F2139 CS

F2139 CS

F2139 CS

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Final Profile Milling Cutter with Carbide Shank<strong>F2139</strong> <strong>CS</strong> Accessories 4

Accessories High precision and rigidity Quickly recovers from damage Flexible tooling system 5

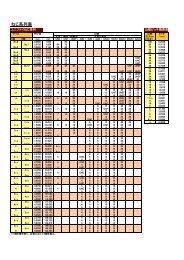

Straight arbor with steel shank for screw-fit toolsType1X1max d1d1d1X1minType2X1max87X1minType3X1maxX1minLLLddd Straight arbor with carbide shank for screw-fit toolsd1d d1d1Type2X1max87X1minType3X1maxX1minLLdd 6

BT shank arbors for screw-fit tools High tool rigidity for high performance Fixed tool length Enables standardization of tools 7

Insert for <strong>F2139</strong> / <strong>F2139</strong> <strong>CS</strong> Previous model number(New model number( Insert grade characteristics and applications 9

Theoretical milling surface roughness of <strong>F2139</strong> [mm]0.020.0180.0160.0140.0120.010.0080.0060.0040.002000.5 1 1.5[mm]Recommended pick feed and milling surface roughness Cutting depth and actual milling diameter (øDe) quick chart Calculation formula for actual milling diameterDapDeRecommended Milling Condition 10

Driver Driver Bit Driver and bit for <strong>F2139</strong> Use safety cover, safety glasses andsafety shoes during operation.Do not touch cutting edges with barehands.Do not touch cutting chips with barehands. Chips will be hot after cutting.Stop cutting when the tool becomes dull.Stop cutting operation immediatelyif you hear any strange cutting sounds.Do not modify tools.Please use correct tools for theoperation.Check dimensions to ensureproper selection. Tool specifi cations subject to change without notice. 0533-82-1134 hp-info@osg.co.jp https://www.osg.co.jp/products/club/index.phpE-mail:cs-info@osg.co.jp g07.03