Eurolux Fermentation Tanks 14.000 Liter in AISI 304 ... - Eurolux AG

Eurolux Fermentation Tanks 14.000 Liter in AISI 304 ... - Eurolux AG

Eurolux Fermentation Tanks 14.000 Liter in AISI 304 ... - Eurolux AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Description:<br />

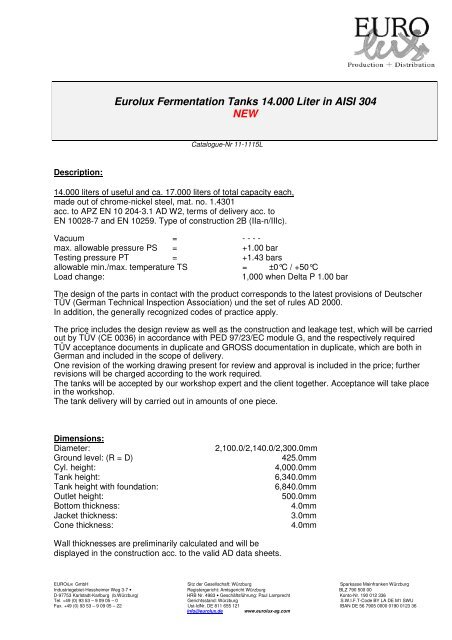

<strong>Eurolux</strong> <strong>Fermentation</strong> <strong>Tanks</strong> <strong>14.000</strong> <strong>Liter</strong> <strong>in</strong> <strong>AISI</strong> <strong>304</strong><br />

NEW<br />

Catalogue-Nr 11-1115L<br />

<strong>14.000</strong> liters of useful and ca. 17.000 liters of total capacity each,<br />

made out of chrome-nickel steel, mat. no. 1.4301<br />

acc. to APZ EN 10 204-3.1 AD W2, terms of delivery acc. to<br />

EN 10028-7 and EN 10259. Type of construction 2B (IIa-n/IIIc).<br />

Vacuum = - - - -<br />

max. allowable pressure PS = +1.00 bar<br />

Test<strong>in</strong>g pressure PT = +1.43 bars<br />

allowable m<strong>in</strong>./max. temperature TS = ±0°C / +50°C<br />

Load change: 1,000 when Delta P 1.00 bar<br />

The design of the parts <strong>in</strong> contact with the product corresponds to the latest provisions of Deutscher<br />

TÜV (German Technical Inspection Association) und the set of rules AD 2000.<br />

In addition, the generally recognized codes of practice apply.<br />

The price <strong>in</strong>cludes the design review as well as the construction and leakage test, which will be carried<br />

out by TÜV (CE 0036) <strong>in</strong> accordance with PED 97/23/EC module G, and the respectively required<br />

TÜV acceptance documents <strong>in</strong> duplicate and GROSS documentation <strong>in</strong> duplicate, which are both <strong>in</strong><br />

German and <strong>in</strong>cluded <strong>in</strong> the scope of delivery.<br />

One revision of the work<strong>in</strong>g draw<strong>in</strong>g present for review and approval is <strong>in</strong>cluded <strong>in</strong> the price; further<br />

revisions will be charged accord<strong>in</strong>g to the work required.<br />

The tanks will be accepted by our workshop expert and the client together. Acceptance will take place<br />

<strong>in</strong> the workshop.<br />

The tank delivery will by carried out <strong>in</strong> amounts of one piece.<br />

Dimensions:<br />

Diameter: 2,100.0/2,140.0/2,300.0mm<br />

Ground level: (R = D) 425.0mm<br />

Cyl. height: 4,000.0mm<br />

Tank height: 6,340.0mm<br />

Tank height with foundation: 6,840.0mm<br />

Outlet height: 500.0mm<br />

Bottom thickness: 4.0mm<br />

Jacket thickness: 3.0mm<br />

Cone thickness: 4.0mm<br />

Wall thicknesses are prelim<strong>in</strong>arily calculated and will be<br />

displayed <strong>in</strong> the construction acc. to the valid AD data sheets.<br />

EUROlux GmbH Sitz der Gesellschaft: Würzburg Sparkasse Ma<strong>in</strong>franken Würzburg<br />

Industriegebiet-Hessheimer Weg 3-7 • Registergericht: Amtsgericht Würzburg BLZ 790 500 00<br />

D-97753 Karlstadt-Karlburg (b.Würzburg) HRB Nr. 4983 • Geschäftsführung: Paul Lamprecht Konto-Nr. 190 012 336<br />

Tel. +49 (0) 93 53 – 9 09 05 – 0 Gerichtsstand: Würzburg S.W.I.F.T-Code BY LA DE M1 SWU<br />

Fax. +49 (0) 93 53 – 9 09 05 – 22 Ust-IdNr. DE 811 655 121 IBAN DE 56 7905 0000 0190 0123 36<br />

<strong>in</strong>fo@eurolux.de www.eurolux-ag.com

covered: effective:<br />

Cool<strong>in</strong>g surface: ca. 7.70m² 12.30m²<br />

<strong>in</strong> the cyl<strong>in</strong>der: ca. 6.60m² 10.60m²<br />

<strong>in</strong> the cone: ca. 1.10m² 1.70m²<br />

Cool<strong>in</strong>g agent: Glycol TE = -3°C<br />

max. allowable pressure PS = +2.00 bars<br />

Test<strong>in</strong>g pressure PT = +2.86 bars<br />

Cool<strong>in</strong>g capacity dur<strong>in</strong>g fermentation: from +12°C to +4°C<br />

(14,500 liters) <strong>in</strong> ca. 24 hours at 2.2% attenuation<br />

Cool<strong>in</strong>g capacity dur<strong>in</strong>g storage: from +4°C to -1°C<br />

(14,000 liters) <strong>in</strong> ca. 48 hours at 0 % attenuation<br />

The heat<strong>in</strong>g/cool<strong>in</strong>g surfaces may only be operated with cool<strong>in</strong>g/heat<strong>in</strong>g agents that do not harm the<br />

material used. The cool<strong>in</strong>g/heat<strong>in</strong>g agent must be free of particles and free<br />

of chlorides and iron.<br />

We will not assume liability for damages caused by the use of <strong>in</strong>appropriate cool<strong>in</strong>g/heat<strong>in</strong>g agents or<br />

detergents.<br />

Total tank weight with cool<strong>in</strong>g system and foundation (without <strong>in</strong>sulation) ca. 1450kg each.<br />

Process<strong>in</strong>g:<br />

<strong>Tanks</strong> welded acc. to the WIG/ Plasma/ M<strong>AG</strong> method.<br />

Weld<strong>in</strong>g seams <strong>in</strong>side ground, ca. 50mm wide gr<strong>in</strong>d<strong>in</strong>g pattern, Ra ≤ 0.6µm.<br />

Weld<strong>in</strong>g seams outside directed and brushed.<br />

Cone and bottom <strong>in</strong>side completely mach<strong>in</strong>e-ground (special gr<strong>in</strong>d<strong>in</strong>g), Ra ≤ 0.6µm.<br />

<strong>Tanks</strong> <strong>in</strong>side and outside fully pickled and passivated.<br />

Equipment:<br />

upper bottom<br />

2 units of transport hooks<br />

2 units of glands with thread DN 65/40 DIN 11851 for clean<strong>in</strong>g-air valve comb<strong>in</strong>ation<br />

Cyl<strong>in</strong>der<br />

1 unit of gland with thread DN 10 DIN 11851 for sampl<strong>in</strong>g<br />

with section pipe for Pt 100 (thermowell), <strong>in</strong>cl. <strong>in</strong>sulation pot DN 200<br />

1 unit of cool<strong>in</strong>g zone with ca. 6.60m² covered cool<strong>in</strong>g surface,<br />

connection: 2 x pipe sockets DN 25 ISO<br />

1 unit of ladder bar<br />

1 unit of type label<br />

Cone<br />

1 unit of conical swift fastener 70°DN 450<br />

with outlet thread DN 65 DIN 11851<br />

1 unit of cool<strong>in</strong>g zone with ca. 1.10 m² covered cool<strong>in</strong>g surface,<br />

connection: pipe sockets DN 25 ISO<br />

4 units of welded on, height adjustable pipe feet with calottes R 1"<br />

and bottom plates ø 140 x 15.0mm out of chrome-nickel-steel<br />

EUROlux GmbH Sitz der Gesellschaft: Würzburg Sparkasse Ma<strong>in</strong>franken Würzburg<br />

Industriegebiet-Hessheimer Weg 3-7 • Registergericht: Amtsgericht Würzburg BLZ 790 500 00<br />

D-97753 Karlstadt-Karlburg (b.Würzburg) HRB Nr. 4983 • Geschäftsführung: Paul Lamprecht Konto-Nr. 190 012 336<br />

Tel. +49 (0) 93 53 – 9 09 05 – 0 Gerichtsstand: Würzburg S.W.I.F.T-Code BY LA DE M1 SWU<br />

Fax. +49 (0) 93 53 – 9 09 05 – 22 Ust-IdNr. DE 811 655 121 IBAN DE 56 7905 0000 0190 0123 36<br />

<strong>in</strong>fo@eurolux.de www.eurolux-ag.com

Supplementary equipment<br />

3 units of ZKT <strong>in</strong>sulations, cyl<strong>in</strong>der and lower bottom.<br />

Design: <strong>in</strong>terspace 80/100mm with m<strong>in</strong>eral fiber mats free of chlorides<br />

and asbestos, stuck on one side to a highly tear-proof alum<strong>in</strong>ium grid foil,<br />

<strong>in</strong>combustible<br />

acc. to DIN 4102. Thermal conductivity at medium temperature<br />

from+40°C = 0.039 W/m.K, cut to the right size and tied on<br />

with sealed jo<strong>in</strong>ts. All edges and seams are neatly bonded with a<br />

self-adhesive pure alum<strong>in</strong>ium tape.<br />

External panel<strong>in</strong>g out of material mat. no. 1.4301/2B, s = 2.5/3.0mm,<br />

tightly welded.<br />

Weld<strong>in</strong>g seams directed and ground.<br />

Insulation jacket fully pickled and passivated.<br />

O p t i o n a l:<br />

Weight ca. 815kg each. Price/Tank/Euro<br />

upon request<br />

Additional charge:<br />

Insulation outside ground optically, Ra ≤ 2.0µm<br />

Pos.<br />

3 3 Set of fitt<strong>in</strong>gs out of chrome-nickel steel consist<strong>in</strong>g of:<br />

a) 1 unit of tank clean<strong>in</strong>g DN 40<br />

with spray ball DN 40,<br />

with pulled down tank clean<strong>in</strong>g pipe DN 40,<br />

end<strong>in</strong>g with pipe DN 40 DIN 11850<br />

b) 1 unit of clean<strong>in</strong>g-air valve comb<strong>in</strong>ation DN 40<br />

Manuf. “Handtmann”, order no. 09902<br />

with vacuum valve DN 40,<br />

and 2nd safety valve DN25, order no. 32504<br />

TÜV – type tested for fluid<br />

Performance: 120 hl/h at 1.0 bar<br />

c) 1 unit of pendentive DN 6/10<br />

Type PEMS II<br />

d) 1 unit of CO2 – and air fitt<strong>in</strong>gs DN 40<br />

Manuf. “Handtmann”, order no. 30802<br />

with safety valve DN 25 for steams and gases,<br />

sett<strong>in</strong>g range up to 1.0 bar,<br />

disk valve DN 40, bung<strong>in</strong>g glass and<br />

Manometer bend with glycer<strong>in</strong> manometer<br />

EUROlux GmbH Sitz der Gesellschaft: Würzburg Sparkasse Ma<strong>in</strong>franken Würzburg<br />

Industriegebiet-Hessheimer Weg 3-7 • Registergericht: Amtsgericht Würzburg BLZ 790 500 00<br />

D-97753 Karlstadt-Karlburg (b.Würzburg) HRB Nr. 4983 • Geschäftsführung: Paul Lamprecht Konto-Nr. 190 012 336<br />

Tel. +49 (0) 93 53 – 9 09 05 – 0 Gerichtsstand: Würzburg S.W.I.F.T-Code BY LA DE M1 SWU<br />

Fax. +49 (0) 93 53 – 9 09 05 – 22 Ust-IdNr. DE 811 655 121 IBAN DE 56 7905 0000 0190 0123 36<br />

<strong>in</strong>fo@eurolux.de www.eurolux-ag.com

4 3 units of temperature displays and controls<br />

respectively consist<strong>in</strong>g of:<br />

1 unit of Negele screw-<strong>in</strong> immersion tube temperature sensor<br />

TFP-40/200/mpu<br />

order no. 7440.2011, our type no. 101465<br />

Type : TFP-40/200/mpu<br />

Measur<strong>in</strong>g resistance : 1 x Pt 100<br />

Connection: : M12<br />

Process connection: : G ½“<br />

Safety pipe dimensions: 12x200mm<br />

Safety pipe mat. no. : 1.4571<br />

Connect<strong>in</strong>g head : <strong>in</strong>cl. Mpu<br />

Operation temperature : -10...+40°C<br />

1 unit of Negele DPM-GS digital display<br />

Our type no. 106054<br />

WxHxD : 96x48x130mm<br />

Protection class : front/rear IP65/IP 20<br />

Entry : 0/4…20 mA / 0…1/10V<br />

Display : 7 segment, four-digit,<br />

Range : -1999…+9999<br />

Sensor supply : 20V DC / max. 30mA<br />

Auxiliary voltage : 230V AC / ca. 7VA<br />

Switch output 2GW : 250 V / 3 A AC switcher<br />

1 unit of 2/2-way pilot operated solenoid valve<br />

with brass body, manuf. "Bürkert" type 5281 R 1”<br />

230/50-60 V/Hz, seal NBR<br />

Scope of delivery with coupler socket<br />

(The temperature control is without assembly and<br />

power supply).<br />

5 1 unit of control cab<strong>in</strong>et with complete <strong>in</strong>stallation<br />

of the temperature control.<br />

Control cab<strong>in</strong>et out of chrome-nickel steel, mat. no. 1.4301,<br />

Surface: brushed outside, seal<strong>in</strong>g with neoprene<br />

Rubber profile, corresponds to protection class IP 55,<br />

3 digital controllers completely <strong>in</strong>stalled and wired,<br />

(4 controllers possible). Dimensions: 400 x 400 x 200mm.<br />

Total price with circuit diagram.<br />

EUROlux GmbH Sitz der Gesellschaft: Würzburg Sparkasse Ma<strong>in</strong>franken Würzburg<br />

Industriegebiet-Hessheimer Weg 3-7 • Registergericht: Amtsgericht Würzburg BLZ 790 500 00<br />

D-97753 Karlstadt-Karlburg (b.Würzburg) HRB Nr. 4983 • Geschäftsführung: Paul Lamprecht Konto-Nr. 190 012 336<br />

Tel. +49 (0) 93 53 – 9 09 05 – 0 Gerichtsstand: Würzburg S.W.I.F.T-Code BY LA DE M1 SWU<br />

Fax. +49 (0) 93 53 – 9 09 05 – 22 Ust-IdNr. DE 811 655 121 IBAN DE 56 7905 0000 0190 0123 36<br />

<strong>in</strong>fo@eurolux.de www.eurolux-ag.com

All prices are valid Ex-Works, excl.VAT Freight Charges: depend<strong>in</strong>g on dest<strong>in</strong>ation and dimensions<br />

Delivery: from D-97753 Karlstadt-Karlburg Subject tp prior sale<br />

Delivery Time: approx.4 Weeks after Order Confirmation<br />

PRICES: upon request<br />

Visit our Web-Site under: www.eurolux-ag.com<br />

EUROlux GmbH Sitz der Gesellschaft: Würzburg Sparkasse Ma<strong>in</strong>franken Würzburg<br />

Industriegebiet-Hessheimer Weg 3-7 • Registergericht: Amtsgericht Würzburg BLZ 790 500 00<br />

D-97753 Karlstadt-Karlburg (b.Würzburg) HRB Nr. 4983 • Geschäftsführung: Paul Lamprecht Konto-Nr. 190 012 336<br />

Tel. +49 (0) 93 53 – 9 09 05 – 0 Gerichtsstand: Würzburg S.W.I.F.T-Code BY LA DE M1 SWU<br />

Fax. +49 (0) 93 53 – 9 09 05 – 22 Ust-IdNr. DE 811 655 121 IBAN DE 56 7905 0000 0190 0123 36<br />

<strong>in</strong>fo@eurolux.de www.eurolux-ag.com