Substrate-step-induced effects on the growth of CaF2 on Si (111)

Substrate-step-induced effects on the growth of CaF2 on Si (111)

Substrate-step-induced effects on the growth of CaF2 on Si (111)

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

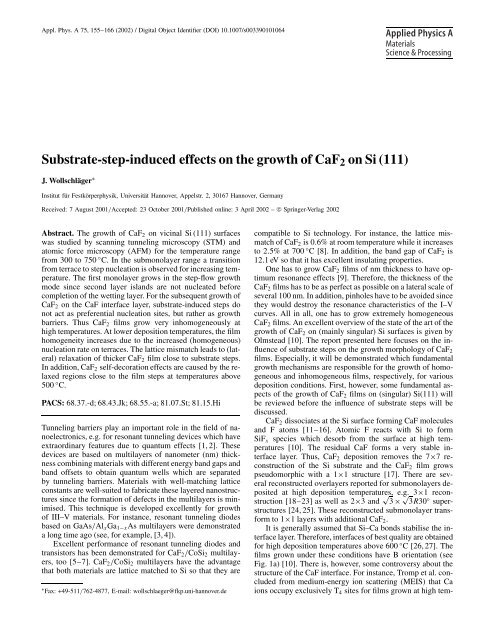

158[<strong>111</strong>](a)(a)<strong>Si</strong>[112]D S T(b)[ 110]<strong>Si</strong>[112][ 110](b)[11 2]250nmFig. 3a,b. Model for a CaF island with B orientati<strong>on</strong> grown at a <strong>Si</strong> substrate<str<strong>on</strong>g>step</str<strong>on</strong>g>. The <strong>Si</strong> substrate has miscut towards <strong>the</strong> [11¯2] directi<strong>on</strong>. a <strong>Si</strong>de view;b top viewterrace width w[nm]5002001005020crit. temperature T c [ 0 C]600 550 500 450<str<strong>on</strong>g>step</str<strong>on</strong>g>nucleati<strong>on</strong>(<str<strong>on</strong>g>step</str<strong>on</strong>g> flow)terracenucleati<strong>on</strong>1.1 1.2 1.3 1.4inv. crit. temperature 1000/T c [1/K]Fig. 4. Kinetic “phase diagram” <strong>of</strong> terrace and <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong>. From <strong>the</strong>slope <strong>of</strong> <strong>the</strong> solid line and (1) a diffusi<strong>on</strong> barrier at E D = 1.8 eV is proposedfor <strong>the</strong> diffusi<strong>on</strong> <strong>of</strong> CaF <strong>on</strong> <strong>Si</strong> (<strong>111</strong>)shows <strong>the</strong> kinetic “phase diagram” we obtain from ourstudies. The larger <strong>the</strong> terrace size <strong>the</strong> larger <strong>the</strong> criticaltemperature to obtain pure <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong> and subsequent<strong>growth</strong> in <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>-flow <strong>growth</strong> mode. Obviously, <strong>the</strong> dependence<strong>of</strong> w <strong>on</strong> <strong>the</strong> critical temperature, T c , exhibits anArrhenius behaviour (solid line in Fig. 4). From <strong>the</strong>oreticalc<strong>on</strong>siderati<strong>on</strong>s,w ∝ exp(−E D /2k B T c ). (1)(c)Fig. 5a,b. STM micrograph for <strong>the</strong> <strong>growth</strong> <strong>of</strong> CaF islands after depositi<strong>on</strong><strong>of</strong> 0.3-TL CaF 2 at 600 ◦ C. a Overview dem<strong>on</strong>strating <strong>the</strong> nucleati<strong>on</strong> and<strong>growth</strong> <strong>of</strong> islands <strong>on</strong> defect-free terraces (T), at <str<strong>on</strong>g>step</str<strong>on</strong>g>s (S) and at anti-phasedomain boundaries (D). No individual island are at <str<strong>on</strong>g>step</str<strong>on</strong>g>s due to <strong>the</strong> progressivecoalescence. b Enlarged micrograph <strong>of</strong> <strong>the</strong> rectangular area in adem<strong>on</strong>strating <strong>the</strong> material c<strong>on</strong>trast between <strong>Si</strong> substrate and CaF decorating<strong>the</strong> <strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>. c Height pr<strong>of</strong>ile <strong>of</strong> <strong>the</strong> line scan marked in b.CaF island heights are apparently higher than <strong>the</strong> <strong>Si</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>s due to materialc<strong>on</strong>trast.is predicted [41, 52, 53]. Here E D and k B denote <strong>the</strong> diffusi<strong>on</strong>barrier for <strong>the</strong> CaF molecule <strong>on</strong> <strong>the</strong> <strong>Si</strong> (<strong>111</strong>) surface and<strong>the</strong> Boltzmann c<strong>on</strong>stant, respectively. Fitting <strong>the</strong> experimentalresults to (1), a diffusi<strong>on</strong> energy <strong>of</strong> E D = 1.8 ± 0.2eV isobtained (solid line in Fig. 4). This value agrees very wellwith <strong>the</strong> diffusi<strong>on</strong> barrier obtained from analysing <strong>the</strong> homogeneousnucleati<strong>on</strong> <strong>on</strong> <strong>the</strong> defect-free terraces [53].After depositi<strong>on</strong> <strong>of</strong> 0.3-TL CaF 2 <strong>the</strong> CaF film leaves <strong>the</strong>nucleati<strong>on</strong> stage and enters <strong>the</strong> island <strong>growth</strong> stage. Duringthis stage <strong>the</strong> CaF islands are growing and <strong>the</strong> coalescence<strong>of</strong> <strong>the</strong> island starts. For depositi<strong>on</strong> at 600 ◦ C, this is dem<strong>on</strong>stratedin Fig. 5. Here, <strong>the</strong> islands which are heterogeneouslynucleated at <str<strong>on</strong>g>step</str<strong>on</strong>g>s or at anti-phase boundaries form l<strong>on</strong>g CaFstripes.Figure 5b presents a closer inspecti<strong>on</strong> <strong>of</strong> <strong>the</strong> film close toa <strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>. One can distinguish easily <strong>Si</strong> and CaF dueto <strong>the</strong> electr<strong>on</strong>ic material c<strong>on</strong>trast involved in <strong>the</strong> tunnelingcurrent used to record STM micrographs (cf. Fig. 5c).

Fur<strong>the</strong>rmore, Fig. 5b dem<strong>on</strong>strates that <strong>the</strong> <strong>growth</strong> <strong>of</strong>type-D islands is stopped at <strong>the</strong> <strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>. The type-DCaF stripe is <strong>on</strong>ly <strong>on</strong> top <strong>of</strong> <strong>the</strong> upper <strong>Si</strong> terrace; no materialis <strong>on</strong> top <strong>of</strong> <strong>the</strong> type-S CaF stripe <strong>on</strong> <strong>the</strong> lower terracerunning perpendicular to <strong>the</strong> type-D stripe. This effect is observedalso for type-T islands (Fig. 5a). Therefore, it can bec<strong>on</strong>cluded that <strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s act as <strong>growth</strong> barriers. Thiswill be discussed in more detail below.(a)1593 Initial stages <strong>of</strong> <strong>growth</strong> <strong>on</strong> <strong>the</strong> CaF interface layerFigure 6 presents an STM micrograph <strong>of</strong> a 1.7-TL CaF 2 filmdeposited at 600 ◦ C <strong>on</strong> a <strong>Si</strong> substrate with very short terraces.The surface exhibits <str<strong>on</strong>g>step</str<strong>on</strong>g>s <strong>of</strong> both m<strong>on</strong>o-atomic and bi-atomicheights.Clearly, <strong>on</strong>e can distinguish two different kinds <strong>of</strong> terraces.On <strong>the</strong> <strong>on</strong>e hand, type-R terraces are covered by“rough” films with many point defects. On <strong>the</strong> o<strong>the</strong>r hand,type-S terraces are extremely smooth and defect free. By investigatingvarious depositi<strong>on</strong> amounts, it is clear that type-Rand type-S terraces are covered by <strong>the</strong> CaF interface layer andCaF 2 films, respectively.Point defects in CaF islands have been reported previously[33]. They are attributed to <strong>the</strong> ejecti<strong>on</strong> <strong>of</strong> <strong>Si</strong> atomsfrom <strong>the</strong> 7 × 7 rec<strong>on</strong>structed surface due to <strong>the</strong> transformati<strong>on</strong><strong>of</strong> <strong>the</strong> 1×1 <strong>Si</strong> interface layer underneath <strong>the</strong> CaF island.These <strong>Si</strong> atoms are incorporated into <strong>the</strong> CaF layer. For <strong>the</strong>additi<strong>on</strong>ally deposited CaF 2 molecules diffusing <strong>on</strong> <strong>the</strong> interfacelayer, however, <strong>the</strong>se defects do not act as str<strong>on</strong>g bindingcenters since no nucleati<strong>on</strong> occurs at <strong>the</strong>se sites. At least <strong>the</strong>nucleati<strong>on</strong> process is str<strong>on</strong>gly suppressed, since <strong>the</strong>re are noislands observed in <strong>the</strong> STM micrograph.Figure 7a presents a UHV–AFM micrograph recorded insitu after <strong>growth</strong> <strong>of</strong> 1.4-TL CaF 2 at 750 ◦ C. Obviously, <strong>the</strong>film covers <strong>the</strong> entire <strong>Si</strong> substrate and generally mimics <strong>the</strong>regularly <str<strong>on</strong>g>step</str<strong>on</strong>g>ped substrate structure.The normal force <strong>on</strong> <strong>the</strong> AFM cantilever was used torecord <strong>the</strong> film topography. Lateral forces are recorded sim-500nm(b)(c)RSFig. 7. a AFM micrograph obtained after depositi<strong>on</strong> <strong>of</strong> 1.4-TL CaF 2 at750 ◦ C. The film covers entirely <strong>Si</strong> substrate terraces. In additi<strong>on</strong>, very fewtriangular protrusi<strong>on</strong>s are observed. b Fricti<strong>on</strong> force micrograph <strong>of</strong> <strong>the</strong> areamarked in a. The fricti<strong>on</strong> c<strong>on</strong>trast is used to distinguish CaF (str<strong>on</strong>g fricti<strong>on</strong>signal, light colored terraces) andCaF 2 layers grown <strong>on</strong> top <strong>of</strong> <strong>the</strong> CaF interfacelayer (small fricti<strong>on</strong> signal, dark colored terraces). c Lateral fricti<strong>on</strong>force obtained from <strong>the</strong> line scan marked in b50nmRRFig. 6. STM micrograph obtained after depositi<strong>on</strong> <strong>of</strong> 1.7-TL CaF 2 at600 ◦ C. The arrows indicate double <str<strong>on</strong>g>step</str<strong>on</strong>g>s. The residual <str<strong>on</strong>g>step</str<strong>on</strong>g>s are m<strong>on</strong>oatomic.Two types <strong>of</strong> terraces can be distinguished: R – terraces coveredwith a rough CaF layer; S – smooth terraces covered with a CaF 2 film. TheCaF 2 film is grown with double layer thickness <strong>on</strong> top <strong>of</strong> <strong>the</strong> CaF interfacelayerultaneously. Figure 7b shows <strong>the</strong> lateral force for <strong>the</strong> areamarked by <strong>the</strong> white rectangle in Fig. 7a. <strong>Si</strong>nce, duringrecording, <strong>the</strong> normal force was kept c<strong>on</strong>stant by a feedbackloop, <strong>the</strong> c<strong>on</strong>trast due to <strong>the</strong> lateral forces is caused by differentfricti<strong>on</strong> forces between probe and film. The str<strong>on</strong>glypr<strong>on</strong>ounced signal (white lines) originates from <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>s. Inadditi<strong>on</strong>, <strong>the</strong>re is a clear c<strong>on</strong>trast between different terraces.Terraces with an exposed CaF interface layer have a largerfricti<strong>on</strong> signal than terraces covered with CaF 2 multilayers[34]. At <strong>the</strong> moment it is not clear whe<strong>the</strong>r <strong>the</strong> increasedfricti<strong>on</strong> is due to <strong>the</strong> <str<strong>on</strong>g>induced</str<strong>on</strong>g> dipole forces between <strong>the</strong> cantilevertip and <strong>the</strong> CaF interface layer or due to topological<str<strong>on</strong>g>effects</str<strong>on</strong>g>, e.g. <strong>the</strong> defects observed by STM (Fig. 6) which cannotbe observed by AFM due to its limited lateral resoluti<strong>on</strong>.

160As emphasized previously, no free-standing islands areobserved in ei<strong>the</strong>r experiment. Therefore, it seems that <strong>the</strong>entire film grows in <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>-flow <strong>growth</strong> mode. As shownabove, this <strong>growth</strong> mode is expected for <strong>the</strong> CaF interfacelayer for <strong>the</strong> terrace size <strong>of</strong> <strong>the</strong> <strong>Si</strong> substrate used here. For <strong>the</strong>CaF 2 layer, however, this cannot be true, since <strong>on</strong>ly very few<strong>of</strong> <strong>the</strong> terraces are type-S terraces. Thus <strong>the</strong> CaF 2 does notform nuclei at every <str<strong>on</strong>g>step</str<strong>on</strong>g>. C<strong>on</strong>sequently, <strong>the</strong> additi<strong>on</strong>al CaF 2double layer does not grow in <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>-flow <strong>growth</strong> mode.This effect <strong>of</strong> very inhomogeneous CaF 2 multilayer<strong>growth</strong> can be attributed to <strong>the</strong> B orientati<strong>on</strong> <strong>of</strong> <strong>the</strong> CaF 2 film.After depositi<strong>on</strong> <strong>of</strong> <strong>the</strong> CaF interface layer, <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>s are nol<strong>on</strong>ger preferential nucleati<strong>on</strong> sites. For instance, at m<strong>on</strong>oatomic<strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s, additi<strong>on</strong>al CaF 2 molecules cannotbind str<strong>on</strong>gly to <strong>the</strong> CaF molecules <strong>on</strong> <strong>the</strong> upper terrace, since(a)(b)(c)a filma <str<strong>on</strong>g>step</str<strong>on</strong>g>MM CaF[<strong>111</strong>]top Fbottom F[<strong>111</strong>][112][ 110]<strong>Si</strong>[112]M si[112]Fig. 8a–c. Models <strong>of</strong> sec<strong>on</strong>d-layer CaF 2 molecules with B orientati<strong>on</strong> adjacentto <strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s. a Comparis<strong>on</strong> <strong>of</strong> <strong>the</strong> b<strong>on</strong>d length in [11¯2]directi<strong>on</strong> for <strong>the</strong> binding at <str<strong>on</strong>g>step</str<strong>on</strong>g>s a <str<strong>on</strong>g>step</str<strong>on</strong>g> and within films projected a film form<strong>on</strong>o-atomic <str<strong>on</strong>g>step</str<strong>on</strong>g>s. b Triangular B-oriented CaF 2 island in fr<strong>on</strong>t <strong>of</strong> a CaFcovered m<strong>on</strong>o-atomic <str<strong>on</strong>g>step</str<strong>on</strong>g>. c Comparis<strong>on</strong> <strong>of</strong> <strong>the</strong> binding at double height<str<strong>on</strong>g>step</str<strong>on</strong>g>s for binding to <strong>the</strong> CaF film (M CaF ) and binding to <strong>the</strong> <strong>Si</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> (M <strong>Si</strong> )<strong>the</strong> lateral distance between <strong>the</strong> CaF 2 molecule <strong>on</strong> <strong>the</strong> regularsite <strong>on</strong> <strong>the</strong> lower terrace and <strong>the</strong> CaF molecule <strong>on</strong> <strong>the</strong> upperterrace is √ 7/3 <strong>of</strong> <strong>the</strong> regular b<strong>on</strong>d length. The binding distanceis too large to have significant interacti<strong>on</strong> between <strong>the</strong>two molecules.The same effect occurs also for multiple substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s,as dem<strong>on</strong>strated by Fig. 8b for a <strong>Si</strong> double <str<strong>on</strong>g>step</str<strong>on</strong>g>. The additi<strong>on</strong>alCaF 2 molecule cannot be simultaneously <strong>on</strong> a regularsite with respect to <strong>the</strong> CaF m<strong>on</strong>olayer (M CaF ) or with respectto <strong>the</strong> <strong>Si</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> atoms (M <strong>Si</strong> ).4 Film <strong>growth</strong>In <strong>the</strong> preceding secti<strong>on</strong>s, it was established that <strong>the</strong> CaFinterface layer can grow in <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>-flow <strong>growth</strong> mode at sufficientlyhigh temperatures (dependent <strong>on</strong> <strong>the</strong> terrace width).This mechanism does not work for <strong>the</strong> subsequent CaF 2 (double)layers, as will be dem<strong>on</strong>strated in this secti<strong>on</strong>.Figure 9 shows UHV–AFM micrographs recorded forCaF 2 films <strong>of</strong> various thicknesses deposited at 750 ◦ C. During<strong>the</strong> first stages <strong>of</strong> film <strong>growth</strong>, <strong>the</strong> topography is governedby terrace-<str<strong>on</strong>g>step</str<strong>on</strong>g> structures <str<strong>on</strong>g>induced</str<strong>on</strong>g> by <strong>the</strong> <strong>Si</strong> substrate. In additi<strong>on</strong>,however, <strong>on</strong>e observes some triangular protrusi<strong>on</strong>s.They grow with increasing coverage and overgrow substrate<str<strong>on</strong>g>step</str<strong>on</strong>g>s.As reported in <strong>the</strong> previous secti<strong>on</strong>, <strong>the</strong> AFM topographysignal is not sensitive to different species <strong>of</strong> <strong>the</strong> CaF 2film, namely <strong>the</strong> CaF interface layer and <strong>the</strong> CaF 2 multilayergrown <strong>on</strong> top <strong>of</strong> <strong>the</strong> interface layer. Therefore, in additi<strong>on</strong>, <strong>the</strong>fricti<strong>on</strong> force signal is used to distinguish between <strong>the</strong> twospecies. Generally, all terraces are covered exclusively ei<strong>the</strong>rby <strong>the</strong> CaF interface wetting layer or by thick CaF 2 ‘islands’.Thus, here, ‘islands’ denote CaF 2 stripes whose boundariesfollow substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s. The c<strong>on</strong>fining mechanism will be discussedbelow.Figure 10a shows <strong>the</strong> analysis <strong>of</strong> <strong>the</strong> fricti<strong>on</strong> force micrographsrecorded from CaF 2 films deposited at 500 and750 ◦ C. For <strong>the</strong> high-temperature depositi<strong>on</strong> large parts <strong>of</strong> <strong>the</strong>interface layer are exposed even after depositi<strong>on</strong> <strong>of</strong> very thickfilms. For depositi<strong>on</strong> at 500 ◦ C, <strong>the</strong> exposed interface layervanishes much faster with increasing film thickness. Practically,<strong>the</strong> interface layer is overgrown after depositi<strong>on</strong> <strong>of</strong>10-TL CaF 2 .Combining both <strong>the</strong> deposited CaF 2 coverage and <strong>the</strong> exposedCaF interface coverage, <strong>on</strong>e can estimate <strong>the</strong> averageheight, t, <strong>of</strong><strong>the</strong>CaF 2 ‘islands’. The result is presented inFig. 10b. The dashed line shows <strong>the</strong> height expected for perfectlayer-by-layer <strong>growth</strong>. On <strong>the</strong> <strong>on</strong>e hand, <strong>the</strong> film grownat 500 ◦ C approaches this <strong>growth</strong> mode after depositi<strong>on</strong> <strong>of</strong>10-TL CaF 2 , c<strong>on</strong>firming <strong>the</strong> <strong>growth</strong> <strong>of</strong> a closed film for thiscoverage. On <strong>the</strong> o<strong>the</strong>r hand, <strong>the</strong> CaF 2 ‘islands’ grown at750 ◦ C are always thicker. Thus, CaF 2 grows in <strong>the</strong> Stranski–Krastanov <strong>growth</strong> mode at <strong>the</strong>se high temperatures, and <strong>the</strong>lateral <strong>growth</strong> is str<strong>on</strong>gly suppressed perpendicular to <strong>the</strong><str<strong>on</strong>g>step</str<strong>on</strong>g>s.In <strong>the</strong> previous secti<strong>on</strong>, it was emphasized that substrate<str<strong>on</strong>g>step</str<strong>on</strong>g>s are not preferential nucleati<strong>on</strong> sites for <strong>growth</strong> <strong>on</strong> top<strong>of</strong> <strong>the</strong> CaF interface layer. In additi<strong>on</strong>, it is obvious from <strong>the</strong>morphology studies presented in this secti<strong>on</strong> that CaF 2 hasdifficulty in overgrowing <strong>the</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s (except for <strong>the</strong>triangular protrusi<strong>on</strong>s). Again, <strong>the</strong> B orientati<strong>on</strong> <strong>of</strong> <strong>the</strong> CaF 2

500nm(a)161(b)CaF 2CaF<strong>Si</strong>(<strong>111</strong>)tFig. 10. a Exposed CaF interface coverage as obtained from fricti<strong>on</strong> forcemicrographs. The interface layer is overgrown more difficultly at higher depositi<strong>on</strong>temperatures. b Average thickness <strong>of</strong> <strong>the</strong> CaF 2 islands obtainedfrom a and assuming that <strong>the</strong> CaF interface layer completely wets <strong>the</strong> <strong>Si</strong>substrate(c)Fig. 9a–c. AFM micrographs obtained after CaF 2 <strong>growth</strong> at 750 ◦ C: a 5TL,b 10 TL, and c 43 TL. With increasing coverage, <strong>the</strong> number <strong>of</strong> triangularprotrusi<strong>on</strong>s increases significantly. For <strong>the</strong> large coverage presented in c,<strong>the</strong> coalescence <strong>of</strong> <strong>the</strong> islands has startedfilm explains that substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s act as <strong>growth</strong> barriers. Thiseffect is dem<strong>on</strong>strated in Fig. 11. If <strong>the</strong> substrate has singleor double <str<strong>on</strong>g>step</str<strong>on</strong>g>s (Fig. 11a and b, respectively) <strong>the</strong> lattices <strong>of</strong>both ‘islands’ do not match. This is different if <strong>the</strong> substrate<str<strong>on</strong>g>step</str<strong>on</strong>g> has a TL height (or any integer multiple <strong>of</strong> it) as seen inFig. 11c. Here, <strong>the</strong> lateral shift due to <strong>the</strong> B orientati<strong>on</strong> can becompensated. <strong>Si</strong>nce most <strong>of</strong> <strong>the</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s have heightsdifferent to (integer multiples <strong>of</strong>) <strong>the</strong> TL height, most <strong>of</strong> <strong>the</strong>mact as <strong>growth</strong> barriers promoting <strong>the</strong> inhomogeneous <strong>growth</strong><strong>of</strong> <strong>the</strong> CaF 2 film.<strong>Si</strong>nce CaF 2 islands cannot nucleate homogeneously at<str<strong>on</strong>g>step</str<strong>on</strong>g>s, nucleati<strong>on</strong> <strong>on</strong> top <strong>of</strong> <strong>the</strong> underlying CaF interfacelayer and <strong>the</strong> pre-grown CaF 2 multilayer is <strong>the</strong> dominatingatomic process for <strong>the</strong> film <strong>growth</strong>. As so<strong>on</strong> as <strong>on</strong>e islandhas been nucleated <strong>on</strong> a terrace it grows immediately intwo dimensi<strong>on</strong>s until its boundary touches <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>s c<strong>on</strong>fining<strong>the</strong> terrace. Thereafter, <strong>the</strong> <strong>growth</strong> perpendicular to <strong>the</strong><str<strong>on</strong>g>step</str<strong>on</strong>g>s is stopped and <strong>the</strong> island grows exclusively parallel to<strong>the</strong>m.This mechanism explains <strong>the</strong> str<strong>on</strong>gly improved homogeneous<strong>growth</strong> at lower temperatures. The nucleus densityincreases with decreasing depositi<strong>on</strong> temperature. Therefore,<strong>the</strong> film starts to grow simultaneously at more sites thanat higher temperatures, and more terraces (within <strong>the</strong> AFMscanning range) are covered by CaF 2 ‘islands’. This modelpredicts that <strong>the</strong> film grows homogeneously if <strong>the</strong> temperaturefalls below <strong>the</strong> critical temperature when <strong>the</strong> average islanddistance is less than <strong>the</strong> terrace width.For <strong>the</strong> terrace width <strong>of</strong> <strong>the</strong> substrates studied here(100–200 nm), this c<strong>on</strong>diti<strong>on</strong> is fulfilled if <strong>the</strong> film is grownat 400 ◦ C, as dem<strong>on</strong>strated by <strong>the</strong> AFM micrograph presentedin Fig. 12a. The entire surface is covered by a homogeneousCaF 2 film. The observed multi-<str<strong>on</strong>g>step</str<strong>on</strong>g>s are due to <strong>the</strong><strong>Si</strong> substrate. On top <strong>of</strong> <strong>the</strong> terraces, <strong>on</strong>e obtains exclusivelym<strong>on</strong>o-atomic islands. In additi<strong>on</strong>, holes <strong>of</strong> m<strong>on</strong>o-atomic (H)depth are observed. Therefore, <strong>the</strong> film grows almost perfectlyin <strong>the</strong> layer-by-layer <strong>growth</strong> mode.

HH162250nmHP P[<strong>111</strong>](a)[112](a)100nm(b)(b)[<strong>111</strong>][112]Fig. 12. a AFM micrograph obtained after depositi<strong>on</strong> <strong>of</strong> 4-TL CaF 2 at400 ◦ C. The entire substrate is covered homogeneously by CaF 2 .Therearem<strong>on</strong>o-atomic islands as well as substrate-<str<strong>on</strong>g>induced</str<strong>on</strong>g> <str<strong>on</strong>g>step</str<strong>on</strong>g>s. In additi<strong>on</strong>, a fewtriangular protrusi<strong>on</strong>s (P) and holes (H) are present. b Enlarged area <strong>of</strong> a toshow more clearly <strong>the</strong> m<strong>on</strong>o-atomic islands <strong>on</strong> <strong>the</strong> terraces. Islands withregular triangular shape and with irregular shape are obtained25(c)[<strong>111</strong>][112]Fig. 11a–c. Comparis<strong>on</strong> <strong>of</strong> <strong>the</strong> structure <strong>of</strong> a 4-TL CaF 2 film grown <strong>on</strong> twoadjacent terraces with a single, b double, and c triple atomic <str<strong>on</strong>g>step</str<strong>on</strong>g> height.For a and b <strong>the</strong> lattices <strong>of</strong> both films do not match, due to <strong>the</strong> B orientati<strong>on</strong><strong>of</strong> <strong>the</strong> film. Coalescence without dislocati<strong>on</strong> can be obtained <strong>on</strong>ly for tripleatomic height <str<strong>on</strong>g>step</str<strong>on</strong>g>s, as dem<strong>on</strong>strated in cThe amount <strong>of</strong> triangular protrusi<strong>on</strong>s (P) observed at substrate<str<strong>on</strong>g>step</str<strong>on</strong>g>s is str<strong>on</strong>gly suppressed compared with that for<strong>growth</strong> at higher depositi<strong>on</strong> temperatures (Figs. 9b and 12a).This points to kinetic <str<strong>on</strong>g>effects</str<strong>on</strong>g> for <strong>the</strong> nucleati<strong>on</strong> <strong>of</strong> triangularprotrusi<strong>on</strong>s.At <strong>the</strong> moment <strong>the</strong> origin for <strong>the</strong> formati<strong>on</strong> <strong>of</strong> <strong>the</strong> triangularprotrusi<strong>on</strong>s is not clear. Probably, defects <strong>of</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s(e.g. kinks) support <strong>the</strong> nucleati<strong>on</strong> <strong>of</strong> <strong>the</strong> protrusi<strong>on</strong>s, sinceprotrusi<strong>on</strong> area [%]protrusi<strong>on</strong> density/10 8 cm 22015105500 o C750 o C(a)01502 3 5 10 20 30 502010521(b).51 2 3 5 10 20 30 50CaF 2 coverage [TL]Fig. 13. a Dependence <strong>of</strong> <strong>the</strong> surface fracti<strong>on</strong> covered by triangular protrusi<strong>on</strong>s.The fracti<strong>on</strong> increases with increasing CaF 2 coverage, since <strong>the</strong>protrusi<strong>on</strong>s <strong>of</strong>ten overgrow <str<strong>on</strong>g>step</str<strong>on</strong>g>s. b Density <strong>of</strong> triangular protrusi<strong>on</strong>s. Afterdepositi<strong>on</strong> <strong>of</strong> 5-TL CaF 2 <strong>the</strong> nucleati<strong>on</strong> is almost c<strong>on</strong>stant

163<strong>the</strong> protrusi<strong>on</strong>s are not distributed homogeneously. Figure 9band c dem<strong>on</strong>strate clearly that some <str<strong>on</strong>g>step</str<strong>on</strong>g>s are decorated by series<strong>of</strong> triangular protrusi<strong>on</strong>s, while o<strong>the</strong>r <str<strong>on</strong>g>step</str<strong>on</strong>g>s are completelyprotrusi<strong>on</strong>-free. In all cases, however, <strong>the</strong>se protrusi<strong>on</strong>s arein fr<strong>on</strong>t <strong>of</strong> CaF 2 -covered terraces, which has been proved byFFM. Therefore, <strong>the</strong> lateral <strong>growth</strong> <strong>of</strong> CaF 2 <strong>on</strong> <strong>the</strong> terrace hasto be previous to <strong>the</strong> formati<strong>on</strong> <strong>of</strong> <strong>the</strong> triangular protrusi<strong>on</strong>sin fr<strong>on</strong>t <strong>of</strong> it. This may be explained by <strong>the</strong> necessity <strong>of</strong> triplesubstrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s which can be overgrown by protrusi<strong>on</strong>s. Thisassumpti<strong>on</strong>, however, cannot be proved strictly because <strong>on</strong>ecan investigate <strong>on</strong>ly <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> heights <strong>of</strong> <strong>the</strong> film, which maydiffer from <strong>the</strong> height <strong>of</strong> <strong>the</strong> underlying substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>.The analysis <strong>of</strong> <strong>the</strong> protrusi<strong>on</strong> densities is presented inFig. 13. First, <strong>the</strong> density and coverage <strong>of</strong> <strong>the</strong>se protrusi<strong>on</strong>sincrease with increasing coverage. In later <strong>growth</strong> stages <strong>the</strong>density <strong>of</strong> protrusi<strong>on</strong>s is almost c<strong>on</strong>stant, while <strong>the</strong> surfacefracti<strong>on</strong> covered with protrusi<strong>on</strong>s increases fur<strong>the</strong>r. This effectis due to <strong>the</strong> over<strong>growth</strong> <strong>of</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s.5 Relaxati<strong>on</strong> at <str<strong>on</strong>g>step</str<strong>on</strong>g>sSome <strong>of</strong> <strong>the</strong> largest triangular protrusi<strong>on</strong>s show hole-likestructures. Figure 14 shows a typical example for a film depositedat 630 ◦ C. The large twin protrusi<strong>on</strong> has rims at <strong>the</strong>free-standing edges which do not point to <strong>the</strong> upper terrace<strong>of</strong> <strong>the</strong> vicinal substrate. The small triangular protrusi<strong>on</strong> <strong>on</strong> <strong>the</strong>back side <strong>of</strong> <strong>the</strong> twin protrusi<strong>on</strong>, however, does not show thiseffect. In additi<strong>on</strong>, <strong>the</strong>re are small gaps (arrows in Fig. 14)running preferentially parallel to substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s. Unfortunately,<strong>the</strong> sample must be at room temperature for <strong>the</strong> AFMmeasurement. Therefore, <strong>on</strong>e has no informati<strong>on</strong> <strong>on</strong> whe<strong>the</strong>r<strong>the</strong>se cracks are formed during <strong>growth</strong> or during <strong>the</strong> coolingfrom <strong>growth</strong> to room temperature.The AFM micrograph shown in Fig. 14 is recorded underambient c<strong>on</strong>diti<strong>on</strong>s. One can distinguish smooth CaF 2 layersand areas covered by small clusters. In a previous report, wehave shown that <strong>the</strong> clusters are formed due to <strong>the</strong> transfer <strong>of</strong><strong>the</strong> sample from UHV c<strong>on</strong>diti<strong>on</strong>s to ambient c<strong>on</strong>diti<strong>on</strong>s [54].The clusters are formed by transformati<strong>on</strong> <strong>of</strong> <strong>the</strong> unstable CaFinterface layer under <strong>the</strong> influence <strong>of</strong> air.Rim-like structures <strong>of</strong> l<strong>on</strong>g CaF 2 stripes are also formedclose to some <strong>of</strong> <strong>the</strong> CaF 2 film <str<strong>on</strong>g>step</str<strong>on</strong>g>s. Figure 15a shows thiseffect for an 8-TL film grown at 630 ◦ C. CaF 2 stripes cover<strong>the</strong> entire <str<strong>on</strong>g>step</str<strong>on</strong>g>s (arrows). The edge <strong>of</strong> <strong>the</strong> stripes pointing to<strong>the</strong> upper terrace is smooth while <strong>the</strong> o<strong>the</strong>r edge pointing to<strong>the</strong> lower terrace is rough. In additi<strong>on</strong>, some small protrusi<strong>on</strong>sare formed at <strong>the</strong> rough edge. Unfortunately, it cannot be determinedusing AFM whe<strong>the</strong>r <strong>the</strong> CaF 2 stripe is formed <strong>on</strong><strong>the</strong> lower or <strong>on</strong> <strong>the</strong> upper terrace. The shape <strong>of</strong> <strong>the</strong> stripe,however, suggests that it is more likely that <strong>the</strong> CaF 2 stripeis formed <strong>on</strong> <strong>the</strong> lower terrace since <strong>the</strong> edge pointing in thisdirecti<strong>on</strong> is rough.A line scan (Fig. 15b taken from <strong>the</strong> white line in Fig. 15a)shows <strong>the</strong> typical height a and width b <strong>of</strong> <strong>the</strong> CaF 2 stripe. Thegeometric dimensi<strong>on</strong>s <strong>of</strong> <strong>the</strong> CaF 2 stripes have been analysedfrom various micrographs. The result <strong>of</strong> <strong>the</strong> analysis is shownby Fig. 16. Although <strong>the</strong> scattering <strong>of</strong> <strong>the</strong> data is not negligible,<strong>the</strong>re is a tendency that <strong>the</strong> stripe height a seems to beindependent from <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> height h while <strong>the</strong> stripe width bincreases with increasing height <strong>of</strong> <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>. CaF 2 stripes areobtained exclusively if <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> height h is larger than 1 nm(equivalent to <str<strong>on</strong>g>step</str<strong>on</strong>g>s <strong>of</strong> triple-layer height). Thus triple-layerhigh<str<strong>on</strong>g>step</str<strong>on</strong>g>s seem to be critical <str<strong>on</strong>g>step</str<strong>on</strong>g> heights for <strong>the</strong> <strong>on</strong>set <strong>of</strong> thisphenomen<strong>on</strong>.One has to c<strong>on</strong>sider <strong>the</strong> small (but not negligible) latticemismatch between CaF 2 and <strong>Si</strong> at <strong>the</strong>se <strong>growth</strong> temperaturesto explain <strong>the</strong> <strong>growth</strong> <strong>of</strong> <strong>the</strong> CaF 2 stripes. <strong>Si</strong>nce CaF 2 hasa larger lattice c<strong>on</strong>stant than <strong>Si</strong> <strong>the</strong> pseudomorphic CaF 2 filmis compressed laterally. At <str<strong>on</strong>g>step</str<strong>on</strong>g>s, however, <strong>the</strong> film <strong>on</strong> <strong>the</strong>upper terrace can relax easily since neighbour molecules are(a)250nmbah(b)Fig. 14. Rim formati<strong>on</strong> at <strong>the</strong> edges <strong>of</strong> a big triangular twin protrusi<strong>on</strong>grownbyCaF 2 depositi<strong>on</strong> at 630 ◦ C (AFM micrograph). The clusters observed<strong>on</strong> <strong>the</strong> terraces close to <strong>the</strong> triangular protrusi<strong>on</strong> are formed after <strong>the</strong>transfer <strong>of</strong> <strong>the</strong> sample from UHV to ambient c<strong>on</strong>diti<strong>on</strong>s due to <strong>the</strong> instability<strong>of</strong> <strong>the</strong> CaF interface layer. Partially, <strong>the</strong>re are cracks in <strong>the</strong> CaF 2 film(see arrows)Fig. 15. a AFM micrograph obtained after depositi<strong>on</strong> <strong>of</strong> 8-TL CaF 2 at630 ◦ C and transfer to ambient c<strong>on</strong>diti<strong>on</strong>s. The arrows mark CaF 2 stripes.b Height pr<strong>of</strong>ile <strong>of</strong> <strong>the</strong> line scan marked in a showing <strong>the</strong> typical geometriclengths to characterize <strong>the</strong> stripes: <str<strong>on</strong>g>step</str<strong>on</strong>g> height, h, stripe height, a, and stripewidth, b

164a(nm)b(nm)2.01.51.00.500602 4 6402000 2 4 6h(nm)(a)(b)Fig. 16a,b. Analysis <strong>of</strong> <strong>the</strong> stripe geometry for an 8-TL CaF 2 film grown at630 ◦ C. a Stripe height, a, andb stripe width, bdiffusingparticleCaF 2<strong>Si</strong>(<strong>111</strong>)missing at <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> (see Fig. 17). In additi<strong>on</strong>, if <strong>the</strong> <strong>Si</strong> substrateexhibits multi-<str<strong>on</strong>g>step</str<strong>on</strong>g>s <strong>the</strong> CaF 2 film <strong>on</strong> <strong>the</strong> lower terracecan relax, too, due to <strong>the</strong> B orientati<strong>on</strong> (see Fig. 17).The (partially) relaxed parts <strong>of</strong> <strong>the</strong> CaF 2 films are preferentialnucleati<strong>on</strong> sites for <strong>the</strong> additi<strong>on</strong>al deposited CaF 2molecules (self-decorati<strong>on</strong>). <strong>Si</strong>nce <strong>the</strong> relaxati<strong>on</strong> increaseswith increasing (local) film thickness it is expected that <strong>the</strong>self-decorati<strong>on</strong> effect is bigger for thicker films. This explainsthat <strong>on</strong>e does not observe CaF 2 stripes due to self-decorati<strong>on</strong>for extremely thin films. Assuming that <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> height h reflects<strong>the</strong> (local) CaF 2 film thickness <strong>the</strong> critical thickness for<strong>the</strong> <strong>on</strong>set <strong>of</strong> self-decorati<strong>on</strong> is more than 1 nm (see Fig. 16).Therefore, at higher depositi<strong>on</strong> temperatures both <strong>the</strong> increasedlattice mismatch (enhancing <strong>the</strong> film relaxati<strong>on</strong> forthinner films) and <strong>the</strong> increased diffusi<strong>on</strong> length proliferate<strong>the</strong> self-decorati<strong>on</strong> effect. A model for this self-decorati<strong>on</strong>process at <str<strong>on</strong>g>step</str<strong>on</strong>g>s is shown in Fig. 17.From this model <strong>on</strong>e expects decorati<strong>on</strong> <strong>of</strong> both films <strong>on</strong><strong>the</strong> upper and <strong>on</strong> <strong>the</strong> lower terrace. Surprisingly, <strong>the</strong> decorati<strong>on</strong><strong>of</strong> <strong>the</strong> lower terrace seems to be preferred due to <strong>the</strong>B orientati<strong>on</strong> (see Fig. 17). This may explain that <strong>the</strong> decorelaxedfilmpreferential<strong>growth</strong> <strong>on</strong>relaxed filmFig. 17. Model <strong>of</strong> <strong>the</strong> self-decorati<strong>on</strong> effect. The CaF 2 film relaxes laterallyclose to <strong>the</strong> underlying substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>. The diffusing CaF 2 moleculesreaching <strong>the</strong> relaxed part <strong>of</strong> <strong>the</strong> film form stripesrati<strong>on</strong> <strong>of</strong> upper terraces is favoured for <strong>the</strong> triangular protrusi<strong>on</strong>swhich have high edges with bigger relaxati<strong>on</strong> <str<strong>on</strong>g>effects</str<strong>on</strong>g>while <strong>the</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>-<str<strong>on</strong>g>induced</str<strong>on</strong>g> film <str<strong>on</strong>g>step</str<strong>on</strong>g>s are decorated at<strong>the</strong> lower terrace.Figure 17 explains also <strong>the</strong> formati<strong>on</strong> <strong>of</strong> cracks (see alsoFig. 11). The higher <strong>the</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g> <strong>the</strong> larger is <strong>the</strong> gapbetween <strong>the</strong> film grown <strong>on</strong> <strong>the</strong> lower and <strong>the</strong> upper terrace,respectively. For thicker films, however, <strong>the</strong> film can coalescedue to <strong>the</strong> progressive relaxati<strong>on</strong> <strong>of</strong> <strong>the</strong>se parts <strong>of</strong> <strong>the</strong>film. Therefore, <strong>on</strong>e would obtain a homogeneously closedbut strained film, as expected due to interface dislocati<strong>on</strong>s.6 Discussi<strong>on</strong> and c<strong>on</strong>clusi<strong>on</strong>sThe study presented here shows clearly that <strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>sact differently for <strong>the</strong> subm<strong>on</strong>olayer range where <strong>the</strong> CaF interfacelayer is formed and <strong>the</strong> subsequent <strong>growth</strong> <strong>of</strong> <strong>the</strong> CaF 2layers.<strong>Si</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>s are preferential nucleati<strong>on</strong> sites in <strong>the</strong> subm<strong>on</strong>olayerrange. Therefore, <strong>the</strong> <strong>growth</strong> mode can be driven from<strong>the</strong> <strong>growth</strong> <strong>of</strong> islands which are homogeneously nucleated<strong>on</strong> terraces to <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>-flow <strong>growth</strong> mode, where <strong>the</strong> CaFmolecules migrate to <strong>the</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s before <strong>the</strong>y are capturedby o<strong>the</strong>r CaF molecules and form nuclei. The criticaltemperature for <strong>the</strong> transiti<strong>on</strong> from terrace to <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong>depends <strong>on</strong> <strong>the</strong> terrace width <strong>of</strong> <strong>the</strong> <strong>Si</strong> substrate.Previous annealing experiments have shown a similar effect[23]. CaF islands which have been grown at lower temperaturescan be dissolved, and <strong>the</strong> material is transportedto <strong>the</strong> <strong>Si</strong> substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s. In additi<strong>on</strong>, <strong>the</strong> 3 × 1 rec<strong>on</strong>structi<strong>on</strong>was formed by annealing at very high temperatures(> 700 ◦ C).The experiments reported here are performed at lowertemperatures. Therefore, <strong>on</strong> <strong>the</strong> <strong>on</strong>e hand, <strong>the</strong> analysis <strong>of</strong><strong>the</strong> transiti<strong>on</strong> from terrace to <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong> is not complicatedby <strong>the</strong> formati<strong>on</strong> <strong>of</strong> <strong>the</strong> 3 × 1 rec<strong>on</strong>structi<strong>on</strong>. On <strong>the</strong>o<strong>the</strong>r hand, however, <strong>the</strong> low depositi<strong>on</strong> temperature has <strong>the</strong>disadvantage that <strong>Si</strong>F x species do not desorb from <strong>the</strong> surface[10, 35]. Thus, <strong>the</strong> CaF diffusi<strong>on</strong> may be influenced by<strong>the</strong> existence <strong>of</strong> F <strong>on</strong> <strong>the</strong> <strong>Si</strong> substrate. Therefore, <strong>the</strong> diffusi<strong>on</strong>barrier <strong>of</strong> E D = 1.8 ± 0.2 eV received from <strong>the</strong> critical temperaturefor <strong>the</strong> transiti<strong>on</strong> from terrace to <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong> isprobably an effective barrier for CaF diffusi<strong>on</strong> <strong>on</strong> <strong>the</strong> partiallyF-covered <strong>Si</strong> (<strong>111</strong>) surface. Both <strong>the</strong> STM study presentedhere and STM studies by o<strong>the</strong>r authors [20–23, 33], however,do not show any evidence for <strong>the</strong> existence <strong>of</strong> <strong>Si</strong>F x species<strong>on</strong> <strong>the</strong> surface. One possible explanati<strong>on</strong> for this discrepancybetween STM experiments and XPS studies is that <strong>the</strong>electr<strong>on</strong>-stimulated desorpti<strong>on</strong> <strong>of</strong> F from <strong>the</strong> <strong>Si</strong> (<strong>111</strong>) surface(see [55] for this effect) is due to <strong>the</strong> tunneling current. Nostructural changes, however, are observed at high tunnelingvoltages such as 9 V and low tunneling currents, in c<strong>on</strong>tradicti<strong>on</strong>to this assumpti<strong>on</strong> [56].Fur<strong>the</strong>r <strong>growth</strong> bey<strong>on</strong>d <strong>the</strong> nucleati<strong>on</strong> stage does not showany nucleati<strong>on</strong> <strong>on</strong> top <strong>of</strong> CaF islands before completi<strong>on</strong> <strong>of</strong><strong>the</strong> layer although <strong>the</strong> CaF has many point defects. Therefore,it can be c<strong>on</strong>cluded that <strong>the</strong> diffusi<strong>on</strong> <strong>of</strong> CaF 2 <strong>on</strong> <strong>the</strong> CaFinterface layer is much faster than <strong>the</strong> diffusi<strong>on</strong> <strong>of</strong> CaF <strong>on</strong><strong>Si</strong>(<strong>111</strong>). This agrees well with <strong>the</strong> diffusi<strong>on</strong> barrier <strong>of</strong> 1.4eVfor CaF 2 /CaF calculated by Denlinger et al. [40] which has tobe compared to 1.8eVforCaF/<strong>Si</strong>(<strong>111</strong>).

165The AFM investigati<strong>on</strong>s presented here are in very goodagreement with previous results for CaF 2 films grown <strong>on</strong><strong>the</strong> CaF interface layer obtained using XPS, XPD andTEM [38, 40, 41]. One obtains laminar <strong>growth</strong> at low temperatures.The film becomes more inhomogeneous when <strong>the</strong>depositi<strong>on</strong> temperature is increased. The applicati<strong>on</strong> <strong>of</strong> a microscopictechnique, however, <strong>of</strong>fers deeper insight into <strong>the</strong>local morphology. For instance, <strong>the</strong> AFM study dem<strong>on</strong>stratesthat <strong>the</strong> substrate-<str<strong>on</strong>g>induced</str<strong>on</strong>g> <str<strong>on</strong>g>step</str<strong>on</strong>g>s <strong>of</strong> <strong>the</strong> CaF interface layer arenot preferential nucleati<strong>on</strong> sites, since <strong>on</strong>ly very few <strong>of</strong> <strong>the</strong>CaF-covered terraces are overgrown by CaF 2 . This effect isattributed to <strong>the</strong> B orientati<strong>on</strong> <strong>of</strong> <strong>the</strong> CaF 2 film <strong>on</strong> top <strong>of</strong> <strong>the</strong>CaF interface layer which suppresses heterogeneous nucleati<strong>on</strong>at <str<strong>on</strong>g>step</str<strong>on</strong>g>s. Therefore, <strong>the</strong> film cannot grow ei<strong>the</strong>r by <str<strong>on</strong>g>step</str<strong>on</strong>g>flow or by nucleati<strong>on</strong> and <strong>growth</strong> <strong>of</strong> 3D islands at <str<strong>on</strong>g>step</str<strong>on</strong>g>s. The<strong>on</strong>ly pathway for CaF 2 nucleati<strong>on</strong> is <strong>the</strong> homogeneous nucleati<strong>on</strong><strong>on</strong> terraces, since <strong>the</strong> point defects observed in <strong>the</strong> CaFlayer are also not preferential nucleati<strong>on</strong> sites.Therefore, <strong>on</strong> <strong>the</strong> <strong>on</strong>e hand, <strong>the</strong> model presented by Hessingeret al. that 3D islands at <str<strong>on</strong>g>step</str<strong>on</strong>g>s induce <strong>the</strong> <strong>growth</strong> <strong>of</strong> inhomogeneousfilms cannot be applied to <strong>the</strong> inhomogeneous<strong>growth</strong> <strong>of</strong> CaF 2 <strong>on</strong> <strong>the</strong> CaF interface layer at high depositi<strong>on</strong>temperatures [52]. On <strong>the</strong> o<strong>the</strong>r hand, <strong>the</strong> result that <strong>the</strong>laminar <strong>growth</strong> at low temperature is due to homogeneousnucleati<strong>on</strong> <strong>on</strong> terraces is in good agreement with <strong>the</strong> studypresented here.The model <strong>of</strong> inhomogeneous CaF 2 film <strong>growth</strong> via homogeneousnucleati<strong>on</strong> includes <strong>the</strong> necessity <strong>of</strong> preferentialnucleati<strong>on</strong> <strong>of</strong> CaF 2 <strong>on</strong> CaF 2 layers compared to nucleati<strong>on</strong><strong>on</strong> <strong>the</strong> CaF interface layer. The driving force for this maybe a smaller surface energy <strong>of</strong> <strong>the</strong> CaF layer compared to<strong>the</strong> CaF 2 film. In additi<strong>on</strong>, <strong>the</strong>re may be some instability <strong>of</strong><strong>the</strong> CaF 2 film <strong>on</strong> <strong>the</strong> CaF layer. A similar effect has beenobserved by LEEM, although <strong>the</strong> authors attributed <strong>the</strong> instabilityto a CaF 2 interface layer which is less str<strong>on</strong>gly bound to<strong>the</strong> <strong>Si</strong> surface than <strong>the</strong> CaF layer [57].A comparis<strong>on</strong> <strong>of</strong> <strong>the</strong> various proposed <strong>growth</strong> models ispresented in Fig. 18.In a previous study, we assumed also that <strong>the</strong> inhomogeneous<strong>growth</strong> at high temperatures is due to <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong>.We deduced from <strong>the</strong> critical temperature for <strong>the</strong> transiti<strong>on</strong>from homogeneous to inhomogeneous <strong>growth</strong> that <strong>the</strong> diffusi<strong>on</strong>barrier for CaF 2 molecules <strong>on</strong> CaF 2 films is 1.4eV.Hessinger et al. c<strong>on</strong>cluded a similar barrier height from <strong>the</strong>irexperimental data. This result, however, is quite problematicin <strong>the</strong> light <strong>of</strong> <strong>the</strong> data and <strong>the</strong> model presented here. Therefore,<strong>on</strong>e has to study <strong>the</strong> (homogeneous) nucleati<strong>on</strong> <strong>of</strong> CaF 2<strong>on</strong> both (probably pre-grown) CaF and CaF 2 films in moredetail. In additi<strong>on</strong>, <strong>the</strong> entire suppressi<strong>on</strong> <strong>of</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong>for <strong>the</strong> <strong>growth</strong> <strong>of</strong> CaF 2 <strong>on</strong> <strong>the</strong> CaF interface layer has tobe proved by appropriate scanning probe microscopy experiments.We will perform <strong>the</strong>se studies in <strong>the</strong> near future.The formati<strong>on</strong> <strong>of</strong> triangular or trapezoidal protrusi<strong>on</strong>shas been reported previously by various groups [46–48].Kim et al. [47] assumed that CaF 2 grows exclusively via <strong>the</strong>seprotrusi<strong>on</strong>s. This is probably due to <strong>the</strong> higher depositi<strong>on</strong>temperature during <strong>the</strong>se experiments.By comparing <strong>growth</strong> <strong>on</strong> vicinal and well-aligned <strong>Si</strong> (<strong>111</strong>)surfaces, it has been proposed that <strong>the</strong> formati<strong>on</strong> <strong>of</strong> protrusi<strong>on</strong>sis due to <strong>the</strong> formati<strong>on</strong> <strong>of</strong> coreless dislocati<strong>on</strong>s at substrate<str<strong>on</strong>g>step</str<strong>on</strong>g>s [47]. It is assumed that <strong>the</strong> film can solve <strong>the</strong>problem <strong>of</strong> overgrowing substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s due to <strong>the</strong> B orien-increasing coverage(a)(b)(c)CaF 2CaF<strong>Si</strong>Fig. 18a–c. Comparis<strong>on</strong> <strong>of</strong> <strong>growth</strong> models for various temperatures. Everypanel shows subsequent phases – from top to bottom: subm<strong>on</strong>olayer nucleati<strong>on</strong>phase, depositi<strong>on</strong> <strong>of</strong> 1-TL CaF 2 , phase directly after depositi<strong>on</strong> <strong>of</strong>1-TL CaF 2 , depositi<strong>on</strong> <strong>of</strong> 2-TL CaF 2 . a Low-temperature <strong>growth</strong>. The filmgrows homogeneously due to homogeneous nucleati<strong>on</strong> <strong>on</strong> many terraces.b High-temperature <strong>growth</strong> due to <str<strong>on</strong>g>step</str<strong>on</strong>g> nucleati<strong>on</strong> proposed by Hessingeret al. [41]. Islands nucleate at all <str<strong>on</strong>g>step</str<strong>on</strong>g>s and grow as 3D islands. c Hightemperature<strong>growth</strong> mode proposed here. On very few terraces are islandsnucleated. Laminar <strong>growth</strong> is suppressed by substrate-<str<strong>on</strong>g>induced</str<strong>on</strong>g> <str<strong>on</strong>g>step</str<strong>on</strong>g>s <strong>of</strong> <strong>the</strong>CaF interface layertati<strong>on</strong> <strong>of</strong> this mechanism. The good agreement between <strong>the</strong>protrusi<strong>on</strong> density and <strong>the</strong> expected dislocati<strong>on</strong> density was<strong>the</strong> main argument. The results presented here do not sustainthis model, since <strong>the</strong> protrusi<strong>on</strong> density depends <strong>on</strong> both temperatureand coverage. Only for <strong>the</strong> high temperatures studiedin [47] did <strong>the</strong> protrusi<strong>on</strong> density saturate very quickly with

166increasing coverage. Therefore, kinetic <str<strong>on</strong>g>effects</str<strong>on</strong>g> play an importantrole in protrusi<strong>on</strong> <strong>growth</strong>.The self-decorati<strong>on</strong> <strong>of</strong> CaF 2 films <strong>on</strong> <strong>the</strong> upper part <strong>of</strong>substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s has been reported previously for CaF 2 m<strong>on</strong>olayersdeposited <strong>on</strong> <strong>the</strong> CaF interface layer after annealing[43]. The authors explain <strong>the</strong> decorati<strong>on</strong> <strong>of</strong> <strong>the</strong> upperterrace by <strong>the</strong> steric effect due to <strong>the</strong> B stacking <strong>of</strong> <strong>the</strong> film.They used vicinal surfaces with miscuts towards <strong>the</strong> [¯1¯12]azimuth where <strong>the</strong> CaF 2 film grows towards <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>. Thesubstrates in our experiments, however, had <strong>the</strong> miscut towards<strong>the</strong> [11¯2] azimuth where <strong>the</strong> film starts to grow at <strong>the</strong><str<strong>on</strong>g>step</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> lower terrace. A critical <str<strong>on</strong>g>step</str<strong>on</strong>g> height for <strong>the</strong> <strong>on</strong>set<strong>of</strong> <strong>the</strong> self-decorati<strong>on</strong> effect is observed in <strong>the</strong> experimentsreported here. It is not completely clear whe<strong>the</strong>r this is duea minimum <str<strong>on</strong>g>step</str<strong>on</strong>g> height <strong>of</strong> <strong>the</strong> <strong>Si</strong> substrate or whe<strong>the</strong>r thisis a film property (relaxati<strong>on</strong> <strong>of</strong> <strong>the</strong> film close to <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g>).The linearly increasing CaF 2 stripe width with <strong>the</strong> <str<strong>on</strong>g>step</str<strong>on</strong>g> height,however, points to relaxati<strong>on</strong> <str<strong>on</strong>g>effects</str<strong>on</strong>g> as expected from elasticproperties and <strong>the</strong> self-decorati<strong>on</strong> <strong>of</strong> relaxed parts <strong>of</strong> thickerfilms.In c<strong>on</strong>clusi<strong>on</strong>, it has been dem<strong>on</strong>strated that <strong>Si</strong> substrate<str<strong>on</strong>g>step</str<strong>on</strong>g>s are advantageous for <strong>the</strong> homogeneous <strong>growth</strong> <strong>of</strong> <strong>the</strong>CaF interface layer. At sufficiently high temperatures CaFnucleates preferentially at substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s and <strong>the</strong> CaF layergrows via <str<strong>on</strong>g>step</str<strong>on</strong>g> flow. The critical temperature to obtain thiseffect depends <strong>on</strong> <strong>the</strong> terrace width (or <str<strong>on</strong>g>step</str<strong>on</strong>g> density) <strong>of</strong> <strong>the</strong><strong>Si</strong> substrate. The CaF 2 film subsequently grown <strong>on</strong> <strong>the</strong> CaFinterface layer cannot nucleate at <str<strong>on</strong>g>step</str<strong>on</strong>g>s due to its B orientati<strong>on</strong>.In additi<strong>on</strong>, substrate-<str<strong>on</strong>g>induced</str<strong>on</strong>g> <str<strong>on</strong>g>step</str<strong>on</strong>g>s are <strong>growth</strong> barriers.Therefore, CaF 2 films grow very inhomogeneously athigh temperatures via terrace nucleati<strong>on</strong> <strong>on</strong> <strong>the</strong> CaF interfacelayer. Homogeneous films via laminar <strong>growth</strong> are obtained atlow temperatures with a sufficiently high terrace nucleati<strong>on</strong>.A preferred nucleati<strong>on</strong> close to <str<strong>on</strong>g>step</str<strong>on</strong>g>s (self-decorati<strong>on</strong>) is observedfor thicker CaF 2 film and multi-substrate <str<strong>on</strong>g>step</str<strong>on</strong>g>s (miscuttowards <strong>the</strong> [11¯2] azimuth) due to film relaxati<strong>on</strong> close to substrate<str<strong>on</strong>g>step</str<strong>on</strong>g> <str<strong>on</strong>g>effects</str<strong>on</strong>g> and B orientati<strong>on</strong>.Acknowledgements. <strong>Si</strong>ncere thanks are given to M. Bierkandt, A. Klust andH. Pietsch for <strong>the</strong>ir tremendous c<strong>on</strong>tributi<strong>on</strong>s to <strong>the</strong> results presented here,performing, analysing and discussing <strong>the</strong> experiments. Financial supportfrom <strong>the</strong> Deutsche Forschungsgemeinschaft (DFG) is acknowledged.References1. L.J. Challis, C<strong>on</strong>temporary Physics 33, <strong>111</strong> (1992)2. G.A. Toombs, F.W. Sheard: In Electr<strong>on</strong>ic Properties <strong>of</strong> Multilayers andLow Dimensi<strong>on</strong>al Semic<strong>on</strong>ductor Structures, ed. by J.M. Chamberlainet al. (New York, Plenum Press 1990) p. 2573. T.C.L.G. Sollner, W.D. Goodhue, P.E. Tannenwald, C.D. Parker,D.D. Peck: Appl. Phys. Lett. 43, 588 (1983)4. T.J. Shewchuk, P.C. Chapin, P.D. Coleman, W. Kopp, R. Fischer,H. Morkoc: Appl. Phys. Lett. 46, 508 (1985)5. M. Watanabe, T. Suemasu, S. Murakte, M. Asada: Appl. Phys. Lett. 62,300 (1993)6. T. Suemasu, M. Watanabe, J. Suzuki, Y. Kohno, M. Asada, N. Suzuki:Jpn. J. Appl. Phys. 33, 57 (1994)7. T. Suemasu, Y. Kohno, W. Saitho, N. Suzuki, M. Watanabe, M. Asada:Jpn. J. Appl. Phys. 33, L1762 (1994)8. L.J. Schowalter, R.W. Fathauer: CRC Crit. Rev. in Solid State Mater.Sci. 15, 367 (1989)9. C. Strahberger, P. Vogl: Phys. Rev. B 62, 7289 (1999)10. M.A. Olmstead: In Thin Films: Heteroepitaxial Systems (World ScientificPublishing, <strong>Si</strong>ngapore 1999) p. 2<strong>111</strong>1. D. Rieger, F.J. Himpsel, U.O. Karlss<strong>on</strong>, F.R. McFeely, J.F. Morar,J.A.Yaram<strong>of</strong>f:Phys.Rev.B34, 7295 (1985)12. M.A. Olmstead, R.I.G. Uhrberg, R.D. Bringans, R.Z. Bachrach: J. Vac.Sci. Technol. B 4, 1123 (1986)13. F.J. Himpsel, F.U. Hillebrecht, H. Hughes, J.L. Jordan, U.O. Karlss<strong>on</strong>,F.R. McFeely, J.F. Morar, D. Rieger: Appl. Phys. Lett. 48, 596 (1986)14. M.A. Olmstead, R.I.G. Uhrberg, R.D. Bringans, R.Z. Bachrach: Phys.Rev. B 35, 7526 (1985)15. F.J. Himpsel, U.O. Karlss<strong>on</strong>, J.F. Morar, D. Rieger, J.A. Yaram<strong>of</strong>f: Mat.Res. Soc. Proc. 94, 181 (1987)16. M.A. Olmstead, R.D. Bringans: J. Electr<strong>on</strong>. Spectrosc. Relat. Phenom.51, 599 (1990)17. J. Wollschläger, A. Meier: J. Appl. Phys. 79, 7373 (1996)18. G.C.L. W<strong>on</strong>g, C.A. Lucas, D. Loretto, A.P. Payne, P.H. Fuoss: Phys.Rev. Lett. 73, 991 (1994)19. C.A. Lucas, D. Loretto, G.C.L. W<strong>on</strong>g: Phys. Rev. B 50, 14 340 (1994)20. T. Nakayama, M. Katayama, G. Selva, M. A<strong>on</strong>o: Phys. Rev. Lett. 72,1718 (1994)21. T. Sumiya, T. Miura, S. Tanaka: Jpn. J. Appl. Phys. 34, L1383 (1995)22. T. Sumiya, T. Miura, S. Tanaka: Surf. Sci. 357–358, 896 (1996)23. T. Sumiya: Appl. Surf. Sci. 156, 85 (2000)24. R. Wolkow, Ph. Avouris: J. Microscopy 152, 167 (1988)25. Ph. Avouris, R. Wolkow: Phys. Rev. Lett. 55, 1074 (1989)26. H. Ishiwara, T. Asano: Appl. Phys. Lett. 40, 66 (1982)27. T. Asano, H. Ishiwara, N. Kaifu: Jpn. J. Appl. Phys. 22, 1474 (1983)28. R.M. Tromp, M.C. Reuter: Phys. Rev. Lett. 61, 1756 (1988)29. J. Zegenhagen, J.R. Patel: Phys. Rev. B 41, 5313 (1990)30. K.G. Huang, J. Zegenhagen, J.M. Phillips, J.R. Patel: Phys. Rev. Lett.72, 2430 (1994)31. K.G. Huang, J. Zegenhagen, J.M. Phillips, J.R. Patel: Physica B 221,192 (1996)32. C.A. Lucas, G.C.L. W<strong>on</strong>g, D. Loretto: Phys. Rev. Lett. 70, 1826 (1993)33. T. Nakayama, M. A<strong>on</strong>o: Phys. Rev. B57, 1855 (1998)34. A. Klust, H. Pietsch, J. Wollschläger: Appl. Phys. Lett. 73, 1967(1998)35. A. Klust, M. Bierkandt, J. Wollschläger, J. Falta, Th. Schmidt,B.H. Müller: in preparati<strong>on</strong>36. N.S. Sokolov, J.C. Alvarez, Y.V. Shusterman, N.L. Yakovlev,R.M. Overney, Y. Itoh, I. Takahashi, J. Harada: Appl. Surf. Sci.104/105, 402 (1996)37. N.S. Sokolov, J.C. Alvarez, S.V. Gastev, Y.V. Shusterman, I. Takahashi,Y. Itoh, J. Harada, R.M. Overney: J. Crystal Growth 169, 40 (1996)38. J.D. Denlinger, E. Rotenberg, U. Hessinger, M. Leskovar, M.A. Olmstead:Appl. Phys. Lett. 62, 2057 (1993)39. G.C.L. W<strong>on</strong>g, D. Loretto, E. Rotenberg, M.A. Olmstead, C.A. Lucas:Phys. Rev. B 48 5716 (1993)40. J.D. Denlinger, E. Rotenberg, U. Hessinger, M. Leskovar, M.A. Olmstead:Phys. Rev. B51, 5352 (1995)41. U. Hessinger, M. Leskovar, M.A. Olmstead: Phys. Rev. Lett. 75, 2380(1995)42. J. Wollschläger, H. Pietsch, A. Klust: Appl. Surf. Sci. 130–132, 29(1998)43. J. Viernow, D.Y. Petrovykh, F.K. Men, A. Kirakosian, J.L. Lin,F.J. Himpsel: Appl. Phys. Lett. 74, 2125 (1999)44. J. Viernow, D.Y. Petrovykh, A. Kirakosian, J.L. Lin, F.K. Men,M. Henzler, F.J. Himpsel: Phys. Rev. 59, 10 356 (1999)45. A. Li, F. Liu, D.Y. Petrovykh, J.L. Lin, J. Viernow, F.J. Himpsel,M.G. Lagally: Phys. Rev. Lett. 85, 5380 (2000)46. B.M. Kim, C.A. Ventrice, T. Mercer, R. Overney, L.J. Schowalter:Appl. Surf. Sci. 104/105, 409 (1996)47. B.M. Kim, S.R. Ross, R. Overney, L.J. Schowalter: Mat. Res. Soc.Proc. 399, 177 (1996)48. V. Ma<strong>the</strong>t, F. Nguyen-Van-Dau, J. Olivier, P. Galtier: J. Crystal Growth148, 133 (1995)49. A.L. Aseev, A.V. Latyshev, A.B. Krasilnikov: Surf. Rev. Lett. 4, 551(1997)50. A. Ishizaka, T. Doi, M. Ichikawa: Appl. Phys. Lett. 58, 902 (1991)51. G. Meyer, N.M. Amer: Appl. Phys. Lett. 53, 1045 (1988)52. A. Myers-Beaght<strong>on</strong>, D.D. Vvedensky: Phys. Rev. B 42, 9720 (1990)53. M. Bierkandt, J. Wollschläger, M.I. Larss<strong>on</strong>: in preparati<strong>on</strong>54. J. Wollschläger, A. Klust, H. Pietsch: Appl. Surf. Sci. 123–124, 496(1998)55. K. Miura, K. Sugiura, H. Sugiura, Surf. Sci. 253, L407 (1991)56. M. Bierkandt, private communicati<strong>on</strong>57. R.M. Tromp, M.C. Reuter: Phys. Rev. Lett. 73, 110 (1994)