers exceptional <strong>welding</strong> properties with all types of electrodes. No shortcircuits, even with rutile-cellulose electrodes.132EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong> 300 / Stick 350Made-to-measure open circuit voltage – forworldwide useThe VRD (voltage reduction device) functionreduces the open circuit voltage to safe levels.This option meets regional requirements andstandards all over the world.Antistick and Arcforce – a strong teamDuring the <strong>welding</strong> process, Arcforce preventsthe electrode from sticking in the weld pool.However, if the electrode does stick, theAntistick automatically switches to minimumcurrent, therefore preventing annealing andkeeping the electrode in serviceable <strong>co</strong>ndition.No pipeline without Pi<strong>co</strong>/Stick CEL100% reliability for vertical-down welds withcellulose electrodes.Polarity can be freely selectedBasic or cellulose electrodes „run“ better withthe minus pole on the workpiece. The weldercan solve the question of the right polaritydirectly on site with the remote <strong>co</strong>ntrol of thePi<strong>co</strong>/Stick pws.Convenient transportHandy carrying handles, stablecarrying bar and carrying strap,slender and <strong>co</strong>nvenient designMetal casing: robust anddurableIdeal for <strong>co</strong>nstruction sites:powder-<strong>co</strong>ated sheet steel,phosphatised to prevent<strong>co</strong>rrosion, impact- and scratchresistantyet extremely lightWell-thought-out casingdesignDust remains outside: closedcasing trough, increased <strong>co</strong>olingair inlets with blade/grill<strong>co</strong>mbinationSafe and reliableIntegrated temperature monitorsprotect against overloadand extend the duty cycleEasy <strong>welding</strong> machine <strong>co</strong>ntrolEverything at a glance: selfexplanatorywith one-knoboperation, display, large rangeof functionsBest protectionOperating and <strong>co</strong>nnectionelements recessed to protectagainst damageEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244133

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>/Stick/TaurusPi<strong>co</strong> 162Pi<strong>co</strong> 162 MVControlsPi<strong>co</strong> 162 (MV) • •Stick 350 cel (pws) – –Pi<strong>co</strong> 300 cel (pws) – –Pi<strong>co</strong> 180 – –Taurus Basic – –Functions<strong>MMA</strong> • •TIG • •Gouging – –Technical dataSetting range for <strong>welding</strong>current10 A - 150 A 10 A - 150 ADuty cycle at ambienttemperature25 °C 40 °C 25 °C 40 °C25 % – – – –30 % – – – –35 % – 150 A – 150 A50 % 150 A – 150 A –60 % – 120 A – 120 A100 % 120 A 100 A 120 A 100 AOpen circuit voltage 105 V 105 VMains frequency 50 Hz / 60 Hz 50 Hz / 60 HzMains fuses (slow-blow) 1 x 16 A 1 x 16 A, 1 x 25 AMains voltage (tolerances) 1 x 230 V (-40 % - +15 %) 1 x 230 V (-40 % - +15 %), 1 x 115 V (-15 % - +15 %)Max. <strong>co</strong>nnected load 5.5 kVA 5.5 kVARe<strong>co</strong>mmended generatorpower7.5 kVA 7.5 kVADimensions, machine,LxWxH in mm430 x 115 x 225 430 x 115 x 225Weight, machine 4.8 kg 5.1 kgProtection classification IP 23 IP 23Insulation class H HStandardsIEC 60 974-1; -10 / CE / S-Safety sign / EMC class AQR Code134EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>/Stick/TaurusPi<strong>co</strong> 180 Pi<strong>co</strong> 300 cel Pi<strong>co</strong> 300 cel pws– – –– – –– • •• – –– – –• • •• • •– – –5 A - 180 A 10 A - 300 A 10 A - 300 A25 °C 40 °C 25 °C 40 °C 25 °C 40 °C– 180 A – 300 A – 300 A180 A – 300 A – 300 A –– – – – – –– – – – – –140 A 130 A 250 A 220 A 250 A 220 A130 A 120 A 190 A 170 A 190 A 170 A100 V 100 V 100 V50 Hz / 60 Hz 50 Hz / 60 Hz 50 Hz / 60 Hz1 x 20 A 3 x 16 A 3 x 16 A1 x 230 V (-40 % - +15 %) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)7.2 kVA 12.1 kVA 12.1 kVA9.7 kVA 16.4 kVA 16.4 kVA470 x 135 x 250 515 x 185 x 350 515 x 185 x 4458.9 kg 16.5 kg 23.5 kgIP 23 IP 23 IP 23H H HIEC 60 974-1; -10 / CE / S-Safety sign / EMC class AEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244135

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>/Stick/TaurusStick 350 celStick 350 cel pwsControlsPi<strong>co</strong> 162 (MV) – –Stick 350 cel (pws) • •Pi<strong>co</strong> 300 cel (pws) – –Pi<strong>co</strong> 180 – –Taurus Basic – –Functions<strong>MMA</strong> • •TIG – –Gouging – –Technical dataSetting range for <strong>welding</strong>current20 A - 350 A 20 A - 350 ADuty cycle at ambienttemperature25 °C 40 °C 25 °C 40 °C30 % – 350 A – 350 A40 % – – – –60 % – 250 A – 250 A100 % – 190 A – 190 AOpen circuit voltage 95 V 95 VMains frequency 50 Hz / 60 Hz 50 Hz / 60 HzMains fuses (slow-blow) 3 x 25 A 3 x 25 AMains voltage (tolerances) 3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)Max. <strong>co</strong>nnected load 17.8 kVA 17.8 kVARe<strong>co</strong>mmended generatorpower23.7 kVA 23.7 kVADimensions, machine,LxWxH in mm700 x 230 x 455 700 x 230 x 455Weight, machine 35.5 kg 37.5 kgProtection classification IP 23 IP 23Insulation class H HStandardsIEC 60 974-1; -10 / CE / S-Safety sign / EMC class AQR Code136EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>/Stick/TaurusTaurus 405 TDMTaurus 505 TDM– –– –– –– –• •• •– –• •5 A - 400 A 5 A - 500 A25 °C 40 °C 25 °C 40 °C– – – –– – 500 A 500 A400 A 400 A 450 A 420 A390 A 360 A 390 A 360 A80 V 80 V50 Hz / 60 Hz 50 Hz / 60 Hz3 x 35 A 3 x 35 A3 x 400 V (-25 % - +20 %) 3 x 400 V (-25 % - +20 %)17.5 kVA 24.6 kVA25 kVA 35 kVA624 x 298 x 535 624 x 298 x 53541 kg 45 kgIP 23 IP 23HHIEC 60 974-1; -10 / CE / S-Safety sign / EMC class AEWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244137

<strong>MMA</strong> <strong>DC</strong> <strong>welding</strong> <strong>machines</strong>Pi<strong>co</strong>/Stick/Taurus • Options/accessoriesOptions/accessoriesTIG torch, rotary gas valveGougingRemote <strong>co</strong>ntrols, 14-poleTIG 17 GDV 4MTIG <strong>welding</strong> torch, rotary gas valve, gas-<strong>co</strong>oled,decentralTIG 26 GDV 4MTIG <strong>welding</strong> torch, rotary gas valve, gas-<strong>co</strong>oled,decentralGT 600 SKK95 3Gouging torchAir arc gouging torch for separating metalsu Suitable carbon electrodes can be found inthe Accessories section of the price list!FR30 14POLRemote <strong>co</strong>ntrol, currentOperating point setting directly at the site of<strong>welding</strong>Robust metal casing with rubber feet, retaining clipand holding magnetFor Stick 350 cel and Stick 350 cel PWSFR30PWS 14POLRemote <strong>co</strong>ntrol, current pole reversalOperating point setting directly at the site of<strong>welding</strong>Robust metal casing with rubber feet, retaining clipand holding magnetFor Stick 350 cel PWSFRF30 14POLRemote <strong>co</strong>ntrol, vertical-down weld, currentOperating point setting directly at the site of<strong>welding</strong>Robust metal casing with rubber feet, retaining clipand holding magnetFor Stick 350 cel and Stick 350 cel PWSFRF30 PWS 14POLRemote <strong>co</strong>ntrol, vertical-down weld, current polereversalOperating point setting directly at the site of<strong>welding</strong>Robust metal casing with rubber feet, retaining clipand holding magnetFor Stick 350 cel PWSRemote <strong>co</strong>ntrols, 14-poleRemote <strong>co</strong>ntrols, 19-poleTransport cartsFR35 14POLRemote <strong>co</strong>ntrol, hot startPotentiometer for hot start current infinitely adjustablein % of maximum main current.Potentiometer for hot start time infinitely adjustablefrom 0 to 2 sec.Operating point setting directly at the site of<strong>welding</strong>Robust metal casing with rubber feet, retaining clipand holding magnetFor Stick 350 cel and Stick 350 cel PWSRT1 19POLRemote <strong>co</strong>ntrol, currentOperating point setting directly at the site of<strong>welding</strong>Robust metal casing with rubber feet, retaining clipand holding magnetFor Tetrix, Pi<strong>co</strong>tig 190 AC/<strong>DC</strong>, Pi<strong>co</strong> 180 and Pi<strong>co</strong> 300cel / cel pws machine seriesRT PWS1 19POLRemote <strong>co</strong>ntrol, vertical-down weld, current polereversalOperating point setting directly at the site of<strong>welding</strong>For all Textrix AC/<strong>DC</strong> <strong>machines</strong> (except Tetrix 230AC/<strong>DC</strong>) and Pi<strong>co</strong> 300 cel PWSRTF1 19POLFoot-operated remote <strong>co</strong>ntrol, current, with <strong>co</strong>nnectioncableStart/stop <strong>welding</strong> operationOperating point setting directly at the site of<strong>welding</strong>For Tetrix, Pi<strong>co</strong>tig 190 AC/<strong>DC</strong>, Pi<strong>co</strong> 180 and Pi<strong>co</strong> 300cel / cel pws machine seriesTrolly 39-1Transport cartsFor transporting a power sourceFor Phoenix 404, 405 / 505 and Taurus 404, 405 /505138EWM HIGHTEC WELDING GmbHTel.: +49 2680 181-0, Fax.: -244