TOWER DRYERS.xps

TOWER DRYERS.xps

TOWER DRYERS.xps

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FFI FEATURES1 Gravity inlet does not require leveling auger,reducing the number of moving parts.2 Motorized grain level monitor designed fortrouble free positive control.3 Self cleaning cushion box on the plenum roofreduces grain damage and plenum roof wear.4 The 12-3/4" grain columns surrounding the heat plenumchamber allows the grain to receive all BTU's from the burner,improving efficiency while providing superior noise reduction.5 Uniform low velocity heated air improvesefficiency and quality as well as reducingparticulate emissions.6 Patented, all stainless steel grain inverters are used toequalize column moisture content and temperature of thegrain column, greatly improving quality and efficiency.7 O p t i o n a l s t a i n l e s s s t e e l o u t s i d el i f e a n d a p p e a r a n c e o f t h e d r y e r .s t a i n l e s s , u t i l i z e . 0 7 8 & . 0 6 2 58 Like all FFI Tower Dryers, the heat chamber floorself cleans in the minimum or maximum coolingpositions.9 Recycling heat from the cooling grain results insignificant fuel savings.10 The sealed discharge section retainsparticulate matter.11 FFI's state of the art Vision Control Panel.12 A specially designed flow control system houses the MoistureControl Sensor. This insures a constant accurate reading fromthe sensor back to the Moisture Control System.

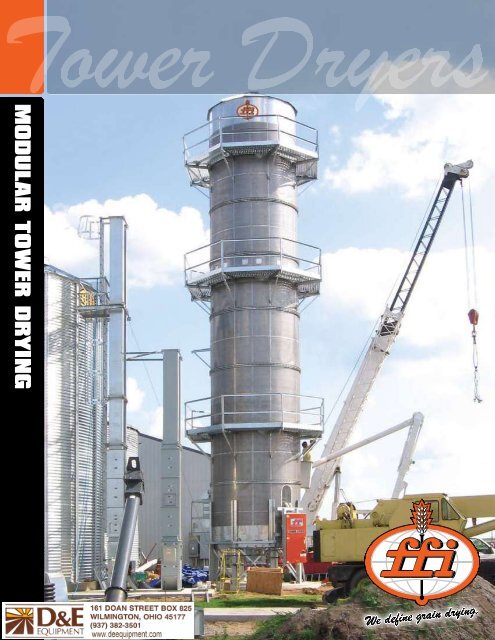

BLOWER & BURNERModular Tower Dryers are designed with the mid-sized to large farm in mind. Capacities rangefrom 800 to 1,690 BPH at 5 point removal. All heat from the grain cooling process is recycledand the long retention times result in very efficient dryer operation.ADDITIONAL FEATURES:Modular constructionContinuous flow dry andvacuum cool mode formaximum efficiencySee through controlpanel doorSolid state ignitionOut of grain-unload cleanoutRemote capable control centerStainless steel flooringstandardCan monitor user suppliedsafety devices.IN-LINE BLOWEREfficient, quiet, adjustablepitch blowers deliverhigh volumes of air at lowhorsepower on all models.OCTAGON BURNERFM-1012 and smaller modelsuse a fuel efficient in-lineoctagon burner to provideeven continuous heat.MAXON NP-LE-AL BURNERF o r F M - 1 0 1 5 o n l y , a M a x o n fefficient, low nox in-lineb u r n e r w i t h e n g i n e e r e d p r o f i l i n gp r o v i d e s e v e n c o n t i n u o u s h e a t .A n a l u m i n u m e x t r u s i o n r e d u c e sb u r n e r m a i n t e n a n c e .MODULAR HEAT CHAMBERThe heat plenum chamber is entirely surrounded by a 12-3/4" grain column. Allheated air must pass through the grain column resulting in total use of heatedair. The galvanized and optional stainless steel smooth sidewall construction with.078” and .0625” perforations helps retain particulate matter.Inside: all 16 gauge panelsHeating section has .078" perforation sidewalls.Cooling section has .0625" perforation to minimize particulate matter.Outside: all 22 gauge panelsHeating & Cooling sections have .078" perforation sidewalls.INVERTERSBURNERBLOWER.078".0625"value and convenience we bring to ourcustomers. FFI products are designedand manufactured to exceed the usersexpectations with features that save timeand money.METERING DRIVEThe SCR variablespeed DC motor andthe single maintenancefree Cyclo gearboxlocated in the coolingchamber providessimple, trouble freeoperation of the dryersmetering system.ADDED VALUE,SWEEP DISCHARGEField proven(patented) Accu-trolMetering System isself cleaning andprovides positivegrain flow.

GRAIN INVERTERSPATENTED, ALL STAINLESS STEEL GRAIN INVERTERSInverters promote more even drying, higher test weights, andhelp reduce operating costs.inside of the grain column to the outside of the column in 6”columns, the patented FFI Grain Inverters put a new twist onthis process.FFI's Grain Inverters move all grain, except the outer twoinches, within the column to eliminate over-dried grain andto maximize drying efficiency and grain quality. These patented Grain Inverters place the warmest grain from the inside of thecolumn next to the wettest grain at the outside of the column. The wet grain at the outer wall is dried by the captured heatwhich would have otherwise escaped the dryer. (See diagram below for visual illustration.)This process maintains optimal grain temperature, thus maximizing grain quality while using less fuel and significantly reducingoperating costs. A convenient clean-out door also provides easy access for quick maintenance.DRYING WITHOUTTHE FFI GRAIN INVERTERS. DRYING WITHOLD GRAIN EXCHANGERS. DRYING WITHTHE FFI GRAIN INVERTERS. KERNEL TEMPERATUREUnder 100°=Seed 100° to 120°=Human Food Grade - Full Nutrition and Taste 120° to 140°=Animal Food Grade - Full Nutrition140° to 160°=Moderate damage & test weight loss starts 160° & above=Severe damage (physical breakage & severe test weight loss)ADDED CONVENIENCEINNER ROOFHeavy galvanizedinner roof andsupport provide260 bushels of wetholding in the garner.The garner is totallysealed to retainparticulate matter.ACCESS DOORS& HATCHESAll areas of thedryer are accessiblethrough doors andfloor hatches foreasy cleaningand maintenance.OUTSIDEPLATFORMSPlatforms, laddersand cages arestandard on allmodels and provideeasy access to theoutside of the dryer.

VISION NETWORK DRYER CONTROLSELECTRICAL CONTROLFEATURES:Exclusive MET (nationally recognizedtesting lab) approved controls.Built to UL 508a specifications:Nationally recognized (US & Canada)CSA electrical compliant.IEC Branch Breakers: IEC controlsare higher quality, rated for morecycles, and meet domestic andinternational electric codes. All dryershave branch breakers for each motor.IEC Motor Overloads: IEC overloadsallow a wide range of adjustment toaccommodate variances in incomingvoltage.Auxiliary Auger IEC Contactors/Overloads*: Load and unloadauxiliary motor branch circuits arestandard. If load and unload HPare specified at time of order, FFIwill install properly sized breaker,contactor, and overload forcustomer's application.Entrelec Terminals: Color-codedEntrelec terminals are used forall computer control circuitsconnections, making for easyinstallation, diagnosis and service.Safety Disconnect*: For safelydisconnecting power from mainpanel for servicing dryer controls.Also provides an easy connectionpoint for incoming electric supply.The light on the outside of the dryerdoubles as a shutdown indicator.* Provides significant cost savings overdryers that neglect these features.OPTIONAL WATCHDOG SOFTWAREdryer functions such as moisture, temperature and dryer status from a webyou advised from the comfort and convenience of your home, office, or personaldigital assistant (PDA). Contact the FFI dealer nearest you for more information.

"DEFINING THE FUTURE OFNETWORK DRYER CONTROLS"Controlling a grain dryer has never been easier.Unmatchedoptions combined with simple, easy to read displaysincluding animated graphics of incoming and outgoinggrain movement and fan and heater operation make Visionthe clear choice for the very best in grain drying results.CONFIGURATION SCREENFree software updates are available for download from the FFI web site.All that is needed to do the update is a simple flash memory card or anyUSB based removable drive.MODIFYING TEMP SETPOINTCONFIGURATION SCREENMOISTURE CONTROL SETUPEXTENDED CONFIGURATIONSELECTION SCREENOn-ScreenOwner'sManualShutdownHelp File

FM-SERIES SPECIFICATIONSFM-1008 FM-1010 FM-1012 FM-1015BLOWER SIZE 43" Axial 43" Axial 43" Axial 48" AxialBLOWER RPM 1775 1775 1775 1775BLOWER HP 40 50 60 75METERING HP / UNLOAD HP 1 / 3 1 / 3 1 / 3 1 / 3DRYING CFM 38,000 45,000 52,000 66,000COOLING CFM 19,500 22,500 26,000 33,000TY ( BTU)AVERAGEHEAT USE (MBTU)5,100,000 6,100,000 7,000,000 8,900,000GRAIN COLUMN 12-3/4" 12-3/4" 12-3/4" 12-3/4"<strong>TOWER</strong> DIAMETER 2 10'-7" 10'-7" 10'-7" 10'-7"WET HOLDING (BU)260 260 260 260HEAT HOLDING (BU) - MIN. COOL 552 726 900 1,074COOL HOLDING (BU) - MIN. COOL 144 144 187 187HEAT HOLDING (BU) - MAX. COOL 450 624 798 972COOL HOLDING (BU) - MAX. COOL 246 246 289 289UNLOAD AREA HOLDING 93 93 50 50NG ( U)DRYER WT (LBS) 17,900 19,200 21,700 23,000OUTSIDE CATWALKS 1 3 3 3BPH (SET IN MIN. COOL)(20% - 15%) 900 1,125 1,350 1,690BPH (SET IN MIN. COOL)(25% - 15%) 542 670 810 1,010BPH (SET IN MAX. COOL)(20% - 15%) 800 1,000 1,200 1,500BPH (SET IN MAX. COOL)(25% - 15%) 480 600 720 9001 At 50 degrees ambiant temperature.23 Optional vertical fill pipe height not included.4 Capacities listed are wet bushels/tonnes, shelled corn at listed moisture content andare estimates based on drying principles, field results and computer simulation.Variance may occur due to grain's physiological factors (kernel size, chemicalcomposition, variety, maturity), excessive fines, adverse weather conditions, etc.5 Capacities with cooling floor set in the lower minimum cool positionand assumes utilization of cooling in bin (dryeration)Discharge Height - Adjustable up to 42" with standard unloadauger and 24" at center discharge with standard legs.2’ leg extensions are optional.FM-100810'-7" dia. x 42'-1" height15'-7" dia. w/CatwalksFM-101010'-7" dia. x 48'-11" height15'-7" dia. w/CatwalksFM-101210'-7" dia. x 55'-9" height15'-7" dia. w/Catwalks10'-7" dia. x 62'-7" height15'-7" dia. w/CatwalksAll models available in natural gas or liquid propane. Liquidpropane pricing includes the price on an internal vaporizer andhigh pressure regulator.All models available in 3 phase 230 or 460 volts.www.fficorp.com1004 East Illinois Street | Assumption, IL 62510 USAPh: 217-226-5400 | Fax: 800-800-5329Farm FansWe define grain drying.FF-026FF-026 MAR/10 Copyright ©2010 by The GSI Group, LLC.Printed in the USA | Due to continual improvements, The GSI Group, LLC.reserves the right to change designs and specifications without notice.