T-849/1359/2012 - Central Farm Machinery Training & Testing Institute

T-849/1359/2012 - Central Farm Machinery Training & Testing Institute

T-849/1359/2012 - Central Farm Machinery Training & Testing Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 1 of 48

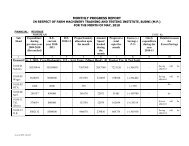

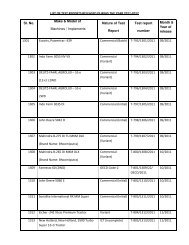

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)16. SUMMARY OF OBSERVATIONS, COMMENTS & RECOMMENDATIONS16.1 Evaluative (mandatory) / Non-evaluation (Non-mandatory) parameters applicable forqualifying Minimum Performance criteria as per Clause-4 (Table-1) of IS: 12207-2008for acceptance of the tractor for the purpose of subsidies/NABARD financing aresummarized as under:Sl. No.CharacteristicCategory(Evaluative/ NonEvaluative)Requirementsas per IS: 12207- 2008Valuesdeclared bythe applicant(D) /Requirement(R)As observedWhethermeetstherequirements(Yes/No.)1 2 3 4 5 6 716.1.1 PTO Performance :a)Declared value to be- Max. powerachieved with aunder 2 h test,33.6 (D) 34.9 Yestolerance of: -5 / +10%(kW ) (Natural Evaluativefor PTO power >35hp.ambient–7.5/+10% for PTOcondition)power ≤ 35 hp.b)Power at ratedengine speed,(kW)NonEvaluative -do- 33.48 (D) 34.9 YesCENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 39 of 48

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)1 2 3 4 5 6 7c)Specific fuelconsumptioncorresponding tomaximum power,(g/kWh)d)Maximumequivalentcrankshafttorque, (Nm)NonEvaluative ± 5% 265 (D) 261 YesNonEvaluative ± 8% 175 (D) 180.3 Yese)Back-up torque,percentNonEvaluative7 percent, min. 7 percent,min.(R)f) Maximum operating temperature ( O C)The declared value shouldnot exceed the max. value1) Engine oilspecified by the oil companyNonand the observed valueEvaluative under high ambient conditionshould not exceed thedeclaration.2)Coolant(water)g) Engine oilconsumption,(g/kWh)EvaluativeEvaluativeThe declared value shouldnot exceed the boilingtemperature of coolantunder the pressurized orotherwise and the observedvalue under high ambientcondition should not exceedthe declaration.Not exceeding 1% of SFC atmax. power under Highambient conditionsh) Smoke level Evaluative Maximum light absorptioncoefficient of 3.25 permetre or equivalentBOSCH No. 5.2 or 75Hatridge value (As perCMVR)16.1.2 Drawbar performance :a) Maximumdrawbar pullwith ballastcorrespondingto 15 percentwheel slip, (kN)b) Maximumdrawbar pullwithout ballastcorrespondingto 15 percentwheel slip, (kN)c) Maximumdrawbar powerwithout ballast,(kW).d) Maximumtransmission oiltemperature( o C)NonEvaluativeEvaluativeEvaluativeNonEvaluativeMinimum 65% of staticmass with ballastMinimum 65% of staticmass of tractor withoutballastMin. 80% of PTO poweras referred in 17.1.1(a)of PTO performanceThe declared valueshould not exceed themaximum valuespecified by oilcompany.27.1 Yes155 (D) 132 Yes120 (D) 102 YesMaximum1% of SFC(R)Max 3.25per meter(R)0.46 Yes0.43 Yes21.93 (D) 28.42 Yes22.06 (R)Minimum13.96 (D) 20.47 Yes14.09 (R)Minimum26.88 (D) 29.9 Yes27.9 (R)Minimum120 (D) 83 YesCENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 40 of 48

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)1 2 3 4 5 6 716.1.3 Power lift and hydraulic pump performance :a) Maximum lifting capacity throughout the range of lift, (kN):1) At hitch Non Evaluative [Tolerance of minus 14.00 (D) 18.17 Yespoints2) With thestandardframeb) Maximum drop inthe height of thepoint of applicationof the force aftereach 5 minutesinterval for a totalduration of 30minute, (mm)EvaluativeNon Evaluative10%]The lift capacityshould at least be18 kg/PTO hp. Andit should be 16kg/engine hp wherethe tractor is notprovided with a PTOshaft.[Tolerance of plus5 mm]9.00(D) 17.58 Yes8.26 (R)Minimum40 (D) 05 Yes16.1.4 Brake performance at 25 kmph:a) Maximum stopping distance at a force, equal to or less than 600 N on brake pedal withballast* (m):1) Cold brake Evaluative 10 10 (R) 5.92 Yes2) Hot brake Evaluative 10 10 (R) 6.28 Yesb) Maximum forceexerted on the brakepedal to achieve adeceleration of 2.5m/s 2 (N)c) Whether parking brakeis effective at a forceof 600 N at footpedal(s) or 400 N athand lever16.1.5 Noise measurement :a) Maximum ambientnoise emitted by thetractor dB(A)b) Maximum noise atoperator’s ear leveldB(A)Evaluative16.1.6 Amplitude of mechanical vibrations at :600 600 (R) 304 to383YesEvaluative Yes / No Yes (R) Yes YesEvaluative As per CMVR 88 (R) 87 YesEvaluative As per CMVR 98 (R) 94 Yes1) Left foot rest100 microns (max) 100 (R) 180 No2) Right food rest 100 (R) 290 NoNon3) Seat (with driverEvaluative-do- 100 (R) 60 Yesseated)4) Steering wheel -do- 100 (R) 160 No16.1.7 Haulage requirements :a) Gross mass of the trailers, (tones):1) Two wheel Non-- 5.0 (D) 5.0 Yes2) Four wheel Evaluative-- 6.0 (D) 6.0 Yesb) Distance travelled / litre of fuel consumption, (km/l):1) Two wheel NonEvaluative-- 4.25 to 6.50(D)4.66 YesCENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 41 of 48

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)1 2 3 4 5 6 72) Four wheel Non-- 4.25 to 6.50 3.72 NoEvaluative(D)c) Fuel consumption (ml/km/tonne):1) Two wheel-- 30 to 50 45.63 Yes2) Four wheelNonEvaluative --(D)25 to 40(D)46.84 NoWetland cultivation :16.1.8Sealing for thefollowing assemblies:1) ClutchassemblyEvaluative-do-2) Brake housings -do-3) Front axle hubs -do-16.1.9 Safety features :The identifiedassembliesshouldessentially meetthe requirementof IS: 11082. Nowater ingress inthe identifiedassembly givenin column-2.If tractor doesnot meet therequirements ofwetlandcultivation, it mayberecommendedfor dry landoperation only.There shouldbe no ingressof waterand/or mudNo ingressof mud and/ or waterwasobserveda) Guards againstAs per CMVR At present no ProvidedEvaluativerequirementsmoving and hot partsYesb) LightingEvaluative As per CMVR -- Provided Yesarrangement16.1.10 Labelling of tractors (Provision of labelling plate):1) Make Evaluative-- DEUTZ- FAHR Yes2) Model Evaluative Should conform -- AGROMAXX 55 Yesto the(4WD)3) Year ofEvaluative requirements of-- 2011 YesmanufactureCMVR alongwithdeclared4) Engine number Evaluative -- 3A30177H11 Yesvalue5) Chassis Evaluativeof PTO HP -- D*10056H11 Yesnumber6) Declaration of Evaluative -- 33.6 YesPTO power,(kW)16.1.11 Discard limit for:(a)Cylinder boreEvaluative To be specifieddiameter, (mm)by the105.1 105.00 to 105.01 Yes(b) Clearance between Non manufacturer 0.42 0.130 to 0.132 Yespiston & cylinder liner Evaluativeat skirt, (mm)Ring end gap (mm):(c)- Top comp. ring.-do- 1.5 0.45 to 0.50 Yes- 2 nd comp. ring. Evaluative -do- 1.5 0.50 to 0.55 Yes- Oil ring. -do- 1.5 0.50 to 0.55 YesCENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 42 of 48Yes

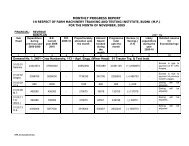

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)1 2 3 4 5 6 7(d) Ring groove clearance (mm):- Top comp. ring.To be specified 0.25 0.138 to 0.147 Yesby theEvaluative manufacturer- 2 nd comp. ring. -do- 0.22 0.065 to 0.071 Yes- Oil ring. -do- 0.15 0.051 to 0.056 YesClearance of main bearings (mm):(e) - DiametricalclearanceEvaluative -do-0.40 0.074 to 0.106 Yes- Crankshaft endfloatEvaluative -do-0.50 0.13 YesClearance of big end bearings, (mm):(f) - Diametrical Evaluative -do- 0.40 0.058 to 0.069 Yes- Axial Evaluative -do- 0.50 0.50 Yes(g)Clearance betweenNonYesking pin and bush,-do- 0.85 0.11Evaluative(mm)(h)Clearance between-do-NonYescenter pin and bush,0.85 0.10Evaluative(mm)16.1.12 CATEGORY OF BREAKDOWNS / DEFECTS :CategorySl. No. Characteristic (Evaluative /NonEvaluative)Requirementsas per IS: 12207-20081. Critical Evaluative There should be no ‘criticalbreakdown’ during its validation afterall tests including Repeat /Supplementary tests.2. Major Evaluative There should not be more than two‘major breakdowns’ and neither ofthem is of repetitive nature.3. Minor Evaluative There should not be more than five‘minor defects’ during the test andfrequency of each should not be morethan two.4. TotalbreakdownsEvaluativeIn no case, the total number ofbreakdowns should exceed five, thatis, (2 major + 3 minor) or 5 minorbreakdowns.AsobservedNoneNoneNoneNone16.2 Optional requirements as per Clause-4 (Table-2) of IS:12207-2008:S. No. Characteristic Requirementsas per IS: 12207-2008As observedWhethermeets therequirements(Yes/No.)YesYesYesYesRemarks1 2 3 4 51. Air cleaner oil pull over, 0.25% (max.) Not applicable --max. oil pull over (%)2.Should meet the requirements of Does not meetSeating requirementsIS: 12343-1998the requirementNo3.Fitment of ROPSWith a provision for fitment ofROPS.If ROPS fitted it should meet therequirement of IS: 11821-1992Not providedNot providedNo--4.Technical requirementsfor PTO shaftShould meet the requirements ofIS: 4931 -1995Meets therequirementsYesCENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 43 of 48

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)1 2 3 4 5Dimensions of three Should meet the requirements of Meets the5.point linkageIS: 4468 (Part-I)-1997Yesrequirements6.Specifications of linkagedrawbarSpecifications ofswinging drawbar7. AccessoriesShould meet the requirements ofIS: 12953-1990.Should meet the requirements ofIS: 12362 Part 3-1994.Trailer hitch, front tow hook,linkage drawbar may be provided.Meets therequirementsYesNot provided --ProvidedYes16.3 Conformity with following IS:i) Guidelines for declaration of power and specific fuelconsumption and labelling of agricultural tractors(First revision) [IS10273: 1987 (Reaffirmed inMarch, 2009)]ii)iii)Agricultural tractors - Rear mounted power take-off- Types 1, 2 and 3 (third revision) [IS:4931-1995(Reaffirmed in March, 2009)]Agricultural wheeled tractors - Rear mounted threepointlinkage: Part 1 Categories 1, 2, 3 & 4 (fourthrevision) [IS 4468 (Part-I):1997 (Reaffirmed inMarch, 2007) / ISO 730-1:1994]iv) Drawbar for agricultural tractors – Link type [IS12953:1990 (Reaffirmed March, 2007)]v) Agricultural tractors - Operator’s seat technicalrequirement [IS: 12343 –1998 (First revision)(Reaffirmed in March, 2009)]vi)Guide for safety & comport of operator of agriculturaltractors: Part 1 General requirements (first revision):[IS: 12239 (Part-1) 1996 (Reaffirmed in March,2007) / ISO 4254-1:1989]vii) Tractors and machinery for agriculture and forestry –Technical means for ensuring safety Part 2: Tractors(first revision) (IS: 12239 (Part-2) 1999) (Reaffirmedin March, 2009)]viii)Guidelines for location and operation of operatorcontrols on agricultural tractors and machinery (firstrevision) IS: 8133-1983 (Reaffirmed in March,2009)]: Conforms: Conform: Conform: Conforms: Does not conform: Does not conform: Does not conform: Conformix)Tractors and machinery for agriculture and forestry,powered lawn and garden equipment - Symbols foroperator controls and other displays [IS: 6283 (Part-1) – 2006 (Reaffirmed in March, 2009) and IS: 6283(Part-2)-2007 (Reaffirmed in March, 2009)]: Conformsx) Agricultural Tractors and <strong>Machinery</strong> - Lighting devicefor travel on public roads (IS: 14683-1999)(Reaffirmed in March, 2009)]: ConformsCENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 44 of 48

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)16.4 Salient Observations:16.4.1 Laboratory tests:16.4.1.1 PTO Performance:i) The backup torque is observed as 27.1%.ii) The specific fuel consumption corresponding to maximum power wasobserved as 261 g/kWh against the declaration of 265 g/kWh, which meet therequirement of IS: 12207-2008 with regard to tolerance.16.4.1.2 Drawbar performance:During drawbar performance ten hour test, creeping of LHS & RHS rear tyre overthe rims was observed as 35 mm & 60 mm respectively, which was considered onhigher side. This should be looked into for necessary corrective action.16.4.1.3 Mechanical Vibration:The amplitude of mechanical vibration on various assemblies marked as (*) inChapter-8 of this test report is on higher side especially at left foot rest, right footrest and steering wheel. This calls for dampening down of vibrations to improve theoperational comfort and service life of components.16.4.1.4 Linkage drawbar:Some of the parameters of linkage drawbar conform to Cat.I and some of themconform to Cat.II. In view of the spirit of standardization, necessary improvementmay be incorporated.16.4.1.5 Operator’s seat:The Length of seat, Inclination of seat towards rear direction and Vertical distancefrom seat index point to the center of steering wheel does not meet therequirements of IS: 12343-1998. This should be looked into for necessary correctiveaction.16.4.1.6 Location and operation of operator’s control:Working clearance between position control lever and the mudguard does not meetthe requirement of the IS: 12239 (Part-2)-1996. This should be looked into fornecessary corrective action.16.4.2 Field performance test:16.4.2.1 Wetland cultivation (Puddling operation):No ingress of mud and / or water was noticed during puddling operation of thetractor and meet the requirements of IS: 11082-1984 (Technical requirements ofagricultural tractors for wetland operation). Therefore, the tractor is recommendedas suitable for wetland operation (Puddling).16.4.2.2 Haulage test:(i)The distance travelled per litre of fuel consumption with four wheel trailer wasobserved as 3.72 km/l against the declaration 4.25 to 6.5 km/l. This does notmeet the requirement of IS: 12207-2008 and therefore, should be looked intofor necessary corrective action.(ii) The fuel consumption with four wheel trailer was observed as 46.84ml/km/tonne against the declaration 25 to 40 ml/km/tonne. This does not meetthe requirement of IS: 12207-2008 and therefore, should be looked into fornecessary corrective action.16.4.3 Wear assessment and final inspection:During wear assessment and final inspection, the axial clearance of big endbearings was observed as 0.50 mm and which approaches to the discard limit of0.50 mm, that too, in 99.7 hours of tractor operation. This should be looked into fornecessary corrective action.CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 45 of 48

T-<strong>849</strong>/<strong>1359</strong>/<strong>2012</strong>DEUTZ-FAHR, AGROMAXX 55 (4WD) TRACTOR-Commercial (Initial)16.5 Maintenance / Service Problems:No noticeable maintenance or service problem was observed during the test.16.6 Recommendation with regard to safety on tractor:The following requirements, inter-alia, may be considered for incorporation on thetractor:i) Provision of spark arresting device in exhaust system.ii) The working clearance between the position control and the mudguard may beprovided as per IS: 12239 (Part-2) – 1999.16.7 Adequacy of Literature supplied with machine:16.7.1 The following literature was supplied with the tractor for reference during the testing.i) Use and Maintenance manual in respect of Agromaxx 40, Agromaxx 45Agromaxx 50, Agromaxx 55 and Agromaxx 60 tractor models.ii)iii)Workshop service manual for Agromaxx series tractors.Spare Parts Catalogue for Agromaxx series tractors.16.7.2 Information related to PTO , Drawbar and hydraulic performance of the tractor suchas, maximum engine power, rated engine power, maximum torque, backup torque,specific fuel consumption, maximum drawbar power & pull, hydraulic pumpdischarge rate, hydraulic power & lifting capacities etc should be included in thetechnical specification of the tractor for the guidance of the user’s.16.7.3 The literatures should also be brought out in national as well as other regionallanguages for the guidance of users and service personnel.TESTING AUTHORITY:C. V. CHIMOTETEST ENGINEERP. K. VERMASENIOR AGRICULTURAL ENGINEERC. R. LOHIDIRECTORTest Report compiled by: Sh. Pramod Yadav and Sh. P. Rishi Prakash, Senior TechnicalAssistants.CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 46 of 48