1_innofill pet drv volume-controlled pressure filling system for pet ...

1_innofill pet drv volume-controlled pressure filling system for pet ...

1_innofill pet drv volume-controlled pressure filling system for pet ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

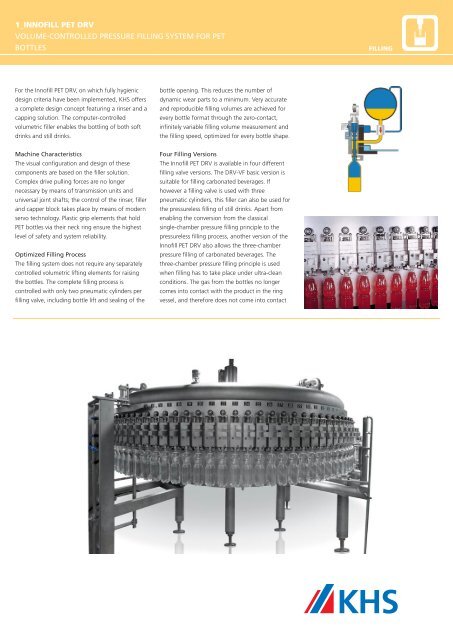

1_INNOFILL PET DRVVOLUME-CONTROLLED PRESSURE FILLING SYSTEM FOR PETBOTTLESFILLINGFor the Innofill PET DRV, on which fully hygienicdesign criteria have been implemented, KHS offersa complete design concept featuring a rinser and acapping solution. The computer-<strong>controlled</strong><strong>volume</strong>tric filler enables the bottling of both softdrinks and still drinks.bottle opening. This reduces the number ofdynamic wear parts to a minimum. Very accurateand reproducible <strong>filling</strong> <strong>volume</strong>s are achieved <strong>for</strong>every bottle <strong>for</strong>mat through the zero-contact,infinitely variable <strong>filling</strong> <strong>volume</strong> measurement andthe <strong>filling</strong> speed, optimized <strong>for</strong> every bottle shape.Machine CharacteristicsThe visual configuration and design of thesecomponents are based on the filler solution.Complex drive pulling <strong>for</strong>ces are no longernecessary by means of transmission units anduniversal joint shafts; the control of the rinser, fillerand capper block takes place by means of modernservo technology. Plastic grip elements that holdPET bottles via their neck ring ensure the highestlevel of safety and <strong>system</strong> reliability.Optimized Filling ProcessThe <strong>filling</strong> <strong>system</strong> does not require any separately<strong>controlled</strong> <strong>volume</strong>tric lifting elements <strong>for</strong> raisingthe bottles. The complete <strong>filling</strong> process is<strong>controlled</strong> with only two pneumatic cylinders per<strong>filling</strong> valve, including bottle lift and sealing of theFour Filling VersionsThe Innofill PET DRV is available in four different<strong>filling</strong> valve versions. The DRV-VF basic version issuitable <strong>for</strong> <strong>filling</strong> carbonated beverages. Ifhowever a <strong>filling</strong> valve is used with threepneumatic cylinders, this filler can also be used <strong>for</strong>the <strong>pressure</strong>less <strong>filling</strong> of still drinks. Apart fromenabling the conversion from the classicalsingle-chamber <strong>pressure</strong> <strong>filling</strong> principle to the<strong>pressure</strong>less <strong>filling</strong> process, another version of theInnofill PET DRV also allows the three-chamber<strong>pressure</strong> <strong>filling</strong> of carbonated beverages. Thethree-chamber <strong>pressure</strong> <strong>filling</strong> principle is usedwhen <strong>filling</strong> has to take place under ultra-cleanconditions. The gas from the bottles no longercomes into contact with the product in the ringvessel, and there<strong>for</strong>e does not come into contact

2_INNOFILL PET DRVVOLUME-CONTROLLED PRESSURE FILLING SYSTEM FOR PETBOTTLESFILLINGwith subsequent bottles. The fourth DRV-VF/NHversion is hot <strong>filling</strong> at normal <strong>pressure</strong> with theadditional option of changing to single-chamber<strong>pressure</strong> <strong>filling</strong>.Capping OptionsThe Innofill PET DRV soft drink filler, <strong>for</strong> <strong>filling</strong>carbonated beverages and still beverages in PETbottles, is available in combination with a standardor a servo capper <strong>for</strong> plastic screw caps. Bothbottle mouths (the 28 mm standard mouth and the28 mm 'shorty' mouth) can be handled withouthaving to convert the filler. Only on the capper dothe feed channel, the pulling disc and the chuckshave to be exchanged. Of course, 28 mm sportscaps can also be handled. In bottling still drinks,26.7 mm and 30.25 mm multi-thread caps can alsobe handled.Technical DataBottle contents:0.3 l to 3.0 lBottling temperature:4 to 20°CHeight:130 to 360 mmDiameter:40 to 125 mmFiling accuracy:0.5 l: s = 1.5 ml1.0 l: s = 2.0 ml1.5 l: s = 2.5 ml2.0 l: s = 3.0 mlDRV fillerStandard capperServo-capperPitch circle — Capacity (bph)Pitch circle — Capacity (bph)Pitch circle — Capacity (bph)2160 — 9,000 to 25,0002880 — 13,000 to 35,0003600 — 16,000 to 45,0004320 — 20,000 to 55,0005040 — 24,000 to 65,0005760 — 28,000 to 70,0006120 — 30,000 to 70,0006480 — 32,000 to 70,000480 — up to 27,000540 — 27,000 to 40,500720 — 36,000 to 54,000880 — up to 49,500900 — 45,000 to 67,500540 — 27,000 to 40,500720 — 36,000 to 54,000900 — 45,000 to 67,5001080 — 54,000 to 81,000Edition: 10/12/11-en. Subject to modification.KHS GmbHPlaniger Strasse 139-14755543 Bad KreuznachGermanyPhone: +49 (0) 671 / 8 52-2714Fax: +49 (0) 671 / 8 52-42714E-mail: heinz.hillmann@khs.comwww.khs.com