Engineered Gasketing Products

Engineered Gasketing Products

Engineered Gasketing Products

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

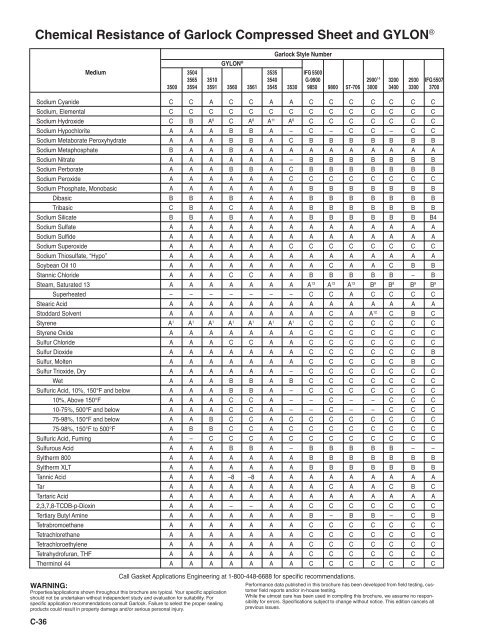

Chemical Resistance of Garlock Compressed Sheet and GYLON ®Garlock Style NumberGYLON ®Medium 3504 3535 IFG 55003565 3510 3540 G-9900 2900 14 3200 2930 IFG 55073500 3594 3591 3560 3561 3545 3530 9850 9800 ST-706 3000 3400 3300 3700Sodium Cyanide C C A C C A A C C C C C C CSodium, Elemental C C C C C C C C C C C C C CSodium Hydroxide C B A 6 C A 6 A 11 A 6 C C C C C C CSodium Hypochlorite A A A B B A – C – C C – C CSodium Metaborate Peroxyhydrate A A A B B A C B B B B B B BSodium Metaphosphate B A A B A A A A A A A A A ASodium Nitrate A A A A A A – B B B B B B BSodium Perborate A A A B B A C B B B B B B BSodium Peroxide A A A A A A C C C C C C C CSodium Phosphate, Monobasic A A A A A A A B B B B B B BDibasic B B A B A A A B B B B B B BTribasic C B A C A A A B B B B B B BSodium Silicate B B A B A A A B B B B B B B4Sodium Sulfate A A A A A A A A A A A A A ASodium Sulfide A A A A A A A A A A A A A ASodium Superoxide A A A A A A C C C C C C C CSodium Thiosulfate, “Hypo” A A A A A A A A A A A A A ASoybean Oil 10 A A A A A A A A C A A C B BStannic Chloride A A A C C A A B B B B B – BSteam, Saturated 13 A A A A A A A A 13 A 13 A 13 B 9 B 9 B 9 B 9Superheated – – – – – – – C C A C C C CStearic Acid A A A A A A A A A A A A A AStoddard Solvent A A A A A A A A C A A 12 C B CStyrene A 1 A 1 A 1 A 1 A 1 A 1 A 1 C C C C C C CStyrene Oxide A A A A A A A C C C C C C CSulfur Chloride A A A C C A A C C C C C C CSulfur Dioxide A A A A A A A C C C C C C BSulfur, Molten A A A A A A A C C C C C B CSulfur Trioxide, Dry A A A A A A – C C C C C C CWet A A A B B A B C C C C C C CSulfuric Acid, 10%, 150°F and below A A A B B A – C C C C C C C10%, Above 150°F A A A C C A – – C – – C C C10-75%, 500°F and below A A A C C A – – C – – C C C75-98%, 150°F and below A A B C C A C C C C C C C C75-98%, 150°F to 500°F A B B C C A C C C C C C C CSulfuric Acid, Fuming A – C C C A C C C C C C C CSulfurous Acid A A A B B A – B B B B B – –Syltherm 800 A A A A A A A B B B B B B BSyltherm XLT A A A A A A A B B B B B B BTannic Acid A A A –8 –8 A A A A A A A A ATar A A A A A A A A C A A C B CTartaric Acid A A A A A A A A A A A A A A2,3,7,8-TCDB-p-Dioxin A A A – – A A C C C C C C CTertiary Butyl Amine A A A A A A A B – B B – C BTetrabromoethane A A A A A A A C C C C C C CTetrachlorethane A A A A A A A C C C C C C CTetrachloroethylene A A A A A A A C C C C C C CTetrahydrofuran, THF A A A A A A A C C C C C C CTherminol 44 A A A A A A A C C C C C C CCall Gasket Applications Engineering at 1-800-448-6688 for specific recommendations.WARNING:Properties/applications shown throughout this brochure are typical. Your specific applicationshould not be undertaken without independent study and evaluation for suitability. Forspecific application recommendations consult Garlock. Failure to select the proper sealingproducts could result in property damage and/or serious personal injury.C-36Performance data published in this brochure has been developed from field testing, customerfield reports and/or in-house testing.While the utmost care has been used in compiling this brochure, we assume no responsibilityfor errors. Specifications subject to change without notice. This edition cancels allprevious issues.