GTS-PP - Canusa-CPS

GTS-PP - Canusa-CPS

GTS-PP - Canusa-CPS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

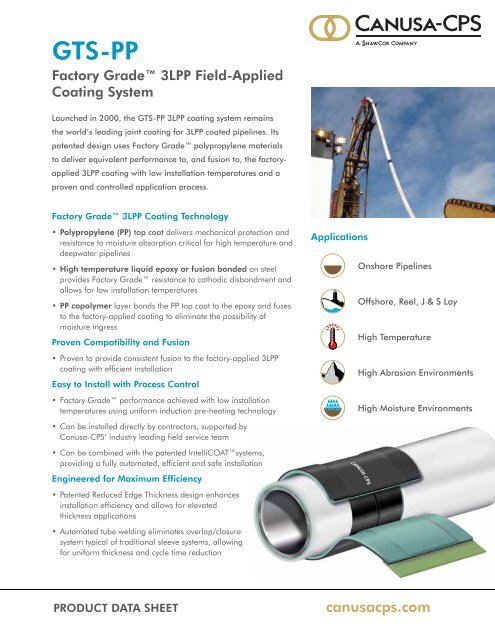

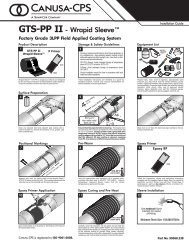

<strong>GTS</strong>-<strong>PP</strong>Factory Grade 3L<strong>PP</strong> Field-AppliedCoating SystemLaunched in 2000, the <strong>GTS</strong>-<strong>PP</strong> 3L<strong>PP</strong> coating system remainsthe world’s leading joint coating for 3L<strong>PP</strong> coated pipelines. Itspatented design uses Factory Grade polypropylene materialsto deliver equivalent performance to, and fusion to, the factoryapplied3L<strong>PP</strong> coating with low installation temperatures and aproven and controlled application process.Factory Grade 3L<strong>PP</strong> Coating Technology• Polypropylene (<strong>PP</strong>) top coat delivers mechanical protection andresistance to moisture absorption critical for high temperature anddeepwater pipelines• High temperature liquid epoxy or fusion bonded on steelprovides Factory Grade resistance to cathodic disbondment andallows for low installation temperatures• <strong>PP</strong> copolymer layer bonds the <strong>PP</strong> top coat to the epoxy and fusesto the factory-applied coating to eliminate the possibility ofmoisture ingressProven Compatibility and Fusion• Proven to provide consistent fusion to the factory-applied 3L<strong>PP</strong>coating with efficient installationEasy to Install with Process Control• Factory Grade performance achieved with low installationtemperatures using uniform induction pre-heating technologyApplicationsOnshore PipelinesOffshore, Reel, J & S LayHigh TemperatureHigh Abrasion EnvironmentsHigh Moisture Environments• Can be installed directly by contractors, supported by<strong>Canusa</strong>-<strong>CPS</strong>’ industry leading field service team• Can be combined with the patented IntelliCOATsystems,providing a fully automated, efficient and safe installationEngineered for Maximum Efficiency• Patented Reduced Edge Thickness design enhancesinstallation efficiency and allows for elevatedthickness applications• Automated tube welding eliminates overlap/closuresystem typical of traditional sleeve systems, allowingfor uniform thickness and cycle time reductionPRODUCT DATA SHEETcanusacps.com

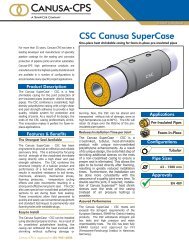

<strong>GTS</strong>-<strong>PP</strong>Factory Grade 3L<strong>PP</strong> Field-Applied Coating SystemSleeve Operating Characteristics Test Method Typical ValuesThe product informationshown here is intended as aguide for standard products.Consult your <strong>Canusa</strong>representative for specificprojects or unique applications.Pipeline Operating Temp.Minimum Installation Temp.Main Line Coating Compatibility<strong>PP</strong> Copolymer PropertiesUp to 140°C (284°F)*175°C (347°F)3L<strong>PP</strong>, FBE<strong>GTS</strong>-<strong>PP</strong> can be combined withthe patented IntelliCOAT system,providing a fully automated FactoryGrade coating system.Melting point ASTM D3418 147°CLap Shear @ 23°C EN 12068 > 600 N/cm 2Lap Shear @ 110°C EN 12068 > 100 N/cm 2<strong>PP</strong> Top Coat (Backing) PropertiesTensile Strength ASTM D638 28 MPaElongation ASTM D638 > 400%Hardness ASTM D2240 65 Shore DVolume Resistivity ASTM D257 2 x 10 17 ohm-cm<strong>GTS</strong>-<strong>PP</strong> 3L<strong>PP</strong> Coating System PropertiesImpact Resistance ISO 21809-1 10 J/mmIndentation Resistance @ 110°C DIN 30678 0.4 mmAdhesion Strength @ 23°C ISO 21809-1 > 250 N/cmAdhesion Strength @ 110°C ISO 21809-1 > 60 N/cmCathodic Disbondment @ 23°C, 28 days ISO 21809-1 < 3 mmCathodic Disbondment @ 95°C, 28 days ISO 21809-1 < 7 mm(CustomHot WaterprojectImmersionthickness@available95°C, 28fromdays1.5 mm to 8 mm.ISOConsult21809-1with your localPass,<strong>Canusa</strong>NoRepresentative.)disbondmentTotal System Thickness Supplied Typical AppliedStandard Product 2.7 mm > 3.0 mm(Custom project thickness available from 1.5 mm to 8 mm. Consult with your local <strong>Canusa</strong> Representative.)<strong>Canusa</strong>-<strong>CPS</strong>A division of ShawCor Ltd.Head Office25 Bethridge Rd.Toronto, ON M9W 1M7 CanadaTel: +1 416 743 7111Fax: +1 416 743 5927CanadaSuite 3200, 450 - 1st Street S.W.Calgary, AB T2P 5H1 CanadaTel: +1 403 218 8207Fax: +1 403 264 3649Americas2408 Timberloch Place, Building C-8The Woodlands, TX 77380 USATel: +1 281 367 8866Fax: +1 281 367 4304Europe, Middle East, Africa & RussiaUnit 3, Sterling Park,Gatwick Road, Crawley, West SussexRH10 9QT United KingdomTel: +44 1293 541254Fax: +44 1293 541777Asia-Pacific101 Thomson Road,#11-03 United Square307591 SingaporeTel: +65 6749 8918Fax: +65 6749 8919<strong>Canusa</strong>-<strong>CPS</strong> is registeredto ISO 9001:2008Exceeds factory-appliedcoating standardsIndustry leadingtrack recordProven compatibilityand fusion* Actual temperature rating is dependant on specific project requirements and conditions. Please consult your local <strong>Canusa</strong> representative.Epoxy usage can be referenced on the Liquid Epoxy, Type P Product Data Sheet.Since 1967, <strong>Canusa</strong>-<strong>CPS</strong> has been a leading developer and manufacturer of specialty pipeline coatingsfor the sealing and corrosion protection of pipeline joints and other substrates. <strong>Canusa</strong>-<strong>CPS</strong> highperformance products are manufactured to the highest quality standards and are available in a numberof configurations to accommodate many specific project applications.<strong>Canusa</strong> warrants that the product conforms toits chemical and physical description and isappropriate for the use stated on theproduct data sheet when used in compliancewith <strong>Canusa</strong>’s written instructions. Since manyinstallation factors are beyond our control,the user shall determine the suitability of theproducts for the intended use and assume allrisks and liabilities in connection therewith.<strong>Canusa</strong>’s liability is stated in the standardterms and conditions of sale. <strong>Canusa</strong> makesno other warranty either expressed or implied.All information contained in this data sheet isto be used as a guide and is subject to changewithout notice. This data sheet supersedes allprevious data sheets on this product. E&OEPDS_<strong>GTS</strong><strong>PP</strong>_rev036