physical model about laser impact on metals and alloys

physical model about laser impact on metals and alloys

physical model about laser impact on metals and alloys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

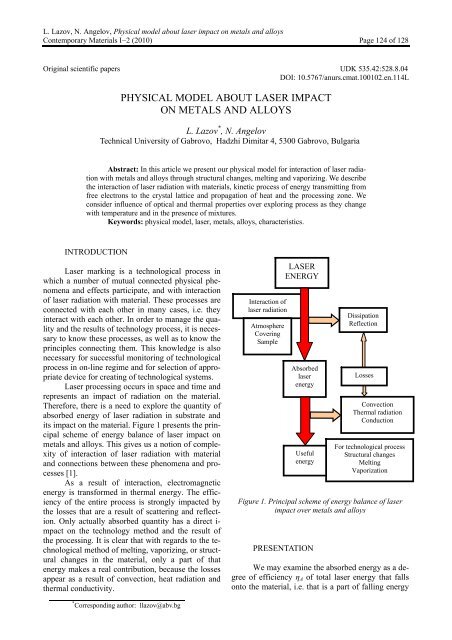

L. Lazov, N. Angelov, Physical <str<strong>on</strong>g>model</str<strong>on</strong>g> <str<strong>on</strong>g>about</str<strong>on</strong>g> <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong> <strong>metals</strong> <strong>and</strong> <strong>alloys</strong>C<strong>on</strong>temporary Materials I−2 (2010) Page 124 of 128Original scientific papers UDK 535.42:528.8.04DOI: 10.5767/anurs.cmat.100102.en.114LPHYSICAL MODEL ABOUT LASER IMPACTON METALS AND ALLOYSL. Lazov * , N. AngelovTechnical University of Gabrovo, Hadzhi Dimitar 4, 5300 Gabrovo, BulgariaAbstract: In this article we present our <str<strong>on</strong>g>physical</str<strong>on</strong>g> <str<strong>on</strong>g>model</str<strong>on</strong>g> for interacti<strong>on</strong> of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong>with <strong>metals</strong> <strong>and</strong> <strong>alloys</strong> through structural changes, melting <strong>and</strong> vaporizing. We describethe interacti<strong>on</strong> of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> with materials, kinetic process of energy transmitting fromfree electr<strong>on</strong>s to the crystal lattice <strong>and</strong> propagati<strong>on</strong> of heat <strong>and</strong> the processing z<strong>on</strong>e. Wec<strong>on</strong>sider influence of optical <strong>and</strong> thermal properties over exploring process as they changewith temperature <strong>and</strong> in the presence of mixtures.Keywords: <str<strong>on</strong>g>physical</str<strong>on</strong>g> <str<strong>on</strong>g>model</str<strong>on</strong>g>, <str<strong>on</strong>g>laser</str<strong>on</strong>g>, <strong>metals</strong>, <strong>alloys</strong>, characteristics.INTRODUCTIONLaser marking is a technological process inwhich a number of mutual c<strong>on</strong>nected <str<strong>on</strong>g>physical</str<strong>on</strong>g> phenomena<strong>and</strong> effects participate, <strong>and</strong> with interacti<strong>on</strong>of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> with material. These processes arec<strong>on</strong>nected with each other in many cases, i.e. theyinteract with each other. In order to manage the quality<strong>and</strong> the results of technology process, it is necessaryto know these processes, as well as to know theprinciples c<strong>on</strong>necting them. This knowledge is als<strong>on</strong>ecessary for successful m<strong>on</strong>itoring of technologicalprocess in <strong>on</strong>-line regime <strong>and</strong> for selecti<strong>on</strong> of appropriatedevice for creating of technological systems.Laser processing occurs in space <strong>and</strong> time <strong>and</strong>represents an <str<strong>on</strong>g>impact</str<strong>on</strong>g> of radiati<strong>on</strong> <strong>on</strong> the material.Therefore, there is a need to explore the quantity ofabsorbed energy of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> in substrate <strong>and</strong>its <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong> the material. Figure 1 presents the principalscheme of energy balance of <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong><strong>metals</strong> <strong>and</strong> <strong>alloys</strong>. This gives us a noti<strong>on</strong> of complexityof interacti<strong>on</strong> of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> with material<strong>and</strong> c<strong>on</strong>necti<strong>on</strong>s between these phenomena <strong>and</strong> processes[1].As a result of interacti<strong>on</strong>, electromagneticenergy is transformed in thermal energy. The efficiencyof the entire process is str<strong>on</strong>gly <str<strong>on</strong>g>impact</str<strong>on</strong>g>ed bythe losses that are a result of scattering <strong>and</strong> reflecti<strong>on</strong>.Only actually absorbed quantity has a direct i-mpact <strong>on</strong> the technology method <strong>and</strong> the result ofthe processing. It is clear that with regards to the technologicalmethod of melting, vaporizing, or structuralchanges in the material, <strong>on</strong>ly a part of thatenergy makes a real c<strong>on</strong>tributi<strong>on</strong>, because the lossesappear as a result of c<strong>on</strong>vecti<strong>on</strong>, heat radiati<strong>on</strong> <strong>and</strong>thermal c<strong>on</strong>ductivity.Interacti<strong>on</strong> of<str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong>AtmosphereCoveringSampleLASERENERGYAbsorbed<str<strong>on</strong>g>laser</str<strong>on</strong>g>energyUsefulenergyFigure 1. Principal scheme of energy balance of <str<strong>on</strong>g>laser</str<strong>on</strong>g><str<strong>on</strong>g>impact</str<strong>on</strong>g> over <strong>metals</strong> <strong>and</strong> <strong>alloys</strong>PRESENTATIONDissipati<strong>on</strong>Reflecti<strong>on</strong>LossesC<strong>on</strong>vecti<strong>on</strong>Thermal radiati<strong>on</strong>C<strong>on</strong>ducti<strong>on</strong>For technological processStructural changesMeltingVaporizati<strong>on</strong>We may examine the absorbed energy as a degreeof efficiency η А of total <str<strong>on</strong>g>laser</str<strong>on</strong>g> energy that falls<strong>on</strong>to the material, i.e. that is a part of falling energy* Corresp<strong>on</strong>ding author: llazov@abv.bg

L. Lazov, N. Angelov, Physical <str<strong>on</strong>g>model</str<strong>on</strong>g> <str<strong>on</strong>g>about</str<strong>on</strong>g> <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong> <strong>metals</strong> <strong>and</strong> <strong>alloys</strong>C<strong>on</strong>temporary Materials I−2 (2010) Page 125 of 128which really participates in processing (structuralchanges, melting, vaporizati<strong>on</strong> in the unit volume).In certain references it is defined as a percentage ofthe total energy falling <strong>on</strong>to the material, necessaryfor c<strong>on</strong>crete processing [1]. Under certain simplificati<strong>on</strong>s,if we ignore the c<strong>on</strong>diti<strong>on</strong>s of working z<strong>on</strong>e(c<strong>on</strong>vecti<strong>on</strong>, heat radiati<strong>on</strong> <strong>and</strong> thermal c<strong>on</strong>ductivity)we assume that it is energy absorbed by thematerial.INTERACTION OF RADIATIONWITH A SAMPLEThe interacti<strong>on</strong> of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> with a sampleis c<strong>on</strong>nected with the level of absorpti<strong>on</strong> А%,which is defined as a percentage of energy absorbedby material from the total energy falling <strong>on</strong>to thematerial. Optical depth of penetrati<strong>on</strong> δ is definedwith absorpti<strong>on</strong> coefficient δ = 1/α. In this case wehave exp<strong>on</strong>ential decrease of radiati<strong>on</strong> intensity withdepth z. For str<strong>on</strong>g absorbing materials, such as <strong>metals</strong><strong>and</strong> <strong>alloys</strong>, the depth of penetrati<strong>on</strong> δ is lowerthan wavelength λ of falling radiati<strong>on</strong>. Total energythat penetrates the material is absorbed <strong>and</strong> it doesnot depend <strong>on</strong> the thickness of the sample [1].The ratio of absorpti<strong>on</strong> according to [2] depends<strong>on</strong>: optical c<strong>on</strong>stants of material - coefficient of reflecti<strong>on</strong>R, absorpti<strong>on</strong> index к / ; <str<strong>on</strong>g>physical</str<strong>on</strong>g> properties of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> – wavelengthλ, polarizati<strong>on</strong>, power density q S ; chemical compositi<strong>on</strong> of surface – oxides, nitride,graphite layers <strong>and</strong> so far; topography of surface (roughness);as well as <strong>on</strong> the angle of radiati<strong>on</strong> falling, temperature<strong>and</strong> aggregate state of material which is under<str<strong>on</strong>g>impact</str<strong>on</strong>g>.The dependence of absorpti<strong>on</strong> ability А <strong>on</strong>wavelength λ for different materials at room temperature<strong>and</strong> angle of falling 0 o (towards normal) to thesurface is presented in Fig. 2 [3].We can see from the graph that absorpti<strong>on</strong>ability (except for Аl) decreases with an increase ofwavelength. Differences in separate groups of metalwhich are under <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> are clearly noticeable.Thus, for example, for precious <strong>metals</strong> (Ag, Cu) absorpti<strong>on</strong>decreases very fast for wavelengths fromvisible spectrum, <strong>and</strong> for transiti<strong>on</strong> <strong>metals</strong> (Fe, Mo)the absorpti<strong>on</strong> change is more smooth <strong>and</strong> exp<strong>and</strong>sto the far infra-red range. Аl, which is a representativeof polyvalent <strong>metals</strong>, has specific change of absorpti<strong>on</strong>with medium maximum for wavelength λ =0,84 µm <strong>and</strong> almost for total range of wave lengthsit has low absorpti<strong>on</strong> [1]. We can see <strong>on</strong> the graphfor industry used <str<strong>on</strong>g>laser</str<strong>on</strong>g>s that there are great differencesc<strong>on</strong>cerning the ratio of absorpti<strong>on</strong> for different<strong>metals</strong>. For example, ir<strong>on</strong> (Fe) under <str<strong>on</strong>g>impact</str<strong>on</strong>g> fromCO 2 -<str<strong>on</strong>g>laser</str<strong>on</strong>g> <strong>and</strong> Nd:YAG <str<strong>on</strong>g>laser</str<strong>on</strong>g> has absorpti<strong>on</strong> capabilitywhich changes 4 times <strong>and</strong> for Аl this differenceis insignificant. If we compare the ratio of absorpti<strong>on</strong>for Аl under <str<strong>on</strong>g>impact</str<strong>on</strong>g> of diode <str<strong>on</strong>g>laser</str<strong>on</strong>g>s (λ = 0,808 -0,940 µm) <strong>and</strong> Nd:YAG <str<strong>on</strong>g>laser</str<strong>on</strong>g>s, the diode <strong>on</strong>es havepriority over others. The temperature of surfacewhich is under processing is very important for increasingabsorpti<strong>on</strong> of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> falling <strong>on</strong> thematerial. This is easy to see in Fig. 3. If we reach themelting point then the absorpti<strong>on</strong> ability changes rapidly.This effect is noticed for Аl with different <str<strong>on</strong>g>laser</str<strong>on</strong>g>sources - CO 2 -<str<strong>on</strong>g>laser</str<strong>on</strong>g>, Nd:YAG <str<strong>on</strong>g>laser</str<strong>on</strong>g> <strong>and</strong> diode <str<strong>on</strong>g>laser</str<strong>on</strong>g>.For <str<strong>on</strong>g>laser</str<strong>on</strong>g>s with shorter wavelength that jump issignificant comparing to CO 2 -<str<strong>on</strong>g>laser</str<strong>on</strong>g>. Other variables,which <str<strong>on</strong>g>impact</str<strong>on</strong>g> absorpti<strong>on</strong>, are polarizati<strong>on</strong> <strong>and</strong> angleof falling of the <str<strong>on</strong>g>laser</str<strong>on</strong>g> beam. (For <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> <str<strong>on</strong>g>impact</str<strong>on</strong>g>s,we have clearly expressed maximum forBrewster’s angle, if electric vector E vibrates parallelto surface of falling. As for the <str<strong>on</strong>g>impact</str<strong>on</strong>g> with polarized<str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong>, if electric vector E vibratesnormally to plane of falling we observe a smooth increaseof absorpti<strong>on</strong> (see fig. 4). Nature of absorpti<strong>on</strong>maximum depends <strong>on</strong> wavelength λ. For λ = 10,6µm the maximum is narrow <strong>and</strong> has a value of <str<strong>on</strong>g>about</str<strong>on</strong>g>80%, <strong>and</strong> for visible range it is wide <strong>and</strong> <str<strong>on</strong>g>about</str<strong>on</strong>g> 30%.The above effects are valid at low power density thatdoes not allow creati<strong>on</strong> of plasma–cloud over theprocessing surface.Figure 2. How absorpti<strong>on</strong> ability А depends <strong>on</strong>wavelength λ for different <strong>metals</strong> <strong>and</strong> steel at roomtemperature <strong>and</strong> angle of falling al<strong>on</strong>g normally to thesurface

L. Lazov, N. Angelov, Physical <str<strong>on</strong>g>model</str<strong>on</strong>g> <str<strong>on</strong>g>about</str<strong>on</strong>g> <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong> <strong>metals</strong> <strong>and</strong> <strong>alloys</strong>C<strong>on</strong>temporary Materials I−2 (2010) Page 126 of 128<str<strong>on</strong>g>impact</str<strong>on</strong>g>, the heat propagates to short distances indepth of the product <strong>and</strong> also <strong>on</strong> its surface. The finalresult is insignificant heat <str<strong>on</strong>g>impact</str<strong>on</strong>g>ed z<strong>on</strong>e as wellas lack of c<strong>on</strong>vecti<strong>on</strong> losses.100%8060λ = 10,6 μmA40λ = 1,064μmFigure 3. Graphics of dependence of absorpti<strong>on</strong> A <strong>on</strong>temperature T for Аl at different wavelengths of <str<strong>on</strong>g>laser</str<strong>on</strong>g>radiati<strong>on</strong>20λ = 0,532 μmTHEORY OF THERMAL CONDUCTIVITYFOR METALSC<strong>on</strong>cerning the <str<strong>on</strong>g>impact</str<strong>on</strong>g> with power densityover certain threshold, when absorbed energy of processingz<strong>on</strong>e is bigger than that <strong>and</strong> is scattered as aresult of heat c<strong>on</strong>ductivity, we see that materialstarts to melt. The size of melting z<strong>on</strong>e depends <strong>on</strong>parameters of processing, absorbed energy per unitlength, but also <strong>on</strong> geometry <strong>and</strong> properties of thesample. For the purpose of marking, we need absorbedenergy to generate such structural or phasechanges in surface layer to obtain the quality of markingwe need. Optimizati<strong>on</strong> of processing c<strong>on</strong>sists ofselecti<strong>on</strong> of such parameters of processing (functi<strong>on</strong>of <str<strong>on</strong>g>physical</str<strong>on</strong>g> processes) which should cause appropriatetemperature fields in material, ensuring desiredgeometry <strong>and</strong> quality of marking z<strong>on</strong>e. By performingpreliminary numeric calculati<strong>on</strong> for temperaturefields at <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> over certain materials, whenwe notice the factors which influence processing, wemay predict <strong>and</strong> optimize the final results. In therange of optical absorpti<strong>on</strong> of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> in themetal, phot<strong>on</strong>-electr<strong>on</strong> interacti<strong>on</strong> occurs, which resultsin absorpti<strong>on</strong> of electromagnetic energy, whichis transformed into heat energy. Propagati<strong>on</strong> of heatin the material is described by phenomen<strong>on</strong> of thermalc<strong>on</strong>ductivity.Laser marking is known by its specific verysmall range of <str<strong>on</strong>g>impact</str<strong>on</strong>g> (several by ten µm), big powerdensity <strong>and</strong> short durati<strong>on</strong> of <str<strong>on</strong>g>impact</str<strong>on</strong>g>. High temperaturegradients for warming <strong>and</strong> cooling of theworking z<strong>on</strong>e are observed. C<strong>on</strong>cerning durati<strong>on</strong> of00 20 40θ, oFigure 4. Graphs of the dependence of absorbance A ofthe angle of incidence θ of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> for Al atdifferent wavelengthsPenetrated in metal, <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> is completelyabsorbed by free electr<strong>on</strong>s in thin layer underthe surface with depth 0,1 1,0 m. That is the reas<strong>on</strong>for their energy to increase <strong>and</strong> intensity of hitsbetween them to grow. For the durati<strong>on</strong> (time11t ~ 10 s ) from the beginning of the <str<strong>on</strong>g>impact</str<strong>on</strong>g>, theyhave delivered a very small part of that energy tocrystal lattice. During that time str<strong>on</strong>g overheatingof electr<strong>on</strong>ic gas occurs ( Te Ti, where Teis thetemperature of electr<strong>on</strong>ic gas <strong>and</strong> T iis the temperatureof crystal lattice). During that time, intensity ofhits between free electr<strong>on</strong>s <strong>and</strong> i<strong>on</strong>s of crystal latticeincreases as well as a stream of energy from electr<strong>on</strong>9gas to the lattice. For time t rel~ 10 s from the beginningof the <str<strong>on</strong>g>impact</str<strong>on</strong>g>, the temperature difference T T e T ibecomes minimum <strong>and</strong> the state inworking volume has a characterizati<strong>on</strong> of sharedtemperature of metal T . The time t relis defined asthe time of relaxati<strong>on</strong>.As explained already, the main part of transmissi<strong>on</strong>of heat in the metal at the <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> occursfrom electr<strong>on</strong> c<strong>on</strong>ductivity. This means that heatprocesses of processing with <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> havethe same <str<strong>on</strong>g>physical</str<strong>on</strong>g> nature as with the <str<strong>on</strong>g>impact</str<strong>on</strong>g> with traditi<strong>on</strong>alsources of heat. That gives the basis to de-6080

L. Lazov, N. Angelov, Physical <str<strong>on</strong>g>model</str<strong>on</strong>g> <str<strong>on</strong>g>about</str<strong>on</strong>g> <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong> <strong>metals</strong> <strong>and</strong> <strong>alloys</strong>C<strong>on</strong>temporary Materials I−2 (2010) Page 127 of 128scribe the heat propagati<strong>on</strong> in the metal caused by<str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> with classic theory of thermal c<strong>on</strong>ductivity.As it was realized, optical depth of penetrati<strong>on</strong>of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> in the metal is in the range of 10 -7- 10 -8 m <strong>and</strong> it is c<strong>on</strong>siderably less than the length ofheat diffusi<strong>on</strong> ( 4а). That is why in this casethe <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong> is c<strong>on</strong>sidered as surface <str<strong>on</strong>g>impact</str<strong>on</strong>g>ingheat source. Differential equati<strong>on</strong> of heat c<strong>on</strong>ductivityisTc div( k grad T ) qS (1 R), (1)twhereby T is temperature; c - specific heat capacity;ρ – density of material; k – coefficient of heat c<strong>on</strong>ductivity;q S – surface power density of <str<strong>on</strong>g>laser</str<strong>on</strong>g> radiati<strong>on</strong>;R – coefficient of reflecti<strong>on</strong>; α – coefficient ofabsorpti<strong>on</strong>.Equati<strong>on</strong> (1) describes heat transfer through h-eat c<strong>on</strong>ductivity in the most general form. One initial<strong>and</strong> two limiting c<strong>on</strong>diti<strong>on</strong>s are necessary for itsapplicati<strong>on</strong>.Initial c<strong>on</strong>diti<strong>on</strong> – temperature of samples atthe moment t = 0 is assumed to be equal to theambient temperatureT o = c<strong>on</strong>st. (2)For <str<strong>on</strong>g>laser</str<strong>on</strong>g> processing, the following applies:C<strong>on</strong>diti<strong>on</strong> of restricti<strong>on</strong> of I stockIt defines distributi<strong>on</strong> of temperature at thesample surface at every moment of the timeT o = c<strong>on</strong>st or T o = T o (t). (3)C<strong>on</strong>diti<strong>on</strong> of restricti<strong>on</strong> of II stockIt is given surface density of heat stream q S atevery point of the surface of the sample at everymoment of time. It is assumed that surface density q Sin every point of head stream across the surface q S =c<strong>on</strong>st or q S = q S (t) i.e. it is c<strong>on</strong>stant or is a functi<strong>on</strong> oftime.Since the surface density is proporti<strong>on</strong>al totemperature’s gradient we may write:T k ) q(S qxS = c<strong>on</strong>st or q S = q S (t). (4)SSoluti<strong>on</strong> of the differential equati<strong>on</strong> of heatc<strong>on</strong>ductivity at assigned initial (2) <strong>and</strong> limiting c<strong>on</strong>diti<strong>on</strong>s(3) <strong>and</strong> (4) allow us to determine the temperaturefield of the sample in the given moment of time,as it is defined as functi<strong>on</strong> T T ( x,y,z,t).For analytic soluti<strong>on</strong> of differential equati<strong>on</strong>we assume the following simplificati<strong>on</strong>s:− Heat losses as result of radiati<strong>on</strong> <strong>and</strong> c<strong>on</strong>vecti<strong>on</strong>are ignored (that is based at pulse <str<strong>on</strong>g>laser</str<strong>on</strong>g> processing);− Dependence of temperature <strong>on</strong> optical <strong>and</strong> thermo-<str<strong>on</strong>g>physical</str<strong>on</strong>g>characteristics of materials is ignored.With these limitati<strong>on</strong>s, the heat source in metalmay be c<strong>on</strong>sidered as moving surface’s heat sourcewith defined geometry of working z<strong>on</strong>e. In thiscase analytic soluti<strong>on</strong> for equati<strong>on</strong> of heat-c<strong>on</strong>ductivityis obtained.The heat c<strong>on</strong>ductivity equati<strong>on</strong> is not ananalytic soluti<strong>on</strong> of a general case <strong>and</strong> that is whynumerical methods are used for its resoluti<strong>on</strong>. Ofmany well known methods for explorati<strong>on</strong> of temperaturefields for <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong> materials, the methodof limited elements (4) is accepted as universal<strong>and</strong> well applied.We have made certain theoretical calculati<strong>on</strong>sfor the evaluati<strong>on</strong> of described <str<strong>on</strong>g>physical</str<strong>on</strong>g> <str<strong>on</strong>g>model</str<strong>on</strong>g>,which we compared with c<strong>on</strong>crete experimental results.A c<strong>on</strong>crete technological process was examined– <str<strong>on</strong>g>laser</str<strong>on</strong>g> marking of products of carb<strong>on</strong> tool steelsУ7, У12 <strong>and</strong> alloyed tool steel Р6М5. Initial parametersfor numeric calculati<strong>on</strong>s were:- diameter of working spot d = 30 μm;- speed of marking v = 50 mm/s;- frequency of pulse repetiti<strong>on</strong> ν = 19 kHz.The trends of theoretical research are directedtowards:− Calculati<strong>on</strong> of critical pulse energy for structuralchanges E imp(sc) <strong>and</strong> critical power density q S(sc)for structural changes (sc);− Calculati<strong>on</strong> of critical pulse energy for meltingE imp(m) <strong>and</strong> critical power density at melting q S(m) ;− Calculati<strong>on</strong> of critical pulse energy for vaporizati<strong>on</strong>E imp(t) <strong>and</strong> critical power density q S(t) for vaporizati<strong>on</strong>.The results of calculati<strong>on</strong>s are presented in table1.Table 1: Calculati<strong>on</strong>s of critical pulse energy <strong>and</strong> criticalpower densityMaterialVariableУ7 У12 Р6М5E imp(sc) , mJ 10,2 11,3 13,8q s(sc) , W/m 2 2,84.10 9 3,12.10 9 3,83.10 9E imp(m) , mJ 19.9 21,9 26,8q s(m) , W/m 2 5,51.10 9 6,09.10 9 7,43.10 9E imp(t) , mJ 31,0 34,1 41,8q s(t) , W/m 2 8,60.10 9 9,49.10 9 1,16.10 10Indicative results of calculati<strong>on</strong>s very wellcorrelate with experimental data, obtained by markingof tool steels with this type of <str<strong>on</strong>g>laser</str<strong>on</strong>g> [5].

L. Lazov, N. Angelov, Physical <str<strong>on</strong>g>model</str<strong>on</strong>g> <str<strong>on</strong>g>about</str<strong>on</strong>g> <str<strong>on</strong>g>laser</str<strong>on</strong>g> <str<strong>on</strong>g>impact</str<strong>on</strong>g> <strong>on</strong> <strong>metals</strong> <strong>and</strong> <strong>alloys</strong>C<strong>on</strong>temporary Materials I−2 (2010) Page 128 of 128CONCLUSIONThe c<strong>on</strong>sidered <str<strong>on</strong>g>model</str<strong>on</strong>g> is applied for receivingpreliminary engineering evaluati<strong>on</strong>s <strong>and</strong> prognosisof results of <str<strong>on</strong>g>laser</str<strong>on</strong>g> processing of <strong>metals</strong> <strong>and</strong> <strong>alloys</strong>with different <str<strong>on</strong>g>laser</str<strong>on</strong>g> sources. It helps selecting a <str<strong>on</strong>g>laser</str<strong>on</strong>g>source during c<strong>on</strong>structi<strong>on</strong> of a technologicalsystem. Specific technological processes are beingoptimized by a mathematical <str<strong>on</strong>g>model</str<strong>on</strong>g> which was created<strong>on</strong> a <str<strong>on</strong>g>physical</str<strong>on</strong>g> basis.REFERENCES[1] F. Dausinger, Strahlwerkzeug Laser:Energieeinkopplung und Prozeßeffektivität, UniversitätStuttgart, Habilitati<strong>on</strong> 1995.[2] Bergmann Ludwig, Schaefer Clemens Lehrbuchder Experimentalphysik, B<strong>and</strong> 3 Optik, Berlin:den Gruyter-Verlag 1987.[3] L<strong>and</strong>olt, Bornstein Daten- und Funkti<strong>on</strong>ssammlungin Wissenschaft und Technik, Berlin,Springer-Verlag 1990.[4] J. Xie, A. Kar, Mathematical <str<strong>on</strong>g>model</str<strong>on</strong>g>ing ofmelting during <str<strong>on</strong>g>laser</str<strong>on</strong>g> materials processing. Journalof Applied Physics, Nr. 81 (7), (1997) S.3015.[5] www.pulslight.comФИЗИЧКИ МОДЕЛ ЗА ЛАСЕРСКО МАРКИРАЊЕ МЕТАЛА И ЛЕГУРАСажетак: У раду је представљен наш физички модел за интеракцију ласерскогзрачења са металном легуром кроз структурне промјене, топљење и испаривање. Објашњенаје интеракција ласерског зрачења са материјалима, кинетички процес преносаенергије слободних електрона у кристалну решетку и ширење топлоте у проводнојзони. Разматран је утицај оптичких и термалних особина преко испитиваних процесакао што су промјене температуре и присуство смјесе.Кључне ријечи: физички модел, ласер, метали, легуре, обиљежја.