The GreenHouse Project's Adventures + Lessons in - ELLEN ...

The GreenHouse Project's Adventures + Lessons in - ELLEN ...

The GreenHouse Project's Adventures + Lessons in - ELLEN ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

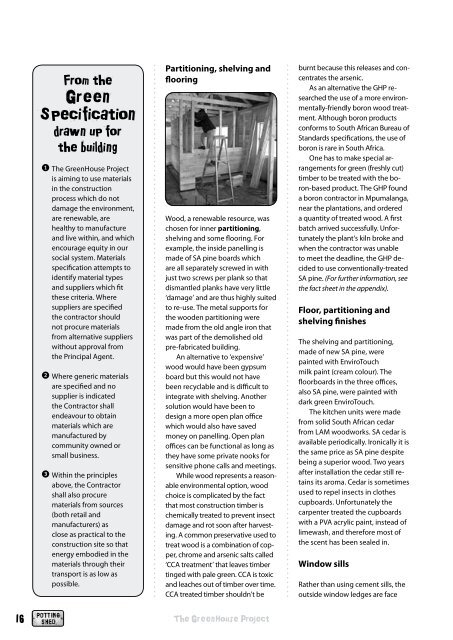

From theGreenSpecificationdrawn up forthe build<strong>in</strong>g1 <strong>The</strong> <strong>GreenHouse</strong> Projectis aim<strong>in</strong>g to use materials<strong>in</strong> the constructionprocess which do notdamage the environment,are renewable, arehealthy to manufactureand live with<strong>in</strong>, and whichencourage equity <strong>in</strong> oursocial system. Materialsspecification attempts toidentify material typesand suppliers which fitthese criteria. Wheresuppliers are specifiedthe contractor shouldnot procure materialsfrom alternative supplierswithout approval fromthe Pr<strong>in</strong>cipal Agent.2 Where generic materialsare specified and nosupplier is <strong>in</strong>dicatedthe Contractor shallendeavour to obta<strong>in</strong>materials which aremanufactured bycommunity owned orsmall bus<strong>in</strong>ess.3 With<strong>in</strong> the pr<strong>in</strong>ciplesabove, the Contractorshall also procurematerials from sources(both retail andmanufacturers) asclose as practical to theconstruction site so thatenergy embodied <strong>in</strong> thematerials through theirtransport is as low aspossible.Partition<strong>in</strong>g, shelv<strong>in</strong>g andfloor<strong>in</strong>gWood, a renewable resource, waschosen for <strong>in</strong>ner partition<strong>in</strong>g,shelv<strong>in</strong>g and some floor<strong>in</strong>g. Forexample, the <strong>in</strong>side panell<strong>in</strong>g ismade of SA p<strong>in</strong>e boards whichare all separately screwed <strong>in</strong> withjust two screws per plank so thatdismantled planks have very little‘damage’ and are thus highly suitedto re-use. <strong>The</strong> metal supports forthe wooden partition<strong>in</strong>g weremade from the old angle iron thatwas part of the demolished oldpre-fabricated build<strong>in</strong>g.An alternative to ‘expensive’wood would have been gypsumboard but this would not havebeen recyclable and is difficult to<strong>in</strong>tegrate with shelv<strong>in</strong>g. Anothersolution would have been todesign a more open plan officewhich would also have savedmoney on panell<strong>in</strong>g. Open planoffices can be functional as long asthey have some private nooks forsensitive phone calls and meet<strong>in</strong>gs.While wood represents a reasonableenvironmental option, woodchoice is complicated by the factthat most construction timber ischemically treated to prevent <strong>in</strong>sectdamage and rot soon after harvest<strong>in</strong>g.A common preservative used totreat wood is a comb<strong>in</strong>ation of copper,chrome and arsenic salts called‘CCA treatment’ that leaves timbert<strong>in</strong>ged with pale green. CCA is toxicand leaches out of timber over time.CCA treated timber shouldn’t beburnt because this releases and concentratesthe arsenic.As an alternative the GHP researchedthe use of a more environmentally-friendlyboron wood treatment.Although boron productsconforms to South African Bureau ofStandards specifications, the use ofboron is rare <strong>in</strong> South Africa.One has to make special arrangementsfor green (freshly cut)timber to be treated with the boron-basedproduct. <strong>The</strong> GHP founda boron contractor <strong>in</strong> Mpumalanga,near the plantations, and ordereda quantity of treated wood. A firstbatch arrived successfully. Unfortunatelythe plant’s kiln broke andwhen the contractor was unableto meet the deadl<strong>in</strong>e, the GHP decidedto use conventionally-treatedSA p<strong>in</strong>e. (For further <strong>in</strong>formation, seethe fact sheet <strong>in</strong> the appendix).Floor, partition<strong>in</strong>g andshelv<strong>in</strong>g f<strong>in</strong>ishes<strong>The</strong> shelv<strong>in</strong>g and partition<strong>in</strong>g,made of new SA p<strong>in</strong>e, werepa<strong>in</strong>ted with EnviroTouchmilk pa<strong>in</strong>t (cream colour). <strong>The</strong>floorboards <strong>in</strong> the three offices,also SA p<strong>in</strong>e, were pa<strong>in</strong>ted withdark green EnviroTouch.<strong>The</strong> kitchen units were madefrom solid South African cedarfrom LAM woodworks. SA cedar isavailable periodically. Ironically it isthe same price as SA p<strong>in</strong>e despitebe<strong>in</strong>g a superior wood. Two yearsafter <strong>in</strong>stallation the cedar still reta<strong>in</strong>sits aroma. Cedar is sometimesused to repel <strong>in</strong>sects <strong>in</strong> clothescupboards. Unfortunately thecarpenter treated the cupboardswith a PVA acrylic pa<strong>in</strong>t, <strong>in</strong>stead oflimewash, and therefore most ofthe scent has been sealed <strong>in</strong>.W<strong>in</strong>dow sillsRather than us<strong>in</strong>g cement sills, theoutside w<strong>in</strong>dow ledges are face16<strong>The</strong> <strong>GreenHouse</strong> Project