Computer-aided design and optimization for pharmaceutical ...

Computer-aided design and optimization for pharmaceutical ...

Computer-aided design and optimization for pharmaceutical ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

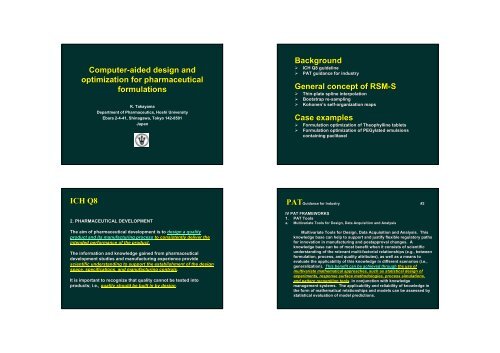

<strong>Computer</strong>-<strong>aided</strong> <strong>design</strong> <strong>and</strong><strong>optimization</strong> <strong>for</strong> <strong>pharmaceutical</strong><strong>for</strong>mulationsK. TakayamaDepartment of Pharmaceutics, Hoshi UniversityEbara 2-4-41, Shinagawa, Tokyo 142-8501JapanBackground‣ ICH ICH Q8 Q8 guideline‣ PAT PAT guidance <strong>for</strong> <strong>for</strong> industryGeneral concept of RSM-S‣ Thin-platespline interpolation‣ Bootstrap re-sampling‣ Kohonen’s self-organization mapsCase examples‣ Formulation <strong>optimization</strong> of of Theophylline tablets‣ Formulation <strong>optimization</strong> of of PEGylated emulsionscontaining paclitaxelICH Q82. PHARMACEUTICAL DEVELOPMENTThe aim of <strong>pharmaceutical</strong> development is to <strong>design</strong> a qualityproduct <strong>and</strong> its manufacturing process to consistently deliver theintended per<strong>for</strong>mance of the product.The in<strong>for</strong>mation <strong>and</strong> knowledge gained from <strong>pharmaceutical</strong>development studies <strong>and</strong> manufacturing experience providescientific underst<strong>and</strong>ing to support the establishment of the <strong>design</strong>space, specifications, <strong>and</strong> manufacturing controls.It is important to recognize that quality cannot be tested intoproducts; i.e., quality should be built in by <strong>design</strong>.PATPATGuidance<strong>for</strong> Industry #2IV PAT FRAMEWORKS1. PAT Toolsa. Multivariate Tools <strong>for</strong> Design, Data Acquisition <strong>and</strong> AnalysisMultivariate Tools <strong>for</strong> Design, Data Acquisition <strong>and</strong> Analysis. Thisknowledge base can help to support <strong>and</strong> justify flexible regulatory ry paths<strong>for</strong> innovation in manufacturing <strong>and</strong> postapproval changes. Aknowledge base can be of most benefit when it consists of scientificificunderst<strong>and</strong>ing of the relevant multi-factorial relationships (e.g., between<strong>for</strong>mulation, process, <strong>and</strong> quality attributes), as well as a means s toevaluate the applicability of this knowledge in different scenarios (i.e.,generalization). This benefit can be achieved through the use ofmultivariate mathematical approaches, such as statistical <strong>design</strong> ofexperiments, response surface methodologies, process simulations,<strong>and</strong> pattern recognition tools, in conjunction with knowledgemanagement systems. The applicability <strong>and</strong> reliability of knowledge inthe <strong>for</strong>m of mathematical relationships <strong>and</strong> models can be assessed d bystatistical evaluation of model predictions.

PATPATGuidance<strong>for</strong> Industry #3IV PAT FRAMEWORKS1. PAT Toolsa. Multivariate Tools <strong>for</strong> Design, Data Acquisition <strong>and</strong> AnalysisMethodological experiments based on statistical principles o<strong>for</strong>thogonality, , reference distribution, <strong>and</strong> r<strong>and</strong>omization, provideeffective means <strong>for</strong> identifying <strong>and</strong> studying the effect <strong>and</strong> interaction ofproduct <strong>and</strong> process variables. Traditional one-factorfactor-at-a-timetimeexperiments do not address interactions among product <strong>and</strong> processvariables.Background‣ ICH ICH Q8 Q8 draft consensus guideline‣ PAT PAT guidance <strong>for</strong> <strong>for</strong> industryGeneral concept of RSM-S‣ Thin-platespline interpolation‣ Bootstrap re-sampling‣ Kohonen’s self-organization mapsCase examples‣ Formulation <strong>optimization</strong> of of Theophylline tablets‣ Formulation <strong>optimization</strong> of of PEGylated emulsionscontaining paclitaxelTrial-<strong>and</strong><strong>and</strong>-error approachFactor Factor BFactor CResponse 1Response 2Response 3SpecificationrequestedOK141NG2NG3NGWhat canI do?Difficulties‣ Relationships between factors <strong>and</strong> responses.‣ Simultaneous <strong>optimization</strong> of several responses.Optimal combination of factors cannot be estimated by a trial-<strong>and</strong><strong>and</strong>-errortesting method.Hey !I’m m here.

<strong>Computer</strong>-<strong>aided</strong> <strong>design</strong> <strong>and</strong> <strong>optimization</strong>Experimental <strong>design</strong>Correlation modelIndividual <strong>optimization</strong>‣ First-order composite <strong>design</strong>‣ Second-order composite <strong>design</strong>‣ Simplex lattice <strong>design</strong>‣ Extreme vertices <strong>design</strong>‣ Linear polynomial equation‣ Quadratic polynomial equation‣ Artificial neural network‣ Multivariate spline interpolation‣ Penalty method‣ Barrier method‣ Augmented Lagr<strong>and</strong>ian method‣ Multiplier methodNon-linear interpolation technique <strong>for</strong>multidimensional data includingexperimental errorsSimultaneous <strong>optimization</strong>‣ Desirability function method‣ Euclidian distance function methodReliability assessment‣ Bootstrap re-sampling‣ Self-organization mapConventional spline interpolationSurface is not natural when the data includesome experimental errors.Thin-plate spline interpolationSmooth surface can be estimated even ifthe data include some experimental errors.Interpolation of observational dataMulti-dimensional data surface incorporating experimental error is interpolated as asum of Green function <strong>and</strong> a linear polynomial equation (from biharmonic spline to thinplatespline using a generalized cross validation (GCV) technique).−1( ) y= α gg⎧dln( d −1),( n = 2)2⎪G( d ) = ⎨lnd , ( n = 4)⎪ 4−n⎩d, ( n ≠ 2, 4)n number of factorsg = G( d ),d =n2∑ ( xij− xik)jk jk jk⎡ y1⎤ ⎡ g11g21Λ g N1⎤ ⎡α1⎤⎢ ⎥ ⎢⎥ ⎢ ⎥⎢y2⎥ = ⎢g12g22Λ g N 2=⎥ = ⎢α2y , g, α ⎥⎢ Μ⎥⎢ Μ Μ Μ Μ⎥⎢ Μ⎥⎢ ⎥ ⎢⎥ ⎢ ⎥⎣ yN⎦ ⎣g1Ng2NΛ g NN ⎦ ⎣αN ⎦i=1Simultaneous <strong>optimization</strong> based on thegeneralized Euclidian distance functionFD 1 (X)SimultaneousoptimaFD 3 (X)FD 2 (X)y ′ = g′α⎡ y′⎡ ′1 ⎤ g11⎢ ⎥ ⎢y′⎢y′2 ⎥ ′ = ⎢g12′ = ,⎢ Μ⎥g ⎢ Μ⎢ ⎥ ⎢⎣y′⎦ ⎣ ′N g1N′ny ′ j = ∑αkG( d′jk ) + p(x1,x2,x3,...,xn)k = 1g′′21 Λ g N1⎤g′′⎥n22 Λ g N 2 ⎥2, g′= ( ′ ) ′ = ∑( − ′jk G d jk , d jk xijxik)Μ Μ Μ ⎥i = 1⎥g′′ ′2NΛ gNN′ ⎦T(X,r,r)) = (Σ[{FDk (X)-FOk (X)}/SDk ] 2 ) 1/2+ r - 1 Σφ i {G i (X)}2 + r - 1 Σ{Hj (X)}2G i(X)) >0 then φ i=1, , else φ i=0Euclidian distanceconstraints

Bootstrap process <strong>for</strong> estimating the accuracy ofan optimal <strong>for</strong>mulationBootstrap samples are generated by sampling with replacement from m the original dataset.The accuracy of bootstrap optimal solutions X * optim, , Y*optimcould be evaluated by their st<strong>and</strong>ard deviations.optimal solutions estimated from bootstrap samplesX * optim Y * optimy**Original dataOptimal solutionIs localy*Bootstrap re-samplingx*X *1 optim , Y*1 optimX *2 optim , Y*2 optimX *B optim , Y*B optimBootstrap re-samplingX *1 , Y *1 X *2 , Y *2 X *B , Y *Bnormal distribution ofbootstrap solutionsx**Optimal solutionIs globaly**X=(X 1 , X 2 ,…, X n )Y=(Y 1 , Y 2 ,…, Y m )bootstrap samplesoriginal datasetx**Risk of local optima involved in the <strong>optimization</strong>process based on bootstrap methodm iOutput layerm i(t+1) = m i(t)) + α i(t)[x(t)-m i(t)]m i1m i2m i3…m inOptimal solutions obtainedby a bootstrap processBootstrap solutions classifiedinto several clustersx 1x 2x 3x nInput layerMixture of global optima <strong>and</strong> local optimain bootstrap solutionsKohonen’s s self-organizingmaps (SOM)T. Kohonen, “Self-Organization <strong>and</strong> Association Memory” Springer Series in In<strong>for</strong>mation Sciences, Vol. . 8, 1984.

Output layerInput vectorX1, X2, … , XnAlgorithm of SOMCompetitive learning of nodes in output layernodeA winner node is defined as the output vector which is the closest to the inputvector, <strong>and</strong> then the neighborhood area is <strong>for</strong>med around the winner node.All nodes entered in the neighborhood area are trained by the learning rule, <strong>and</strong>the size of neighborhood area is reduced as a function of iterative number oftrainings.Background‣ ICH ICH Q8 Q8 draft consensus guideline‣ PAT PAT guidance <strong>for</strong> <strong>for</strong> industryGeneral concept of RSM-S‣ Thin-plate spline interpolation‣ Bootstrap re-sampling‣ Kohonen’s s self-organization mapsCase examples‣ Formulation <strong>optimization</strong> of of Theophylline tablets‣ Formulation <strong>optimization</strong> of of PEGylated emulsionscontaining paclitaxel·Formulation variablesX 1: Mixing ratio of lactose (%)X 2: Mixing ratio of corn starch (%)X 3: Mixing ratio ofmicrocrystalline cellulose (%)·Response variablesY 1: Hardness (kg/cm 2 )Experimetal <strong>design</strong>X 1·Process variablesZ 1: Amount of magnesium stearate (mg)Z 2: Mixing time (min)Y 2: 63.2% Drug released time (min)HybridZ 1 Z 2Estimated (kg/cm 2 )Leave-one-out cross-validation results ofeach response variable252015105Y 1 Hardnessr = 0.986Estimated (min)Y 2 63.2% Drug released time25020015010050r = 0.967X 2 X 3Simplex lattice <strong>design</strong>Central composite sphericalsecond- order experimental <strong>design</strong>00 5 10 15 20 25Experimental (kg/cm 2 )00 50 100 150 200 250Experimental (min)

Simultaneous optimal solutionestimated by RSM-SX 1 (%)20.2Formulation factors <strong>and</strong> process variablesX 2 (%)35.6X 3 (%)44.2Z 1 (mg)2.4Z 2 (min)11.7FrequencyHistograms <strong>for</strong> optimal factorsestimated by bootstrap re-samplingX1 (%)2001801601401201008060402000 10 20 30 4025020015010050X2 (%) X3 (%)030 35 40 45 50 5520018016014012010080604020035 40 45 50 55 60Response variablesY 1 (kg/cm 2 ) Y 2 (min)11.26.8The original samples consist of 63 <strong>for</strong>mulation data.FrequencyZ1 (mg)2502001501005001.5 1.8 2.1 2.4 2.7 3.0Z2 (min)45040035030025020015010050010.0 12.5 15.0 17.5 20.0The bootstrap re-sampling was repeated 1000 times.Histograms <strong>for</strong> optimal responsevariables estimated by bootstrapre-samplingSOM clusters of bootstrap optimalsolutionsSOM (1000 nodes)δ (%)FrequencyY1 (kg/cm 2 )30025020015010050010 11 12 13Frequency200180160140120100806040200Y2 (min)4 6 8 10 12C 3C 1C 2 C 4C 6C 7C 580604020C 70C 5X 1 X 23X 3 Z 1 Z 2 Y1 C 1CY2The bootstrap re-sampling was repeated 1000 times.Optimal solution estimated from original sample is located in Cluster 1.

95% Confidence interval <strong>for</strong> optimalsolution estimated by RSM-S(Percentile method)Experimental <strong>design</strong>Number ofnodesX 1(%)X 2(%)500 7501000lower upper lower upper lower upper13.9 22.4 14.6 22.4 14.4 24.534.4 38.1 34.2 38.0 33.1 38.3Factorsx 1 : amount of soybean oilx 2 : amount of PEG-DSPEx 3 : amount of polysorbate 80PEG-DSPEX 3(%)Z 1(mg)Z 2(min)42.82.1011.448.62.4913.343.22.2011.447.92.4612.642.32.0711.347.92.4613.5Responsesy 1 : entrapment efficiencyy 2 : particle sizeSoybean oilY 1(kg/cm 2 )Y 2(min)10.86.511.48.310.86.711.48.610.66.711.48.5Number of dataset = 48Polysorbate 80Leave-oneone-out out cross-validation results ofentrapment efficiency <strong>and</strong> particle sizeby using thin-plate splineEntrapment efficiencyParticle sizeResponse surfaces of entrapment efficiency <strong>and</strong>particle size as a function of x 1 <strong>and</strong> x 2 at x 3 =36 mg/mLEntrapment efficiency (%)Particle size (nm)100r = 0.963 350r = 0.990Predicted (%)90Predicted (nm)3253002758080 90100250250 275 300 325 350Experimental (%)Experimental (nm)

Histograms <strong>for</strong> optimal factors estimated bybootstrap methodn=300 n=1000Simultaneous optimaEuclidian distance surfacesgenerated as a function ofx 1 , x 2 <strong>and</strong> x 3Self-organizing maps of factors in BSoptimal solutionsx1: : soybean oil x2: : PEG-DSPEx3: : polysorbate 80Statistics <strong>for</strong> optimal factors <strong>and</strong> responsesestimated from Cluster 1Cluster 1Cluster 2Cluster 1Cluster 2Cluster 1Cluster 2X 1(g/L)X 2(g/L)X 3(g/L)Y 1(%)Y 2(nm)Original data 5.75 2.32 44.6 97.3 269Cluster 1Cluster 3 Cluster 3Cluster 3Cluster 2Cluster 3SOM clusters in BS solutionsOptimal solution estimatedfrom original datais located in Cluster 1.BootstrapMeanBootstrapSDBootstrapδ (%)BootstrapCV (%)5.88 2.27 45.3 98.0 2710.10 0.05 0.6 0.5 12.21 2.20 2.21 0.71 0.591.70 1.98 1.35 0.51 0.44

ConclusionsA response surface method incorporating a thin-platespline interpolation can be applied to the <strong>design</strong> <strong>and</strong><strong>optimization</strong> of <strong>pharmaceutical</strong> product <strong>for</strong>mulations.Bootstrap re-sampling <strong>and</strong> self-organizing maps areuseful means evaluating a reliability of optimal<strong>for</strong>mulations.Sensitivity analysis <strong>and</strong> setup of <strong>design</strong> space weresuccessfully accomplished by using a Monte Carlosimulation techniques.AcknowledgementsHoshi UniversityDr. Y. OnukiMr. K. OhyamaDr. Y. MaitaniPekin UniversityDr. T. FunYamatake CorporationMr. C. KasedaA novel method to setupthe <strong>design</strong> spacex 1y 1Thank you very much <strong>for</strong> your attention !x 2RSM-Sy 2x ny mOptimal x i valuesOptimal y j values

A novel method to setup the <strong>design</strong> spaceSuper spherical solution vectors which satisfyspecifications of response variablesLeave-oneone-factor-out out method(Simulated gene knockout method)Optimal solutions estimated from bootstrap samplesWild typeKnockoutx3rSolution vectorssatisfiedspecificationsof responsevariablesY * optim, originalY * optim, LOFOBootstrap samplingDifference of mean <strong>and</strong> SD betweenY * optim, original <strong>and</strong> Y * optim, LOFO couldrepresent the statistical importance ofrelevant factor.CentroidX=(X 1 , X 2 ,…, X n )Y=(Y 1 , Y 2 ,…, Y m )X=(X 1 , X 2 ,…X i ,…, X n )Y=(Y 1 , Y 2 ,…, Y m )X ix2x1Original datasetLOFO datasetLeave-one-factor-out fromthe original dataset.Case studyPowder properties of theophylline powder <strong>for</strong>mulations·Formulation factorsX 1: mixing ratio of lactoseX 2: mixing ratio of corn starchX 3: mixing ratio of microcrystalline cellulose·Response variablesY 1: angle of reposeY 3: degree of cohesionExperimental <strong>design</strong>X 1Y 2: compressibility ratioY 4: dispersion ratio·Process variablesZ 1: amount of magnesium stearateZ 2: mixing timeCase studyFormula <strong>optimization</strong> of ketoprofen hydrogel using RSM-SFormulation factorsX 1: 1-O-ethyl1ethyl-3-n-butylcyclohexanol(OEBC) (%)Response variablesY 1: Penetration rate (Rp) (µg/h)(Y 2: Total irritation score (TIS)X 2: Diisopropyl adipate (DIA) (%)X 3: Isopropanol (IPA) (%)Simultaneous optimal solutionFormulation factorsOEBC(%)DIA(%)IPA(%)1.264.8731.7Z 1Z 2Response variablesRp(µg/h)TISX 2 X 3Simplex lattice <strong>design</strong>Central composite sphericalsecond- order experimental <strong>design</strong>341.64.17

Design space <strong>for</strong> ketoprofen hydrogelsSpecification of response variables: Rp ≥ 300µg/h <strong>and</strong> TIS ≤ 5.0Design space of<strong>for</strong>mulation factorsOEBC (%) : 1.21 – 1.32DIA (%) : 4.76 – 5.00IPA (%) : 30.9 – 32.4Background‣ ICH ICH Q8 Q8 draft consensus guideline‣ PAT PAT guidance <strong>for</strong> <strong>for</strong> industryGeneral concept of RSM-S‣ Thin-plate spline interpolation‣ Bootstrap re-sampling‣ Kohonen’s s self-organization mapsCase examples‣ Formulation <strong>optimization</strong> of of Theophylline tablets‣ Formulation <strong>optimization</strong> of of PEGylated emulsionscontaining paclitaxelResponse surfaces generated by thin-plate spline as afunction of smoothing parameter (λ)(actual surfacewith λ too largeFactor levels predicted as an optimal conditionFactorQPE a) ANN b) MVS c)x 1 : amount of soybean oil (mg/mL) 5.60 5.52 5.75x 2 : amount of PEG-DSPE (mg/mL) 2.26 2.18 2.32x 3 : amount of polysorbate 80 (mg/mL) 42.5 35.9 44.6a) Predicted by the quadratic polynomial equation.b) Predicted by the artificial neural network.c) Predicted by the multivariate spline interpolation.with λ too smallwith λ estimated by GCVResponse levels predicted as an optimal conditionResponseQPEANNMVSy 1 : entrapment efficiency (%)a)95.9 101 97.3y 2 : particle size (nm) 265 262 269a) The amount of paclitaxel initially loaded was fixed to be 0.6 mg/mL. mG. Wahba, Spline Models <strong>for</strong> Observational Data,Siam, Philadelphia, Pennsylvania, pp48-50, 1990.

Bootstrap process <strong>for</strong> estimating the accuracy ofan optimal <strong>for</strong>mulationBootstrap samples are generated by sampling with replacement from m the original dataset.The accuracy of bootstrap optimal solutions X * optim, Y*optim could be evaluated by their st<strong>and</strong>ard deviations.optimal solutions estimated from bootstrap samplesX *1 optim , Y*1 optimX *2 optim , Y*2 optimX *1 , Y *1 X *2 , Y *2 X *B , Y *BX=(X 1 , X 2 ,…, X n )Y=(Y 1 , Y 2 ,…, Y m )X *B optim , Y*B optimX * optimY * optimnormal distribution ofbootstrap solutionsbootstrap samplesoriginal datasetFrequencyFrequencyFrequency distribution of bootstrapoptimal responses on the LOFOY 11.8Originalbootstrap1.5mean1.246.25°0.90.60.30FrequencyY 21.2Originalbootstrapmean0.930.64%0.60.3044 45 46 47 4826 28 30 32 34Angle of reposeCompressibility ratioY 3Y 41.2OriginalOriginal0.25bootstrapbootstrapmeanmean0.20.97.2336.2%0.150.60.10.30.050023 28 33 38 43 485 6 7 8 9 10 11FrequencyDegree of cohesionDispersion ratioOriginalLeave-X1-outLeave-X2-outLeave-X3-outLeave-Z1-outLeave-Z2-outBeyond next hump !!!dataNESIA<strong>design</strong> Navigator using Experimental data<strong>and</strong> Spline Interpolation AlgorithmIndex of trueness <strong>for</strong> optimal solutionsF B m−. Fδ (%) = × 100F B.mF optimal solution derived from original sampleF B.m mean of optimal solutions derived from bootstrap samplesIndex of reproducibility <strong>for</strong> optimal solutionsSDBCV =B(%) × 100FB.mSD B St<strong>and</strong>ard deviation of optimal solutions derived frombootstrap samples

AlgorithmBasic concept of biharmonic spline interpolation is a boundary element method. Greenfunctions of the biharmonic operator are used <strong>for</strong> minimum curvature interpolation ofmulti-dimensional data points.−1( ) y= α gg⎡ y1⎤ ⎡ g11g Λ g ⎤ ⎡α1⎤21N1⎢ ⎥ ⎢⎥ ⎢ ⎥⎢y2⎥ = ⎢g12g22Λ g N 2=⎥ = ⎢α2y , g, α ⎥⎢ Μ⎥⎢ Μ Μ Μ Μ⎥⎢ Μ⎥G( d⎢ ⎥ ⎢⎥′ ′ ′⎢y′2′ ⎥ ⎢g12g 22 Λ g N 2′⎥ ′ ′ ′)⎢ ⎥⎣ yN⎦⎢⎣g1g Λ g⎥⎦⎢ ⎥⎣αN ⎦N 2NNNg = G( d ),d =n2∑ ( xij− xik)njk jk jki=1y ′ = g′α⎡ y′1 ⎤ ⎡ g′11 g′21 Λ g′N 1 ⎤= ,⎢ Μ⎥⎢ ⎥⎣ y′N ⎦=⎢ Μ⎢⎣g′1N′Μ Μ, gΜ ⎥= G jkg′2 Λ g′NN⎥⎦N ′′⎧dln( d −1),( n = 2)2⎪= ⎨lnd , ( n = 4)⎪ 4−n⎩d, ( n ≠ 2, 4) number of factors( d jk),d =n2∑ ( x − ′ ij xik)jki=1Statistics of BS optimal solutionsin SOM clustersδ (%)2520151050Trueness (δ)(Reproducibility (CV(B )x 1 x 2 x 3BS solutionsy 1 y 2C3C2C1SOM SOM clusters clustersCV B(%)100806040200x 1 C3x 2x C23y 1C1y 2BS solutionsSOM SOM clusters clusters