NCT-Extruder - John Wood & Associates

NCT-Extruder - John Wood & Associates

NCT-Extruder - John Wood & Associates

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

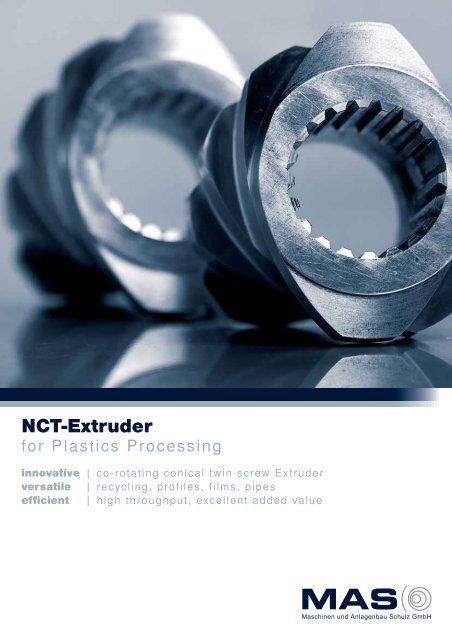

<strong>NCT</strong>-<strong>Extruder</strong>for Plastics Processinginnovative | co-rotating conical twin screw <strong>Extruder</strong>versatile | recycling, profiles, films, pipesefficient | high throughput, excellent added value

Plastics Processingwith New Conical Technology (<strong>NCT</strong>)From flake to pellets ...... from regrind to value added pelletsinnovative | the technology<strong>NCT</strong>-<strong>Extruder</strong>s by MAS are the economical alternative for optimumcompounding and processing of plastics. New Conical Technology(<strong>NCT</strong>), developed by MAS, is based on a conical, co-rotating TwinScrew <strong>Extruder</strong>. The latter has a distinctly higher volume at the intakesection and permits greater torques than conventionalCompounders. This results in a higher screw fill level, which meansthe highest throughput with comparatively high pressure ratios andlow melt temperatures. Due to the generously dimensioned screwshaft, <strong>NCT</strong>-<strong>Extruder</strong>s by MAS are extremely robust and with a longservice life.versatile | the processing spectrum<strong>NCT</strong>-<strong>Extruder</strong>s by MAS are versatile in use. They are suitable forall applications in the extrusion sector:efficient | the cost-effectiveness<strong>NCT</strong>-<strong>Extruder</strong>s by MAS offer major technological andeconomic advantages, as well as highest added valuein production:› Large intake volume› Low melt temperature› Short dwell time› High pressure build-up› Careful treatment› Good degasification› Excellent mixing› High productivity› Simple operation› Robust design› Processing of grinding stock and regrind› Homogenisation of dyes› Compounding of talcum, calcium carbonate and glass fibres› De-gassing of plastic melts› Manufacture of granulates and master batches› Direct extrusion of profiles, cast films or tubes› Extrusion of WPC (wood plastic composites) and PPC(paper plastic composites)02MAS / <strong>NCT</strong>-EXTRUDER

convenient | the operation<strong>NCT</strong>-<strong>Extruder</strong>s by MAS are equipped either with conventionalcontrol technology or an industrial PC In both cases, operation issimple and convenient. The industrial PC has a high-quality visu-al display system with a touch screen, control panel and remotemaintenance function, as well as electrical integration of downstreamequipment such as the granulating head, extrusion tools, calibration,extraction, etc.Extremely compact and robust:<strong>NCT</strong> 55 <strong>Extruder</strong>MAS / <strong>NCT</strong>-EXTRUDER 03

<strong>NCT</strong> - user-friendly technologywith a universal application spectrumcompact | the designLiquid coolingsystemVariabledegasification unitOpening formaterial infeedGenerously-sizedcontrol cabinetSwivel-out barrelConical screws withreplaceable elementsRobusttransfer gearboxEfficient oil/airheat exchangerFrequency-controlledAG driveLow-maintenancevacuum unit<strong>NCT</strong> 55 <strong>Extruder</strong> machine designsimple | the screw changeoverThe mixing and plasticizing capacity is done by changing the screwelements. Due to the conical design, an extremely fast screw changeoveris possible. The downstream equipment in location, the barrelis swivelled out and the screws can be pulled out to the rear withoutfurther tools.04 MAS / <strong>NCT</strong>-EXTRUDER Plasticizing unit

conical | the plasticizing unitPumpingDegasificationMixingFlow restrictionMeltingDrawing inExchangeableshear and mixing partsindividual | the configurationThe screw assembly of the <strong>NCT</strong>-<strong>Extruder</strong> consists of a feeder and an extractorscrew. Each of them is manufactured from one piece and available in a numberof different pitches and number of flights. In between are mixing and shearingparts which can be designed to suit the customer’s specific requirements.The barrel zones are equipped with heating trays and liquid cooling. The threepartbarrel can also be assembled according to needs (with/without degasification,position of degasification openings, etc.).MAS / <strong>NCT</strong>-EXTRUDER 05

High filling level,high throughput rate, high torquesOversized dimensioned back-thrust bearingsperfected | the mechanismThanks to innovative mechanics, <strong>NCT</strong>-<strong>Extruder</strong>s by MAS are particularlyrobust, long-lived and easy to maintain. The conical designof the screw causes low mechanical stress in the screw shaft,even at extremely high torques. The large shaft-centre distances inthe intake enable the use of maximum-sized drive shafts. Theback-thrust bearings are also well-dimensioned. The compact designof the <strong>NCT</strong>-<strong>Extruder</strong> results in a very short overall length.optimised | the performanceThe excellent process engineering characteristics of <strong>NCT</strong>-<strong>Extruder</strong>sare achieved first and foremost by the high disposable volume andhigh coverage of the co-rotating screw shaft. <strong>NCT</strong>-<strong>Extruder</strong>s thushave first-class homogenisation and mixing properties.zone the screws have an exceptionally large diameter ratio Da/Di.High discharge rates can therefore be achieved even at low speedsand high melt pressures at low melt temperatures. Melt pumpsare in most cases unnecessary.robust | the material and the designPremium quality steel, robust design and solid workmanship guaranteehigh availability and a long life time. Barrels and screws aredesigned to be particularly wear-resistant: The barrels are made ofPM steel or case-hardened steel (standard), the screws are temperedand nitrogen hardened (standard). If required, the screws arebuild-up welded with wear resistance alloys.Due to the conical design of the screw assembly the intake volumeis significantly greater than the discharge volume, resulting inan extremely high screw filling level. Furthermore, in the melting06MAS / <strong>NCT</strong>-EXTRUDER

MAS – Your specialistfor plastics recyclingOutput shaft with couplingwell-founded | our expertiseOver 40 years of experience in plastics machinery construction (especiallyin the extrusion sector) and a 30 year history in recyclingare reflected in the development of <strong>NCT</strong>-<strong>Extruder</strong>s by MAS. Our experiencedteam will optimally adapt the components to your processengineering requirements.advantageous | our Technology Centre<strong>NCT</strong>-<strong>Extruder</strong>s by MAS are a highly cost-effective alternative to themixing of additives and fillers in PP, PE, PS, PA and PET, as wellas their degasification. See for yourself! Our Technology Centre isequipped with:› Grinder› Single-shaft shredderprofessional | our serviceExtensive advisory, planning and project management servicesare key elements of the MAS service portfolio – for fast change overof your production system. In addition, the process is backed up bytest runs at the MAS Technology Centre. Our service technicianssupervise the start-up on site and instruct your operating personnel.Following start-up, MAS customer service is on call for prompt,all-round service.› DRD 18 dry cleaner› <strong>NCT</strong> 55 <strong>Extruder</strong>powerful | the range<strong>NCT</strong> 55 90Throughput*) PE 500 kg/h 1,000 kg/hPP 450 kg/h 800 kg/hDrive power 132 kW 280 kW* At a bulk density of approx. 600 g/lMAS / <strong>NCT</strong>-EXTRUDER 07

MAS head offices in Pucking/Upper Austria with adjoining assembly shop and Technology Centre.MAS was founded by Helmuth Schulz.www.querkraft.bizM-A-S Maschinen- und Anlagenbau Schulz GmbHA-4055 Pucking, Hobelweg 1Telefon: 0043/7229/78 999-11Fax: 0043/7229/78 999-10info@mas-austria.comwww.mas-austria.com