DeltaSol BS Plus - Ika

DeltaSol BS Plus - Ika

DeltaSol BS Plus - Ika

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

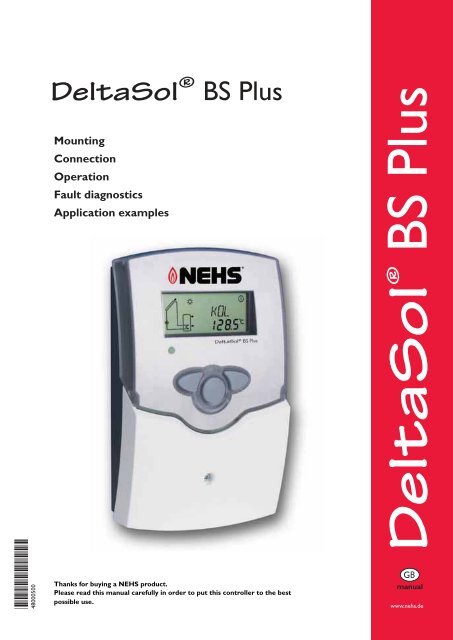

*48000500*48000500<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>MountingConnectionOperationFault diagnosticsApplication examplesThanks for buying a NEHS product.Please read this manual carefully in order to put this controller to the bestpossible use.<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>Bmanualwww.nehs.de

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>ContentsImprint .................................................................................2Safety regulations ................................................................2Technical data and overview of functions ........................31. Installation .............................................................41.1 Mounting .................................................................................. 41.2 Electrical Connection ........................................................... 41.2.1 Data communication / Bus .................................................. 51.2.2 Standard solar system ........................................................... 51.2.3 Solar system and heat exchange ........................................ 61.2.4 Solar system and afterheating ............................................. 61.2.5 Solar system and store charge in layers ........................... 71.2.6 2-store-solar system valve logic ......................................... 71.2.7 2-store-Solar system pump logic ........................................ 81.2.8 Solar system with 2 collectors ........................................... 81.2.9 Solar system afterheating by solid fuel boiler.................. 91.2.10 Solar system with heating circuit return flow incr.......... 92. Opearation and function ....................................102.1 Adjustment buttons ............................................................102.2 System monitoring display .................................................102.2.1 Channel indication ...............................................................102.2.2 Tool bar ..................................................................................102.2.3 System screen .......................................................................112.3 Blinking codes .......................................................................112.3.1 System-Screen Blinking codes ...........................................112.3.2 LED blinking codes ..............................................................113. Primary commissioning ......................................124. Control parameter and display channels ..........134.1 Channel overview ................................................................134.1.1-6 Indication channels ..............................................................154.1.6-21 Adjustment channels ...........................................................165. Tips for fault localization ....................................215.1 Various ..................................................................226. Accessory .............................................................24Security advicePlease pay attention to the following security advice in orderto avoid danger and damage to people and property.InstructionsAttention should be paid- to the statutory provisions for prevention of industrialaccidents,- to the statutory provisions for environmental protection,- to the Health and Safety at Work Act 1974- to Part P of the Building Regulations 2005- to <strong>BS</strong>7671 Requirements for electrical installations andrelevant safety regulations of DIN, EN, DVGW, TRGI, TRFand VDE.This instruction is exclusively addressed to authorisedskilled personnel.- Only qualified electricians should carry out electricalworks.-Initial installation should be effected by named qualifiedpersonnelDeclaration of conformityWe, NEHS Produktions & Vertriebs GmbH, declare underour sole responsibility that our product <strong>DeltaSol</strong> <strong>BS</strong> Procomplies with the following standards:EN 55 014-1EN 60 730-1According to the regulations of the above directives, theproduct is labelled with :89/336/EWG73/ 23/EWG© NEHS_07333_deltasol_bs_plus.mon.indd| 2

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong> Pt1000 pump speed control ® controlled) of the system by Service Cen ter; Software is posible simple handling and compact dimensions, easyto installScope of delivery:1 x <strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>1 x accessory bag1 x spare fuse T4A2 x screws and dowels4 x strain relief and screws1 x condenser 4,7 nFAdditionally enclosed in the full kit:2 x sensor FKP62 x sensor FRP6Technical data© NEHS_07333_deltasol_bs_plus.mon.inddplastic, PC-A<strong>BS</strong> and PMMAProtection type: IP 20 / DIN 40050Ambient temp.: 0 ... 40 °CSize: 172 x 110 x 46 mmMounting: wall mounting, mountinginto patch-panels is possibleDisplay: System screen for systemvisualisation, 16-segment display,7-segment display, 8 symbols for systemstatus and operating control lampOperation: by 3 pushbuttons in thefront of the housingFunctions: Differential temperaturecontroller with optional add-on systemfunctions. Func ti on con trol accordingto BAW-standards, operating hourscounter for solar pump, tube collectorspecial function, pump speed control,thermostat function and heat quantitybalancing.Inputs: for 4 temperature sensorsPt1000Outputs: 2 semi-conductor relays VBus ®Power supply:220 ... 240 V~Switching capacities:1 (1) A 220 ... 240 V~(semiconductor-relay)1 (1) A 220 ... 240 V~(semiconductor-relay)3 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>1. Installation Warning!1.1 Mounting opening the housing.displaycoverpushbuttonThis unit must only be located internally. It is not suitablefor installation in hazardous locations and should not besited near to any electromagnetic field. The controller mustadditionally be equipped with an all-polar gap of at least 3 mmor with a gap according to the valid installaton regulations,e.g. LS-switches or fuses. Please ensure sensor cables andac power supply are separatedcable conduits with strainrelieffasteningcan fuse 4A1. Unscrew the cross-head screw of the cover and removeit from the housing.2. Mark the upper fastening point on the subsurfaceand premount the enclosed dowel and screw.3. Mount the housing to the upper fastening point and markthe lower fastening point on the subsurface (pitch of hole130 mm), afterwards set the lower dowel.4. Mount the housing to the top and fix it with the lower.fastening screw..fixing1.2 Electrical connection| 4Temp. SensorPt1000S1 S2 S31 2 3 4 5 6Sensor clampS4 VBus7 8 910 12 13 14VBusground clampDangerous voltage on contact!fuseT4A220 ... 240 V~R1 1 (1) A ( 220 ... 240) V~R2 1 (1) A (220 ... 240) V~N R2 N R1 N L15 16 17 18 19 20consumer clampsnet clampsPlease note:The relays are semi-conductor-relays for pump speed control - they needa minimum load of 20 W (power consumption of the consumer) forfaultless function. When connecting auxiliary relays, motor valves, etc. areindividually to the condenser which is enclosed in the mounting material,must be connected parallely to the relevant relay output.Attention: for connection of auxiliary relays or valves, the minimum pumpspeed must be adjusted to 100 %.Electrostatic discharge can lead to damages of electroniccomponents!The power supply to the controller must only be made by anexternal power supply switch (last step of installation!) andthe line voltage must be 220 ... 240 Volt (50...60 Hz). Flexiblelines are to be fixed at the housing by enclosed strain reliefsupports and screws.The controller is equipped with 2 standard relays, to whichthe consumers e.g. pumps, valves etc. can be connected: 18 = conductor R117 = neutral conductor N13 = ground clamp 16 = conductor R215 = neutral conductor N14 = ground clampThe temperature sensors (S1 up to S4) will beconnected to the following terminals independently of thepolarity:1 / 2 = Sensor 1 (e.g. Sensor collector 1)3 / 4 = Sensor 2 (e.g. Sensor store 1)5 / 6 = Sensor 3 (e.g. Sensor collector 2)7 / 8 = Sensor 4 (e.g. Sensor store 2)The power supply is effected to the clamps:19 = neutral conductor N20 = conductor L12 = ground clamp© NEHS_07333_deltasol_bs_plus.mon.indd

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong> The controller comes with a VBus ® for data commmunicationand energy supply of external modules. Theconnection is effected with optional polarity at the clampsmarked with„VBus“. Via this data Bus you can install one ormore VBus ® modules, e.g.:VBusconnection clamps Additionaly, the controller can be connected to the PC withthe help of a RS-COM adapter. With the SERVICE CEN -TER SOFTWARE (R C S) the controller parameterscan be changed, measurements can be read out, processedand visualised. The software enables an easy function controland adjustment of the system.1.2.2 Allocation of clamps for system 1 Standard solar system with 1 store, 1 pump and 3sensors. Sensor S4 / TRF can optionally be used for heatquantity balancing.Arr 1S1© NEHS_07333_deltasol_bs_plus.mon.inddR1S4 / TRLS3S2SymbolS1S2S3S4 / TRLR1collector sensorlower store sensorupper store sensor(optional)sensor for heat quantitymeasurement (optional)solar pump5 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>1.2.3 Allocation of clamps for system 2 Solar system and heat exchange of existing storewith 1 store, 4 sensors and 2 pumps.Arr 2S1R1Store 1S3Store 2 Symbol S1 collector sensorS2 lower store sensorS3 upper store sensorS2S4(optional)S4 store sensor 2R2R1solar pumpR2 pump for heat exchange1.2.4 Allocation of clamps for system 3 with 1 store, 3 sensorsand after-heating. Sensor S4 / TRF can optionally be used forheat quantity balancing.Arr 3S1R1S4 / TRLS2S3R2SymbolS1S2S3S4/TRFR1R2collector sensorlower store sensorupper store sensor(optional)sensor for heat quantitybalancing (optional)solar pumppump for heat exchange© NEHS_07333_deltasol_bs_plus.mon.indd| 6

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>1.2.5 Allocation of clamps for system 4Solar system and store charge in layers with 1 store,3 sensors, 1 solar pump and 3-way-valve for store chargein layers. Sensor S4 / TRF can optionally be used for heatquantity balancing.Arr 4S1R1S4 / TRLR2S3S2SymbolS1S2S3S4/TRFR1R2collector sensorlower store sensorupper store sensor(optional)sensor for heat quantitybalancing (optional)solar pump3-way-valve1.2.6 Allocation of clamps for system 5 with 2 stores, 3sensors, 1 solar pump and 1 3-way-valve. Sensor S4 / TRFcan optionally be used for heat quantity balancing.Arr 5S1R2R1© NEHS_07333_deltasol_bs_plus.mon.inddS4 / TRLStore 1 Store 2S2S3Symbol S1 collector sensorS2 store sensor 1S3 store sensor 2S4/TRF sensor for heat quantitybalancing (optional)R1solar pumpR23-way-valve7 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>1.2.6 Allocation of clamps for system 6 with 2 stores, 3sensors and 2 solar pumps.Arr 6S1S4 / TRLR1R2Store 1 Store 2S2S3Symbol S1 collector sensorS2 store sensor 1S3 store sensor 2S4 measuring sensor(optional)R1solar pumpR23-way-valve1.2.7 Connection of system 7 , 1 store,3 sensors and 2 solar pumps.Arr 7S1S3R1R2S2Symbol S1 collector sensorS2 store sensor 1S3 collector sensor 2S4 measuring sensor(optional)R1 solar pump collector 1R2 solar pump collector 2© NEHS_07333_deltasol_bs_plus.mon.indd| 8

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>1.2.8 Connection of system 8 with 1 store, 4 sensors, 1 solar pump and 1 pump for afterheating.Arr 8S1R1S2S3R2S4SymbolS1S2S3S4R1R2collector sensorlower store sensorupper store sensorsensor for solid fuelboilersolar pumppump for solid hot fuelboiler Solar system and heating circuit reverse raisingwith 1 store, 4 sensors, 1 solar pump and 1 3-way-valve forheating circuit reverse raising.Arr 9S1R1© NEHS_07333_deltasol_bs_plus.mon.inddS3S2S4R2SymbolS1S2S3S4R1R2collector sensorlower store sensorupper store sensorheating circuit returnsolar pump3-way-valve |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>2. Opeartion and function2.1 Pushbuttons for adjustmentThe controller is operated by 3 pushbuttons below thedisplay. The forward-key (1) is used for scrolling forwardthrough the indication menu or to increase the adjustmentvalues. The backwards-key (2) is accordingly used for thereverse function.backwardforward231For adjustment of last indication channel, keep button 1pressed for 3 seconds. If an adjustment value is shown onthe display, SET is indicated. In this case you can press thekey „Set“ (3) in order to change into input mode.SET(selection / adjustment mode)Select a channel by keys 1 and 2Shortly press key 3, so that SET is blinking.Adjust the value by keys 1 and 2Shortly press key 3, so that SET permanently appears,the adjusted value is now saved.2.2 System monitoring displayThe system monitoring display consists of 3 blocks: indication of the channel, tool bar and system screen(active system scheme).Full Monitoring-Display2.2.1 Channel indication2.2.2 Tool barindication channel onlyThe indication channel consists of two lines. The upperline is an alphanumeric 16-segment indication in which mainlythe channel names / menu items are shown. In the lower7-segment indication, the channel values and the adjustmentparameter are indicated.Temperatures and temperature differences are indicatedin or .The additional symbols of the tool bar indicate the currentsystem status.tool bar onlySymbol normal blinkendrelay 1 activerelay 2 activemaximum store limitationactive / maximum storetemperature exceededoption antifreeze functionactive+ sensor defectcollector cooling function activerecooling function activecollector minimum limitationactive antifreeze functionactivecollector security shutdownactive or store securtiy shutdownactive+ manual operation activeSET-mode© NEHS_07333_deltasol_bs_plus.mon.indd| 10

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>2.2.3 System screenSystem Screen onlyThe system screen (active system scheme) shows theschemes selected on the controller. It consists of severalsystem component symbols, which are - depending on thecurrent status of the system - either flashing, permanentlyshown or hidden.Sensorsupper sensor storeCollector 2Heating circuitCollector 1ValvePumpsValveSensorAdditional symbol foroperation of the burnerStore heat-exchangerStoreStore 2 or afterheating (withan additional symbol)Collectorswith collector sensorStores 1 and 2 with heatexchangerThe flow direction or thecurrent breaking capacityis always shown.Temperature sensor PumpAfterheatingwith burner symbol© NEHS_07333_deltasol_bs_plus.mon.indd 2.3.1 System screen blinking codes2.3.2 LED blinking codes Pumps are blinking during starting phase Sensors are blinking if the respective sensor-indicationchannel is selected. Sensors are quickly blinking in case of sensor defect. Burner symbol is blinking if after-heating is activatedConstantly green: everything all rightRed/green blinking: initialisation phasemanual operationRed blinking: sensor defect(sensor symbol is quickly blinking)11 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>3. Primary commissioningFor primary commissioning the system scheme has to be adjusted firstoperating controllampbackward231forward1. AC power supply must be activated at first. The controllerpasses an initialisation phase during which the operatingcontrol lamp is blinking red and green. After having finishedthe initialisation, the controller is in automatic operationwith factory settings. The preadjusted system scheme isArr 1.2. Clock time adjustment in channel TIME. By pressing thebutton once you can adjust hours, pressing itonce again the minutes.The time can be adjusted by buttons1 and 2 and saved by pressing the button.3. - select adjustment channel Arr- change into -mode (see 2.1)SET(selection / adjustment mode)- adjustment are saved by pressing buttonNow the controller is ready for operation and should enablean optimum operation of the solar system with the factorysettings.Arr 1 Arr 2System survey:Arr 1 : standard solar systemArr 2 : solar system with heat exchangeArr 3 : solar system with after-heatingArr 3 Arr 4Arr 4 : solar system with store charge in layersArr 5 : 2-store solar system with valve logicArr 6 : 2-store solar system with pump logicArr 7 : solar system with 2 collectors and 1 storeArr 5 Arr 6Arr 8 : solar system with after-heating by solid hot fuelboilersArr 9 : solar system with heating circuit reverse raisingArr 7 Arr 8Arr 9© NEHS_07333_deltasol_bs_plus.mon.indd| 12

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>4. Control parameter and indication channelsLegend:xCorresponding channel is available.x*Corresponding channel is available if the appropriate optionis activated.Please note:S3 and S4 are only indicated in case of sensors connectedCorresponding channel is only available if the option heatquantity measurement is activated (OHQM).Corresponding channel is only available if the option heatquantity measurement is deactivated (OHQM).MEDTThe channel antifreeze content (MED%) is only shownif Adjustments concerning the antifreezecontent will only make sense if the antifreeze is used in thesolar circuit.© NEHS_07333_deltasol_bs_plus.mon.inddchannel1 2 3 4Arr5 6 7 8 9specificationpageCOL x x x x x x x x Temperature Collector 1 15COL 1 x Temperature Collector 1 15TST x x Temperature Store 1 15TSTL x x x x Temperature Store 1 below 15TST1 x x x Temperature Store 1 below 15TSTU x x x x x Temperature Store 1 at the top 15TST2 x x x Temperature Store 2 below 15TFSB x Temperature solid hot fuel boiler 15TRET x Temperature heating circuit 15COL2 x Temperature collector 2 15S3 x Temperature sensor 3 15TRF Temperature return sensor 15S4 x x Temperature sensor 4 15n % x x x x Pump speed relay 1 15n1 % x x x x x Pump speed relay 1 15n2 % x x x x Pump speed relay 2 15hP x x x x Operating hours relay 1 16h P1 x x x x x Operating hours relay 1 16h P2 x x x x x Operating hours relay 2 16kWh Heat quantity kWh 16MWh Heat quantity MWh 16time x time 15Arr 1-9 System 12DT O x x x x x x Switch-on temperature diff 17DT1O x x x Switch-on temperature diff 1 17DT F x x x x x x Switch-off temperature diff 1 17DT S x x x x x x Nominal temperature difference 17RIS x x x x x x Increase 17DT1F x x x Switch-off temperature difference 17DT1S x x x Rise 1 17RIS1 x x x Maximum temperature store 1 17S MX x x x x x x Maximum temperature store 1 17S1 MX x x x Maximum temperature store 1 17DT2O x x x Switch-on temperature difference 2 17DT2F x x x Switch-off temperature difference 2 17DT2S x x x nominal temperature difference 2 17RIS2 x x x Increase 2 17S2MX x x x Maximum temperature store 2 17EM x x x x x x x x emergency temperature collector 1 18EM1 x emergency temperature collector 1 1813 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>channel1 2 3 4Arr5 6 7 8 9specificationpageOCX x x x x x x x x option collector cooling collector 1 18OCX1 x option collector cooling collector 1 18CMX x* x* x* x* x* x* x* x* maximum temperature collector 1 18CMX1 x* maximum temperature collector 1 18OCN x x x x x x x x option minimum limitation collector 1 18OCN1 x option minimum limitation collector 1 18CMN x* x* x* x* x* x* x* x* minimun temperature collector 1 18CMN1 x* minimun temperature collector 1 18OCF x x x x x x x x option antifreeze collector 1 18OCF1 x option antifreeze collector 1 18CFR x* x* x* x* x* x* x* x* antifreeze temperature collector 1 18CFR1 x* antifreeze temperature collector 1 18NOT2 x emergency temperature collector 2 18OCX2 x option collector cooling collector 2 18CMX2 x* maximum temperature collector 2 18OCN2 x option miminum limitation collector 2 18CMN2 x* minium temperature collector 2 18OCF2 x option antifreeze collector 2 18CFR2 x* antifreeze temperature collector 2 18PRIO x x x priority 19tST x x x stop time 19tRUN x x x Ciruclation time 19OREC x x x x x x x x x option reccoling 19O TC x x x x x x x x x option tube collector 19DT3O x x switch-on temperature difference 3 17DT3F x x switch-off temperature difference 3 17DT3S x x nominal temperature T3 17RIS3 x x Rise T3 17MX3O x x switch-on treshold for maximumtemp. 17MX3F x x switch-off treshold for maximum temp. 17MN3O x x switch-on treshold for minimum temp. 17MN3F x x switch-off treshold for minimum temp. 17AH O x switch-on temp. for thermostat 1 20AH F x switch-off temp. for thermostat 1 20t1on x Switch on time 1 thermostat 20t1off x Switch off time 1 thermostat 20t2on x Switch on time 2 thermostat 20t2off x Switch off time 2 thermostat 20t3on x Switch on time 3 thermostat 20t3off x Switch off time 3 thermostat 20OHQM x x x x FMAX maximum flowMEDT antifreeze typeMED% MEDT MEDT MEDT MEDT antifreeze content 20nMN x x x x minimum pump speed relay 1 20n1MN x x x x x minimum pump speed relay 1 20n2MN x x x x minimum pump speed relay 2 20HND1 x x x x x x x x x manual operation relay 1 20HND2 x x x x x x x x x manual operation relay 2 20LANG x x x x x x x x x language 20PROG XX.XX program numberVERS X.XX version number© NEHS_07333_deltasol_bs_plus.mon.indd| 14

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>4.1.1 Indicataion of collector temperaturesCOL, COL1, COL2:Collector temperaturedisplay range: -40 ... +250 °CShows the current collector temperature. COL : collector temperature (1-collector-system) COL1 : collector temperature 1 COL2 : collector temperature 24.1.2 Indication of store temperaturesTST1, TST2:Store temperaturesDisplay range: -40 ... +250 °CShows the current store temperature. TST : store temperature (1-store-system) TSTL : store temperature lower TSTU : store temperature above TST1 : temperature store 1 TST2 : temperature store 24.1.3 Indication of sensor 3 and sensor 4S3, S4:S3, S4:Sensor temperaturesDisplay range: -40 ... +250 °CShows the current temperature of the corresponding additionalsensor (without control function). S3 : temperature sensor 3 S4 : temperature sensor 4Please note:S3 and S4 are only shown if the temperature sensors areconnected.4.1.4 Indication of other temperaturesother mea sured tempe raturesDisplay range: -40 ... +250 °CShows the current temperature of the correspondingsensor. TFSB : temperature solid fuel boiler TRET : temperature heating reverse raising TRF : temperature return flow4.1.5 Indication of current pump speedn %, n1 %, n2 %:current pump speedDisplay range: 30 ... 100 %4.1.6 TimeShows the current pump speed of the correspondingpump. n % : current pump speed (1-pump-system) n1 % : current pump speed pump 1 n2 % : current pump speed pump 2© NEHS_07333_deltasol_bs_plus.mon.inddIn this channel the current time is indicated.By pressing button for 2 seconds the hours, by pressingit again the minutes are displayed blinking. The time canbe set by buttons 1 and 2 and saved by pressing thebutton.15 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>4.1.6 Operating hours counterh P / h P1 / h P2:operating hours counterIndication channelThe operating hours counter adds up the solar operatinghours of the respective relay (h P / h P1 / hP2). Full hoursare shown on the display.After the operating hours are added up, they can be reset.As soon as one operating hours channel is selected, symbolis permanently shown on the display. The button SET(3) must pressed for approx. 2 seconds in order to get backinto the RESET-mode of the counter. The display-symbolis blinking and the operating hours will be set to 0. Inorder to finish the RESET-procedure, the button mustbe pressed in order to confirm the data.In order to interrupt the RESET-procedure, don’t press anybutton for about 5 seconds. The controller returns automaticallyinto the indication mode. :Heat quantity measurementAdjustment range: OFF ... ONFactory setting: OFFFMAX: Volume flow inl/minAdjustment range 0 ... 20in steps of 0,1Factory setting 6,0MEDT: antifreezeAdjustment range 0 ... 3Factory setting 1MED%: Concentration ofantifreeze in (Vol-) %MED% is blinded out byMEDT 0 and 3.Adjustement range 20 ... 70Factory setting 45kWh/MWh:Heat quantityin kWh / MWhDisplay channel| 16A heat quantity balancing is possible for the basic systems(Arr) 1, 3, 4 and 5 in conjunction with a flowmeter. Youjust have to activate the option heat quantity balancing inchannel The volume flow readable at the flowmeter (l/min) mustbe adjusted in the channel FMAX. Antifreeze type andconcentration of the heat transfer medium are indicated onchannels MEDT and MED%.Type of antifreeze:0 : water1 : propylene glycol2 : ethylene glycol3 : Tyfocor ® LS / G-LSThe heat quantity transported is measured by the indicationof the volume flow and the reference sensor of feedflow S1 and return flow T-. It is shown in kWh-parts in theindication channel kWh and in MWh-parts in the indicationchannel MWh. The sum of both channels form the totalheat output.The heat quantity added up can be reset. As soon as one ofthe display channels of the heat quantity is selected, symbolis permanently shown on the display. The SET (3) buttonmust pressed for approx. 2 seconds in order to get back intothe RESET-mode of the counter. The display-symbol isblinking and the value for heat quantity will be set to 0. Inorder to finish the RESET-procedure, the button mustbe pressed in order to confirm the data.In order to interrupt the RESET-procedure, no buttonshould be pressed for about 5 seconds. The controller returnsautomatically into the indicaton mode.© NEHS_07333_deltasol_bs_plus.mon.indd

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>4.1.8 DT E / DT1E / DT2E /DT3E:Switch on temperature diff.Adjustment range 1,0 ... 20,0 KFactory setting 6.0DT A / DT1A / DT2A /DT3A:Switch-off temperature diff.Adjustment range 0,5 ... 19,5 KPlease note: Switch-on temperature difference DO mustbe at least 1 K higher than the switch-off tempe raturedifferenceDF.DT S / DT1S / DT2S /DT3S:Nominal temperature differenceAdjustment range 1,5 ... 30,0 KFactory setting 10.0RIS / RIS1 / RIS2 / RIS3:RiseAdjustment range 1 ... 20 KFactory setting 2 KFirst the controller works in the same way as a standarddifferential controller. If the switch-on difference (DT E /DT1E / DT2E) is reached, the pump is activated and afterhaving received a start mpulse (10 s) a minimum pump speed(nMN = 30 %) is run. If the temperature difference reachesthe set nominal value (DT S / DT1S / DT2S / DT3S) , thepump speed is increased by one step (10%). If the differenceis increased by 2 K(ANS/ ANS1 / ANS2/ANS3), the pumpspeed is increased by 10 % in each case until the maximumpump speed of 100 % is reached. The response of thecontroller can be adjusted by means of the parameter „rise“.If the adjusted switch-off temperature is underrun (DT A /DT1A / DT2A), the controller switches-off.DT E and DT S are locked against each other. DT S hasto be at least by 0,5 above DT E. S MX / S1MX / S2MX:S MX / S1MX / S2MX:Maximum store temp.Adjustment range 2 ... 95 °CFactory setting 60 °CIf the adjusted maximum temperature is exceeded, a furtherloading of the store is stopped so that a damaging overheatingcan be avoided. If the maximum store temperature isexceeded, symbol is shown on the display.Please note: The controller is equipped with a securityswitch-offof the store, which avoids a further loading of thestore if 95 °C is reached at the store.4.1.10 (solid fuel boiler and heat exchange)© NEHS_07333_deltasol_bs_plus.mon.inddMaximum temperature limitationMX3E / MX3A:Maximum temperaturelimitationAdjustment range0,0 ... 95,0 °CFactory settingMX3E 60,0 °CMX3A 58,0 °CMinimum temperature limitationMN3E / MN3A:Minimum temperature limitationAdjustment range0,0 ... 90,0 °CFactory setting:Arr = 2MN3O 5,0 °CMN3F 10,0 °CArr = 8MN3O 60,0 °CMN3F 65,0 °CThe controller is equipped with an independent temperaturedifferential regulation for which minimum andmaximum temperature limations as well as correspondingswitch-on and -off temperatures can be separately adjusted.Only possible for Arr = 2 and 8 (e.g. for solid fuel boilers orheat exchange regulation).If the adjusted value MX3E is exceeded, relay 2 willbe deactivated. When falling below MX3A, the relaywill be switched on again.Reference sensor:S3 by Arr 8 (TSTU)S4 by Arr 2 (TST2)Is the adjusted value MN3E underrun relay 2 willbe deactivated. By falling below MN3A, the relaywill be switched on again.Reference sensor:S4 by Arr 8 (TFSB)S3 by Arr 2 (TSTU)Both switch on- and switch off temperature differencesDT3E and DT3A apply parallely for the maximal- andminimal temperature limit.17 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>4.1.11 Collector temperature limitationEmergency shut down of the collectorEM / EM1 / EM2:temperature limitation correctorAdjustment range110 ... 200 °C,Factory setting 140 °CIf the adjusted collector limit temperature (EM / EM1 /EM2) is exceeded the solar pump (R1/R2) is deactivatedin order to avoid a damaging overheating of the solarcomponents (collector emergency shutdown). The factorysetting for the temperature limitation is 140 °C - it can bechanged within the adjustment range of 110 ... 200 °C. Symbolis shown on the display (blinking).4.1.12 System cooling If the adjusted maximum store temperature is reached, thesolar system switches-off. If now the collector temperatureOCX / OCX1 / OCX2:Option System coolingrises to the adjusted maximum collector temperature(CMX / CMX1 / CMX2), the solar pump remains activatedAdjustment range OFFuntil this temperature limitation value is again underrun.... ON FactoryThe store temperature might continue to rise (subordinatedsetting OFFactive maximum store temperature), but only up to 95 °CCMX / CMX1 / CMX2:(emergency shutdown of the store). If the store temperatureis higher than the maximum store temperature (S MXcollector maximum temperature/ S1MX / S2MX) and the collector temperature is by atAdjustment range 100...least 5K lower than the store temperature, the solar system190 °Cremains activated until the store is cooled down again byFactory setting 120 °Cthe collector and the tubes below the adjusted maximumtemperature (S MX / S1MX / S2MX)(only by activatedOREC function).In case of an activated system is shown on the display(blinking). Due to the cooling function, the solar system canbe kept operable for a longer period on hot summer daysand a thermal release of the collector and the heat transfermedium is ensured as well.4.1.13 Option collector minimum limitationOCN / OCN1 / OCN2: collectorminimum limitationOFF / ONFactory setting OFFCMN / CMN1 / CMN2:col. minimum temperatureAdjustment range 10 ... 90 °CFactory setting 10 °CThe minimum collector temperature is a minimum switchingtemperature which must be exceeded so that the solarpump (R1/R2) is switched-on. The minimum temperatureshall avoid a steady starting-up of the solar pump (or solidfuel boiler charging pumps) for low collector temperatures.If the minimum temperature is underrun, is shown onthe display (blinking).4.1.14 Option antifreezeOCF / OCF1 / OCF2:antifreeze functionAdjustment range OFF / ONFactory setting OFFCFR / CFR1 / CFR2:antifreeze temperatureAdjustment range -10 ... 10 °CFactory setting 4,0 °C| 18The antifreeze function activates the loading circuit betweencollector and store if the adjusted antifreeze function is underrunin order to protect the medium against freezing or„thickening“. If the adjusted frost protection temperature isexceeded by 1 °C, the loading circuit will be deactivated.Please note:As there is only a limited heat quantity of the store availablefor this function, the antifreeze function should only be usedin regions with few days of temperatures around freezingpoint.© NEHS_07333_deltasol_bs_plus.mon.indd

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>4.1.18 Thermostat function (Arr = 3)Afterheatinguse of surplus energyThe thermostat function works independently from thesolar operation and can e.g. be used for the use of surplusenergy or after-heating. < the thermostat function is used for after-heating > the thermostat function is used for use of surplusenergySymbol will be shown on the display if the secondrelay output is activated. Thermostat-switch-ontem peratureAdjustment range:0,0 ... 95,0 °CFactory setting: 40,0 °Ct1 E, t2 E, t3 E:Thermostat switch-on timeAdjustment range:00:00 ... 23:45Factory setting: 00:00 Thermostat-switch-off temperatureAdjustment range:0,0 ... 95,0 °CFactory setting: 45,0 °Ct1 A, t2 A, t3 A:Thermostat switch-off timeAdjustment range:00:00 ... 23:45Factory setting: 00:00In order to block the thermostat function for a certaintime span, there are 3 time frames t1 ... t3. If the functionshould be activated only between e.g. 6:00 and 9:00, 6:00should be set for t1 E and 9:0 should be set for t1 A. Thefactory setting for the thermostat function is in continuousoperation.If all time frames should stop at 00:00 o’ clock, the thermostatfunction is continuously in operation(factory setting). nMN, n1MN, n2MN:Pump speed controlAdjustment range:30 ... 100Factory setting: 304.1.20 4.1.20 Operating modeOperating modeAdjustment range:OFF, AUTO, ONFactory setting: AUTO LANG:Adjustment of languageAdjustment range: dE, EnFactory setting: En| 20A relative minimum pump speed is specified for pumpsconnected at the outputs R1 and R2 via adjustment channelsnMN, n1MN and n2MN.Attention: not pump speed controlled, the value must be setto 100 % in order to deactivate the pump speedcontrol.For control- and service works the operating mode ofthe controller can be manually adjusted by selecting theadjustment value MM in which the following adjustmentscan be made: Operating modeOFF : relay off (blinking) +AUTO : relay in automatic operationON : relay on (blinking) +The menu language can be adjusted in this channel. dE : German En : English© NEHS_07333_deltasol_bs_plus.mon.indd

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>5. Tips for fault localizationcan fuse 4AT4A220 ... 240 V~If a malfunction occurs, it will be indicated on the display ofthe controller:Temp. SensorPt1000S1 S2 S31 2 3 4 5 6S4 VBus7 8 910 12 13 14R1 1 (1) A ( 220 ... 240) V~R2 1 (1) A (220 ... 240) V~N R2 N R1 N15 16 17 18 19L20Warning symbolOperating control lampOperating control lamp is blinking red. Symbolsymbol appear on the display.andOperating control lamp is permanently extinct .Line break. Check the line.888.8 If the control lam is extinct the power supplyof the controller has to be checkedThe powersupply of the controller has to be checked.Line break. Checkthe line.Short-circuit. Checkthe line.Pt1000-temperature sen sors pinched off canbe checked with an ohmmeter. In the followingthe resistance values corresponding to differenttemperatures are listed.noo.k.The can fuse of the controller is defective. It isaccessible after having removed the cover andcan then be replaced (a spare fuse accessorybag).© NEHS_07333_deltasol_bs_plus.mon.inddresistance values ofPt1000 Sensors21 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>5.1 VariousPump is overheated, but no heat transfer from collectorto the store, feed flow and return flow are equally warm,perhaps also „bubble“ in the lines.Pump starts for a short moment, switches-off, switches-onagain, etc. („controller after-running“)“).Air in the system?noyesIs the collector circuitblocked at the dirt trap?Vent the system; increasesystem pressure to atleast static primary pressureplus 0,5 bar; if necessarycontinue to increasethe pressure, switch thepump off and on for ashort time.Is the temperature differenceat the controllertoo small?noyesWrong placing of thecollector sensor?Change Ton and Toffaccordingly.noo.k.yesClean the dirt trap.noyesPlausibility control of theoption tube collector specialfunction?Mount the collector sensorat solar feed flow(warmest collector output);use the immersionsleeve of the respectivecollector.Pump starts up very late and stops working soon.The temperature difference between store and collectorincreases enormously during operation; the collector circuitcannot dissipate the heat.Switch-on-temperaturedifference Ton toolarge?Collector circuit pumpdefective ?noyesCollector sensor un favourablyplaced (e.g. contactsensor instead of immersionsleeve sensor?)yesChange Ton and Toffaccordingly.If necessary, activate tubecollector function.noyesHeat exchanger calcified?noyesTest / replace it.Decalcify it.o.k.Heat exchanger plugged?noyesClean it.Heat exhcanger toosmall?yesRecalculation of thedimensioning.© NEHS_07333_deltasol_bs_plus.mon.indd| 22

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>Stores are cooled during the night.aControl the return flowpreventer in warm watercirculation- o.k.?bPlease also check furtherpumps connected to thesolar store.Does collector circuitpump run during thenight?noyesCollector temperature isat night higher than ambienttemperature.noyesIs store insulation sufficient?Check the controllerfunctions.Check the return flowpreventer in feed flow andreturn flow with regard tothe functional efficiency.yesnoThe gravitation circu lationin the circulation line istoo strong; insert a strongerreturn flow pre venteror an electric 2-way valvebehind the circulationpump; the 2-way valve isopen in pump operation,other wise it is closed,connect-pump and 2-wayClean or replace it.valve parallely; activatethe circulation again! Thespeed control has to bedeactivated again!yesnoIntensify the insulation.The solar circuit pump does not work although the collectoris obviously warmer than the store.Is the insulation closeenough to thestore?yesnoReplace or intensify theinsulation.Is the control LED illuminated?There is no current; checkfuses / replace them andcheck power supply.Are the store connectionsinsulated?yesnoyes no Insulate connections.Warm water outflowupwards?noyesChange connection andlet the water flow sidewardsor through a siphon(downwards elbow pipe);less store losses now?noyesDoes the pump start upin manual operation?noyesIs the current of thepump released by thecontroller?noyesThe adjusted tempe raturedifference for starting thepump is too high; choose amore reasonable value.Is the pump stuck?© NEHS_07333_deltasol_bs_plus.mon.inddDoes warm water circulationrun for a very longtime?noyesSwitch-off the circulationpump and the blockingvalve for 1 night; less storelosses?yesanoUse the circulation pumpwith timer and switch-offthermostat (energy efficientcirculation)Check the pumps of theafter-heating circuit accordingto nightly run anddefective return flow preventer;problem solved?nobo.k.Are the fuses of thecontroller o.k.?noreplace the fusesyesyesPut the pump into oprationby means of a screwdriver;is it passable now ?noIs the pump defective -replace it.controller seems to bedefective - replace it.23 |

<strong>DeltaSol</strong> ® <strong>BS</strong> <strong>Plus</strong>6. AccessorySensorsOur product range comprises high-precision platin temperaturesensors, flatscrew sensors, ambient temperaturesensors, indoor temperature sensors, cylindrical clip-onsensors and irradiation sensors, also to be used as completesensors with sensor pocket.Overvoltage protectionWe highly recommend to install the overvoltage protectionin order to avoid overvoltage damages at the collector (e.g.by lightening).FlowmeterIn order to effect a heat quantity balancing, you need a flowmeterfor measuring the volume flow in your system. By means of a RS-COM Adapters the controller can beconnected to a PC.Service Center SoftwareThe controller can be visualized and configured comfortablyby PC with the Service Center Software.NEHS Produktions & Vertriebs GmbHKeltenring 8D-85658 EgmatingTel.: +49 (0) 80 95-87 97-0Fax: +49 (0) 80 95-87 97-50www.nehs.deinfo@v-d-nehs.orgYour specialist dealer:Please note:The design and the specifications are to be changed without notice.The illustrations may differ from original product.| 24© NEHS_07333_deltasol_bs_plus.mon.indd