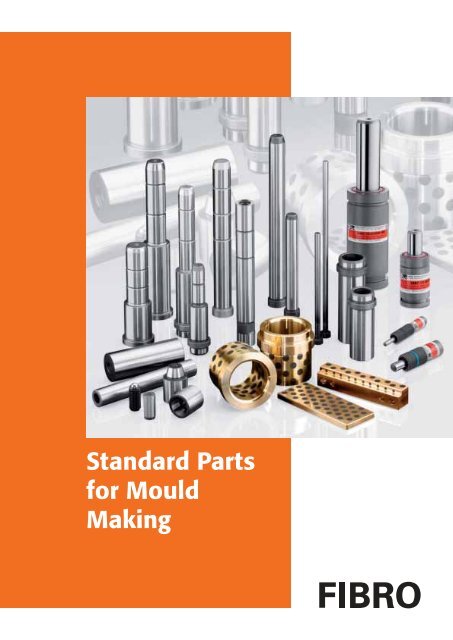

Standard Parts for Mould Making

Standard Parts for Mould Making

Standard Parts for Mould Making

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Standard</strong> <strong>Parts</strong><br />

<strong>for</strong> <strong>Mould</strong><br />

<strong>Making</strong>

2 · 20818 · 2006 · 1 Q

2 · 20819 · 2006 · 1 Q<br />

Index<br />

Your Production Partner 4-5<br />

Guide Elements Locating units, round 8<br />

Locating units, flat 8<br />

Compensation Discs 9<br />

Adjusting washers 9<br />

Ejector rods 10<br />

Centering sleeves 11<br />

Guide pillars 12-13<br />

Guide pillars, shouldered 14-17<br />

Locating guide pillars, shouldered 18-21<br />

Guide pillars with flange 22<br />

Guide pillars (diagonal load pillars) 24<br />

Guide sleeves 25<br />

Guide bushes 26<br />

Locating guide bushes 27<br />

Guide bushes, Bronze with Non-Liquid Lubricant 28-32<br />

Angled Guide Gibs, Bronze with Non-Liquid Lubricant 33<br />

Flat Guide Bars, Bronze with Non-Liquid Lubricant 34-35<br />

Ball bearing guides 36<br />

Rectangular guides with rollers 37-38<br />

General <strong>Mould</strong> Components Socket Head Cap Screws 40-42<br />

Countersunk Head Cap Screws 43<br />

Flat mushroom head screw 44<br />

Setscrews 46<br />

Collar Nuts 46-47<br />

Washers 47<br />

T-Head Bolts 48<br />

Spring,- Fit- and Spacer Units 49<br />

Shoulder Screws 50<br />

Spring Plungers 51-55<br />

Lifting Eyebolts 56-58<br />

Hoisting Snap Links 59<br />

Rotary Safety Eye Bolts 60-61<br />

Precision Dowel Pins 62-65<br />

FIBROZIPP 66<br />

Forming / Demoulding Bolt Guides 68-69<br />

Ejector Pins 70-77<br />

Ejector Sleeves 78-79<br />

Date insert 80-81<br />

Quill holders <strong>for</strong> core tempering 82<br />

O-rings 83<br />

Gas Springs <strong>Mould</strong> Line Gas Springs 85-101<br />

Gas Springs Accessories 104-136<br />

Auxiliary Equipment Chemical Tooling Aids 138-139<br />

Representatives 142-143<br />

subject to alterations 3

4<br />

FIBRO - your production partner<br />

FIBRO – an internationally successful company.<br />

As a market leader in <strong>Standard</strong> <strong>Parts</strong>, Rotary Indexing<br />

Tables and Automation, FIBRO provides products and<br />

solutions to ensure your production keeps moving.<br />

So what is the secret of the FIBRO success? Products<br />

developed in-house, tailor-made <strong>for</strong> the market with<br />

uncompromising quality.<br />

Weinsberg plant<br />

Indexing Tables<br />

From 1962 onwards FIBRO pioneered the design and<br />

manufacture of indexing tables and soon gained an<br />

enviable reputation.<br />

FIBROTAKT ® indexing tables with face gear and ultrahigh<br />

precision indexing, together with dependable<br />

rigidity. Drive options: pneumatic, hydraulic via rack and<br />

pinion or electric with worm drive.<br />

FIBROPLAN ® NC – indexing tables with backlash<br />

adjustment worm drive or torque motor <strong>for</strong> use in<br />

machine tools <strong>for</strong> universal positioning and round and<br />

multi-axis processes (simultaneous operation).<br />

FIBROTOR ® revolving tables and indexing tables with<br />

positive drive cam, offering very short cycle times even<br />

when transporting heavy loads. Mainly used in nonmachining<br />

applications. Thousands of FIBRO units are<br />

in use world-wide as integral key components in highoutput<br />

machinery.<br />

But good products are not enough on their own.<br />

FIBRO combines excellent products, the know-how and<br />

service competence of an internationally focused company,<br />

matched to the actual needs of customers -<br />

wherever they are.<br />

Hassmersheim plant<br />

<strong>Standard</strong> <strong>Parts</strong><br />

Today the <strong>Standard</strong> <strong>Parts</strong> Division operates from<br />

the Hassmersheim and Weinsberg works, which<br />

manufacture a comprehensive range of standard parts<br />

and maintain stocks ready <strong>for</strong> immediate despatch<br />

world-wide. The machine tool, mechanical engineering<br />

and systems engineering product ranges have been<br />

developed to meet the needs of customers.<br />

They include steel die sets, guide elements, oilless<br />

guide elements and precision components such as<br />

punches and matrixes, special steel compression<br />

springs, gas springs, <strong>for</strong>ming materials, metal bonding<br />

agents, moulding resins, peripheral equipment <strong>for</strong><br />

pressing and tool making, tool slides with cam or roller<br />

slides and hydraulic cam systems.<br />

FIBRO has become renowned world-wide <strong>for</strong> its<br />

comprehensive range of products in stock and its<br />

readiness to deliver.<br />

subject to alterations<br />

0 · 17774·2005·2 Q

0 · 17775 ·2005·2 Q<br />

FIBRO is customer-focused – world-wide. A well-developed<br />

network of sales and service points and strategic<br />

partners ensure that help is always at hand. This ensures<br />

technical advance, world-wide experience in applications<br />

and rapid availability of products.<br />

Hassmersheim plant<br />

FIBRO has been active in the field of automation and<br />

robotics since 1974 and offers one of the most comprehensive<br />

ranges in this field. A cleverly designed<br />

modular system based on translation units, rotary<br />

units, grippers, and guide gantries with trolleys make<br />

<strong>for</strong> easy construction of individual machines and complete<br />

systems, ranging from simple pick & place units<br />

right up to multi-axis robots. These series-manufactured<br />

modules with electric, pneumatic or hydraulic<br />

drive, guarantee both high functional reliability and<br />

cost-effective prices.<br />

The modular gantry systems can solve virtually any<br />

transporting problem using linear gantries, surface<br />

gantries and extension gantries. These systems are<br />

being used successfully in many industries worldwide.<br />

Applications include linking machine tools<br />

(automotive production), tool changing in machining<br />

facilities, palletising work pieces, unloading injection<br />

moulding dies, PCB feeders, press linking, palletising,<br />

stacking, loading and unloading, transporting and flexible<br />

linking, storage and buffering of work pieces of<br />

different sizes.<br />

subject to alterations<br />

Facts and figures on FIBRO:<br />

- founded 1958<br />

- approximately 900 staff<br />

- 80 representatives and service stations world-wide<br />

- branches in France, USA, India, Switzerland and<br />

Singapore<br />

- ISO 9001:2000 Quality Assurance and VDA 6.4<br />

certification<br />

- a company in the LÄPPLE Group<br />

Automation<br />

Since its establishment in 1974 GSA Automation<br />

GmbH has developed to become a world market leader<br />

in the manufacture of handling equipment and<br />

transport systems. Over this period GSA has installed<br />

over 200 fully automated systems <strong>for</strong> all the leading<br />

automotive and machine tool manufacturers. GSA has<br />

been a member of the FIBRO group since 2004.<br />

Our production range consists of linear and surface<br />

gantry systems, transport systems such as precision<br />

roller guides, accumulating chain conveyors, pallet<br />

accumulating conveyors and flexible decoupling<br />

modules,shelf stacking systems and pallet mechanical<br />

handling systems.<br />

We can provide our customers with dependable state<br />

of the art high per<strong>for</strong>mance systems from our standard<br />

range. We take complete responsibility <strong>for</strong> the<br />

complete project, starting with designing the solution<br />

concepts at the design phase, right through to the<br />

final handover of the ready-to-go system.<br />

5

6<br />

subject to alterations<br />

2 · 20820 · 2006 · 1 Q

2 · 20821 · 2006 · 1 Q<br />

subject to alterations<br />

Guide Elements<br />

7

8<br />

Locating units, round 2442.12.<br />

Locating units, flat 2442.13.<br />

Mounting Example<br />

2442.12. Locating unit, round (without<br />

compensation disc)<br />

2442.12. Locating unit, round Description:<br />

d1 d2 l1 l2 l3 m m1 s1<br />

12 8 34 6 4 4 4 17<br />

14 10 34 7,5 6 5 5 17<br />

16 10 34 7,5 6 5 5 17<br />

20 15 54 12 9 8 8 27<br />

25 20 54 12 10 8 8 27<br />

26 20 54 12 10 8 8 27<br />

30 25 72 15 14 10 10 36<br />

32 25 72 15 14 10 10 36<br />

42 35 92 15 18 10 10 46<br />

2442.13. Locating unit, flat<br />

d1 d l1 l2 l3 v s1 t m<br />

30 4 72 5 10 18 36 5 10<br />

42 5 92 6 14 23 46 7 10<br />

54 6 112 8 17 30 56 8 12<br />

80 8 152 8 27 42 76 11 16<br />

s 1<br />

s 1<br />

l 3<br />

l 2<br />

d 1 h6<br />

m 1<br />

m<br />

d 2<br />

15°<br />

Conical centring inserts are used to increase repeat accuracy in<br />

mould, die and machine-making.<br />

Ordering-code (example):<br />

1<br />

1<br />

l 1<br />

Locating unit, round, two-part = 2442.<br />

Conical angle = 15° = 2442.12.<br />

d1 = 25 mm = 2442.12.025.<br />

l1 = 54 mm = 2442.12.025.054<br />

Order No = 2442.12.025.054<br />

2442.13. Locating unit, flat<br />

m<br />

1,6<br />

1,5<br />

s1<br />

0,4<br />

l 2<br />

0,5<br />

15°<br />

0,5<br />

l 3<br />

l +0,4<br />

1 +0,2<br />

s1<br />

l 2<br />

d H8<br />

t<br />

Ordering-code (example):<br />

Locating unit = 2442.<br />

flat = 2442.13.<br />

d1 = 42 mm = 2442.13.042.<br />

l1 = 92 mm = 2442.13.042.092<br />

Order No = 2442.13.042.092<br />

0,4<br />

1,6<br />

m<br />

v<br />

1,6<br />

e7<br />

1<br />

d<br />

h6<br />

1<br />

d<br />

subject to alterations<br />

2 · 20822 · 2006 · 1 Q

2 · 20823 · 2006 · 1 Q<br />

2442.12.3. Compensation Discs<br />

2442.12.4. Adjusting washers<br />

2442.12.3. Compensation Discs<br />

h +0,2<br />

+0,1<br />

k ±0,1<br />

1,6<br />

1,6<br />

d<br />

d1<br />

d ±0,1<br />

2<br />

d3<br />

d -0,2<br />

4 -0,4<br />

s<br />

2442.12.3. Compensation Discs<br />

d1 s d d1 s d d1 s d d1 s d<br />

12 10 4,5 20 9 8,5 26 9 8,5 42 10 10,5<br />

10 10 20<br />

15 20 30<br />

14 5 5,5 20 30<br />

10 30 30 10 12,5<br />

14 40 20<br />

19 25 9 10,5 30<br />

16 5 6,5 10 40<br />

10 15 50<br />

15 20 32 10 12,5<br />

19 25 20<br />

20 35 30<br />

25 45 40<br />

55 50<br />

2442.12.4. Adjusting washers<br />

2442.12.4. Adjusting washers<br />

d4 d3 d2 h k<br />

14 5,5 16 5 3,2<br />

20 8,5 25,5 9 6,3<br />

26 8,5 31,5 9 6,3<br />

30 11 35,5 10 6,3<br />

42 11 47,5 10 6,3<br />

°<br />

°<br />

Ordering-code (example):<br />

Locating unit, round = 2442.12.<br />

Compensation Disc = 2442.12.3.<br />

d1 = 25 mm = 2442.12.3.025.<br />

s = 10 mm = 2442.12.3.025.010<br />

Order No = 2442.12.3.025.010<br />

Ordering-code (example):<br />

Locating unit, round = 2442.12.<br />

Adjusting washer = 2442.12.4.<br />

d4 = 30 mm = 2442.12.4.030<br />

Order No = 2442.12.4.030<br />

subject to alterations 9

d1<br />

g6<br />

d 2<br />

d1 l d2 l2 l4 A/F<br />

10 60 M 6 16 9 9<br />

70<br />

80<br />

100<br />

120<br />

140<br />

14 60 M 8 16 11 12<br />

70<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

18 100 M10 20 12 14<br />

120<br />

140<br />

160<br />

180<br />

200<br />

220<br />

240<br />

20 100 M12 25 14 16<br />

120<br />

140<br />

160<br />

180<br />

200<br />

220<br />

240<br />

10<br />

Ejector rods 3300.10.<br />

3300.10. Ejector rods<br />

3300.10. Ejector rods<br />

l 2<br />

R Z 4<br />

SW<br />

l js12<br />

l 4<br />

d 2<br />

d1 l d2 l2 l4 A/F<br />

24 120 M12 25 14 19<br />

140<br />

160<br />

180<br />

200<br />

240<br />

30 180 M16 30 16 24<br />

220<br />

260<br />

300<br />

Ordering-code (example):<br />

Ejector rod = 3300.10.<br />

d 1 = 20 mm = 3300.10.020.<br />

l = 140 mm = 3300.10.020.140<br />

Order No = 3300.10.020.140<br />

subject to alterations<br />

2 · 20824 · 2006 · 1 Q

2 · 20825 · 2006 · 1 Q<br />

d3<br />

k6<br />

d2<br />

l2<br />

3100.04. Centering sleeves<br />

3100.04. Centering sleeves<br />

l1<br />

3100.04. Centering sleeves<br />

l ±0,5<br />

R Z 4<br />

d3 l d2 d1 l1 l2<br />

14 20 M 6 11 8 2<br />

30<br />

40<br />

50<br />

60<br />

70<br />

80<br />

100<br />

20 30 M 8 16 13 2<br />

40<br />

60<br />

80<br />

100<br />

120<br />

140<br />

160<br />

26 30 M10 21 13 2,5<br />

40<br />

60<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

30 40 M12 25 13 2,5<br />

60<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

200<br />

240<br />

42 40 M16 33 13 4,5<br />

60<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

200<br />

220<br />

260<br />

300<br />

subject to alterations 11<br />

+0,5<br />

j6<br />

1<br />

d3<br />

d<br />

d3 l d2 d1 l1 l2<br />

54 60 M20 43 13 4,5<br />

80<br />

120<br />

160<br />

200<br />

240<br />

280<br />

Ordering-code (example):<br />

Centering sleeve<br />

= 3100.04.<br />

d3 = 26 mm = 3100.04.026.<br />

l = 30 mm = 3100.04.026.030<br />

Order No = 3100.04.026.030

12<br />

3202.12.<br />

Guide pillars 3202.13.<br />

3202.12. Guide pillars<br />

d1 l d4 k l1<br />

12 80 16 4 4<br />

100<br />

120<br />

18 120 22 6 7<br />

140<br />

160<br />

30 160 36 6 7<br />

200<br />

240<br />

3202.13. Guide pillars<br />

d1 l l1<br />

12 100 3<br />

125<br />

18 125 4<br />

160<br />

30 160 6<br />

240<br />

3202.12. Guide pillars<br />

h4<br />

1<br />

d<br />

8°<br />

R2<br />

l1<br />

3202.13. Guide pillars<br />

8°<br />

R2<br />

l1<br />

Ordering-code (example):<br />

Guide pillar = 3202.12.<br />

d1 = 18 mm = 3202.12.018.<br />

l = 160 mm = 3202.12.018.160<br />

Order No = 3202.12.018.160<br />

Ordering-code (example):<br />

Guide pillar = 3202.13.<br />

d1 = 18 mm = 3202.13.018.<br />

l = 160 mm = 3202.13.018.160<br />

Order No = 3202.13.018.160<br />

l<br />

l<br />

3<br />

-0,2<br />

4<br />

d<br />

0,4x45°<br />

k ±0,05<br />

8°<br />

h4<br />

1<br />

d<br />

subject to alterations<br />

2 · 20826 · 2006 · 1 Q

2 · 20827 · 2006 · 1 Q<br />

3111.10. Guide pillars<br />

3111.10. Guide pillars<br />

g6<br />

1<br />

d<br />

l1<br />

R Z 2,5<br />

3111.10. Guide pillars<br />

d1 l d4 k l1 l2<br />

10 40 12 3 4 17<br />

60<br />

80 22<br />

100 27<br />

12 60 16 6 7 17<br />

80 22<br />

100 27<br />

120 36<br />

14 60 18 8 7 17<br />

80 22<br />

100 27<br />

120 36<br />

140 46<br />

160<br />

16 60 20 8 7 22<br />

80 27<br />

100<br />

120 36<br />

140 46<br />

160<br />

18 80 22 8 7 27<br />

100<br />

120 36<br />

140 46<br />

160<br />

180 56<br />

200<br />

20 80 24 8 7 27<br />

100<br />

120 36<br />

140 46<br />

160<br />

180 56<br />

200<br />

22 100 26 15 7 36<br />

120 46<br />

140<br />

160 56<br />

180<br />

200 76<br />

220<br />

24 100 28 15 7 36<br />

120 46<br />

140<br />

160 56<br />

180<br />

200 76<br />

220<br />

30 160 36 15 7 56<br />

200<br />

240 76<br />

l<br />

k ±0,2<br />

l2<br />

subject to alterations 13<br />

m6<br />

1<br />

d<br />

-0,2<br />

4<br />

d<br />

d1 l d4 k l1 l2<br />

32 160 36 15 7 56<br />

200<br />

240 76<br />

40 200 48 15 10 56<br />

240 76<br />

300 96<br />

50 200 58 15 10 56<br />

240 76<br />

300 96<br />

60 240 68 20 12 76<br />

300 96<br />

360 116<br />

Ordering-code (example):<br />

Guide pillar = 3111.10.<br />

d1 = 22 mm = 3111.10.022.<br />

l = 140 mm = 3111.10.022.140<br />

Order No = 3111.10.022.140

14<br />

Guide pillars, shouldered 3111.20.<br />

3111.20. Guide pillars, shouldered<br />

-0,2<br />

4<br />

d<br />

d1 s l d3 d4 l1 k<br />

9/10 12 45 14 16 4 3<br />

17 20<br />

30<br />

35<br />

22 25<br />

35<br />

55<br />

27 25<br />

30<br />

35<br />

50<br />

36 25<br />

35<br />

45<br />

46 30<br />

45<br />

55<br />

75<br />

14/15 22 20 20 25 7 6<br />

35<br />

40<br />

45<br />

50<br />

55<br />

65<br />

70<br />

90<br />

110<br />

27 20<br />

35<br />

40<br />

45<br />

55<br />

65<br />

85<br />

105<br />

36 20<br />

35<br />

40<br />

45<br />

55<br />

65<br />

75<br />

95<br />

46 20<br />

35<br />

45<br />

65<br />

85<br />

105<br />

3111.20. Guide pillars, shouldered<br />

k6<br />

3<br />

d<br />

A 0,8<br />

k ±0,05<br />

s -0,5<br />

-1,0<br />

e7<br />

3<br />

d<br />

0,8<br />

ø0,01 A<br />

d1 s l d3 d4 l1 k<br />

14/15 56 20 20 25 7 6<br />

35<br />

55<br />

75<br />

95<br />

66 55<br />

65<br />

95<br />

76 55<br />

95<br />

86 55<br />

95<br />

18/20 22 20 26 31 7 6<br />

35<br />

40<br />

45<br />

50<br />

55<br />

60<br />

65<br />

70<br />

80<br />

85<br />

115<br />

27 20<br />

35<br />

40<br />

45<br />

50<br />

55<br />

60<br />

65<br />

70<br />

80<br />

85<br />

105<br />

125<br />

Ordering-code (example):<br />

Guide pillar, shouldered = 3111.20.<br />

d1 = 14 mm = 3111.20.014.<br />

s = 36 mm = 3111.20.014.036.<br />

l = 75 mm = 3111.20.014.036.075<br />

Order No = 3111.20.014.036.075<br />

l<br />

l1<br />

g6<br />

1<br />

d<br />

subject to alterations<br />

2 · 20828 · 2006 · 1 Q

2 · 20829 · 2006 · 1 Q<br />

3111.20. Guide pillars, shouldered<br />

3111.20. Guide pillars, shouldered<br />

-0,2<br />

4<br />

d<br />

k6<br />

3<br />

d<br />

A 0,8<br />

k ±0,05<br />

s -0,5<br />

-1,0<br />

e7<br />

3<br />

d<br />

3111.20. Guide pillars, shouldered<br />

d1 s l d3 d4 l1 k<br />

18/20 36 20 26 31 7 3<br />

35<br />

40<br />

45<br />

50<br />

55<br />

60<br />

65<br />

70<br />

75<br />

80<br />

95<br />

115<br />

135<br />

46 20<br />

45<br />

65<br />

85<br />

105<br />

135<br />

165<br />

56 20 26 31 7 6<br />

35<br />

55<br />

75<br />

95<br />

66 55<br />

75<br />

95<br />

76 55<br />

75<br />

95<br />

86 55<br />

75<br />

95<br />

96 55<br />

95<br />

116 115<br />

22/24 27 25 30 35 7 6<br />

45<br />

50<br />

60<br />

65<br />

70<br />

80<br />

85<br />

105<br />

125<br />

165<br />

0,8<br />

l<br />

ø0,01 A<br />

subject to alterations 15<br />

l1<br />

g6<br />

1<br />

d<br />

d1 s l d3 d4 l1 k<br />

22/24 36 25 30 35 7 6<br />

45<br />

50<br />

55<br />

60<br />

70<br />

75<br />

80<br />

95<br />

115<br />

135<br />

165<br />

46 25<br />

45<br />

50<br />

60<br />

65<br />

70<br />

80<br />

85<br />

105<br />

125<br />

165<br />

56 25<br />

45<br />

55<br />

75<br />

95<br />

115<br />

165<br />

66 55<br />

75<br />

95<br />

76 25<br />

45<br />

55<br />

75<br />

95<br />

115<br />

Ordering-code (example):<br />

Guide pillar, shouldered = 3111.20.<br />

d1 = 24 mm = 3111.20.024.<br />

s = 76 mm = 3111.20.024.076.<br />

l = 115 mm = 3111.20.024.076.115<br />

Order No = 3111.20.024.076.115

16<br />

Guide pillars, shouldered 3111.20.<br />

3111.20. Guide pillars, shouldered<br />

-0,2<br />

4<br />

d<br />

d1 s l d3 d4 l1 k<br />

22/24 86 55 30 35 7 6<br />

75<br />

95<br />

96 55<br />

75<br />

95<br />

116 75<br />

115<br />

155<br />

136 135<br />

30/32 27 45 42 47 7 6<br />

65<br />

105<br />

165<br />

36 55<br />

75<br />

95<br />

115<br />

155<br />

46 45<br />

65<br />

85<br />

105<br />

125<br />

165<br />

56 55<br />

75<br />

95<br />

115<br />

135<br />

175<br />

66 55<br />

75<br />

95<br />

115<br />

135<br />

175<br />

76 55<br />

75<br />

95<br />

115<br />

155<br />

86 55<br />

75<br />

95<br />

115<br />

155<br />

96 55<br />

75<br />

95<br />

115<br />

155<br />

3111.20. Guide pillars, shouldered<br />

k6<br />

3<br />

d<br />

A 0,8<br />

k ±0,05<br />

s -0,5<br />

-1,0<br />

e7<br />

3<br />

d<br />

0,8<br />

ø0,01 A<br />

d1 s l d3 d4 l1 k<br />

30/32 116 75 42 47 7 6<br />

115<br />

155<br />

136 95<br />

115<br />

155<br />

156 115<br />

155<br />

196 155<br />

195<br />

40/42 56 75 54 60 7 10<br />

115<br />

155<br />

195<br />

66 75<br />

135<br />

76 75<br />

115<br />

175<br />

86 75<br />

135<br />

96 75<br />

115<br />

155<br />

116 95<br />

135<br />

195<br />

136 95<br />

135<br />

215<br />

156 115<br />

155<br />

215<br />

196 155<br />

195<br />

235<br />

Ordering-code (example):<br />

Guide pillar, shouldered = 3111.20.<br />

d1 = 32 mm = 3111.20.032.<br />

s = 116 mm = 3111.20.032.116.<br />

l = 115 mma = 3111.20.032.116.115<br />

Order No = 3111.20.032.116.115<br />

l<br />

l1<br />

g6<br />

1<br />

d<br />

subject to alterations<br />

2 · 20830 · 2006 · 1 Q

2 · 20831 · 2006 · 1 Q<br />

3111.20. Guide pillars, shouldered<br />

3111.20. Guide pillars, shouldered<br />

-0,2<br />

4<br />

d<br />

k6<br />

3<br />

d<br />

A 0,8<br />

k ±0,05<br />

s -0,5<br />

-1,0<br />

e7<br />

3<br />

d<br />

3111.20. Guide pillars, shouldered<br />

d1 s l d3 d4 l1 k<br />

50 96 115 66 72 10 10<br />

155<br />

195<br />

116 135<br />

155<br />

195<br />

136 135<br />

155<br />

195<br />

156 135<br />

155<br />

195<br />

196 175<br />

195<br />

235<br />

60 96 115 80 86 10 20<br />

155<br />

195<br />

116 135<br />

155<br />

195<br />

136 135<br />

155<br />

195<br />

156 155<br />

195<br />

235<br />

196 175<br />

195<br />

235<br />

246 195<br />

235<br />

275<br />

315<br />

0,8<br />

l<br />

ø0,01 A<br />

subject to alterations 17<br />

l1<br />

g6<br />

1<br />

d<br />

Ordering-code (example):<br />

Guide pillar, shouldered = 3111.20.<br />

d1 = 60 mm = 3111.20.060.<br />

s = 96 mm = 3111.20.060.096.<br />

l = 195 mm = 3111.20.060.096.195<br />

Order No = 3111.20.060.096.195

18<br />

Locating guide pillars, shouldered 3111.21.<br />

-0,2<br />

4<br />

d<br />

e7<br />

3<br />

d<br />

0,8<br />

ø0,01 A<br />

3111.21. Locating guide pillars, shouldered<br />

d1 s l d3 d4 l1 k f<br />

9/10 12 25 14 16 7 3 3<br />

45<br />

65<br />

17 20<br />

25<br />

30<br />

35<br />

50<br />

55<br />

70<br />

75<br />

22 25<br />

35<br />

55<br />

75<br />

95<br />

27 20<br />

25<br />

30<br />

45<br />

50<br />

70<br />

90<br />

36 25<br />

35<br />

45<br />

65<br />

85<br />

46 30<br />

35<br />

45<br />

70<br />

56 35<br />

60<br />

14/15 17 35 20 25 7 6 9<br />

55<br />

75<br />

95<br />

22 30<br />

50<br />

70<br />

90<br />

110<br />

125<br />

150<br />

27 30<br />

45<br />

65<br />

85<br />

105<br />

125<br />

145<br />

165<br />

3111.21. Locating guide pillars, shouldered<br />

k<br />

A<br />

±0,05<br />

f s -0,5<br />

-1,0<br />

0,8<br />

e7<br />

3<br />

d<br />

k6<br />

3<br />

d<br />

l<br />

0,8<br />

ø0,01 A<br />

l1<br />

g6<br />

1<br />

d<br />

d1 s l d3 d4 l1 k f<br />

14/15 36 35 20 25 7 6 9<br />

55<br />

75<br />

95<br />

125<br />

155<br />

46 35<br />

45<br />

65<br />

85<br />

105<br />

125<br />

145<br />

56 35<br />

55<br />

75<br />

95<br />

135<br />

66 55<br />

65<br />

95<br />

125<br />

76 55<br />

95<br />

86 55<br />

95<br />

96 55<br />

95<br />

116 75<br />

18/20 17 35 26 31 7 6 9<br />

55<br />

75<br />

120<br />

22 35<br />

45<br />

65<br />

85<br />

115<br />

Ordering-code (example):<br />

Locating guide pillar, shouldered = 3111.21.<br />

d1 = 15 mm = 3111.21.015.<br />

s = 27 mm = 3111.21.015.027.<br />

l = 85 mm = 3111.21.015.027.085<br />

Order No = 3111.21.015.027.085<br />

subject to alterations<br />

2 · 20832 · 2006 · 1 Q

2 · 20833 · 2006 · 1 Q<br />

3111.21. Locating guide pillars, shouldered<br />

3111.21. Locating guide pillars, shouldered<br />

-0,2<br />

4<br />

d<br />

e7<br />

3<br />

d<br />

0,8<br />

ø0,01 A<br />

k<br />

A<br />

±0,05<br />

f s -0,5<br />

-1,0<br />

0,8<br />

e7<br />

3<br />

d<br />

k6<br />

3<br />

d<br />

3111.21. Locating guide pillars, shouldered<br />

d1 s l d3 d4 l1 k f<br />

18/20 27 35 26 31 7 6 9<br />

45<br />

65<br />

85<br />

105<br />

125<br />

165<br />

225<br />

245<br />

36 35<br />

55<br />

75<br />

95<br />

115<br />

135<br />

165<br />

225<br />

255<br />

46 35<br />

45<br />

65<br />

85<br />

105<br />

135<br />

165<br />

245<br />

56 35<br />

55<br />

75<br />

95<br />

155<br />

66 35<br />

55<br />

75<br />

95<br />

145<br />

76 55<br />

75<br />

95<br />

135<br />

86 55<br />

75<br />

95<br />

125<br />

96 55<br />

95<br />

116 75<br />

115<br />

136 135<br />

l<br />

0,8<br />

ø0,01 A<br />

subject to alterations 19<br />

l1<br />

g6<br />

1<br />

d<br />

d1 s l d3 d4 l1 k f<br />

22/24 17 35 30 35 7 6 9<br />

55<br />

75<br />

22 35<br />

55<br />

75<br />

105<br />

130<br />

27 35<br />

45<br />

65<br />

85<br />

105<br />

125<br />

165<br />

205<br />

245<br />

285<br />

36 35<br />

55<br />

75<br />

95<br />

115<br />

135<br />

165<br />

205<br />

245<br />

285<br />

46 35<br />

45<br />

65<br />

85<br />

105<br />

125<br />

165<br />

205<br />

56 35<br />

55<br />

75<br />

95<br />

115<br />

165<br />

205<br />

Ordering-code (example):<br />

Locating guide pillar, shouldered = 3111.21.<br />

d1 = 20 mm = 3111.21.020.<br />

s = 46 mm = 3111.21.020.046.<br />

l = 105 mm = 3111.21.020.046.105<br />

Order No = 3111.21.020.046.105

20<br />

Locating guide pillars, shouldered 3111.21.<br />

-0,2<br />

4<br />

d<br />

e7<br />

3<br />

d<br />

0,8<br />

ø0,01 A<br />

3111.21. Locating guide pillars, shouldered<br />

d1 s l d3 d4 l1 k f<br />

22/24 66 35 30 35 7 6 9<br />

55<br />

75<br />

95<br />

155<br />

76 55<br />

75<br />

95<br />

115<br />

145<br />

86 55<br />

75<br />

95<br />

135<br />

96 55<br />

75<br />

95<br />

125<br />

116 75<br />

115<br />

155<br />

136 95<br />

135<br />

156 155<br />

30/32 27 45 42 47 7 6 9<br />

65<br />

105<br />

165<br />

185<br />

245<br />

285<br />

36 55<br />

75<br />

95<br />

115<br />

155<br />

245<br />

285<br />

46 45<br />

65<br />

85<br />

105<br />

125<br />

165<br />

245<br />

285<br />

56 55<br />

75<br />

95<br />

115<br />

135<br />

175<br />

245<br />

295<br />

3111.21. Locating guide pillars, shouldered<br />

k<br />

A<br />

±0,05<br />

f s -0,5<br />

-1,0<br />

0,8<br />

e7<br />

3<br />

d<br />

k6<br />

3<br />

d<br />

l<br />

0,8<br />

ø0,01 A<br />

l1<br />

g6<br />

1<br />

d<br />

d1 s l d3 d4 l1 k f<br />

30/32 66 55 42 47 7 6 9<br />

75<br />

95<br />

115<br />

135<br />

175<br />

245<br />

295<br />

76 55<br />

75<br />

95<br />

115<br />

155<br />

225<br />

86 55<br />

75<br />

95<br />

115<br />

155<br />

225<br />

96 55<br />

75<br />

95<br />

115<br />

155<br />

205<br />

116 75<br />

115<br />

155<br />

136 95<br />

115<br />

155<br />

156 115<br />

155<br />

196 155<br />

195<br />

Ordering-code (example):<br />

Locating guide pillar, shouldered = 3111.21.<br />

d1 = 32 mm = 3111.21.032.<br />

s = 86 mm = 3111.21.032.086.<br />

l = 95 mm = 3111.21.032.086.095<br />

Order No = 3111.21.032.086.095<br />

subject to alterations<br />

2 · 20834 · 2006 · 1 Q

2 · 20835 · 2006 · 1 Q<br />

3111.21. Locating guide pillars, shouldered<br />

3111.21. Locating guide pillars, shouldered<br />

-0,2<br />

4<br />

d<br />

e7<br />

3<br />

d<br />

0,8<br />

ø0,01 A<br />

k<br />

A<br />

±0,05<br />

f s -0,5<br />

-1,0<br />

0,8<br />

e7<br />

3<br />

d<br />

k6<br />

3<br />

d<br />

3111.21. Locating guide pillars, shouldered<br />

d1 s l d3 d4 l1 k f<br />

40/42 46 95 54 60 7 10 12<br />

165<br />

56 75<br />

115<br />

155<br />

195<br />

66 75<br />

135<br />

76 75<br />

115<br />

175<br />

86 75<br />

135<br />

96 75<br />

115<br />

155<br />

116 95<br />

135<br />

195<br />

136 95<br />

135<br />

215<br />

156 115<br />

155<br />

215<br />

196 155<br />

195<br />

235<br />

246 165<br />

245<br />

l<br />

0,8<br />

ø0,01 A<br />

subject to alterations 21<br />

l1<br />

g6<br />

1<br />

d<br />

Ordering-code (example):<br />

Locating guide pillar, shouldered = 3111.21.<br />

d1 = 42 mm = 3111.21.042.<br />

s = 96 mm = 3111.21.042.096.<br />

l = 115 mm = 3111.21.042.096.115<br />

Order No = 3111.21.042.096.115

22<br />

Guide pillars with flange 3111.31.<br />

Material:<br />

Steel<br />

Surface hardness: case hardened<br />

62+2 HRC<br />

Hardness<br />

penetration depth: 1.2 mm<br />

Model:<br />

Ground<br />

Note:<br />

Holding fixture bore H7.<br />

Delivery does not include screws.<br />

Fixing:<br />

socket head screw DIN EN ISO 4762<br />

M 8x20<br />

M 10x25<br />

M 12x30<br />

M 14x35<br />

M 16x40<br />

should be used<br />

3111.31. Guide pillars with flange<br />

radiussed<br />

3111.31. Guide pillars with flange<br />

d1 32 40 50 63 80<br />

d2 40 50 63 80 100<br />

d3 76 92 112 138 170<br />

d5 55 68 84 105 130<br />

d6 9 11 14 16 18<br />

d7 15 18 20 24 26<br />

r 1,6 2 2,5 2,5 3<br />

r1 4 4 5 6 8<br />

l2 11 13 14 16 20<br />

l3 6 6 8 8 10<br />

l5 15,1 18,4 22,5 27,4 32,1<br />

l6 11 13 14 16 20<br />

l7 19 23 28 34 40<br />

l8 8 9 10 13 15<br />

l9 9 10 12 15 18<br />

l10 1,5 1,5 2 3 4<br />

l1 (l) (l) (l) (l) (l)<br />

067 97<br />

080 110 116<br />

095 125 131 137<br />

112 142 148 154 162<br />

132 168 174 182 192<br />

160 202 210 220<br />

190 240 250<br />

224 284<br />

436 486<br />

Ordering code (example):<br />

Guide pillar with flange = 3111.31.<br />

d1 = 32 mm = 3111.31.032.<br />

l1 = 112 mm = 3111.31.032.112<br />

Order no. = 3111.31.032.112<br />

subject to alterations<br />

2 · 20500 · 2006 · 1 ◽

2 · 20519 · 2006 · 1 ◽<br />

subject to alterations 23

24<br />

Guide pillars (diagonal load pillars) 3110.11.<br />

g6<br />

1<br />

d<br />

3110.11. Guide pillars (diagonal load pillars)<br />

3110.11. Guide pillars (diagonal load pillars)<br />

d1 8 9 10 12 14 15 16 18 20 22 24 30 32 40 50<br />

d4 10 12 12 16 18 18 20 22 24 26 28 36 36 48 58<br />

k 3 3 3 6 8 8 8 8 8 15 15 15 15 15 15<br />

l1 4 4 4 7 7 7 7 7 7 7 7 7 7 10 10<br />

l<br />

40 b b b b b<br />

60 b b b b b b b b b<br />

80 b b b b b b b b b b b<br />

100 b b b b b b b b b b b b b<br />

120 b b b b b b b b b b b b<br />

140 b b b b b b b b<br />

160 b b b b b b b b b b b b<br />

180 b b b b b b b<br />

200 b b b b b b b b b<br />

220 b b<br />

240 b b b b b b b b<br />

300 b b b b b b<br />

360 b b b b<br />

l1<br />

l<br />

R Z 2,5<br />

Ordering-code (example):<br />

Guide pillar (diagonal load pillar) = 3110.11.<br />

d1 = 20 mm = 3110.11.020.<br />

l = 180 mm = 3110.11.020.180<br />

Order No = 3110.11.020.180<br />

-0,2<br />

4<br />

d<br />

k -0,2<br />

subject to alterations<br />

2 · 20836 · 2006 · 1 Q

2 · 20837 · 2006 · 1 Q<br />

3100.09. Guide sleeves<br />

3100.09. Guide sleeves<br />

g6<br />

1<br />

d<br />

3100.09. Guide sleeves<br />

R Z 4<br />

d1 10 14 18 24 30<br />

d2 6,2 8,3 10,4 12,5 16,5<br />

l<br />

20 b<br />

30 b b<br />

40 b b b<br />

50 b b<br />

60 b b b b<br />

70 b b<br />

80 b b b b b<br />

100 b b b b b<br />

120 b b b b b<br />

140 b b b b b<br />

160 b b b b<br />

180 b b b b<br />

200 b b<br />

220 b b<br />

240 b b<br />

260 b<br />

300 b<br />

l js10<br />

subject to alterations 25<br />

d 2<br />

Ordering-code (example):<br />

Guide sleeve = 3100.09.<br />

d1 = 10 mm = 3100.09.010.<br />

l = 100 mm = 3100.09.010.100<br />

Order No = 3100.09.010.100

26<br />

Guide bushes 3120.40.<br />

3120.40. Guide bushes<br />

d1 s l d3 d4 k<br />

9/10 9 9 14 16 3<br />

12 12<br />

17 17<br />

22 22<br />

27 27<br />

36 36<br />

46 46<br />

56 46<br />

66 46<br />

12 17 17 18 23 6<br />

22 22<br />

27 27<br />

36 36<br />

46 46<br />

56 56<br />

14/15 12 12 20 25 6<br />

17 17<br />

22 22<br />

27 27<br />

36 36<br />

46 46<br />

56 56<br />

66 56<br />

76 56<br />

86 56<br />

96 56<br />

16 17 17 22 25 6<br />

22 22<br />

27 27<br />

36 36<br />

46 46<br />

56 56<br />

18/20 17 17 26 31 6<br />

22 22<br />

27 27<br />

36 36<br />

46 46<br />

56 56<br />

66 66<br />

76 76<br />

86 76<br />

96 76<br />

116 76<br />

22/24 17 17 30 35 6<br />

22 22<br />

27 27<br />

36 36<br />

46 46<br />

56 56<br />

66 66<br />

76 76<br />

86 86<br />

96 96<br />

3120.40. Guide bushes<br />

d4<br />

-0,2<br />

d1 H7<br />

s -0,5<br />

-1,0<br />

A<br />

k ±0,05<br />

ø0,01 A<br />

l<br />

e7<br />

3<br />

d<br />

k6<br />

3<br />

d<br />

d 1 +0,2<br />

+0,5<br />

s -0,5<br />

-1,0<br />

d1 s l d3 d4 k<br />

22/24 116 96 30 35 6<br />

136 96<br />

156 96<br />

30/32 27 27 42 47 6<br />

36 36<br />

46 46<br />

56 56<br />

66 66<br />

76 76<br />

86 86<br />

96 96<br />

116 116<br />

136 116<br />

156 116<br />

176 116<br />

40/42 46 46 54 60 10<br />

56 56<br />

66 66<br />

76 76<br />

86 86<br />

96 96<br />

116 116<br />

136 136<br />

156 136<br />

196 136<br />

246 136<br />

50 76 76 66 72 10<br />

96 96<br />

116 116<br />

136 136<br />

156 136<br />

196 136<br />

60 76 76 80 86 20<br />

96 96<br />

116 116<br />

136 136<br />

156 136<br />

196 136<br />

246 136<br />

Ordering-code (example):<br />

Guide bush = 3120.40.<br />

d1 = 32 mm = 3120.40.032.<br />

s = 116 mm = 3120.40.032.116<br />

Order No = 3120.40.032.116<br />

l<br />

0,8<br />

0,8<br />

d1 H7<br />

subject to alterations<br />

2 · 20838 · 2006 · 1 Q

2 · 20839 · 2006 · 1 Q<br />

f<br />

3120.42. Locating guide bushes<br />

3120.42. Locating guide bushes<br />

d4<br />

-0,2<br />

d3<br />

e7<br />

l (l )<br />

1<br />

s -0,5<br />

-1,0<br />

A<br />

k ±0,05<br />

ø0,01 A ø0,01 A<br />

d1 H7<br />

e7<br />

3<br />

d<br />

k6<br />

3<br />

d<br />

d 1 +0,2<br />

+0,5<br />

3120.42. Locating guide bushes<br />

0,8 0,8<br />

d1 s l l1 d3 d4 f k<br />

9/10 12 15 15 14 16 3 3<br />

17 20 20<br />

22 25 25<br />

27 30 30<br />

36 39 39<br />

46 46 49<br />

56 46 59<br />

66 46 69<br />

14/15 17 26 26 20 25 9 6<br />

22 31 31<br />

27 36 36<br />

36 45 45<br />

46 55 55<br />

56 56 65<br />

66 56 75<br />

76 56 85<br />

86 56 95<br />

96 56 105<br />

116 56 125<br />

18/20 17 26 26 26 31 9 6<br />

22 31 31<br />

27 36 36<br />

36 45 45<br />

46 55 55<br />

56 65 65<br />

66 75 75<br />

76 76 85<br />

86 76 95<br />

96 76 105<br />

116 76 125<br />

136 76 145<br />

22/24 17 26 26 30 35 9 6<br />

22 31 31<br />

27 36 36<br />

36 45 45<br />

46 55 55<br />

56 65 65<br />

66 75 75<br />

76 85 85<br />

86 95 95<br />

96 105 105<br />

116 96 125<br />

136 96 145<br />

156 96 165<br />

0,8<br />

l1<br />

d1 s l l1 d3 d4 f k<br />

30/32 27 36 36 42 47 9 6<br />

36 45 45<br />

46 55 55<br />

56 65 65<br />

66 75 75<br />

76 85 85<br />

86 95 95<br />

96 105 105<br />

116 125 125<br />

136 116 145<br />

156 116 165<br />

176 116 185<br />

196 116 205<br />

40/42 46 58 58 54 60 12 10<br />

56 68 68<br />

66 78 78<br />

76 88 88<br />

86 98 98<br />

96 108 108<br />

116 128 128<br />

136 136 148<br />

156 136 168<br />

196 136 208<br />

246 136 258<br />

Ordering-code (example):<br />

Locating guide bush = 3120.42.<br />

d1 = 24 mm = 3120.42.024.<br />

s = 96 mm = 3120.42.024.096<br />

Order No = 3120.42.024.096<br />

subject to alterations 27<br />

s -0,5<br />

-1,0<br />

l<br />

d1 H7

28<br />

Oilless Guide Bushes with collar<br />

Bronze with Non-Liquid Lubricant, 2087.70.<br />

Material:<br />

Bronze with Non-Liquid Lubricant,<br />

oilless lubricating.<br />

Note:<br />

Fit <strong>for</strong> receiving bore: H 7.<br />

Direction of Motion<br />

Embedded non-liquid lubricant<br />

(section)<br />

Ordering-code (example):<br />

Guide bush = 2087.70.<br />

d1 = 18 mm = 018.<br />

l2 = 27 mm = 027<br />

Order No = 2087.70.018.027<br />

2087.70.<br />

d1 9 10 14 15 18 20 22 24 30 32 40 42<br />

d2 14 20 26 30 42 54<br />

d3 16 25 31 35 47 60<br />

l3 3 6 6 6 6 10<br />

l4 1,5 2 2 3 4 5<br />

l5 3 6 8 8 8 12<br />

r 0,5 1 2 3 3 3<br />

l1<br />

l2<br />

15 12 ●<br />

20 17 ●<br />

23 17 ●<br />

25 17 ● ●<br />

25 22 ●<br />

28 22 ●<br />

30 22 ● ●<br />

30 27 ●<br />

33 27 ●<br />

35 27 ● ● ●<br />

39 36 ●<br />

42 36 ●<br />

44 36 ● ● ●<br />

49 46 ●<br />

52 46 ●<br />

54 46 ● ● ●<br />

58 46 ●<br />

59 56 ●<br />

62 56 ●<br />

64 56 ● ● ●<br />

68 56 ●<br />

69 66 ●<br />

72 66 ●<br />

74 66 ● ● ●<br />

78 66 ●<br />

82 76 ●<br />

84 76 ● ● ●<br />

88 76 ●<br />

92 86 ●<br />

94 86 ● ● ●<br />

98 86 ●<br />

104 96 ● ● ●<br />

108 96 ●<br />

124 116 ● ● ●<br />

128 116 ●<br />

144 136 ● ●<br />

148 136 ●<br />

164 156 ●<br />

168 156 ●<br />

208 196 ●<br />

subject to alterations<br />

2·9760·9·2 °

2·11230·9·2 °<br />

2087.72.<br />

l1 ( 2 x d1)<br />

2087.72.<br />

1<br />

min. 2 x d<br />

Oilless Guide Bushes with collar<br />

2087.72. Bronze with Non-Liquid Lubricant,<br />

l 3<br />

l 4<br />

r<br />

R1<br />

d 3<br />

+0,5<br />

d 1 +0,2<br />

H7 d 1<br />

d 2 e7<br />

H7 d 2 k6<br />

Ordering code (Example):<br />

Guide bush = 2087.72.<br />

d1 = 18 mm = 2087.72.018.<br />

l1 = 27 mm = 2087.72.018.027<br />

Order No = 2087.72.018.027<br />

R1<br />

r<br />

l 4<br />

A<br />

l 3<br />

l1 ( 2 x d1)<br />

Ø0,01 A<br />

Material:<br />

Bronze with Non-Liquid Lubricant,<br />

oilless lubricating.<br />

Note:<br />

Fit <strong>for</strong> receiving bore: H 7.<br />

Direction of Motion<br />

Embedded non-liquid lubricant<br />

(section)<br />

d1 9/10 12 14/15 16 18/20 22/24 25 30/32 40/42 50 60<br />

d2 14 18 20 22 26 30 32 42 54 66 80<br />

d3 16 23 25 27 31 35 38 47 60 72 86<br />

r 0,5 1 1 2 2 3 3 3 3 3 3<br />

l3 3 6 6 6 6 6 6 6 10 10 20<br />

l4<br />

l1<br />

1,5 2 2 2 2 3 3 4 5 5 5<br />

12 ●<br />

17 ● ● ● ● ● ●<br />

22 ● ● ● ● ● ●<br />

27 ● ● ● ● ● ● ●<br />

36 ● ● ● ● ● ● ●<br />

46 ● ● ● ● ● ● ● ● ●<br />

56 ● ● ● ● ● ● ● ● ●<br />

66 ● ● ● ● ●<br />

76 ● ● ● ● ● ●<br />

86 ● ● ● ● ●<br />

96 ● ● ● ● ●<br />

116 ● ● ● ●<br />

136 ● ● ●<br />

156 ● ● ●<br />

196 ● ●<br />

subject to alterations 29

30<br />

Oilless Guide Bushes with collar<br />

Bronze with Non-Liquid Lubricant, 2087.71.<br />

Material:<br />

Bronze with Non-Liquid Lubricant,,<br />

oilless lubricating.<br />

Note:<br />

Fit <strong>for</strong> receiving bore: H7.<br />

2087.71.<br />

Direction of Motion<br />

Embedded non-liquid lubricant<br />

(section)<br />

d1 14 15 18 20 22 24 30 32<br />

d2 20 26 30 42<br />

d3 25 31 35 47<br />

r 1 1,5 2 2<br />

l1 26 39 49 63<br />

l2 17 22 27 36<br />

l5 9 17 22 27<br />

2087.71.<br />

1<br />

l<br />

( l 5)<br />

2<br />

l<br />

6<br />

2<br />

d 3<br />

d 2 e7<br />

d 1 H7<br />

d 2 e7<br />

H7<br />

d 2 k6<br />

r<br />

Ordering-code (example):<br />

Guide bush = 2087.71.<br />

d1 = 20 mm = 2032.70.020.<br />

l2 = 22 mm = 2032.70.020.022<br />

Order No = 2087.71.020.022<br />

r<br />

A<br />

Ø0,01 A<br />

Ø0,01 A<br />

subject to alterations<br />

2·10706·9·3 °

2 · 21481 · 2008 · 1 ◽<br />

3120.70.<br />

3120.71.<br />

3120.70. / 3120.71.<br />

3120.70. Guide bushes, bronze with solid lubricant<br />

3120.71. Guide bushes, bronze<br />

Ordering-code (example):<br />

Guide bush = 3120.70.<br />

d1 = 40 mm = 3120.70.040.<br />

d2 = 50 mm = 3120.70.040.050<br />

l1 = 80 mm = 3120.70.040.050.080<br />

Order number = 3120.70.040.050.080<br />

Ordering-code (example):<br />

Guide bush = 3120.71.<br />

d1 = 40 mm = 3120.71.040.<br />

d2 = 50 mm = 3120.71.040.050<br />

l1 = 80 mm = 3120.71.040.050.080<br />

Order number = 3120.71.040.050.080<br />

Material:<br />

3120.70. Bronze with solid lubricant, low maintenance.<br />

3120.71. Bronze<br />

Note:<br />

Recommended holding fixture bore H7.<br />

Bushes can be used radially and axially.<br />

Fixing:<br />

Connecting with adhesive or if needed secure with threaded pin or<br />

flat mushroom head screw 2192.61.<br />

Direction of Motion<br />

Embedded non-liquid lubricant<br />

(section)<br />

d1 8 10 12 13 14 15 16 18 19 20 24 25 28 30 31,5 32 35 38 40 45<br />

d2 12 14/15 18 19 20 21 22 24 25 26/28/30 32 32/33/35 38 38/40/42 40 42 44/45 48 50/55 55/56/60<br />

r 0,5 0,5 0,5 0,5 0,5 0,75 0,75 0,75 0,75 0,75 0,75 0,75 0,75 0,75 0,75 0,75 0,75 1,5 1,5 1,5<br />

l4 2 2 2 2 2 2 2 2 4 4 4 4 4 4 4 4 4 4 4 4<br />

l1 8 b b/–<br />

10 b b/b b b b b b<br />

12 b b/– b b b b<br />

15 b b/– b b b b b b –/ b/–<br />

16 b b b b b –/ b/b – /b/b<br />

20 b/– b b b b b b –/ b/b – /b/b b/b/– – /b b/–<br />

25 b b b b b –/ b/b – /b/b b/b/– b/b b/b<br />

30 b b b b b –/ b/b – /b/b b b/b/– b b b/b b b/b b/b/b<br />

35 b b –/ b/b – /b/b b/b/– b/b b/b b/b/b<br />

37 b –/ b/–<br />

40 b b b/b/b – /b/b b b/b/– b b b/b b b/b b/b/b<br />

47 b – /b/–<br />

50 –/ b/– b/b/b b/b/– b/b b/b b/b/b<br />

60 – /b/– b/b/b b b/b b/b b/b/b<br />

70 b/– –/–/b<br />

77 b b/–<br />

80 b/– –/–/b<br />

subject to alterations 31

32<br />

Guide bushes, bronze with solid lubricant 3120.70.<br />

Guide bushes, bronze 3120.71.<br />

Material:<br />

3120.70. Bronze with solid lubricant, low maintenance.<br />

3120.71. Bronze<br />

Note:<br />

Recommended holding fixture bore H7.<br />

Bushes can be used radially and axially.<br />

Fixing:<br />

Connecting with adhesive or if needed secure with threaded pin or<br />

flat mushroom head screw 2192.61.<br />

Direction of Motion<br />

Embedded non-liquid lubricant<br />

(section)<br />

3120.70. / 3120.71.<br />

3120.70.<br />

3120.71.<br />

Ordering-code (example):<br />

Guide bush = 3120.70.<br />

d1 = 40 mm = 3120.70.040.<br />

d2 = 50 mm = 3120.70.040.050<br />

l1 = 80 mm = 3120.70.040.050.080<br />

Order number = 3120.70.040.050.080<br />

Ordering-code (example):<br />

Guide bush = 3120.71.<br />

d1 = 40 mm = 3120.71.040.<br />

d2 = 50 mm = 3120.71.040.050<br />

l1 = 80 mm = 3120.71.040.050.080<br />

Order number = 3120.71.040.050.080<br />

d1 50 55 60 63 65 70 75 80 85 90 100 110 120 125 130 140 150 160<br />

d2 60/62/65 70 74/75 75 80 85/90 90/95 96/100 100 110 120 130 140 145 150 160 170 180<br />

r 1,5 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2<br />

l4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4<br />

l1 30 b/b/b b/b<br />

35 b/b/– b/b b/–<br />

37<br />

40 b/b/b b b/b b/– b/b<br />

47<br />

50 b/b/b b b/b b b/b b/b<br />

60 b/b/b b b/b b b b/b b/b b/b b b<br />

70 b/b/b b b/b b b b/b b/b b/b b b<br />

77<br />

80 b/–/b b/b b b b/b b/b b/b b b b b b<br />

95 b/–/–<br />

100 –/–/b –/b b/– b/b b/b b b b b b b b b b<br />

120 b b/b b b b b b b<br />

130 b<br />

140 – /b b b b<br />

150 b b<br />

subject to alterations<br />

2·21482·2008·1 ◽

2 · 20840· 2006 · 1 Q<br />

d<br />

H7<br />

3<br />

d<br />

Angled Guide Gibs<br />

2962.83. Bronze with Non-Liquid Lubricant<br />

2962.83. Angled Guide Gibs<br />

2<br />

Form B<br />

t1 ±0,1<br />

R Z 6,3<br />

Form A<br />

F7 h3 t 2<br />

h2 ±0,1<br />

R Z 6,3<br />

t 3<br />

d +0,7<br />

+1<br />

3<br />

g6<br />

b<br />

2962.83. Angled Guide Gibs<br />

l4 ±0,1<br />

d<br />

1<br />

Number of<br />

Order No Shape b h1 l1 l2 l3 l4 d1 d2 d3 t1 t2 t3 h2 h3 screw holes<br />

2962.83.016.012.050 A 16 12 50 34 14 9,5 10 5,5 5 5 5,7 – 11 4 2<br />

016.012.071 A 71 55 35 2<br />

016.012.090 B 90 74 54 3<br />

2962.83.020.020.080 A 20 20 80 64 40 12 11 6,6 6 5 6,8 9,5 19 5 2<br />

020.020.100 A 100 84 60 2<br />

020.020.125 B 125 109 85 3<br />

2962.83.025.032.100 A 25 32 100 80 50 15,5 15 9 8 6 9 19 31 6 2<br />

025.032.125 A 125 105 75 2<br />

025.032.160 B 160 140 110 3<br />

2962.83.030.050.125 A 30 50 125 95 55 18 18 11 10 7 11 34 49 8 2<br />

030.050.160 A 160 130 90 2<br />

030.050.200 B 200 170 130 3<br />

l4 ±0,01<br />

l3 ±0,01<br />

l2 ±0,1<br />

l1-0,2<br />

Ordering-code (example):<br />

Angled Guide Gib = 2962.83.<br />

b = 16 mm = 2962.83.016.<br />

h1 = 12 mm = 2962.83.016.012.<br />

l1 = 50 mm = 2962.83.016.012.050<br />

Order No = 2962.83.016.012.050<br />

subject to alterations 33

Material:<br />

Bronze with Non-Liquid Lubricant,,<br />

oilless lubricating.<br />

Execution:<br />

Sliding faces ground.<br />

Direction of Motion<br />

Embedded non-liquid lubricant<br />

(section)<br />

2961.76. Flat Guide Bars<br />

Order No b s a<br />

2961.76.025.005.050 25 5 50<br />

2961.76.025.005.071 71<br />

2961.76.025.005.090 90<br />

2961.76.025.006.050 25 6 50<br />

2961.76.025.006.063 63<br />

2961.76.025.006.080 80<br />

2961.76.025.006.100 100<br />

2961.76.025.006.125 125<br />

2961.76.040.005.050 40 5 50<br />

2961.76.040.005.071 71<br />

2961.76.040.005.090 90<br />

2961.76.040.006.080 40 6 80<br />

2961.76.040.006.100 100<br />

2961.76.040.006.125 125<br />

2961.76.040.006.160 160<br />

2961.76.040.006.200 200<br />

2961.76.063.006.080 63 6 80<br />

2961.76.063.006.100 100<br />

2961.76.063.006.125 125<br />

2961.76.063.006.160 160<br />

2961.76.063.008.125 63 8 125<br />

2961.76.063.008.160 160<br />

2961.76.063.008.200 200<br />

2961.76.063.008.250 250<br />

2961.76.063.008.315 315<br />

Ordering-code (example):<br />

Flat Guide Bar = 2961.76.<br />

b = 25 mm = 2961.76.025.<br />

s = 6 mm = 2961.76.025.006.<br />

a = 50 mm = 2961.76.025.006.050<br />

Order No = 2961.76.025.006.050<br />

34<br />

Flat Guide Bars<br />

Bronze with Non-Liquid Lubricant 2961.76.<br />

2961.76. Flat Guide Bars<br />

R Z 4<br />

h k9<br />

l1-0,2<br />

-0,1<br />

-0,25<br />

b<br />

subject to alterations<br />

2· 17313·2002·1 °

2· 17318·2002·1 °<br />

Flat Guide Bars<br />

2961.77. Bronze with Non-Liquid Lubricant<br />

2961.77. Flat Guide Bars<br />

s 0<br />

-0,015<br />

2961.77. Flat Guide Bars<br />

0<br />

500 -0,5<br />

Order No b s l<br />

2961.77.025.006.500 25 6 500<br />

2961.77.040.006.500 40 6 500<br />

2961.77.063.008.500 63 8 500<br />

2961.77.080.010.500 80 10 500<br />

Ordering-code (example):<br />

Flat Guide Bar = 2961.77.<br />

b = 25 mm = 2961.77.025.<br />

s = 6 mm = 2961.77.025.006.<br />

l = 500 mm = 2961.77.025.006.500<br />

Order No = 2961.77.025.006.500<br />

subject to alterations 35<br />

-0,1<br />

-0,2<br />

b<br />

Material:<br />

Bronze with Non-Liquid Lubricant,,<br />

oilless lubricating.<br />

Execution:<br />

Sliding faces ground.<br />

Direction of Motion<br />

Embedded non-liquid lubricant<br />

(section)

36<br />

Ball bearing guides 3120.65.<br />

3120.65. Ball bearing guides<br />

d1 l l1 l2 d3 d4 f s2 Strokemax.<br />

12 24 40 2,1 22 26 6 18 50<br />

56 82<br />

18 34 45 3 30 35 11 23 44<br />

56 66<br />

71 96<br />

30 54 56 4,8 46 52 21 33 32<br />

75 78<br />

95 110<br />

3120.65. Ball bearing guides<br />

Strokemax.<br />

Ordering-code (example):<br />

Ball bearing guide = 3120.65.<br />

d1 = 18 mm = 3120.65.018.<br />

l1 = 56 mm = 3120.65.018.056<br />

Order No = 3120.65.018.056<br />

subject to alterations<br />

2 · 20841· 2006 · 1 Q

2·21483·2008·1 ◽<br />

3131.80.<br />

3131.80. Rectangular guides with rollers<br />

Material:<br />

Steel<br />

Hardness: ~56-58 HRC<br />

Surface: burnished<br />

Description:<br />

The rectangular guides with rollers guarantee the greatest<br />

precisionwhen their mould is moved together. The rectangular<br />

guides must always be installed in the outer area of the mould<br />

plates to ensure problem-free functionality.<br />

The maximum operating temperature is 150°C.<br />

Advantages: no play or friction, low maintenance and no<br />

lubrication<br />

3131.80.<br />

Order No t w a b c d e h r s1 s2 s3 d1 d2 t1<br />

3131.80.032.063 32 63 46 46 27 21 12,1 92 8 9 11 35 15 9 9<br />

3131.80.040.100 40 100 66 66 36 33 19,5 132 10 13 18 48 20 13,5 13<br />

Ordering-code (example):<br />

Rectangular guide with rollers = 3131.80.<br />

t = 32 mm = 3131.80.032.<br />

w = 63 mm = 3131.80.032.063<br />

Order number = 3131.80.032.063<br />

subject to alterations 37

38<br />

Rectangular guides 3131.40.<br />

Material:<br />

Steel with solid lubricant<br />

surface: case hardened<br />

580+40 HV 30<br />

Steel<br />

surface: case hardened<br />

700+60 HV 30<br />

Operating temperature up to 200°C.<br />

3131.40.<br />

3131.40.<br />

Order No l2 b2 l1 r t3 t2 t1 d2 d1 l4 l3 b3 b1<br />

3131.40.022.016.020 22 16 20 6 11 6,8 20 11 6,6 7 15 26 40<br />

.040 40<br />

3131.40.027.020.025 27 20 25 6 13 6,8 22 11 6,6 7 19 31 45<br />

.025 50<br />

3131.40.036.025.032 36 25 32 8 14 6,8 25 11 6,6 9 27 35 50<br />

.050 50<br />

3131.40.046.032.040 46 32 40 8 19 9 32 15 9 11 35 45 63<br />

.080 80<br />

3131.40.056.040.050 56 40 50 10 22 11 36 18 11 15 40 60 85<br />

.100 100<br />

3131.40.066.050.056 66 50 56 10 24 13 40 20 14 18 48 74 100<br />

.112 112<br />

Ordering-code (example):<br />

Rectangular guide = 3131.40.<br />

l2 = 22 mm = 3131.40.022.<br />

b2 = 16 mm = 3131.40.022.016.<br />

l1 = 40 mm = 3131.40.022.016.040<br />

Order no. = 3131.40.022.016.040<br />

subject to alterations<br />

2·21484·2008·1 ◽

2 · 20842 · 2006 · 1 Q<br />

subject to alterations<br />

General <strong>Mould</strong> Components<br />

39

Strength class 8.8<br />

M<br />

4<br />

l<br />

12<br />

l1 10<br />

d<br />

7<br />

k<br />

4<br />

s<br />

3<br />

4 16 14 7 4 3<br />

4 20 18 7 4 3<br />

4 25 23 7 4 3<br />

5 20 18 8.5 5 4<br />

5 25 23 8.5 5 4<br />

5 30 22 8.5 5 4<br />

6 16 13 10 6 5<br />

6 20 17 10 6 5<br />

6 25 22 10 6 5<br />

6 30 27 10 6 5<br />

6 35 24 10 6 5<br />

6 40 24 10 6 5<br />

6 45 24 10 6 5<br />

6 50 24 10 6 5<br />

6 55 24 10 6 5<br />

6 60 24 10 6 5<br />

6 70 24 10 6 5<br />

6 80 24 10 6 5<br />

6 90 24 10 6 5<br />

8 16 12 13 8 6<br />

8 20 16 13 8 6<br />

8 25 21 13 8 6<br />

8 30 26 13 8 6<br />

8 35 31 13 8 6<br />

8 40 28 13 8 6<br />

8 45 28 13 8 6<br />

8 50 28 13 8 6<br />

8 60 28 13 8 6<br />

10 16 11 16 10 8<br />

10 20 15 16 10 8<br />

10 25 20 16 10 8<br />

10 30 25 16 10 8<br />

10 35 30 16 10 8<br />

10 40 35 16 10 8<br />

10 50 32 16 10 8<br />

10 60 32 16 10 8<br />

12 25 20 18 12 10<br />

12 30 25 18 12 10<br />

12 35 30 18 12 10<br />

12 40 35 18 12 10<br />

12 45 40 18 12 10<br />

12 50 45 18 12 10<br />

12 70 36 18 12 10<br />

12 80 36 18 12 10<br />

40<br />

Socket Head Cap Screws<br />

DIN 912/ISO 4762 2192.10.<br />

2192.10. Socket Head Cap Screws DIN 912/ISO 4762<br />

Ordering-code (example):<br />

Socket head cap screw = 2192.10<br />

Thread M8 = .08<br />

Length 50 mm = .050<br />

Order No = 2192.10.08.050<br />

M l l 1 d k s<br />

16 30 24 24 16 14<br />

16 35 29 24 16 14<br />

16 40 34 24 16 14<br />

16 45 39 24 16 14<br />

16 50 44 24 16 14<br />

16 55 49 24 16 14<br />

16 60 54 24 16 14<br />

16 100 44 24 16 14<br />

20 50 42 30 20 17<br />

20 60 52 30 20 17<br />

20 70 62 30 20 17<br />

20 90 52 30 20 17<br />

20 120 52 30 20 17<br />

24 60 51 36 24 19<br />

24 70 61 36 24 19<br />

24 80 71 36 24 19<br />

24 120 60 36 24 19<br />

24 140 60 36 24 19<br />

30 140 72 72 20 22<br />

2192.10.<br />

s<br />

d<br />

k<br />

l<br />

l 1<br />

M<br />

subject to alterations<br />

2·11828·9·1 °

2·11617·8·1 ◽<br />

2192.12.<br />

s<br />

d<br />

2192.12. Socket Head Cap Screws DIN 912/ISO 4762<br />

Strength class 12.9<br />

M<br />

3<br />

l<br />

8<br />

l1 6<br />

d<br />

5.5<br />

k<br />

3<br />

s<br />

2.5<br />

4 10 8 7 4 3<br />

6 10 7 10 6 5<br />

6 20 17 10 6 5<br />

6 25 22 10 6 5<br />

6 30 27 10 6 5<br />

6 35 24 10 6 5<br />

6 40 24 10 6 5<br />

6 45 24 10 6 5<br />

6 50 24 10 6 5<br />

6 55 24 10 6 5<br />

6 60 24 10 6 5<br />

6 70 24 10 6 5<br />

6 80 24 10 6 5<br />

6 85 24 10 6 5<br />

6 90 24 10 6 5<br />

6 100 24 10 6 5<br />

6 160 24 10 6 5<br />

6 200 24 10 6 5<br />

8 16 12 13 8 6<br />

8 30 26 13 8 6<br />

8 35 31 13 8 6<br />

8 40 28 13 8 6<br />

8 45 28 13 8 6<br />

8 50 28 13 8 6<br />

8 55 28 13 8 6<br />

8 60 28 13 8 6<br />

8 70 28 13 8 6<br />

8 75 28 13 8 6<br />

8 80 28 13 8 6<br />

8 90 28 13 8 6<br />

8 100 28 13 8 6<br />

8 110 28 13 8 6<br />

8 120 28 13 8 6<br />

10 30 25 16 10 8<br />

10 35 30 16 10 8<br />

10 40 35 16 10 8<br />

10 45 32 16 10 8<br />

10 50 32 16 10 8<br />

10 55 32 16 10 8<br />

10 60 32 16 10 8<br />

10 65 32 16 10 8<br />

10 70 32 16 10 8<br />

10 75 32 16 10 8<br />

k<br />

Socket Head Cap Screws<br />

2192.12. DIN 912/ISO 4762<br />

Ordering-code (example):<br />

Socket head cap screw = 2192.12<br />

Thread M8 = .08<br />

Lenght 100 mm = .100<br />

Order No = 2192.12.08.100<br />

l<br />

l 1<br />

M<br />

M l l 1 d k s<br />

10 80 32 16 10 8<br />

10 90 32 16 10 8<br />

10 100 32 16 10 8<br />

10 110 32 16 10 8<br />

10 120 32 16 10 8<br />

10 130 32 16 10 8<br />

10 150 32 16 10 8<br />

10 180 32 16 10 8<br />

10 220 32 16 10 8<br />

12 40 35 18 12 10<br />

12 45 40 18 12 10<br />

12 50 45 18 12 10<br />

12 55 36 18 12 10<br />

12 60 36 18 12 10<br />

12 70 36 18 12 10<br />

12 80 36 18 12 10<br />

12 90 36 18 12 10<br />

12 100 36 18 12 10<br />

12 110 36 18 12 10<br />

12 120 36 18 12 10<br />

12 130 36 18 12 10<br />

12 140 36 18 12 10<br />

12 150 36 18 12 10<br />

12 180 36 18 12 10<br />

12 220 36 18 12 10<br />

16 40 34 24 16 14<br />

16 50 44 24 16 14<br />

16 60 54 24 16 14<br />

16 65 44 24 16 14<br />

16 70 44 24 16 14<br />

16 80 44 24 16 14<br />

16 90 44 24 16 14<br />

16 100 44 24 16 14<br />

16 110 44 24 16 14<br />

16 120 44 24 16 14<br />

16 130 44 24 16 14<br />

16 140 44 24 16 14<br />

16 150 44 24 16 14<br />

16 160 44 24 16 14<br />

16 180 44 24 16 14<br />

16 200 44 24 16 14<br />

16 220 44 24 16 14<br />

16 240 44 24 16 14<br />

16 260 44 24 16 14<br />

M l l 1 d k s<br />

16 280 44 24 16 14<br />

16 300 44 24 16 14<br />

20 100 52 30 20 17<br />

20 110 52 30 20 17<br />

20 120 52 30 20 17<br />

20 130 52 30 20 17<br />

20 140 52 30 20 17<br />

20 150 52 30 20 17<br />

20 160 52 30 20 17<br />

20 180 52 30 20 17<br />

20 190 52 30 20 17<br />

20 200 52 30 20 17<br />

20 220 52 30 20 17<br />

20 230 52 30 20 17<br />

20 240 52 30 20 17<br />

20 260 52 30 20 17<br />

20 280 52 30 20 17<br />

20 300 52 30 20 17<br />

24 130 60 36 24 19<br />

24 140 60 36 24 19<br />

24 150 60 36 24 19<br />

24 160 60 36 24 19<br />

24 180 60 36 24 19<br />

24 200 60 36 24 19<br />

subject to alterations 41

42<br />

Socket Head Cap Screws DIN 7984<br />

with low profile head 2192.40.<br />

2192.40. Socket Head Cap Screws DIN 7984<br />

Festigkeitsklasse 8.8 = Code Nr.: 0.<br />

M I l1 d k s<br />

4 8 5,9 7 2,8 2,5<br />

10 7,9 7 2,8 2,5<br />

12 9,9 7 2,8 2,5<br />

16 13,9 7 2,8 2,5<br />

20 17,9 7 2,8 2,5<br />

25 14 7 2,8 2,5<br />

30 14 7 2,8 2,5<br />

35 14 7 2,8 2,5<br />

40 14 7 2,8 2,5<br />

5 8 5,6 8,5 3,5 3<br />

10 7,6 8,5 3,5 3<br />

12 9,6 8,5 3,5 3<br />

16 13,6 8,5 3,5 3<br />

20 17,6 8,5 3,5 3<br />

25 22,6 8,5 3,5 3<br />

30 16 8,5 3,5 3<br />

35 16 8,5 3,5 3<br />

40 16 8,5 3,5 3<br />

6 10 7 10 4 4<br />

12 9 10 4 4<br />

16 13 10 4 4<br />

20 17 10 4 4<br />

25 22 10 4 4<br />

30 18 10 4 4<br />

35 18 10 4 4<br />

40 18 10 4 4<br />

8 12 8,25 13 5 5<br />

16 12,25 13 5 5<br />

20 16,25 13 5 5<br />

25 21,25 13 5 5<br />

30 26,25 13 5 5<br />

13 35 22 13 5 5<br />

40 22 13 5 5<br />

45 22 13 5 5<br />

50 22 13 5 5<br />

60 22 13 5 5<br />

10 20 15,5 16 6 7<br />

25 20,5 16 6 7<br />

30 25,5 16 6 7<br />

60 26 16 6 7<br />

80 26 16 6 7<br />

90 26 16 6 7<br />

12 30 24,75 18 7 8<br />

35 29,75 18 7 8<br />

Ordering-code (example):<br />

Cap Screw = 2192.<br />

DIN 7984 = 2192.4<br />

Strength class 8.8 = 2192.40.<br />

M10 = 2192.40.10.<br />

l = 30 mm = 2192.40.08.030<br />

Order No = 2192.40.10.030<br />

2192.40.<br />

s<br />

d<br />

k<br />

l<br />

l 1<br />

M<br />

subject to alterations<br />

2·16582·2001·1 °

2·11838·9·1 °<br />

2192.30.<br />

s<br />

90°<br />

Countersunk Head Cap Screws<br />

2192.30. DIN 7991/ISO 10642<br />

d<br />

k<br />

l g<br />

l<br />

2192.30. Countersunk Head Cap Screws DIN 7991/ISO 10642<br />

Strenght class 8.8 = Code Nr. 0.<br />

M l l g d k s<br />

3 6 3.2 6 1.7 2<br />

3 8 3.2 6 1.7 2<br />

3 10 3.2 6 1.7 2<br />

4 8 4.4 8 2.3 2.5<br />

5 10 5.2 10 2.8 3<br />

5 12 5.2 10 2.8 3<br />

6 10 6.3 12 3.3 4<br />

6 12 6.3 12 3.3 4<br />

6 16 6.3 12 3.3 4<br />

6 20 6.3 12 3.3 4<br />

6 25 6.3 12 3.3 4<br />

8 16 8.2 16 4.4 5<br />

8 20 8.2 16 4.4 5<br />

8 25 8.2 16 4.4 5<br />

10 20 10 20 5.5 6<br />

10 25 10 20 5.5 6<br />

12 30 11.8 24 6.5 8<br />

Ordering Code (example):<br />

M<br />

Countersunk Head Cap Screw = 2192.<br />

DIN 7991/ISO 10642 = 2192.3<br />

Strenght class 8.8 = 2192.3 0.<br />

M8 = 2192.3 0.08.<br />

l = 16 mm = 2192.3 0.08.016<br />

Order No = 2192.30.08.016<br />

subject to alterations 43

44<br />

Flat mushroom head screw 2192.61.<br />

2192.61.<br />

Mounting example<br />

Material:<br />

Strength class 10.9 = Code No. 1.<br />

2192.61. Flat mushroom head screw<br />

M l k s c a d a d R<br />

6 12 3.2 4 1.2 2 7 13.27 5.6<br />

6 16 3.2 4 1.2 2 7 13.27 5.6<br />

6 20 3.2 4 1.2 2 7 13.27 5.6<br />

8 16 4.3 5 1.5 2.5 9.2 17.77 7.5<br />

8 20 4.3 5 1.5 2.5 9.2 17.77 7.5<br />

8 25 4.3 5 1.5 2.5 9.2 17.77 7.5<br />

10 20 5.3 6 1.75 3 11.2 22.18 10<br />

Ordering-code (example):<br />

Flat mushroom head screw = 2192.61<br />

Thread 8 mm = .08<br />

Lenght 16 mm = .016<br />

Order No = 2192.61.08.016<br />

subject to alterations<br />

2 · 20520 · 2006 · 1 ◽

2 · 20851 · 2006 · 1 Q<br />

Änderungen vorbehalten 45

M e m s<br />

M 8 15,0 12 13<br />

M10 18,2 15 16<br />

M12 20,4 18 18<br />

M14 23,8 21 21<br />

M16 27,7 24 24<br />

M18 31,2 27 27<br />

M20 34,6 30 30<br />

M22 38,6 33 34<br />

M24 41,6 36 36<br />

M30 53,1 45 46<br />

46<br />

Setscrews 2140.02.<br />

Hexagon Nuts DIN 6330 B 2140.32.<br />

2140.02. Setscrews<br />

M d2 d3 k l<br />

M10 16 30 8 39<br />

M12 20 36 10 48<br />

M16 25 42 13 55<br />

M20 25 50 16 69<br />

M24 34 60 20 87<br />

Ordering-code (example):<br />

Setscrew = 2140.02.<br />

M16 = 2140.02.16<br />

Order No = 2140.02.16<br />

2140.32. Hexagon Nuts DIN 6330 B<br />

2140.02.<br />

Material:<br />

Heat-treated<br />

Strength class 8.8<br />

2140.32.<br />

Material:<br />

Heat-treated<br />

Strength class 10.9<br />

Note:<br />

d 2<br />

M<br />

d 3<br />

k<br />

Use washers con<strong>for</strong>ming to DIN 6340.<br />

e<br />

l<br />

m<br />

s<br />

Ordering Code (example):<br />

Hexagon Nut, DIN 6330 B = 2140.32.<br />

M20 = 2140.32.20<br />

Order No = 2140.32.20<br />

M<br />

subject to alterations<br />

2·11623·9·1 °

2·11624·9·1 °<br />

2140.33.<br />

Material:<br />

Turned and milled<br />

Heat-treated<br />

Strength class 10.9<br />

Thread length 1,53M<br />

2140.34.<br />

Material:<br />

Heat-treated<br />

Strength 1200–1400 N/mm2 2140.33. Collar Nuts DIN 6331<br />

2140.34. Washers DIN 6340<br />

a<br />

d 1<br />

Ordering-code (example):<br />

Collar Nut DIN 6331 = 2140.33.<br />

M12 = 2140.33.12<br />

Order No = 2140.33.12<br />

Ordering-code (example):<br />

Washer DIN 6340 = 2140.34.<br />

M10 = 2140.34.10<br />

Order No = 2140.34.10<br />

e<br />

M<br />

d 2<br />

d 1<br />

m<br />

s<br />

s<br />

°<br />

°<br />

2140.33. Collar Nuts DIN 6331<br />

M a d 1 e m s<br />

M 8 3,5 18 15,0 12 13<br />

M10 4,0 22 18,2 15 16<br />

M12 25 20,4 18 18<br />

M14 4,5 28 23,8 21 21<br />

M16 5,0 31 27,7 24 24<br />

M18 34 31,2 27 27<br />

M20 6,0 37 34,6 30 30<br />

M22 40 38,6 33 34<br />

M24 45 41,6 36 36<br />

M30 6,0 58 53,1 45 46<br />

2140.34. Washers DIN 6340<br />

M d1 d2 s<br />

M 8 8,4 23 4<br />

M10 10,5 28 4<br />

M12 13,0 35 5<br />

M14 15,0 40 5<br />

M16 17,0 45 6<br />

M18 19,0 45 6<br />

M20 21,0 50 6<br />

M22 23,0 50 8<br />

M24 25,0 60 8<br />

M30 31,0 68 10<br />

subject to alterations 47

48<br />

T-Head Bolts DIN 787 2140.30.<br />

2140.30.<br />

Material:<br />

Forged, T-slot milled,<br />

rolled thread<br />

d 1<br />

a<br />

e<br />

a 1<br />

b<br />

l<br />

k<br />

M 6 – M12 heat-treated to strength class 10.9<br />

M14 – M24 heat-treated to strength class 8.8<br />

°<br />

2140.30. T-Head Bolts DIN 787<br />

a1 a b d1 e k l<br />

8 7,7 22 M 8 13 6 32<br />

35 50<br />

50 80<br />

10 9,7 30 M10 15 6 40<br />

45 63<br />

60 100<br />

12 11,7 35 M12 18 7 50<br />

40 63<br />

55 80<br />

75 125<br />

120 200<br />

14 13,7 35 M12 22 8 50<br />

45 63<br />

55 80<br />

75 125<br />

120 200<br />

16 15,7 45 M14 25 9 63<br />

65 100<br />

125 160<br />

150 250<br />

16 15,7 45 M16 25 9 63<br />

55 80<br />

65 100<br />

100 160<br />

125 200<br />

150 250<br />

18 17,7 45 M16 28 10 63<br />

55 80<br />

65 100<br />

100 160<br />

125 200<br />

150 250<br />

20 19,7 55 M20 32 12 80<br />

65 100<br />

85 125<br />

110 160<br />

125 200<br />

150 250<br />

190 315<br />

22 21,7 55 M20 35 14 80<br />

65 100<br />

85 125<br />

115 160<br />

125 200<br />

150 250<br />

190 315<br />

24 23,7 70 M24 40 16 100<br />

85 125<br />

110 160<br />

125 200<br />

150 250<br />

190 315<br />

240 400<br />

28 27,7 70 M24 44 18 100<br />

85 125<br />

110 160<br />

125 200<br />

150 250<br />

190 315<br />

240 400<br />

36 35,6 80 M30 54 22 125<br />

110 160<br />

135 200<br />

150 250<br />

200 315<br />

300 500<br />

Ordering-code (example):<br />

T-Head Bolt DIN 787 = 2140.30.<br />

d1 = M14 = 2140.30.14.<br />

a1 = 16 mm = 2140.30.14.16.<br />

l = 160 mm = 2140.30.14.16.160<br />

Order No = 2140.30.14.16.160<br />

subject to alterations<br />

2·11622·9·1 °

2·8787·7·2 °<br />

244.16. Spring,- Fit- and Spacer Units<br />

Description:<br />

These units can be used as an alternative<br />

to shoulder screws.<br />

Advantages:<br />

Precision length adjustments by way of<br />

grinding. The units have many uses – as<br />

can be seen from the installation examples<br />

below.<br />

Execution:<br />

Spacer tube:<br />

Tensile strength 1200–1300 N/mm 2<br />

Outside diameter ground to<br />

tolerance h9<br />

Supplied with socket cap screw<br />

DIN EN ISO 4762 (12.9)<br />

Note:<br />

The units are supplied with a retaining<br />

O-ring which must be removed be<strong>for</strong>e application.<br />

244.16.<br />

Installation Examples<br />

244.16.<br />

244.16.<br />

h<br />

±0,1<br />

l 1<br />