A Flow Controls & Accessories

A Flow Controls & Accessories

A Flow Controls & Accessories

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

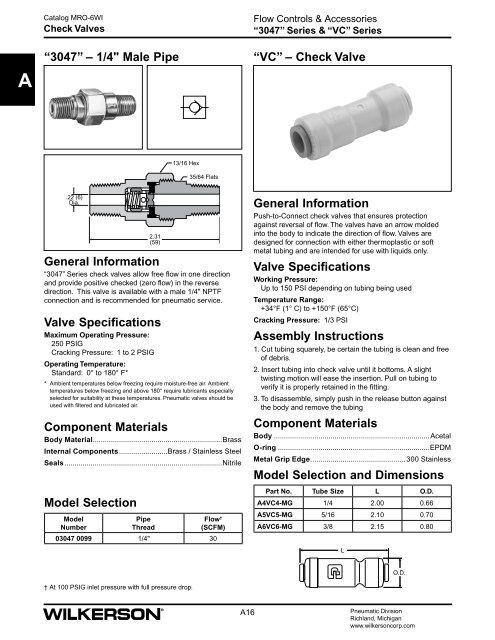

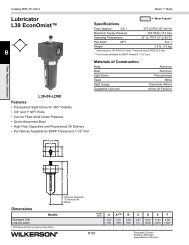

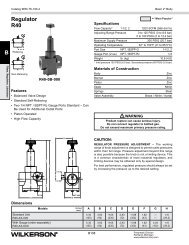

Catalog MRO-6WICheck Valves<strong>Flow</strong> <strong>Controls</strong> & <strong>Accessories</strong>“3047” Series & “VC” SeriesA“3047” – 1/4" Male Pipe“VC” – Check Valve13/16 Hex35/64 Flats.22 (6)Dia.General Information“3047” Series check valves allow free flow in one directionand provide positive checked (zero flow) in the reversedirection. This valve is available with a male 1/4" NPTFconnection and is recommended for pneumatic service.Valve SpecificationsMaximum Operating Pressure:250 PSIGCracking Pressure: 1 to 2 PSIGOperating Temperature:Standard: 0° to 180° F** Ambient temperatures below freezing require moisture-free air. Ambienttemperatures below freezing and above 180° require lubricants especiallyselected for suitability at these temperatures. Pneumatic valves should beused with filtered and lubricated air.Component MaterialsBody Material................................................................BrassInternal Components........................Brass / Stainless SteelSeals...............................................................................NitrileModel SelectionModelNumber2.31(59)PipeThread<strong>Flow</strong> †(SCFM)03047 0099 1/4" 30General InformationPush-to-Connect check valves that ensures protectionagainst reversal of flow. The valves have an arrow moldedinto the body to indicate the direction of flow. Valves aredesigned for connection with either thermoplastic or softmetal tubing and are intended for use with liquids only.Valve SpecificationsWorking Pressure:Up to 150 PSI depending on tubing being usedTemperature Range:+34°F (1° C) to +150°F (65°C)Cracking Pressure: 1/3 PSIAssembly Instructions1. Cut tubing squarely, be certain the tubing is clean and freeof debris.2. Insert tubing into check valve until it bottoms. A slighttwisting motion will ease the insertion. Pull on tubing toverify it is properly retained in the fitting.3. To disassemble, simply push in the release button againstthe body and remove the tubingComponent MaterialsBody..............................................................................AcetalO-ring............................................................................EPDMMetal Grip Edge............................................... 300 StainlessModel Selection and DimensionsPart No. Tube Size L O.D.A4VC4-MG 1/4 2.00 0.66A5VC5-MG 5/16 2.10 0.70A6VC6-MG 3/8 2.15 0.80L† At 100 PSIG inlet pressure with full pressure drop.O.D.A16Pneumatic DivisionRichland, Michiganwww.wilkersoncorp.com