You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

page 100 <strong>Optical</strong> <strong>Systems</strong><br />

Introduction to Laser beam Homogenizer<br />

Many applications, e.g. from microscopy and material processing,<br />

require a very even distribution of the illuminating light.<br />

For this purpose, micro lens based homogenizers are available nowadays<br />

for numerous light sources, ranging from excimer lasers to high<br />

power LEDs.<br />

Two general types are distinguished, Non-Imaging and Imaging<br />

Homogenizers. Both types split the incident beam into small sub<br />

beams. This is achieved by passage either through arrays of cylindrical<br />

lenses in a crossed configuration, or through arrays of micro lenses.<br />

The sub beams are then superimposed by a spherical lens in its focal<br />

plane, leading to a homogeneously illuminated field. This spherical<br />

lens is called Fourier lens, as it effectively performs a two dimensional<br />

Fourier transformation.<br />

The application itself should be considered when choosing between<br />

Non-Imaging and Imaging Homogenizer. As an orientation aid one<br />

should consider the Fresnel number, which is defined for micro lens<br />

homogenizers by<br />

where P LA represents the pitch of the micro lens array, D FT the size of<br />

the flat top in the plane of homogenization, f FL the focal length of the<br />

Fourier lens, and λ is the wavelength. The Fresnel number is the most<br />

important determinant for laser beam homogenizers based on micro<br />

lens arrays. As a general rule, the uniformity of the flat top increases<br />

with higher Fresnel numbers.<br />

Non-imaging homogenizers<br />

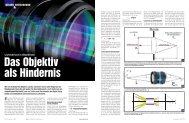

Non-Imaging Homogenizers are built from one micro lens array and<br />

one spherical lens (see figure above). The plane of homogenization<br />

lies in the focal plane of the Fourier lens (FL), the size of the<br />

homogeneously illuminated area is determined by:<br />

LINOS, USA<br />

Phone +1 (508) 478-6200<br />

E-mail info@linos.com<br />

LINOS, UK<br />

Phone +44 (0) 1908 262525<br />

E-mail sales@linos.co.uk<br />

Non-Imaging Homogenizers often show dominant diffraction effects<br />

due to Fresnel diffraction at the micro lens array. In practice, Fresnel<br />

numbers of FN >10, or better FN >100, lead to homogeneous intensities.<br />

Due to the connection of the Fresnel number with the size of the<br />

flat top, Non-Imaging Homogenizers are the first choice for illuminating<br />

large areas. For small Fresnel numbers of FN < 10, or when a<br />

very even distribution is required, Imaging Homogenizers should be<br />

chosen..<br />

Imaging homogenizers:<br />

Imaging Homogenizers are built from two micro lens arrays and one<br />

spherical lens (see figure above). The plane of homogenization lies in<br />

the focal plane of the Fourier lens (FL), the size of the homogenized<br />

area is defined by:<br />

LINOS, France<br />

Phone +33 (0)4 72 52 04 20<br />

E-mail info-fr@linos.com<br />

with<br />

Here, a 12 denotes the distance between the two micro lens arrays. As<br />

with Non-Imaging Homogenizers, the incident beam is split into many<br />

small sub beams with the first micro lens array. The second micro lens<br />

array then acts, in combination with the spherical lens, like an array<br />

of objective lenses, overlapping the sub beams of the first array in the<br />

plane of homogenization. As the size of the flat top depends in this<br />

case on the distance between the two arrays, it can easily be adjusted<br />

by moving the second array. However, great care has to be taken that<br />

the second array is not moved into the focus plane of the first array,<br />

where it could be damaged by focussed high energy laser light.<br />

Imaging Homogenizers usually use micro lens arrays of identical pitch.<br />

The shape of the flat top is determined by the shape of the micro<br />

lenses (e.g. square, round, hexagonal).<br />

LINOS, Germany<br />

Phone +49 (0)551 69 35-0<br />

E-mail sales@linos.de