Optimizing Brewed Coffee Quality Through Proper Grinding

Optimizing Brewed Coffee Quality Through Proper Grinding

Optimizing Brewed Coffee Quality Through Proper Grinding

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Optimizing</strong> <strong>Brewed</strong> <strong>Coffee</strong> <strong>Quality</strong><strong>Through</strong> <strong>Proper</strong> <strong>Grinding</strong>Daniel EphraimPresidentModern Process Equipment

First and foremost …Is there a particular grinding problem or issuethat you would like to see addressed today?THERE’S S NOTHING WORSE THANSITTING THROUGH A PRESENTATION ANDWALKING AWAY “EMPTY HANDED”!

• The <strong>Coffee</strong> <strong>Quality</strong> Cycle• Brewing Theory:– Key factors in <strong>Coffee</strong> Brewing or Extraction:• Particle size• Particle uniformity• TimePresentation Outline– The “Big Picture” in <strong>Coffee</strong> Brewing• Effect of Temperature on Ground <strong>Coffee</strong>• Analyzing and Testing Ground <strong>Coffee</strong>• <strong>Grinding</strong> for Pods and Espresso <strong>Coffee</strong>Questions andDiscussions

<strong>Proper</strong> coffee grinding is amost essential, and oftenneglected, part of the coffeequality process.So let’s explore the processfrom the beginning withselected coffee quality tippingpoints …

Theoretical <strong>Coffee</strong><strong>Quality</strong> = 100%Maximum Possible <strong>Coffee</strong>Beverage <strong>Quality</strong> = 100%

Theoretical <strong>Coffee</strong><strong>Quality</strong> = 100%Maximum Possible <strong>Coffee</strong>Beverage <strong>Quality</strong> = 100%We cannot improve onMother Nature!

<strong>Coffee</strong> ProcessingTipping PointPoor Preparation<strong>Quality</strong> Decreases

<strong>Coffee</strong> TransportationTipping PointExposure to Adverse Conditions<strong>Quality</strong> Decreases

<strong>Coffee</strong> RoastingTipping PointOver/Under Roasted<strong>Quality</strong> Decreases

Theoretical <strong>Coffee</strong><strong>Quality</strong> = 100%Maximum Possible <strong>Coffee</strong>Beverage <strong>Quality</strong> = 100%TreeCupProcessingThe <strong>Coffee</strong>Brewing<strong>Quality</strong> CycleTransportation<strong>Grinding</strong>WarehouseRoasting

The great thing about cupping coffee is that itpretty well defines the quality of the bean.

BUT, the tough part is grinding the coffee toachieve the same quality of the bean to thebrew.

We don’t t brew whole bean coffee!X

<strong>Proper</strong> Extraction and Strength<strong>Coffee</strong> beans arecomposed of soluble solids,which must be extractedinto the coffee brew.

<strong>Proper</strong> Extraction and StrengthThe amount ofsoluble solidsextracted from thecoffee bean into thebrew must be thecorrect amount orpercentage.

This is a much magnified view of a ground coffee particle using anelectron microscope.The cellular walls are about 30 microns in diameter, and thecolloidal material fills the voids within the ground coffee and cellularstructures. Part of this colloidal material is what we want to extract,but with a limit.

<strong>Proper</strong> Extraction and Strength18%22%Approx. 98.5%Water1.35%1.15%Ideal Extraction of thecoffee particle’s solublesolids is 18-22%Ideal Brew Strengthis 1.15-1.35%brewed solids

One Example of Overextractionis Turkish <strong>Coffee</strong>… Where the entire bean is ground and dissolved into hot water.100%… Excess solidssettle on the bottomof the cup, which istypically consideredundrinkable.

The Center of the Universe for <strong>Coffee</strong> <strong>Grinding</strong> isEXTRACTION!Specifically … PROPER EXTRACTION!The key to PROPER EXTRACTIONis creating, through GRINDING, theIDEAL EXPOSED COFFEE SURFACE AREAS

Effect of Grind Size on Surface Area1 Bean = 3.4 cm 22 Particles = 4.4 cm 24 Particles = 5.4 cm 21000 Particles = 34 cm 2

Grind Comparison100 – 300 particlesFrench Press, Coarse500 – 800 particlesDrip, FilterLegend= One <strong>Coffee</strong> Bean1,000 – 3,000 particlesVending, Filter Fine3,500 particlesEspresso15,000 – 35,000 particlesTurkish

Grind Sizes• Typically expressed in:– Mesh– Microns (um)25,400 microns = 1 inchor100 microns = 0.004 Inch = Thickness of One Hair!

Average Particle Size by GrindAverage Particle Size by Grind1,2001,000800600400200E.P.UrnADCDripFinePodEspresso MediumVendingEspresso FineTurkish-CoarseTurkish-Fine0Average Size in Microns

Average Size vs. Surface Area(1 Bean = 3.4 cm 2 = Size of a Postage Stamp)Surface Area Increases as Brewing Time Decreases!Average Size in Microns1,2001,0008006004002000E.P.Size of aBusiness CardUrnADCDripFinePodEspresso MediumSize of aBusinessEnvelopeVendingEspresso FineTurkish-CoarseTurkish-Fine300250200150100500Exposed Surface Area (cm2)

Micro Analysis of ExtractionIdeal Grind Size (drip)H2O4 min. brew cycle600 particles (850 um avg.)850 um1 particleRESULT:20%Ideal Extraction(Good Taste)

Micro Analysis of ExtractionIdeal Grind Size (drip)H2O4 min. brew cycle600 particles (850 um avg.)500 umFactors:1) 1) Time Time is is consistent.2) 2) Particle size size has has decreased.1 particleResult:Since Since the the coffee coffee particle is issmaller than than ideal, ideal, the the surfacearea area is is greater and and the the extractionrate rate will will be be excessive.RESULT:30% Overextraction(Poor/Bitter Taste)

The Importance of Grind UniformityTypical Ground <strong>Coffee</strong> Particle Size24,500 microns = 1 inchE.P.RegularADCDripFineEspresso CoarseEspresso MediumVendingEspresso FineTurkish-Coarse1,2001,0008006004002000Particle SizeAverage Size in MicronsTurkish-Fine

The Importance of Grind UniformityTypical Ground <strong>Coffee</strong> Particle Size24,500 microns = 1 inchE.P.RegularADCDripFineEspresso CoarseEspresso MediumVending1,2001,0008006004002000Particle SizeParticle UniformityAverage Size in MicronsEspresso FineTurkish-CoarseTurkish-Fine

Grind Uniformity ComparisonNon-Uniform Particle SizeUniform Particle Size

Uniform vs. Non-Uniform<strong>Coffee</strong> Grind% Retained (Non-Cumulative)WornRollerGrinderPoor <strong>Quality</strong>,Non-Uniform,<strong>Coffee</strong> Grind<strong>Proper</strong>lyMaintained Ideal,UniformRollerGrinder<strong>Coffee</strong> GrindOversizeDesired SizeUndersize

Roller vs. Disc Grinder% Retained (Non-Cumulative)RollerGrinderDiscGrinderOversizeDesired SizeUndersize

Impact of Improper <strong>Grinding</strong> Practiceon Grind <strong>Quality</strong>(Poor Methodology, Excessive Wear, etc.)% Retained (Non-Cumulative)650 um/ 3.0 σ645 um/1.35 σUniformground coffeedistribution(good)Non-uniformground coffeedistribution(bad)OversizeDesired Size650 umUndersize

Micro Analysis of ExtractionIdeal Grind Size (drip)H2O4 min. brew cycle600 particles (850 um avg.) 500 um850 umFactors:1) 1) Time Time is is consistent.1,000 um2) 2) Particle uniformity is isinconsistent.RESULT:30% Overextraction(Poor/Bitter Taste)RESULT:20% Ideal Extraction(Good Taste)RESULT:Underextraction(Tea-Like Taste)Result: Result:Since Since some some of of the the coffee coffee particles particles are are smaller smallerand and larger larger than than ideal, ideal, the the surface surface areas areas are aregreater greater and and lesser lesser and and the the extraction extraction rates rates will willbe be excessive excessive or or insufficient.insufficient.

Micro Analysis of ExtractionH2OConclusion #2:Ideal extraction is is a function ofproper particle size uniformity.

Optimal Brew Time vs. Particle SizeBrew Time vs. Particle Size toAchieve 20% Extraction Rate1000900Particle Size (microns)80070060050040020% Extraction RateParticle Size Dictates Brew Time!Brew Time Dictates Particle Size!300Espresso0 1 2 3 4 5 6 7 8Pod Fine Drip UrnBrewing Time (minutes)

Effect of Extraction Time on Taste

Effect of Cycle Time on TasteCourtesy of the <strong>Coffee</strong> Brewing Center

Micro Analysis of ExtractionIdeal Grind Size (drip)H2O4 min. brew cycle600 particles (850 um avg.)850 um1 particleRESULT:20%Ideal Extraction(Good Taste)

Micro Analysis of ExtractionIdeal Grind Size (drip)H2O8 min. brew cycle600 particles (850 um avg.)850 umFactors:1) 1) Particle size size is is consistent.2) 2) Time Time has has changed.Result:Since Since the the brewing time time is is too toolong long for for the the relative particle size, size,the the extraction rate rate is is excessive.1 particleRESULT:30-35%Overextraction(Poor/Bitter Taste)

Macro Analysis of ExtractionEspresso Brewer225 um grindH2O20 sec.H2OOptimumBrew

Macro Analysis of ExtractionEspresso Brewer225 um grindH2OH2O20 sec. 1 min.H2OOptimumBrewOverExtractedBrew

Macro Analysis of ExtractionEspresso Brewer225 um grindFilter Basket Brewer850 um grindH2O H2O H2O H2O H2O H2O20 sec. 1 min. 4 min.OptimumBrewOverExtractedBrewOptimumBrew

Macro Analysis of ExtractionEspresso Brewer225 um grindFilter Basket Brewer850 um grindH2O H2O H2O H2O H2O H2O20 sec. 1 min. 4 min. 2 min.OptimumBrewOverExtractedBrewOptimumBrewUnderExtractedBrew

Macro Analysis of ExtractionEspresso Brewer225 um grindFilter Basket Brewer850 um grindH2O H2O H2O H2O H2O H2O20 sec. 1 min. 4 min. 2 min. 8 min.OptimumBrewOverExtractedBrewOptimumBrewUnderExtractedBrewOverExtractedBrew

Micro Analysis of ExtractionH2OConclusion #3:Ideal extraction is is a function ofproper brew time for the methodand grind.

Macro Grind Challenge64 oz. H2OH2OExtract for4 min.Approx. 6 oz.water retentionin grounds3.75 oz.Good Grind Goal:Good Grind Goal:20% extraction of soluble solids58 oz. liquid(64 oz. – 6 oz.)Soluble Solids:1.3%(0.75 oz./58 oz.) 58 oz. brew20% * 3.75 = .75 oz.

The “Gold Cup” Standard CalculationStrongUnder-DevelopedStrongStrongBitterToo Fine soExtractionRateToo HighHow do we calculatebrewed solids?TooCoarse soExtractionRateToo LowUnder-DevelopedWeakUnder-DevelopedOptimumBalanceWeakBitterWeakBitter1. Use 64 oz. of water forbrewing2. Subtract water absorbed incoffee grounds (6 fl/oz.)3. Use 3.75 oz. of ground coffeeto extract 20% solids4. Brew to “Gold Cup” Standardthat will extract 20% of solids:20% x 3.75 oz. = 0.75 oz.5. Calculate brewed solids aspercentage of liquid:0.75 oz./58 oz. = 1.3%

Evaluation of the same grind (average particle size)but different uniformitiesParticle Size/Particle Uniformity:StrongUnder-DevelopedStrongStrongBitter645 um/1.35 σ (Good <strong>Quality</strong> Grind)Under-DevelopedOptimumBalanceBitter650 um/ 3.0 σ (Poor <strong>Quality</strong> Grind)WeakUnder-DevelopedWeakWeakBitter

The Key Principals of <strong>Coffee</strong> Extraction• The rate of soluble solids extraction from a coffeeparticle is directly related to the amount of exposedsurface area to the hot water.• The time that the hot water will be exposed to the coffeeparticle must be directly proportional to the exposedsurface area, or particle size, of the ground coffee.• If particle size, uniformity and brewing time arematched correctly, with all other factors being equal,a 20% extraction rate can be achieved.

Ideal Matrix of Grind vs. TimeGrindCoarse Optimal FineExcessiveStrongUnder-DevelopedStrongStrongBitterBrew TimesOptimalTooShortUnder-DevelopedWeakUnder-DevelopedOptimumBalanceWeakBitterWeakBitter<strong>Brewed</strong> <strong>Coffee</strong> Taste Profiles

Ideal Matrix of Grind vs. TimeGrindCoarse Optimal FineExcessiveStrongUnder-DevelopedStrongStrongBitterBrew TimesOptimalTooShortMostCommonProblemsUnder-DevelopedWeakUnder-DevelopedOptimumBalanceWeakBitterWeakBitter<strong>Brewed</strong> <strong>Coffee</strong> Taste Profiles

Heat vs. <strong>Grinding</strong>Goal:We only want toroast coffee once,and that isin the roaster!=OK!Challenge:Maintain lowtemperaturesduring grinding.=NOTOK!

Temperature Rise During <strong>Grinding</strong>170IncreasingLoss ofFlavors &Aromatics<strong>Coffee</strong> Temperature (Deg F)15013011090Disc-Style <strong>Coffee</strong>Grinder w/oWater-Cooling700 5 10 15 20Grinder Run Time (Minutes)High Temperature/Vapor PressureFlavors and AromaticsMedium Temperature/Vapor PressureFlavors and AromaticsLow Temperature/Vapor PressureFlavors and Aromatics<strong>Coffee</strong>Darkens

Temperature Rise During <strong>Grinding</strong>170IncreasingLoss ofFlavors &Aromatics<strong>Coffee</strong> Temperature (Deg F)15013011090Disc-Style <strong>Coffee</strong>Grinder w/Water-CoolingDisc-Style <strong>Coffee</strong>Grinder w/oWater-CoolingHigh Temperature/Vapor PressureFlavors and AromaticsMedium Temperature/Vapor PressureFlavors and AromaticsLow Temperature/Vapor PressureFlavors and Aromatics700 5 10 15 20Grinder Run Time (Minutes)<strong>Coffee</strong>Darkens

One Example of the Results from aWater-Cooled Disc-Style GrinderTemperature (F)Temperature (F)99999898979796969595949493939292Ground <strong>Coffee</strong> Discharge Temperatures Over TimeGround <strong>Coffee</strong> Discharge Temperatures Over Time(Standard Drip Grind Size = Approx. 700 um)(Standard Drip Grind Size = Approx. 700 um)919190900 2 4 6 8 10 12 14 16 180 2 4 6 8 10 12 14 16 18Time (min.)Time (min.)202022222424262628283030Log. Without (W/OWater-Log. Without (W/OWater-Water-Cooling)Water-Cooling)Log. WithLog. With (With Water-(With Water-Water-Cooling)Water-Cooling)Model GPX.WCI (Water-Cooling Integrated)Disc-Style <strong>Coffee</strong> Grinder

Questions?

Is Evaluating Ground <strong>Coffee</strong>“By Eye” Reliable?

What do you see?

What do you see?

Which Line is Longer?

Which Line is Longer?

Which Line is Longer?

Which Line is Longer?

Which Line is Longer?

They’re the same length.

Which box is bigger?

They’re both the same size.

Is this line straight?

Nope.

Which grind is smaller?This one.

Analyzing and TestingGround <strong>Coffee</strong>

The Ro-Tap Method

The Ro-Tap Method% Retained (Non-Cumulative)ScreenSize10 14 20 28PanOversizeDesired SizeUndersize

The Ro-Tap Method% Retained (Non-Cumulative)ScreenSize10 14 20 28PanMESH Weight(Tyler) (grams)10 0.6142028PANOversizeDesired SizeUndersize

The Ro-Tap Method% Retained (Non-Cumulative)ScreenSize10 14 20 28PanMESH Weight(Tyler) (grams)10 0.614 4.42028PANOversizeDesired SizeUndersize

The Ro-Tap Method% Retained (Non-Cumulative)ScreenSize10 14 20 28PanMESH Weight(Tyler) (grams)10 0.614 4.420 28.928PANOversizeDesired SizeUndersize

The Ro-Tap Method% Retained (Non-Cumulative)ScreenSize10 14 20 28PanMESH Weight(Tyler) (grams)10 0.614 4.420 28.928 42.2PANOversizeDesired SizeUndersize

The Ro-Tap Method% Retained (Non-Cumulative)ScreenSize10 14 20 28PanMESH Weight(Tyler) (grams)10 0.614 4.420 28.928 42.2PAN 23.9OversizeDesired SizeUndersize

Ro-TapCalculationTEST #DATE:NOTES125-Apr-03Fine Drip GrindSampleMESH grams %(Tyler)10 0.6 0.6%14 4.4 4.4%20 28.9 28.9%28 42.2 42.2%PAN 23.9 23.9%

Ro-Tap Graph45.0%40.0%% Retained (Non-Cumulative)35.0%30.0%25.0%20.0%15.0%10.0%5.0%0.0%10 14 20 28 PANDrip Grind 0.6% 4.4% 28.9% 42.2% 23.9%Screen Size (Tyler Mesh)

Laser Particle Size Analysis

Principle of Laser Particle Size AnalysisFocusing LensScattered LightLaser BeamCentralDetectorParticlesMainDetectorf

Laser Analysis Results%201080706050403020100010.0 100.0 1000.0 10000.0Particle Diameter (µm.)100D(v,0.1) = 306 um90Path: <strong>Coffee</strong> C:\SIZERX\DATA\Result: Sieve ASTM E11:61 TableID: Run No: 1 Measured:File: EXAMPLE2 Rec. No: 2 Analy sed: 3/5/01 11:50AMSource: Input10% PercentileRange: 1000 mm Beam: 10.00 mm Sampler: Obs': 20.0 %Presentation: 2RHA Analy sis: Poly disperse Residual: 0.000 %Modif ications: NoneD(v,0.5) = 478 umConc. = 0.3076 %Vol Density = 1.000 g/cm^3 S.S.A.= 0.0144 m^2/gDistribution: Volume D[4, 3] = 513.70 um D[3, 2] = 416.72 umD(v , 0.1) = 305.95 um D(v , 0.5) = 477.80 um D(v , 0.9) = 772.27 umSpan = 9.760E-01Unif ormity = 3.054E-01Average Particle SizeMeshNoApertureumVolumeIn%VolumeBelow%10 2000 100.000.1412 168099.860.3114 141099.550.8316 119098.721.5018 100097.223.9920 84193.237.2625 70785.9710.7030 59575.2719.5835 50055.6920.4740 42035.2214.9645 35420.2711.8050 2978.475.0360 2503.44D(v,0.9) = 772 um90% PercentileMeshNoApertureumVolumeIn%VolumeBelow%60 250 3.442.2570 2101.190.5980 1770.600.26100 1490.340.09120 1250.250.05140 1050.200.03170 880.170.02200 740.160.01230 630.150.01270 530.140.01325 440.130.01400 370.12

Two Different Fine Grinds% Retained (Non-Cumulative)AverageParticle Sizesare the same.BrewQualities aredifferent!OversizeDesired SizeUndersize

Use about 50 grams24 mesh/700 umscreen sizeThe MPE Single Sieve“Hand” Ro-Tap MethodShake and rotate for fiveminutes, occasionallytapping on a tablePercentageAbovePanUse Single Sieve chart to determine theaverage particle size by referencing thepercentage of coffee retained on the sieve.PercentageBelow

The MPE Single Sieve“Hand” Ro-Tap MethodWeigh your results using aportable scale.

%RetainedRetainedononScreenScreenThe The MPE MPE Single Single Sieve Sieve Reference Reference Chart ChartSample result was60% retained on topof 24 Mesh screenDisc-StyleDisc-Style<strong>Coffee</strong><strong>Coffee</strong>GrinderGrinder80807575707030 Mesh656524 Mesh606020 Mesh5555505045454040Calculated Particle size:3535800 um30305005006006007007008008009009001000100011001100Euro Fine Fine/DripAverageAverageParticleDripParticleSizeSize(um)Coarse/Drip Perc/Urn(um)Average Particle Size (um)30 Mesh24 Mesh20 MeshNote: Use Roller-Style Reference Chart forRoller-Style <strong>Coffee</strong> Grind ResultsCopyright MPE, 2009

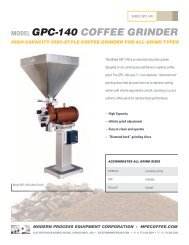

SizeConversionand GrindReferenceTableAvailable online at: www.mpechicago.com/coffeeSIZE CONVERSION AND GRIND REFERENCE TABLEU.S. Mesh Tyler Mesh Inches Microns Grind*4 4 0.1850 46995 5 0.1560 39626 6 0.1310 33277 7 0.1100 27948 8 0.0930 236210 9 0.0780 198112 10 0.0650 165114 12 0.0550 139716 14 0.0460 1168Extract Grinds andFrench PressSIZE CONVERSION AND GRIND REFERENCE TABLEU.S. Mesh Tyler Mesh Inches Microns Grind*25 24 0.0276 701 Fine GrindE.P and Regular18 16 0.0390 991Grind20 20 0.0328 833 Drip Grind25 24 0.0276 701 Fine Grind30 28 0.0232 589 Euro Filter Fine35 32 0.0195 495 Espresso Coarse40 35 0.0164 417 Vending45 42 0.0138 351 Espresso Fine50 48 0.0116 29560 60 0.0097 24670 65 0.0082 20880 80 0.0069 175 Coarse Turkish100 100 0.0058 147120 115 0.0049 124 Medium Turkish140 150 0.0041 104170 170 0.0035 89 Fine Turkish200 200 0.0029 74230 250 0.0024 61270 270 0.0021 53325 325 0.0017 43400 400 0.0015 38Modern Process Equipment, Inc. Chicago, Illinois USA*=Average Particle Size

SegregationOnce coffee is ground, care must betaken so that the particles don’t“declassify” between the grinder and thepackage, pod or other delivery container.

SegregationSegregation VideoCourtesy of Jenike and Johanson, Inc.

Espresso andSingle-CupServing methodsare the toughestgrinds to achieve!

Filter-Type Packages

… or shaped like these

Pod vs. Fresh BrewPerformance ComparisonBrewingDynamics1 Pod/8 oz. cupEquivalent<strong>Coffee</strong> Packfor 64 oz.BrewRatio<strong>Coffee</strong> Weight9 grams3.75 oz.1/12th theweightWater Pressure(psi)10 – 70Gravity:0.1 – 0.5Brew Time10 – 15 sec.3 – 6 min.Grind Size(microns)400 - 600800 – 900

Pod vs. Fresh BrewPerformance ComparisonBrewingDynamics1 Pod/8 oz. cupEquivalent<strong>Coffee</strong> Packfor 64 oz.BrewRatio<strong>Coffee</strong> Weight9 grams3.75 oz.1/12th theweightWater Pressure(psi)10 – 70Gravity:0.1 – 0.5130 times thewaterpressureBrew Time10 – 15 sec.3 – 6 min.Grind Size(microns)400 - 600800 – 900

Pod vs. Fresh BrewPerformance ComparisonBrewingDynamics1 Pod/8 oz. cupEquivalent<strong>Coffee</strong> Packfor 64 oz.BrewRatio<strong>Coffee</strong> Weight9 grams3.75 oz.1/12th theweightWater Pressure(psi)10 – 70Gravity:0.1 – 0.5130 times thewaterpressureBrew Time10 – 15 sec.3 – 6 min.1/20th thetimeGrind Size(microns)400 - 600800 – 900

Pod vs. Fresh BrewPerformance ComparisonBrewingDynamics1 Pod/8 oz. cupEquivalent<strong>Coffee</strong> Packfor 64 oz.BrewRatio<strong>Coffee</strong> Weight9 grams3.75 oz.1/12th theweightWater Pressure(psi)10 – 70Gravity:0.1 – 0.5130 times thewaterpressureBrew Time10 – 15 sec.3 – 6 min.1/20th thetimeGrind Size(microns)400 - 600800 – 9001/2 the grindsize

A pod grind is one of the mosttechnical and challenging grinds,yet is typically produced on the mostbasic, limited grinder as a matter of convenience.The grind must be thecorrect size and uniformityto produce a comparable coffee brew!

Now let’s take acloser look atEspresso <strong>Grinding</strong>:Two apparently contradictory needsmust be satisfied to prepare a goodcup of espresso:1) On the one hand, a shortpercolation time is required;2) On the other hand, a highconcentration of soluble solidsmust be reached.

… Both requirements can only be attained if a close contact betweensolid particles and extraction water can be achieved.Thus, espresso percolation needs a plurimodal particle size distribution,where the finer particles enhance the exposed extraction surface (chemical need)and the coarser ones allow the water flow (physical need).40 um (20%)280 um (80%)

Let’s look at an espresso particle distribution using an electron microscope.Upon further magnification, we can see the cellular structure and hexagonalstructure in more detail, as well as the “fines” which are an essential andintegral part of espresso grinding.We can also see the rupture of the cellular walls, which are 30 um indiameter, which is the same size as the “superfines” that are a requiredelement in espresso grinding.

Ideal Espresso <strong>Grinding</strong>It is typically desirable to generate “fines” (20-40 um) when grinding forespresso to promote the proper infusion.Optimum Espresso Grindw/ 20-40 um “fines”

Basic Illustration ofBimodal/PlurimodalConceptModern Roller <strong>Grinding</strong> with EFT*

How do you determine theoptimal grind for your application?1) Use a grind reference document (SCAA, MPE, etc.)to determine the correct grind for your applicationor, alternatively:2) Perform a grind test using the ro-tap,hand ro-tap or laser method to ensurethat your actual grind matches your target.3) In conjunction with the above, utilize asoluble solids tester* to establish:- Your brewed solids and;- Your desired grind to achieve or maintain those brewedsolids.* Either a hydrometer or soluble solids “Ultrameter”can be used for the above.

Questions?