Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

In order to test the performance capabilitiesof AMSOIL Synthetic 15W-40 Heavy DutyDiesel and Marine Oil (AME), AMSOILsought a partner with a fleet that operatedin truly severe conditions. The perfectmatch was found in Duluth, Minn.-basedNordic Waste. Nordic Waste operates afl eet of 10 International refuse haulers,providing trash and recycling pickup toresidential and commercial customers inthe greater Duluth/Superior, Wis. region.Nordic’s trucks operate in the bitter cold of sub-zerowinters as well as on humid summer days that can topout at over 90ºF. In addition, Lake Superior’s influenceon the area’s weather patterns can create extremetemperature swings just miles from the lake, somethingNordic’s trucks encounter regularly. The company’sfleet runs 12 hours a day with frequent stops and redlinedstarts, all while hauling up to 22,000 lbs. of refuseand navigating the seriously steep hills of Duluth.As if the geographic challenges aren’t enough, perhapsthe greatest strain these refuse haulers’ enginesface is dumping the refuse. This action requires theengine to remain near or above redline throughout theprocess and shakes the truck enough to nearly lift thefront tires off the ground. Nordic’s trucks dump theircontents twice daily, challenging the oil’s shear stabilityon a regular basis.Navistar DT466Nordic Waste was chosen to participate in this studynot only because refuse haulers in general provide asevere operating environment for oil, but also becauseof the particular engine in the company’s 2006International 7400 rear-loading truck. Notoriously hardon oil, the Navistar DT466 diesel engine is a 7.6L inlinesix-cylinder designed specifically for use in large, commercialInternational trucks. Nordic Waste initiallyinstalled Shell Rotella T 15W-40 (239 hours), and theoil was monitored through oil analysis for the durationof the drain interval. For the subsequent drain interval,Nordic installed AMSOIL Synthetic 15W-40 Heavy DutyDiesel and Marine Oil and monitored the oil’s performancevia oil analysis. Both oils’ shear strength andTBN retention ability were examined using ASTM test-ing procedures. The subject truck maintained its usualoperating procedure throughout the test period, andthe same driver operated the truck on the same routethe entire time. AMSOIL used the oil analysis resultsfrom the initial drain interval, the subsequent draininterval and a thorough teardown and inspection by anindependent, certified International mechanic to evaluatethe performance of AMSOIL Synthetic 15W-40Diesel and Marine Oil.HEUIThe Navistar DT466 engine employs a hydraulicallyactuated,electronically-controlled unit injector (HEUI)system that uses engine oil pressure to run the fuel injectors.The HEUI system was designed to produce lowercombustion noise and reduce hydrocarbon and nitrousoxide levels during combustion, offering quieter, cleanerdiesel engine operation. HEUI systems feature a variablepump (in addition to the oil pump) that pressurizesthe oil according to the fuel injection system’s needs,placing a considerable amount of additional strain onengine oil. HEUI systems can raise oil pressure to ashigh as 3,500 psi, creating great potential for shearingand adding significant stress to motor oil that is alreadyoperating in a severe environment. The HEUI system’sreputation for shearing less robust motor oils made theDT466 engine the perfect choice for testing the durabilityof AMSOIL Heavy Duty Diesel and Marine Oil.2 FIELD STUDY

983-HOUR DRAIN INTERVALUsed Oil AnalysisWear metal levels were tracked through oil analysis forthe duration of the drain interval. As the results reveal,AMSOIL Diesel Oil contained wear metals well belowInternational’s published condemnation limits, evenafter more than 900 hours of use.Figure 1 displays the accumulation of copper wearparticles in AMSOIL Synthetic Diesel and Marine Oilover 983 hours. Due to the extreme environment createdby the HEUI system, the condemning limit forcopper levels in the DT466 engine is 60 parts per million(ppm). The HEUI system’s tendency to cause oilshearing thins out lesser oils at normal operating temperaturesand increases the likelihood for abnormalengine wear. As the results demonstrate, AMSOILSynthetic 15W-40 Diesel Oil provided outstandingshear stability for the duration of the 983-hour draininterval.Parts Per Million60504030201002 21Copper Levels35 4 4Condemning Limit6 7 710 81 180 234 394 506 617 780 929 983Hours of ServiceFigure 1Figure 2 charts the rate at which iron wear particlesdeveloped. Once again, the extraordinary demand theengine’s HEUI system places on engine oil results in alow condemnation limit of 200 ppm of iron. Even after983 hours of use, AMSOIL Synthetic Diesel and MarineOil contained less than 100 ppm of iron.Figure 3 details the accumulation of lead particlesover the drain interval. The condemnation limit for leadcontent is 60 ppm. A sudden spike in lead levels orlevels that approach the condemning limit indicate anabnormal wear situation and can indicate the need todrain the oil. AMSOIL Synthetic Diesel and Marine Oilmaintained consistently low lead levels throughout the983-hour drain interval.Parts Per Million6050403020100123 3Lead Levels631 110 81 180 234 394 506 617 780 929 983Hours of ServiceCondemning Limit5 5 5Figure 3Maximum DurabilityAMSOIL Synthetic 15W-40 Diesel and Marine Oil maintainedexceptional lubrication properties for the durationof the 983-hour drain interval. It maintainedviscosity better than Shell Rotella T did, measuring12.33 centi stokes (cSt) when drained. Shell Rotella T,on the other hand, measured 10.17 cSt after its 239-hour oil drain interval. AMSOIL Diesel Oil demonstratedsuperior shear stability over an extended drain interval,even in severe service.Figure 4 shows kinematic viscosity of Shell RotellaT and AMSOIL Diesel and Marine Oil for the durationof their respective drain intervals. The trend line for ahigh-quality motor oil should remain relatively flat forthe entire service period. AMSOIL 15W-40 Diesel andMarine Oil shows a stable trend over the extendedservice period, well beyond the OEM-recommendeddrain interval.200Iron LevelsCondemning Limit16Viscosity @ 100˚CASTM D-445March 2008 Test ResultsParts Per Million1501007392 89cSt14125026 23 2331 30 324310010 81 180 234 394 506 617 780 929 983Hours of ServiceFigure 280 100 200 400 600 800 1000Hours of ServiceFigure 4FIELD STUDY 3

Superior Corrosion ProtectionAn oil’s ability to maintain corrosion protection throughoutits service life is measured by Total Base Number(TBN). AMSOIL Synthetic 15W-40 Diesel and MarineOil is formulated with a high 12 TBN to ensure corrosionprotection from combustion blow-by and exhaust gasrecirculation (EGR) for the life of the oil. AMSOIL DieselOil displayed excellent TBN retention ability for theentire 983-hour drain interval.Figure 5 shows TBN results for AMSOIL Synthetic15W-40 and Shell Rotella T for the duration of theirrespective drain intervals. TBN levels and hours ofservice have an inverse relationship; as hours increase,TBN decreases. It is important that the slope of theTBN trend line is gradual and spans the life of the lubricant.A sharp downward trend indicates poor protection,which, if not addressed, can result in pistondeposits and ring sticking. AMSOIL Diesel Oil’s performancein the TBN test is in line with how a high-qualityoil should perform. It maintains TBN levels to effectivelyneutralize acidic by-products of combustion and keepengine components free of deposits and corrosion.TBN13121110987654Total Base NumberASTM D-2896March 2008 Test Results0 100 200 400 600 800 1000Hours of ServiceFigure 5ROUTINE ENGINE TEARDOWNAt approximately 8,000 hours of use, Nordic Wastebrought its International 7400 refuse hauler to certifiedInternational Truck mechanic Dan Lee for a routineteardown. Lee, who specializes in the DT466 engine,examined the pistons, rings, wrist pins and bearings,while the top and bottom cylinder (bore) diameterswere measured by PDQ Engine and Machine inDuluth, Minn.Deposit-FreeFigure 6 shows the subject truck’s valvetrain. Thevalvetrain is typically prone to varnish and sludgedeposits on non-moving parts and valve springs.Sludge and varnish buildup appears as a thick, darkresidue. Many times, sludge is baked into a hard-to-removecarbonaceous consistency associated withan engine lubricant being overloaded with insolubles.AMSOIL Synthetic Diesel and Marine Oil’s robust additivepackage and high TBN kept the DT466 cylinderhead and valvetrain free of deposits and sludge.Figure 6Reduced WearFigure 7 shows one of the cylinder liners from theDT466 in Nordic’s truck. Lubrication is essential for thebore to remain operational. If sufficient lubrication is notprovided, excess heat may cause thermal expansion,which can force the cylinder out of round and significantlyincrease the potential for wear. After nearly8,000 hours of operation, the OEM cross-hatch patternin the cylinder is still evident, demonstrating AMSOILDiesel Oil’s excellent wear control in spite of the extremeshaking, jarring and revving the motor is subjected toon a daily basis. Though it is slight, the most wearoccurred at the top dead center of piston movement,where there is only light oil film lubrication. Figure 8shows top and bottom bore measurements along withthe OEM specifications. Measurements for the sixthcylinder were unavailable as International Truck retainedthat sample for their records.Figure 74 FIELD STUDY

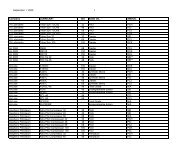

Piston cleanliness in this engine was representativeof an engine that had accumulated far fewer hours. Infact, Lee indicated that each piston was suitable forcontinued use. AMSOIL Synthetic 15W-40 Diesel andMarine Oil resisted oxidation and volatility to allowminimal carbon deposit development between compressionrings, on the crown and inside the ring landarea. Conventional lubricants can allow unnecessarycarbon buildup in these areas, which can cause pistonring sticking and unnecessary wear. After nearly 8,000hours of service, the piston rings and skirts in Nordic’struck measured within OEM specifications for a newDT466 engine.Figure 8 shows the top and intermediate piston ringmeasurements. Piston rings are measured by determiningthe gap in each ring. As piston rings experiencewear, additional room for ring expansion is created,widening the ring gap. Lower measurements equate toless wear, yet any measurement within OEM specificationsis equivalent to rings when new. All of the toppiston rings were still within International specificationlimits for new engines, with an average measurementof 0.015 inches. All of the intermediate rings but onemeasured 0.074 inches, which is within Internationalspecifications. Since all of the other rings had identicalmeasurements, it is possible that the ring that was outof specified limits had been so since it was installed.Figure 9 shows ring locations.Figure 10 shows Lee measuring a piston skirt inorder to determine the amount of wear that hadTop RingFigure 10occurred. Skirt measurements are determined by measuringthe outer diameter of the piston, halfway betweenthe crown (top) and base. The diameters of each pistonskirt from Nordic’s truck were identical, measuring4.585 inches (see Figure 8). The piston skirts showedno measurable wear and were within Internationalspecifications for a new DT466 engine.Figure 11 shows an example of the piston skirt andcrown from Nordic’s DT466. Lee indicated that pistoncleanliness was similar to engines that had accumulatedsignificantly less hours and were suitable for continueduse. None of the pistons showed any signs of abnormalor visual wear.Int. RingFigure 9Figure 11Top Bore Bottom Bore Top Ring Intermediate Ring Piston Skirt Wrist PinOEM Spec 4.590 - 4.591” 4.590 - 4.591” 0.014 - 0.026” 0.065 - 0.075” 4.584 - 4.586” 1.8249 - 1.8251”Part Set A 4.5915” 4.5905” 0.016” 0.074” 4.585” 1.826”Part Set B 4.5905” 4.590” 0.015” 0.074” 4.585” 1.825”Part Set C 4.591” 4.590” 0.018” 0.082” 4.585” 1.825”Part Set D 4.591” 4.590” 0.015” 0.074” 4.585” 1.825”Part Set E 4.591” 4.5905” 0.014” 0.074” 4.585” 1.825”Figure 8FIELD STUDY 5

Figure 12 shows one of the wrist pins from Nordic’struck. Extreme force in the combustion chamber transfersthe load directly to the wrist pin, creating the needfor a durable, shear-stable oil in order to prohibit metalto-metalcontact. The wrist pins from the Nordic Wastetruck measured within OEM specifi cations. No fl atspottingoccurred and, even after daily severe serviceover extended drain intervals, the wrist pins’ measurementswere similar to when originally pressed into thepiston by the engine manufacturer. (See Figure 8 formeasurements.) Higher measurements equate to lesswear because as wear occurs, wrist pin diameters arereduced. AMSOIL Synthetic Diesel and Marine Oil’ssuperior fi lm strength deliveredexceptional protection inthis severe environment,effectively preventing componentwear.Figure 13 shows the bearingsfrom Nordic’s DT466engine. No copper lining ordiscoloration was evident onthe bearings, proving that verylittle wear occurred. Theywere very clean and showedinsignificant levels of pitting inthe bearing surface. Accordingto Lee, each bearing was ingood condition and showedwear levels consistent withthose of a light-duty enginereceiving four times as manyoil changes.“The lack of copper showingon the bearings provesminimal wear has occurred,”Figure 12said Lee. “For the hours on this unit, these bearingslook very good. If it weren’t for the routine maintenanceinterval requiring replacement, these bearings are stillin good enough condition to be reused.” Lee attributedthe minor wear on the bearings to break-in wear whenthe engine was new. “What little wear was evident onthe bearings was from engine break-in and the bearingslook far better than many I have seen,” said Lee. Enginebearings cannot be measured without the piston rodsand end caps, which were put back into the motor priorto Lee’s inspection.USE OF AMSOIL DIESEL OILSAVES MONEYNordic’s Experience WithConventional OilsBetween the unique climate and geographic challenges,the HEUI system, constant use of the truck’shydraulic applications and regular near-redline operation,Nordic Waste’s trucks provide a serious challengefor any motor oil. In fact, it was Nordic’s search for anoil that could withstand the punishment doled out byits vehicles every day that led the company toAMSOIL.“With the big hills, high heat and extreme cold wework in, nothing has performed better,” said NordicWaste Owner Brian Johnson. Johnson noted thatNordic Waste had installed other diesel oils in its trucksbut none were able to provide the level of protectionoffered by AMSOIL Diesel Oil. Prior to discoveringAMSOIL, the conventional lubricants Nordic used wouldshear out of viscosity-grade rapidly and need to bechanged at approximately 200 hours of service. Uponswitching to AMSOIL Synthetic 15W-40 Diesel andMarine Oil, Nordic Waste increased the average draininterval for its trucks from approximately 200 hours tonearly 1,000 hours.Extreme-Temperature PerformanceThe extreme temperatures faced in the Duluth/Superiorregion place great strain on Nordic’s fleet. Winter temperaturesdropping below -30°F are not unusual, socold starts and hydraulic functions are especially sensitiveareas for Nordic Waste.“Cold starts were a primary concern for us,” saidJohnson. “Even though we use block heaters in thewinter, you never know when you might come to workand find that the breaker tripped or a driver forgot toplug in the truck the previous evening.” Nordic’s driversbegin their day around 3:30 a.m., so there is no timefor troubleshooting or engine repairs prior to beginningtheir routes. The cold-start issues plagued NordicWaste for nearly six months out of every year, until thecompany switched to AMSOIL products.Figure 136 FIELD STUDY

“With conventional lubricants, when trucks weren’tplugged in, starting would be difficult, if even possible,and even if the trucks turned over, engine protectionwould be minimal because no oil pressure would appearon the gauge,” said Johnson. The test truck’s operator,Wayne Carlson, noticed the difference with AMSOILDiesel Oil right away. “The truck has excellent performancein winter,” said Carlson. “It fires right up withoutbeing plugged in and there is instant oil pressure withAMSOIL. In trucks I have driven using conventionallubricants, it could take more than a minute to build anyoil pressure when cold, providing little engine protection.”AMSOIL Synthetic 15W-40 Diesel and Marine Oilis formulated to provide exceptional cold-temperatureperformance. Its cold-flow properties have savedNordic Waste time and money, and delivered peace ofmind with the knowledge that the company’s trucks willstart on even the coldest winter morning.AMSOIL Diesel Oil Saves MoneyUse of AMSOIL Synthetic 15W-40 Diesel and MarineOil, along with oil analysis, has allowed Nordic Wasteto extend its trucks’ oil drain intervals to nearly 1,000hours – four times the length of service possible whenusing Shell Rotella T. Nordic’s trucks are well-protectedand experience optimum fuel economy, so they stayout of the shop and on the road.“We experience less downtime and have seen reductionsin costs associated with engine overhauls andreplacement parts,” said Johnson. Refuse haulers arevery expensive, so maintaining spare trucks is not affordablefor a small company. Operating with a minimalnumber of trucks requires maximum uptime to ensurecustomers are serviced properly. By delivering superiorprotection over extended drain intervals and improvingengine reliability, AMSOIL Synthetic Diesel and MarineOil provides Nordic Waste consistent dependability andreduced maintenance (increased uptime). Increaseduptime has helped Nordic Waste maintain an accurateschedule and provide excellent customer service –trucks are more readily available for routes when theyaren’t in the shop for service. In addition to improvingthe company’s operations, extended drain intervals saveNordic a considerable amount of money annually.“We buy significantly less oil, fewer filters and weexperience lower labor costs,” said Johnson. “Our biggestsavings have been the reduced number of engineoverhauls and replacement parts.”Use of AMSOIL Synthetic 15W-40 Diesel and MarineOil saves Nordic Waste thousands of dollars in oilalone, in addition to reduced expenses for labor, filtersand waste oil and used filter disposal. Figure 14 showsthe annual savings realized by converting one truck toAMSOIL Synthetic Diesel and Marine Oil. AMSOILDiesel and Marine Oil is installed in all 10 of NordicWaste’s trucks, providing an annual savings of$3,963.60* in oil costs alone.Environmental BenefitsUse of AMSOIL Synthetic 15W-40 Diesel and MarineOil helps Nordic Waste reduce its environmental impact,something that’s important to a company that providesrecycling services. Nordic’s extended drain intervalshave reduced the amount of oil the company disposesof by up to 75%. In addition, AMSOIL Diesel Oil’s superiorthermal resistance helps it effectively resist volatilization(burn-off) better than conventional oils. “Thistruck hardly ever consumes any oil; less than one quartper oil change, which is very good compared to oils inother trucks I have driven,” said Carlson.ConclusionAMSOIL Synthetic 15W-40 Diesel and Marine Oil providessuperior performance in the harsh environmentfaced by refuse haulers. Through oil analysis, NordicWaste has been able to safely extend the oil drain intervalsin the company’s fleet to more than four times thedrain interval possible using Shell Rotella T. In this fieldstudy, AMSOIL Diesel Oil demonstrated excellent wearprotection for the entire 983-hour drain interval. Its TBNretention was excellent, it provided exceptional corrosionprotection and minimized sludge formation, as evidencedby the absence of corrosive areas or sludgebuildup on engine components during the routine teardown.AMSOIL Synthetic Diesel and Marine Oil preventedsoot-thickening, resisted oxidation and minimizedwear. It also maintained proper viscosity for the durationof the 983-hour drain interval in spite of the severe operatingenvironment and HEUI injection system. Adversely,Shell Rotella T 15W-40 sheared out of viscosity-graderapidly, requiring an oil change after only 239 hours ofservice. Nordic Waste’s use of AMSOIL Synthetic15W-40 Diesel and Marine Oil has improved the fleet’sperformance and longevity, and reduced the company’smaintenance costs. AMSOIL Diesel Oil saves NordicWaste a significant amount of money annually.Money Saved by Using AMSOIL *AMSOIL SyntheticShell Rotella TDiesel and Marine OilAnnual Hours 2,500 2,500Oil Drain Interval (Hours) 250 900Oil Changes Per Year 10 3Cost Per Gallon $14.60 $31.05Cost Per Oil Change (7.5 Gal.) $109.50 $232.88Annual Cost Per Truck $1,095.00 $698.64Annual Savings$396.36 Per TruckFigure 14*May 2009 suggested retail pricing.AMSOIL accounts buy at wholesale pricing, saving even more.FIELD STUDY 7

“In the two years I’ve been riding withAMSOIL, I’ve never experienced a singleengine problem.”– Wayne CarlsonOperator, Nordic Waste“With AMSOIL, we buyless oil, fewer filters,experience lowerlabor costs and save onengine overhauls andreplacement parts.”– Brian JohnsonOwner, Nordic WasteAMSOIL products and Dealership information areavailable from your local AMSOIL Dealer.AMSOIL INC., AMSOIL Bldg., Superior, WI 54880 (715) 392-7101 Fax: (715) 392-5225, (715) 392-5267 Printed in U.S.A. © Copyright 2009 G2695 6/09